alternator HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1211 of 1413

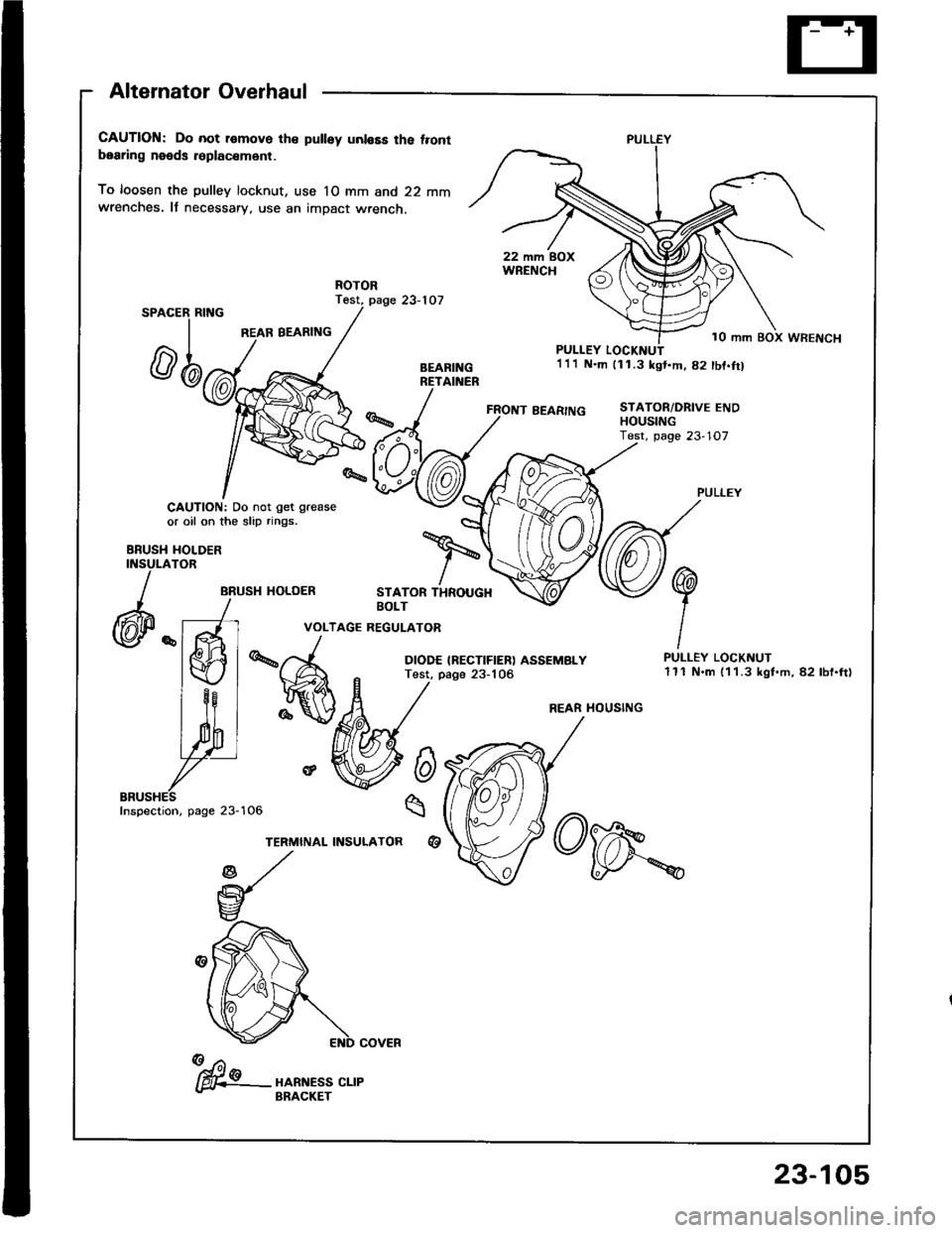

Alternator Overhaul

CAUTION: Do not r€move th€ pulley unl€Es the t.ontbearing needs r6placsm6nt.

To loosen the pulley locknut, use 10 mm and 22 mmwrenches. It necessary, use an impact wrench.

Test, page 23-107SPAC

REAR BEARING

ER RING

rl

@n

CAUTION: Do not get grease

or oil on the slip rings.

HOLDERTOR

ARUSH HOLOER

FRONT BEARING

PULLEY LOCKI{UT1'll N.m 111.3 kgt.m,82 tbf.trl

STATOR/DRIVE ENDHOUStt{G

BBUSHINSULA

)

(@P "

STATOR THROUGHBOLT

VOLTAGE REGULATOR

DIODE IRECTIFIER) ASSEMBLYTest, page 23-106

6

q

%A

re

TERMINAL INSULATORqt

PULLEY LOCKNUT111 N.m (1 1.3 kgt.m, 82 lbf.ft)

PULLEY

10 mm BOX WRENCH

REAR HOUSING

Inspection, page 23-

fu"- "o*n.r" ".,"- BRACKET

23-105

Page 1212 of 1413

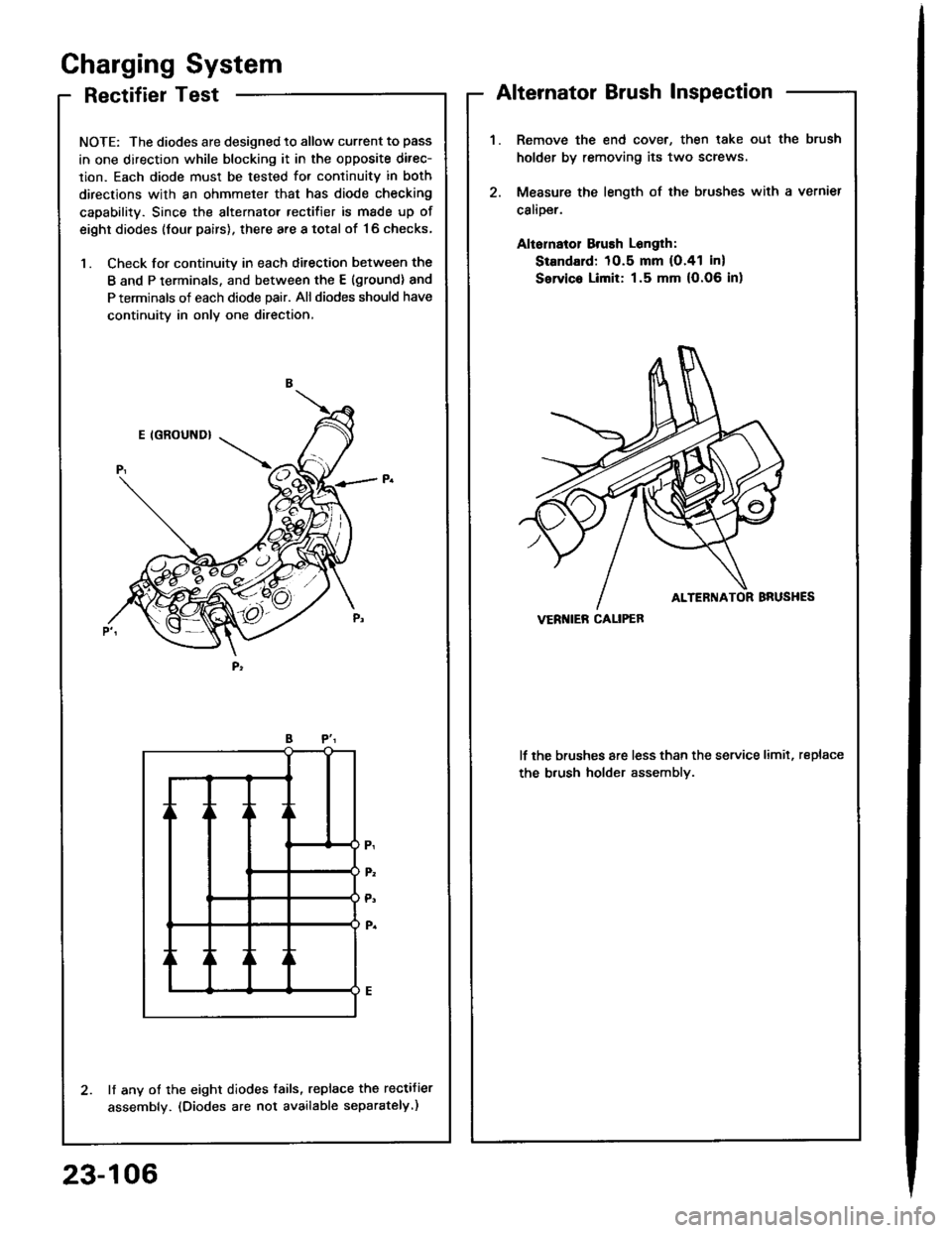

RectifierTest

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc-

lion. Each diode must be tested for continuitv in both

directions with an ohmmeter that has diode checking

capability. Since the alternator rectifier is made up of

eight diodes (four pairs), there are a total of '16 checks,

1. Check for continuity in each ditection between the

B and P terminals, and between the E (ground) and

P terminals of each diode pair. All diodes should have

continuity in only one direction,

lf any of the eight diodes tails, replace the rectifier

assembly. (Diodes are not available separately.)

Gharging System

Alternator Brush Inspection

Remove the end cover, then lake oul the brush

holder by removing its two screws

Measure the length of the brushes with a vernier

calioer.

Aliornatol Brush Longlh:

Standard: 10.5 mm (O.41 in)

Servic. Limit: 1.5 mm (O.06 in)

lf the brushes are less than the service limit, replace

the b.ush holder assemblv.

VERI{IEB CALIPEB

23-106

Page 1213 of 1413

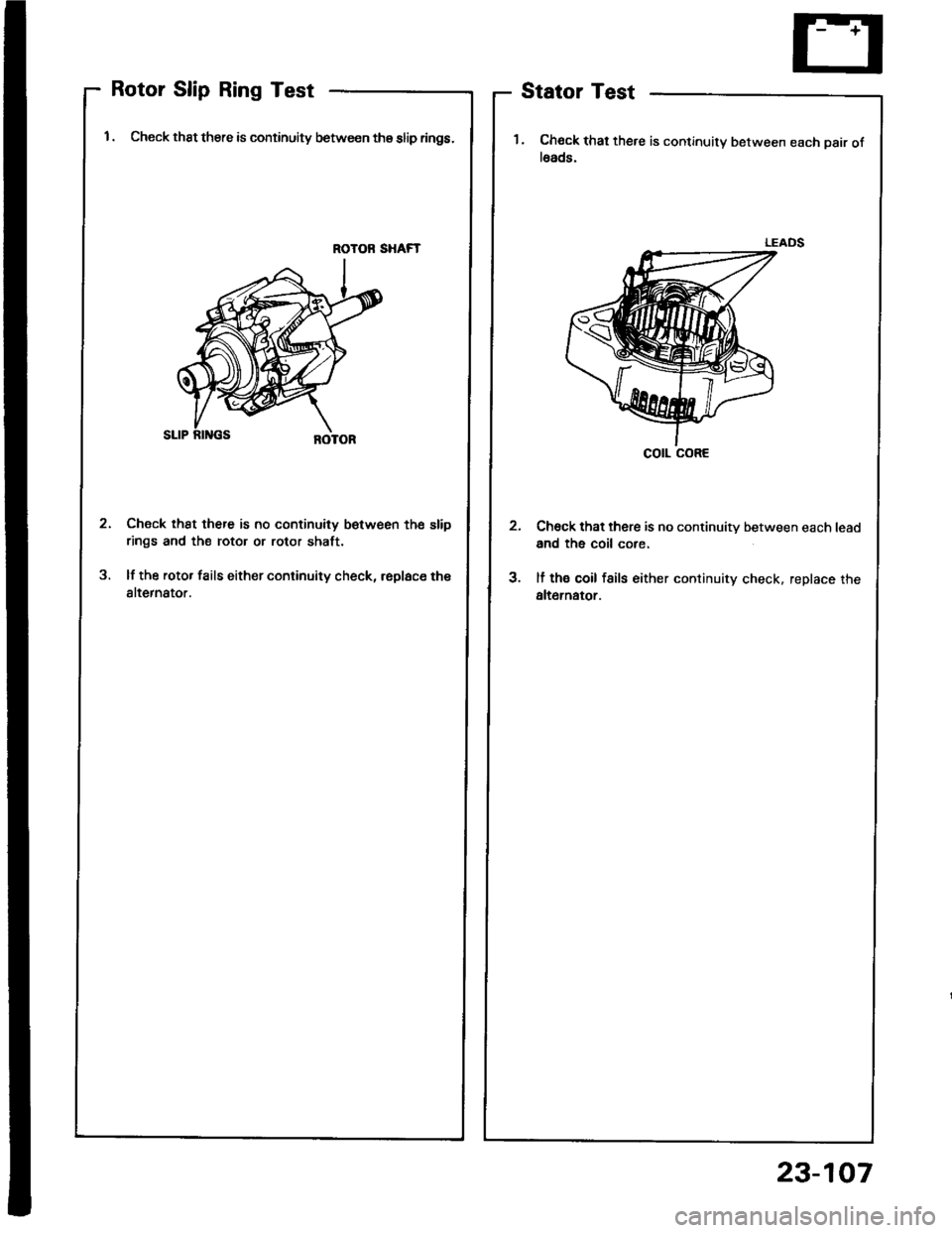

Rotor Slip Ring Test

1 . Check thst there is continuity between thg slip rings.

ROTOR SHAFT

Check th8t there is no continuity betw€en the slip

rings and the rotor or rotor shaft.

lf the rotor fails either continuity check, rsplace th€

alternator.

2

3

Stator Test

1. Chock that there is continuity between each pair ofl6ads.

Ch6ck that there is no continuity between each lead

and the coil core.

lf th€ coil fsils either continuity check. replace the

alt6rnator.

cotl coRE

23-107

Page 1214 of 1413

Charging System

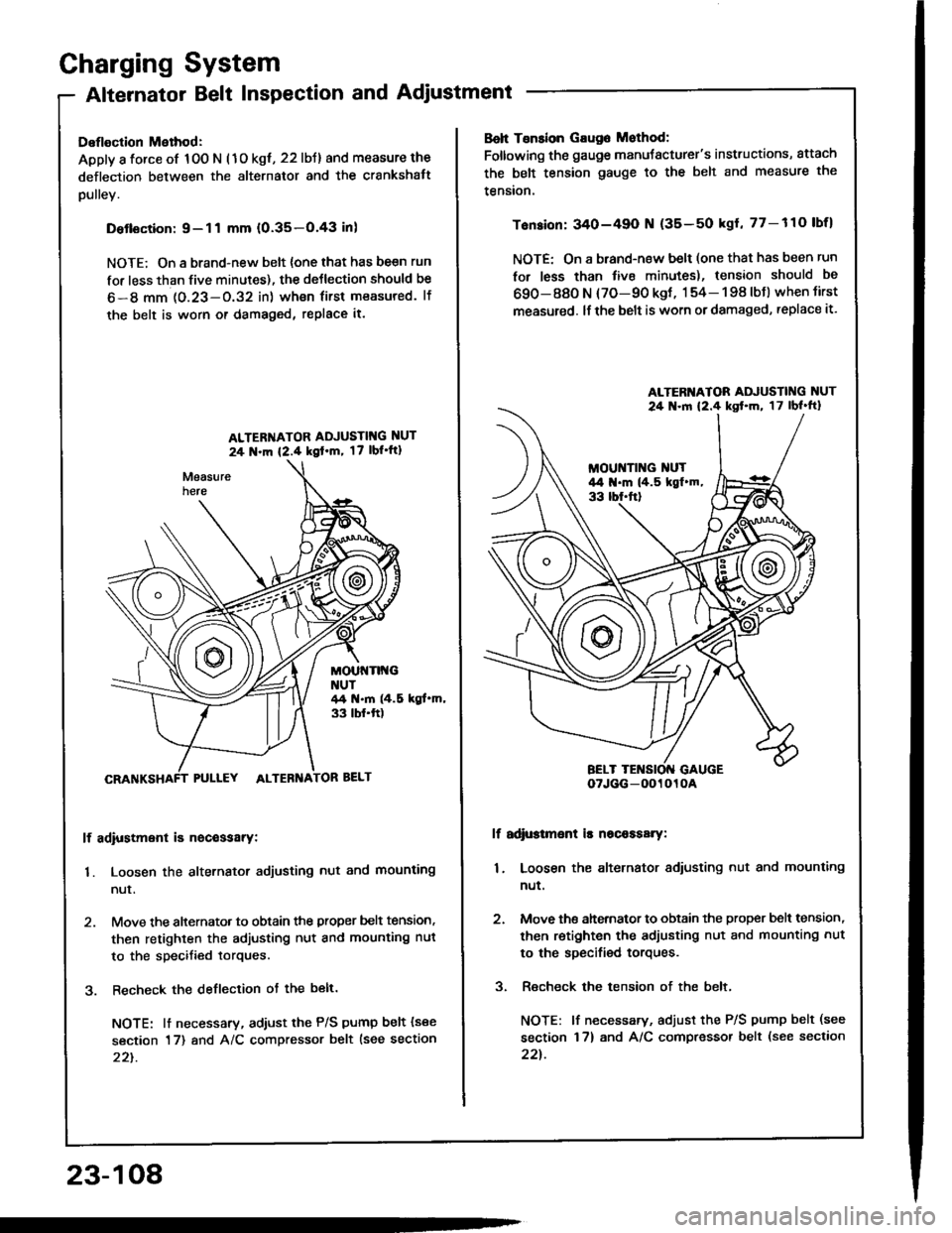

Alternator Belt Inspection and Adjustment

Deflection Method:

Apply a force of 100 N (1o kgt, 22 lbJ) and measure the

deflection between the alternator and the crankshatt

pulley.

Detlsction:9-11 mm (0.35-O.43 inl

NOTE; On a brand-new belt {one that has be€n run

for less than five minutes), the deJlection should be

6-8 mm 1O.23-O.32 in) wh€n first measured. lf

the belt is worn or damaged, replace it.

ALTER'{ATOR ADJUSTIT{G NUT

24 N.m {2.4 kgl'm, 17 lbl'ft1

MOUt{Tlt{GNUT44 t{.m (4.5 kgt.m,33 tbf.ft)

PULLEY ALTEBNA

lf adiustment is nocessarY:

1. Loosen the alternator adjusting nut and mounting

nur.

2. Move the alternator to obtain the proper belt tension,

then retighten the adjusting nut and mounting nut

to the specified torques.

3. Recheck the deflection ot the belt.

NOTE: lt necessary, adiust the P/S pump belt (see

section 17) and A/C compressor belt lsee section

22t.

23-108

Boh Tsnsion Gaug6 Mothod:

Foltowing the gauge manuJacturer's instructions, attach

the belt tension gauge to the belt and measure the

tension.

Tension: 340-49O N (35-50 kgl, 77-110 lbfl

NOTE: On a brand-new belt (one that has been run

for less than tive minutes), tension should be

690-880 N (70-90 kgt, 154- 198 lbJ) when tirst

measured. lf the belt is worn or damaged, replace it.

lf adi$tmsnt is nscaasary:

1. Loosen the alternator adiusting nut and mounting

nut.

2. Move ths ahernator to obtain the proper bslt tension,

then retighten the adjusting nut and mounting nut

to the specified torques.

3. Recheck the tension of the belt,

NOTE: lf necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

22t.

ALTERI{ATOR ADJUSTING NUT

24 .ln 12.4 kst'm, 17lbl'ft}

oTJGG-0O1010A