Piston ring HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 110 of 1413

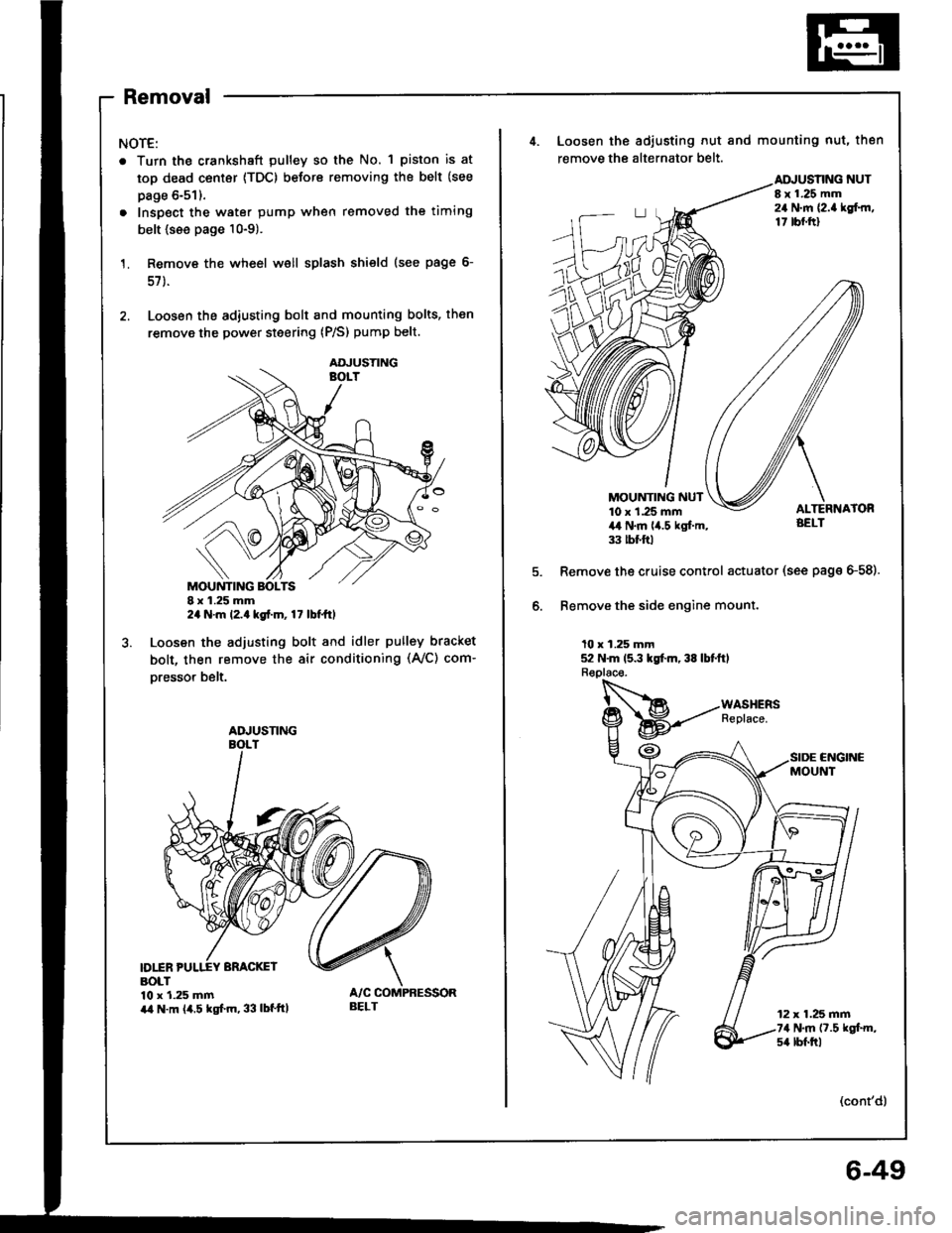

Removal

NOTE:

. Turn the crankshaft pulley so the No. 1 piston is at

top dead center {TDC) before removing the belt (see

page 6-51).

. Inspect the water pump when removed the timing

belt {see page 10-9).

Remove the wheel well splash shield (see page 6-

57 ).

Loosen the adiusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt.

I x 1.25 mm2a N.m l2.a kgt.m, 17 lbt ttl

Loosen the adjusting bolt and idler pulley bracket

bolt, then remove the air conditioning (Ay'C) com-

oresso. belt.

D1INBOLT10 x 1.25 mmira N.m (4.5 kgf.m, 33 lbf'ttl

AOJUSTING

ADJUSNNG

BELT

4. Loosen the adiusting nut and mounting nut, then

remove the alternator belt.

NUTI x 1.25 mm24 N.m {2.a lgf.rn,17 tbf.ftl

MOUNTING NUT10 x 1.25 mm4,t N.m lia.5 kgl.m,33 tbt ftl

Remove the cruise control actuator (see page G58).

Bemove the side engine mount.

10 x 1.25 mm52 N.m 15.3 kgt m, 38 lbtftl

CNGINCMOUNT

12 x 1.25 mm74 N.m (7.5 kgt m,s4 lbf.trl

(cont'd)

6-49

Page 136 of 1413

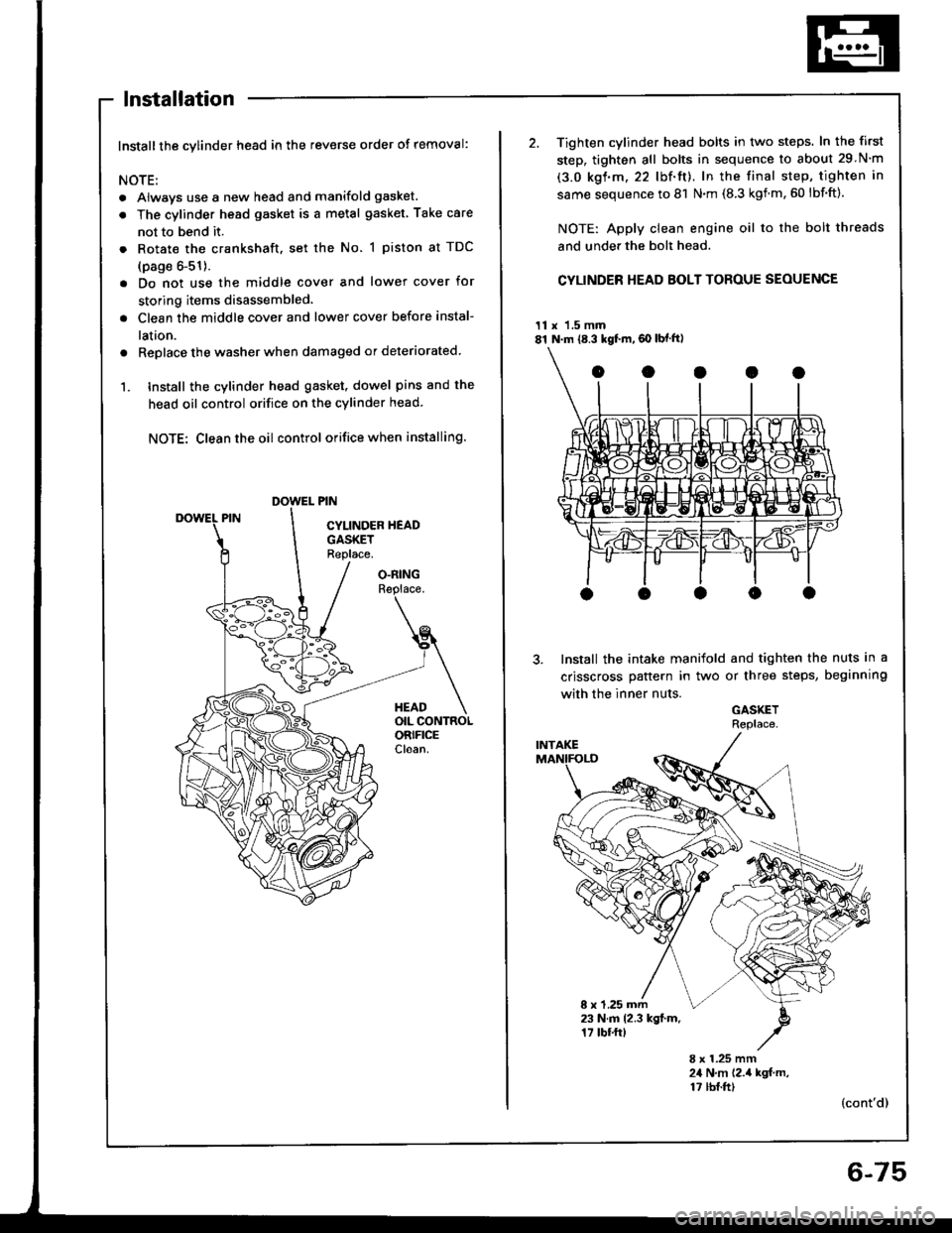

lnstallation

Installthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head and manifold gasket.

. The cylinder head gasket is a metal gasket Take care

not to bend it.

. Rotate the crankshaft, set the No. 1 piston at TDC

(page 6-51).

. Do not use the middle cover and lower cover for

storing items disassembled.

. Clean the middle cover and lower cover before instal-

lation.

a Replace the washer when damaged or deteriorated

1. tnstall the cylinder head gasket. dowel pins and the

head oil control orifice on the cylinder head

NOTE: Clean the oil control orifice when installing.

O.RINGReplace.

HEADOIL CONTROLORIFICECloan.

2. Tighten cylinder head bolts in two steps. In the first

step, tighten all bolts in sequence to about 29 N'm

(3.0 kgf.m.22 lbf'ft). In the final step, tighten in

same sequence to 81 N.m (8.3 kgnm.60 lbf'ft).

NOTE: Apply clean engine oil to the bolt threads

and under the bolt head.

CYLINDER HEAD BOLT TOROUE SEOUENCE

11 x 1.5 mm81 N.m {8.3 kgf.m,60 lbf ft)

Install the intake manifold and tighten the nuts in a

crisscross pattern in two or three steps, beginning

with the inner nuts.

GASKETRePlace

8 x 1.25 mm23 N.m 12.3 kgl.m.17 tbf.ftt

8 x 1.25 mm24 N,m 12.,4 kgf m,17 tbf.ft)(cont'd)

6-75

Page 141 of 1413

Engine Block

Speciaf Tools .............7'2

lllustrated Index ................................... 7-3

Flywheel and Drive Plate

Repfacement .........7-7

Main Bearings

Clearance ,.............. 7-8

Selection ................ 7-8

Connecting Rod Bearings

Clearance ............... 7-9

Selection ................ 7-9

Crankshaft

Removal .................7-10

End Play .................7-12

lnspection ........,,,.,,7-12

fnstallation .............7'22

Cylinder Block

Inspeetion ..............7-13

Bore Honing .....,.,,.7'14

Pistons

Inspaction ..............7-15

Installation .............7-16

Piston Rings

Replacement .........7-16

End Gap .................7-17

Ring-To-Groove C|earance,,,,.,,,...... 7 -17

Alignment ..............7-18

Piston Pins

Removal ........,........7-18

Installation (818B1 engine) ............. 7-19

fnstaffation (818C1 enginel ............. 7-20

fnspection ..............7-2O

Connecting Rods

End Play .................7-21

Sefeetion ..........,,,,,,7-22

Oil Seal

fnstaffation .............7-25

Installation

(engine removal not requiredl.. .......7-26

Page 142 of 1413

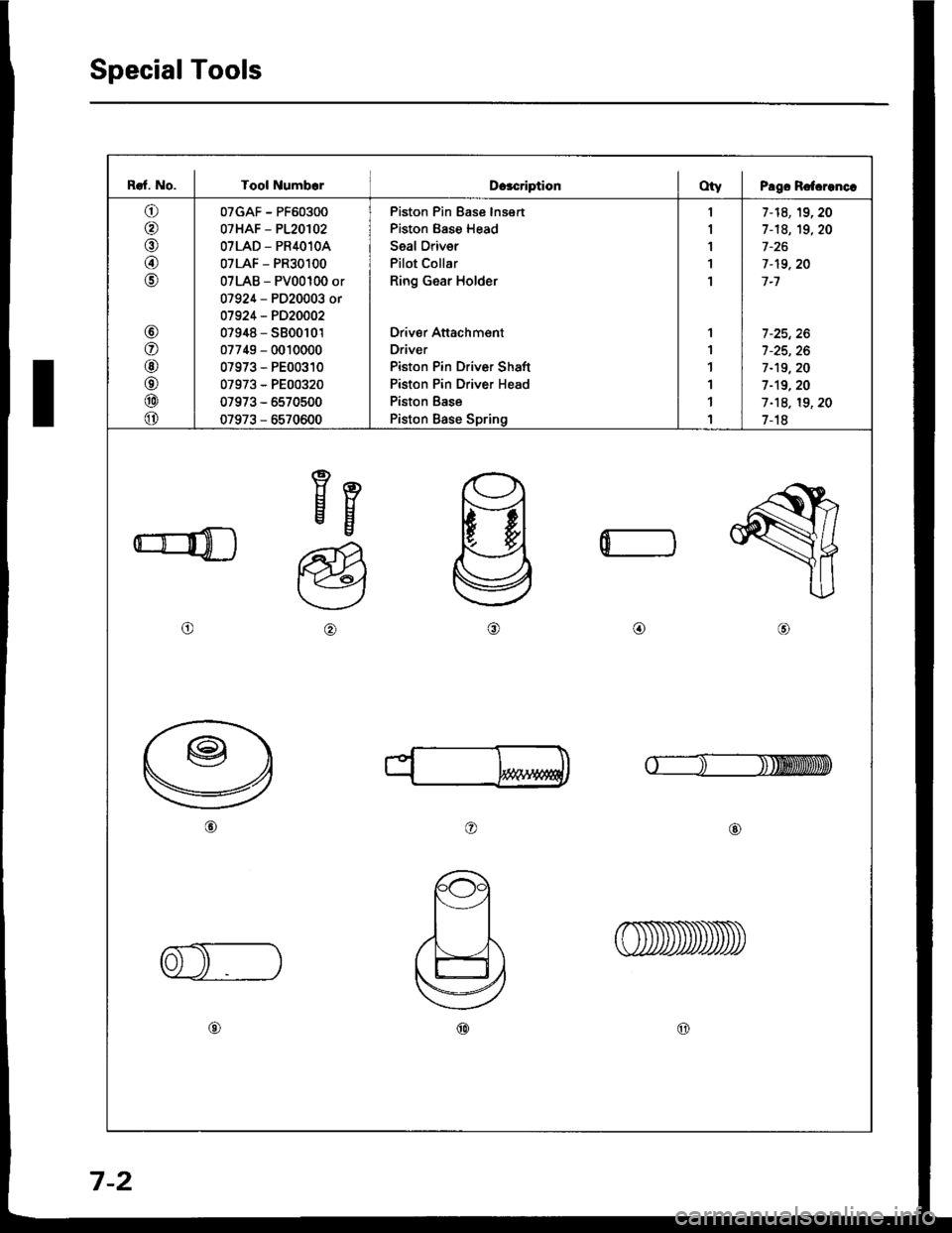

Special Tools

I

Raf. No. I Tool NumbcrDcacriptionOty I Pago Rotcrenc.

o

@

@

@

o

@

o

@

o

@

o

07GAF - PF60300

07HAF - P120102

OTLAD _ PR4O1OA

07LAF - PR30100

07LAB - PV00100 or

07924 - PD20003 or

01924 - PD20002

07948 - S800101

07749 - 0010000

07973 - PE00310

07973 - PE00320

07973 - 5570500

07973 - 6570600

Piston Pin Ease lnsert

Piston Base Head

Seal Oriver

Pilot Collar

Ring Gear Holder

Driver Attachment

Driver

Piston Pin Driver Shaft

Piston Pin Driver Head

Piston Base

Piston Base Spring

1

I

1'I

1

1

1

1

1

1

1

7-14,19,20

1-18, 19,20

7-19,20

7-1

7 -25, 26

7-19,20

1-19.20

1-18, 19, 20

1-18

Eg

o@,a\

o@

@@

0

7-2

Page 146 of 1413

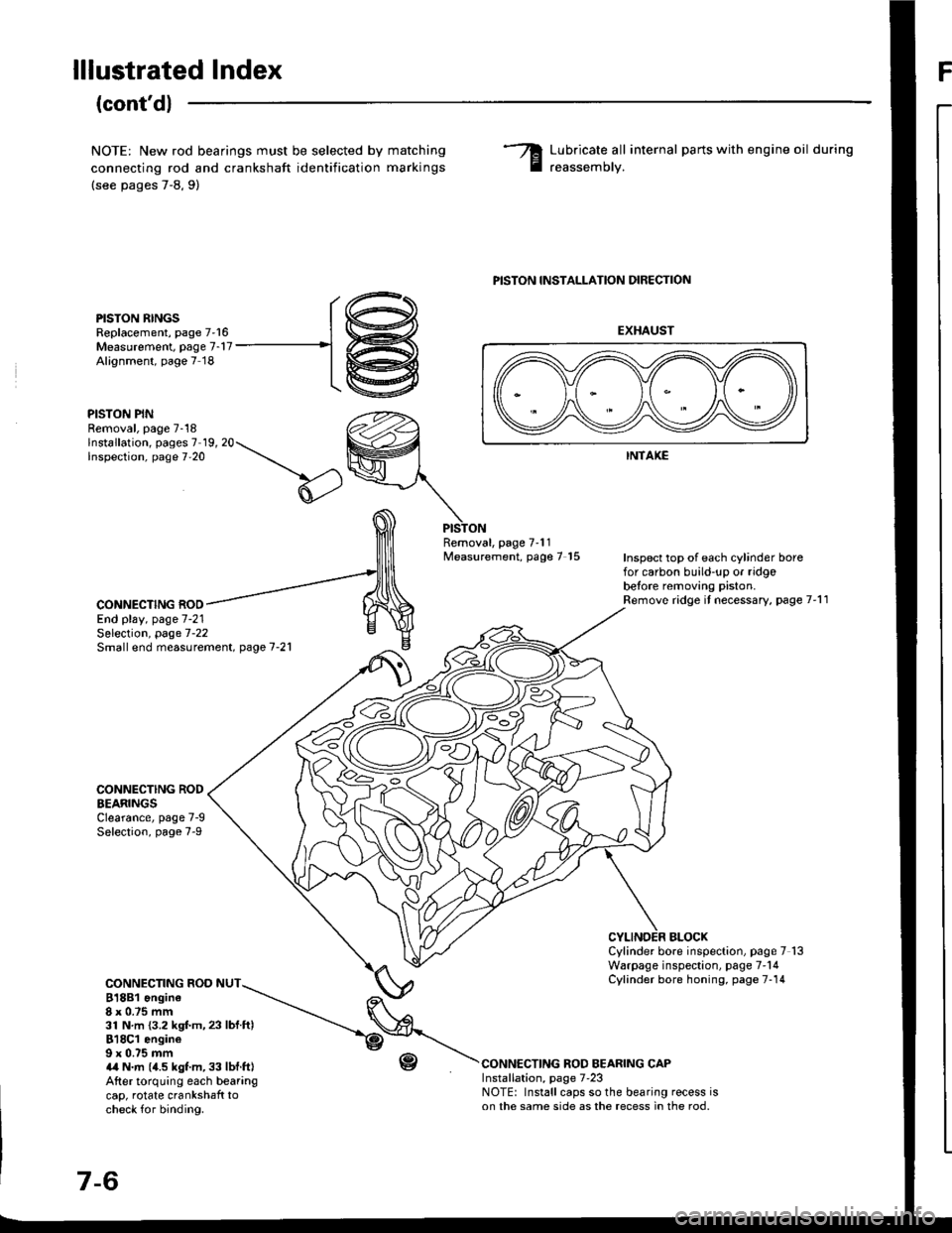

lllustrated IndexF

(cont'd)

NOTE: New rod bearings must be selected by

connecting rod and crankshaft identification

(see pages 7-8,9)

matching

marKrngs

Lubricate all internal parts with engine oil during

reassemorv.

PISTON RINGSReplacement, page 7'16Measurement. page 7-17Alignment, page 7 18

PISTON PINRemoval, page 7-18lnstallation, pages 7 19, 20Inspection, page 7'20

PISTON INSTALLATION DIRECTION

EXHAUST

INTAKE

Removal, page 7'11Measurement, page 7 15Inspect top of each cylinder borefor carbon build-up or ridgobetore removing piston.Remove ridge it necessary, page 7'11CONNECTING ROOEnd play, page 7-21

CONNECTING RODEEARINGSClearance, page 7-9Selection, page 7-9

CONNECTING ROD NUT818B1 ongine8x 0.75 mm31 N.m {3.2 kgf.m,23 lbf ftl818C1 engine9 x 0.75 mma,a N.m (4.5 kgt m, 33 lbf.ft|After torquing each bearangcap, rotate crankshaft tocheck for binding.

r-(,

Selection, page 7-22Small end measurement. page 7-21

BLOCXCylinder bore inspection, page 7 13Warpage inspection, page 7'14Cylinder bore honing, page 7-14

CONNECTING ROD BEARING CAPInstallation, page 7'23NOTE: Install caps so the bearing recess ison the same side as the recess in the rod.

r@

-1@

Page 151 of 1413

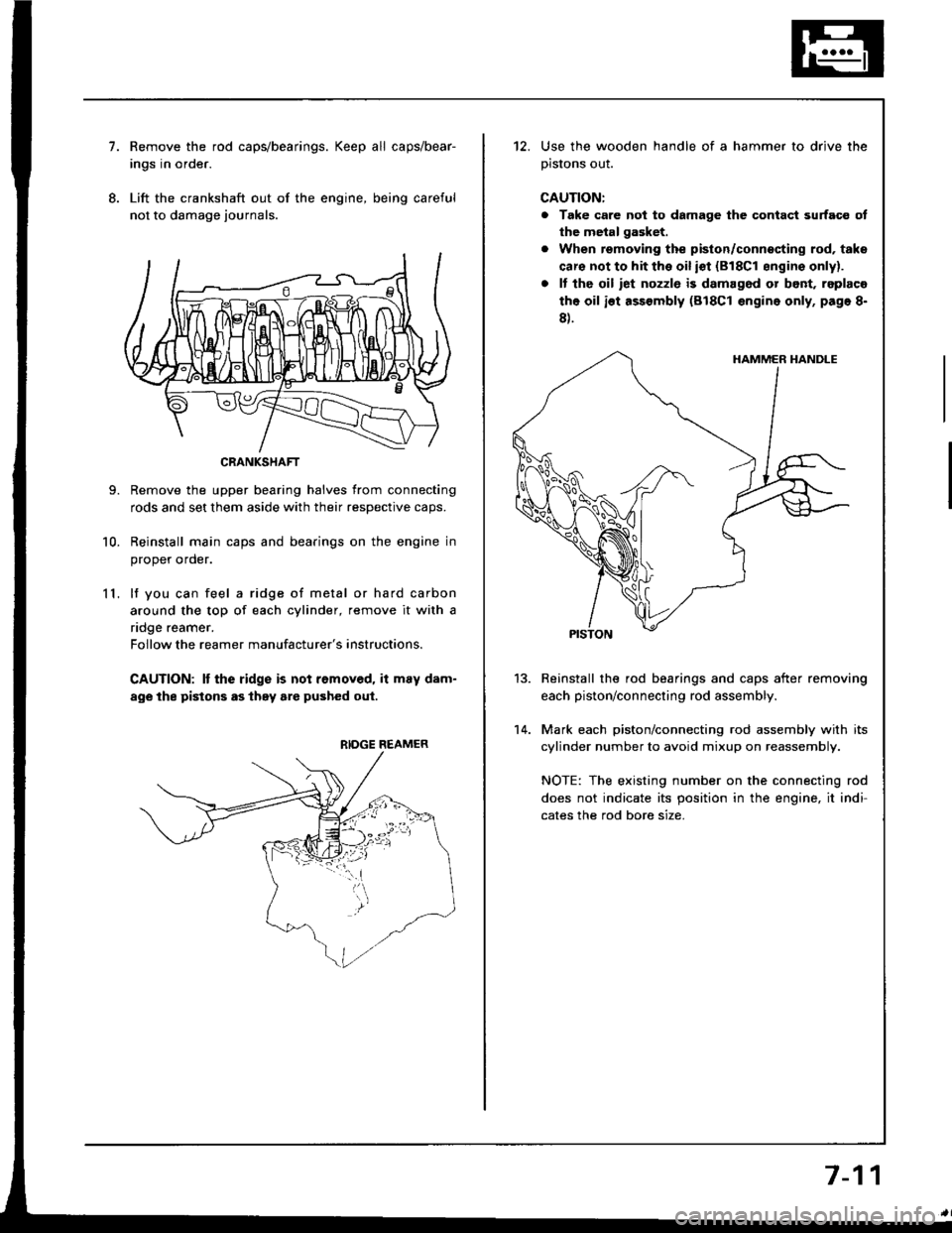

7.

8.

11.

9.

10.

Remove the rod caps/bearings. Keep all caps/bear-

ings in order.

Lift the crankshaft out of the engine, being careful

not to damage journals.

Remove the upper bearing halves from connecting

rods and set them aside with their resDective caDs.

Reinstall main caps and bearings on the engine in

oroDer order.

lf you can feel a ridge of metal or hard carbon

around the top of each cylinder, remove it with a

ndge reamer.

Follow the reamer manufacturer's instructions.

CAUTION: It the ridge is not removed, it may dam-

age the pistons as they are pushed oul.

CRANKSHAFT

RIDGE REAMER

12. Use the wooden handle of a hammer to drive the

prslons ouI.

CAUTION:

a Take care not to damage the contact surfaco ot

the metal gasket.

. When removing the piston/connecting rod, taks

caro not to hit the oil iot {818C1 sngins onlyl.

. It tho oil iet nozzlo is damag6d or bont, replaco

the oil ist assembly (818C1 engine only, page 8-

8).

Reinstall the rod bearings and caps after removing

each piston/connecting rod assembly.

Mark each piston/connecting rod assembly with its

cylinder number to avoid mixup on reassembly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

13.

14.

7-11

Page 153 of 1413

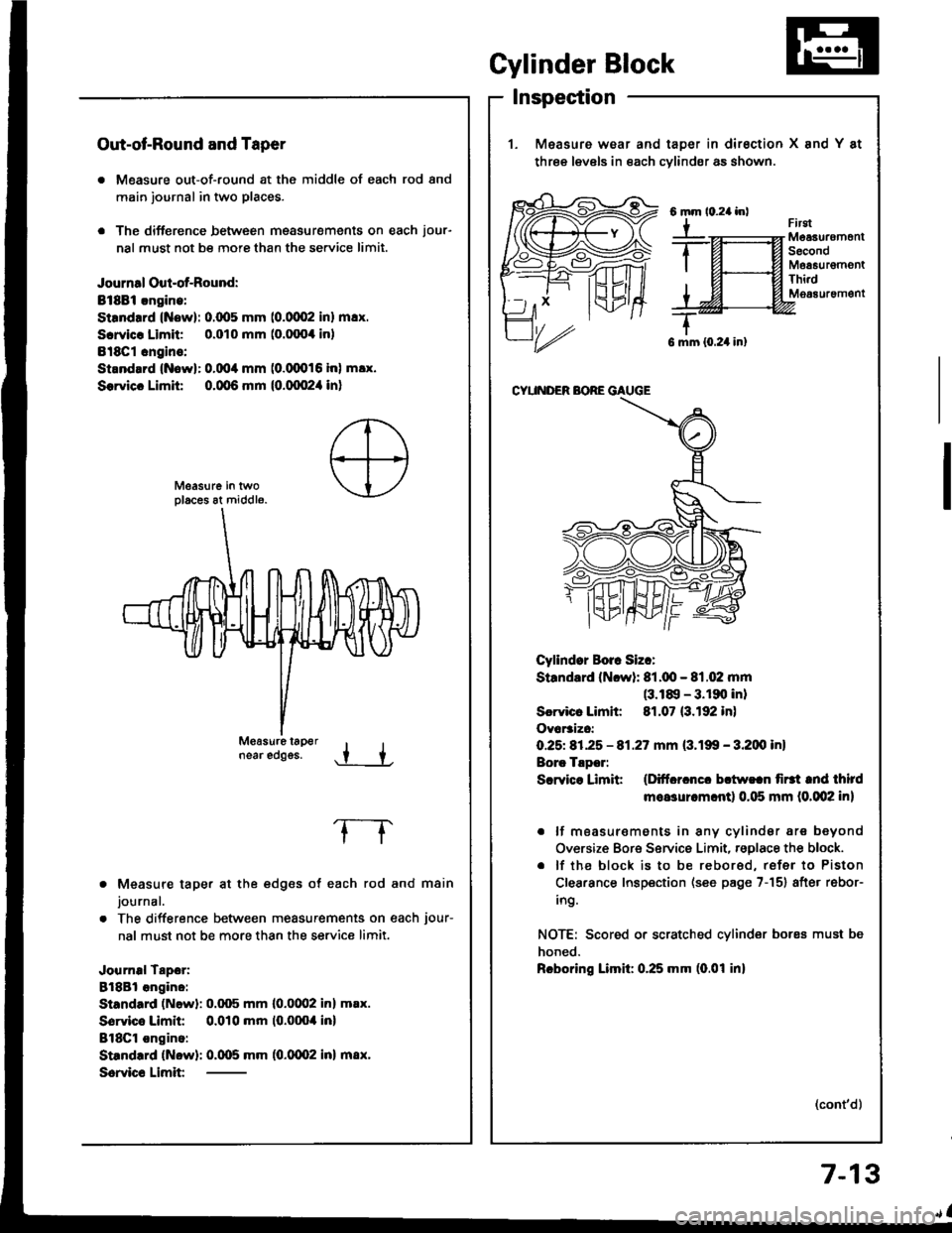

Out-ot-Round and Taper

. Measure out-of-round at the middle of each rod and

main journal in two places.

. The difference between msasurements on each jour-

nal must not be more than the se.vice limit.

Journal Oul-of-Round:

Bt8Bi.ngine:

Strndrrd (Now): 0.(x15 mm (0.0002 inl m!x.

Scrvicr Limit 0.010 mm (o.fixx inl

Bl8Cl cngins:

Strnd.rd {Nowl: 0.004 mm (0.(XD16 inl m!x.

Sorvicc Limit 0.qt6 mm {0.qx!2,1 in}

near edggs..t +

Measure taper at the edges of each rod and main

journal.

The difference between measurements on each jour-

nal must not be more than the service limit.

Journal Tapor:

8l8Bl angino:

Standard (Newl: 0.q)5 mm l0.0(Xl2 inl m.x.

Sorvico Limit 0.010 mm (0.0004 inl

BlSCl ongino:

Standrrd (Now): 0.005 mm (0.0002 inl m8x.

Scrvic€ Limit

frrgtMeaauremonlSecondMoa6urgmontThi.dM063uremgnt

G mm {0.24 in}

CYUNDER BORE GAUGE

Cyllndor Borr Siz.:

Standard (Ncwl: 81.q!- 81.02 mm(3.18, - 3.190 inl

Scrvicr Limh: 81.07 (3.192 in)

Ovar3izc:

O.25t 81.25 - 81.27 mm (3.199 - 3.200 inl

Borc Tlpor:

Scrvice Limit (Ditfcrcncc bctw!.n firtt tnd third

moasurcm.ntl 0.115 mm (0.002 in)

. lf moasur€ments in any cylindsr are beyond

Oversize Bore Service Limit, rsglace the block.

. lf the block is to be rebored, refer to Piston

Clearance Inspection (see page 7-151 after rebor-

ing.

NOTE: Scored or scratched cylinder bores must be

honed.

Rcboring Limil: 0.25 mm (0.01 inl

(cont'd)

Gylinder Block

Inspection

1. Measure wear and taDer in dirsction X and Y at

three levels in each cvlindsr as shown.

6mm

Y

7-13

Page 156 of 1413

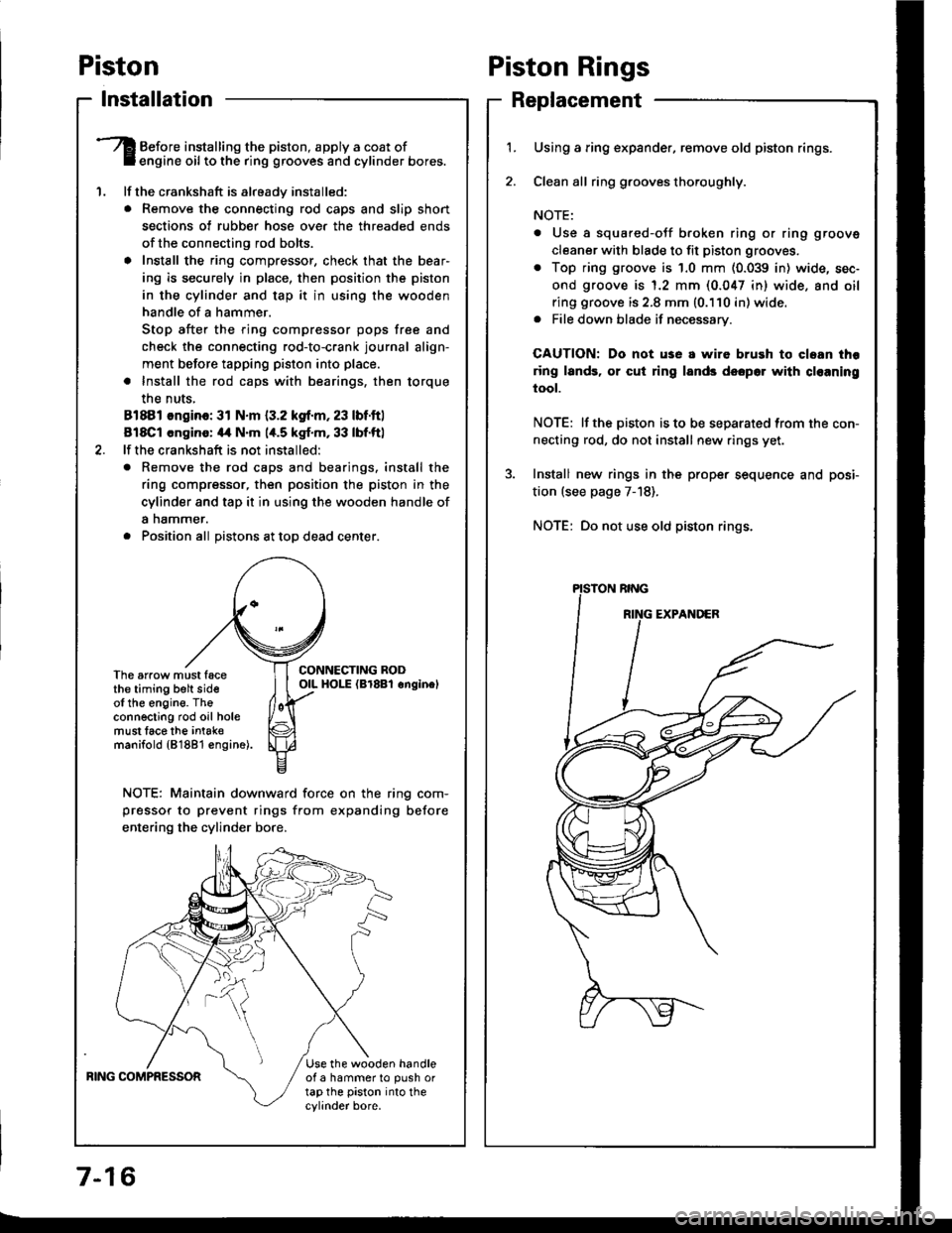

Piston

lnstallation

'1.

Before installing the piston, apply a coat ofengine oil to the ring grooves and cylinder bores.

lf the crankshaft is already installed:

. Remove the connecting rod caps and slip short

sections of rubber hose ove. the threaded ends

of the connecting rod bolts.

a Install the ring compressor, check that the bear'

ing is securely in place, then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free and

check the connecting rod-to-crank journal align-

ment before tapping piston into place.

. Install the rod caps with bearings, then torque

the nuts,

81881 ongino: 31 N.m {3.2 kgf.m, 23 lbf.ftl

818C1 cngino: 44 N'm 1,t.5 kgf.m, 33 lbf.ftl

lf the crankshaft is not installed:

o Remove the rod caps and bearings. install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a nammer.

. Position all Distons at toD dead center.

CONNECTING RODOIL HOI-E (Br8Bl onginelThe arrow must facethe timing belt sideof the engine. Theconnecting rod oil holemust lace the intak€manifold {81881 €ngine).

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore,

BING COMPRESSORUse the wooden handleof a hammer to push ortap the piston into thecylinder bore.

Piston Rings

Replacement

1.Using a ring expander, remove old piston rings.

Clean all ring g.ooves thoroughly.

NOTE:

. Use a squared-oJf broken ring or ring groove

cleaner with blade to fit piston grooves.

. Top ring groove is 1.0 mm (0.039 in) wide, sec-

ond groove is 1.2 mm (0.047 in) wide. and oil

ring groove is 2.8 mm (0.110 in) wide.. File down blade if necessary.

CAUTION: Do not use a wire brush to cloan thr

ring lands, or cut ring lands dsopo. with cl€aning

tool.

NOTE: lf the piston is to be separated from the con-

necting rod, do not install new rings yet.

Install new rings in the prope. sequence and posi-

tion (see page 7-18).

NOTE: Do not use old piston rings.

Page 157 of 1413

I

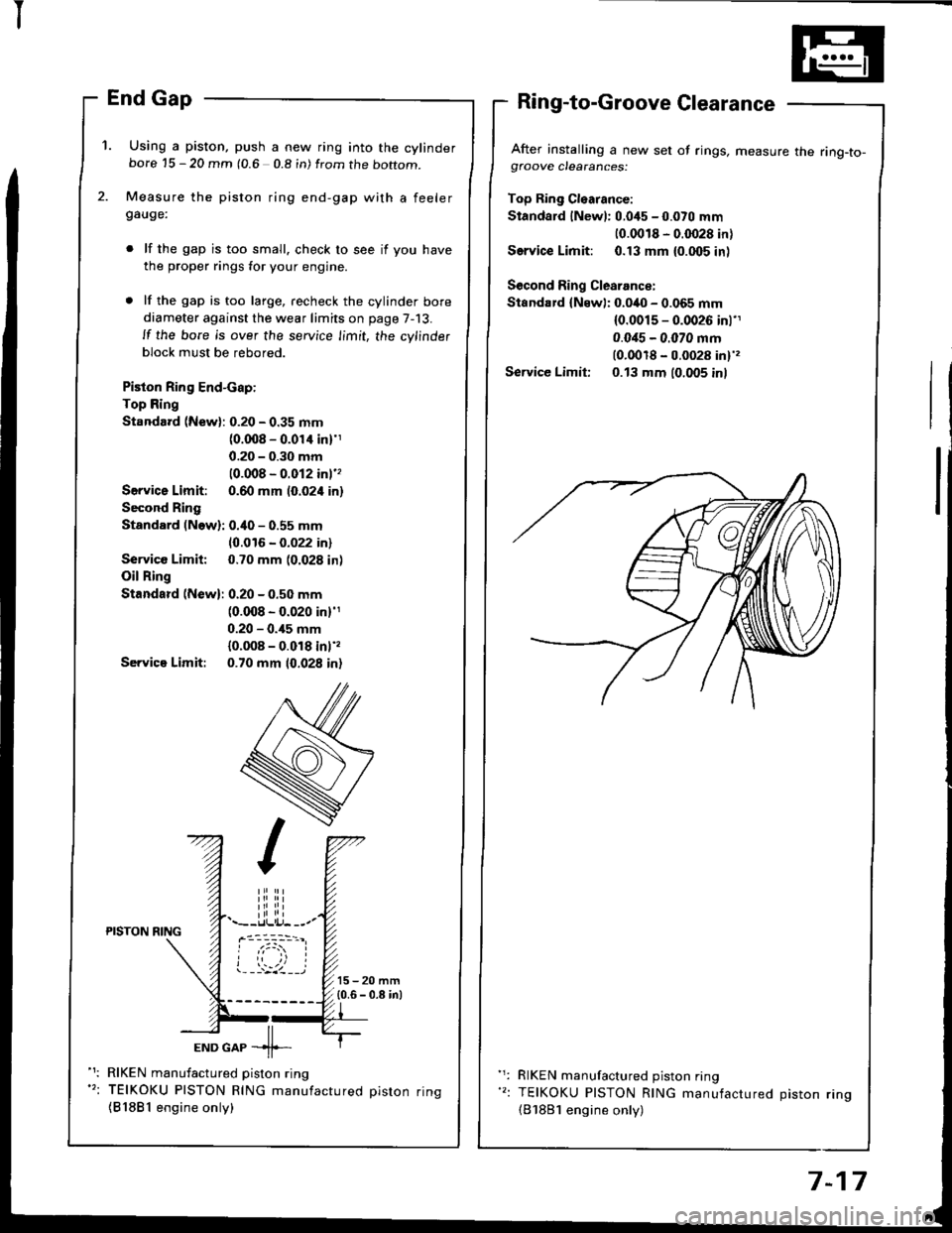

'1. Using a piston, push a new ring into the cylinderbore 15 - 20 mm (0.6 0.8 in) from the boftom.

Measure the piston ring end-gap with a feelergauge:

lf the gap is too small. check to see if you have

the proper rings for your engine.

lf the gap is too large, recheck the cylinder bore

diameter against the wear limits on page 7-13.

ll the bore is over the service limit, the cylinder

block must be rebored.

Piston Ring End-cap:

Top Ring

Standard (New): 0.20 - 0.35 mm(0.008 - 0.01'l inl'1

0.20 - 0.30 mm

10.008 - 0.012 inl''

Servica Limit: 0.60 mm (0.024 in)

Second Ring

Standard (Now): 0.40 - 0.55 mm

10.016 - 0.022 in)

Service Limit: 0.70 mm (0.028 in)

Oil Ring

Standard (New): 0.20 - 0.50 mm(0.008 - 0.020 in)'1

0.20 - 0.,15 mm

{0.008 - 0.018 inl',

Servica Limit: 0.70 mm 10.028 in)

After installing a new set of rings, measure the ring-to-gfoove clearances:

Top Ring Cl€arance:

Standard lNewl: 0.045 - 0.070 mm

10.0018 - 0.0028 in)

Service Limit: 0.13 mm {0.005 inl

Second Ring Clearance:

Standard {Newl: 0.040 - 0.065 mm(0.0015 - 0.0026 inl'1

0.0i15 - 0.070 mm(0.0018 - 0.0028 in)',

Service Limit: 0.13 mm (0.005 inl

iliiii.--r.llli.j- --.-PISTON NING

ioi

---'z llEND GAP -11--

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured oiston rinq

{81881 engine only)

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured Diston rino(B'1881 engine only)

7-17

Page 158 of 1413

Piston Rings

Alignment

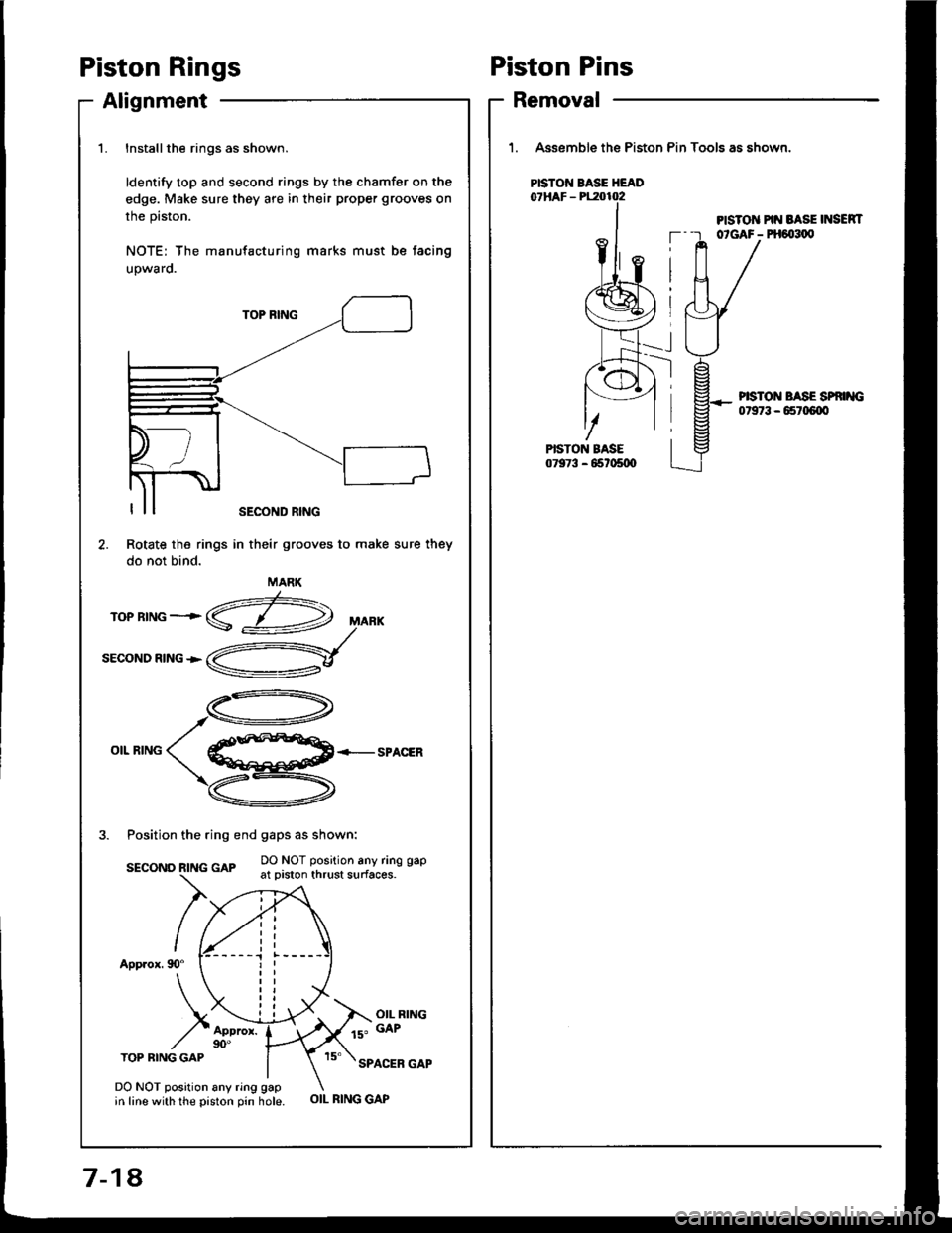

1.Installthe rings as shown.

ldentify top and second rings by the chamfer on the

edge. Make sure they are in their proper grooves on

the prston.

NOTE: The manufacturing marks must be facing

upwaro.

TOP BING

OIL RINGSPACER

3. Position the ring end gaps as shown:

DO NOT position any ring gapsEcoNo R|NG GAp -.- :': :.-"' : - ' '----'-- { _- - - at prston thrust surfaces.

App.ox. 90"

OIL RING

ls" GAP

TOP BING GAPSPACER GAP

Rotate the rings

do not bind.

DO NOT position any ring gapin line with the piston pin hole.

SECOND RING

in their grooves to make sure they

MARK

OIL RING GAP

Piston Pins

Removal

1. Assemble the Piston Pin Tools as shown.

PISTO]T PIN BASE INSEN|T--r otGAF- PH6{t1,0

PISTON BASE HEAD

--l

PISTON BASE SP '{G07973 - 65r06{X'

7-18,