check oil HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 481 of 1413

NOTES

A.See flushing procedure, page l4-168 and 169.

B.Set idle rpm in gear to specitied idle speed. lf still no good, adiust motor mounts as outlined in engine

section of service manual.

lf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

lf the clutch pack is seized or is excessively worn, inspect the other clutches Jor wear, and check the

orifice control valves and throttle valves for free movement.

E.It throttle valve B is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed, the transmission will not upshift. lI stuck open, the transmission

has no lst gear.

H.lf the 2-3 orifice control valve is stuck, inspect the 2nd and 3rd clutch packs for wear.

ll the orifice cont.ol valve is stuck, inspect the 3rd and 4th clutch packs for wear.

lf the clutch Dressure control valve is stuck closed, the transmission will not shilt out of 1st gear.

K.improper alignment or main valve body and torque converter housing may cause oil pump seizure. The

symptoms ale mostly an rpm-related ticking noise or a high-pitched squeak.

L.ll the ATF strainer is ctogged with panicles of steel or aluminum, inspect the oil pump and ditferential

pinion shaft. lt both are OK and no cause lor the contamination is found, replace the torque converter.

M.lf the 1st clutch feedpipe guide in the right side cover is scored by the mainshaft, inspect the ball bear-

ing for excessive movement in the transmission housing. lf OK. replace the right side cover as it is dent-

ed. The O-ring under the guide is probably worn.

N.ReDlace the mainshstt if the bushing for the 4th feedpipe is loose or damaged.

It the 4th feedpipe is damaged or out ot tound, replace the right side cover'

Replace the subjshaft it thtbushing for the 1st-hold Jeedpipe is loose or damaged.

lf the 1st-hold feedpipe is damaged or out of round, replace it.

Replace the mainshaft if the bushing lor the 1st feedpipe is loose or damaged.

lf the lst feedpipe is damaged or out ot round, replace it.

o.A *o- r, da."s"d "p-g clutch is mostly a result of shifting the transmission in El or Lq! position

while the wheels rotate in reverse, such as rocking the car in snow.

P.InsDect the frame for collision damage.

o.Inspect for damage or wear:

1. Reverse selector gear teeth chamfers.

2. Engagement teeth chamters of countershaft 4th and reverse gear.

3. Shift fork for scutt marks in center.

4. Differential Dinion shaJt for wear under pinion gears.

5. Bottom of 3rd clutch for switl marks.

Replace items 1 , 2, 3 and 4 it worn or damaged. lf transmission makes clicking, grinding or.whirring

noise, atso replace mainshaft 4th gear and reverse idler gear and countershaft 4th gear in addition to

1,2,3ot4.lf ditiersntial Dinion shaft is worn, overhaul differential assembly, and replace ATF strainel, and thoroughly

clean transmission, tlush torque convertet, cooler and lines.

lf bottom of 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and tinal

driven gear.

R.Be wry careful not to dsmage the torque converter housing when replacing the main ballbearing. You

may al;o damage the oil pump when you torque down the main valve body. This will result in oil pump

seizure it not detected. Use proper tools.

qInstall the main seal tlush with the torque converter housing, lf you push it into the torque converter

housing until it bottoms out. it will block the oil return passage and result in damage.

T,Harsh do\/vnshiJt"\./l,'hen coasting to a stop with zero th.ottle may be caused by a bent-in throttle valve

retainer/cam stopper. Throttle cable adjustment may clear this problem.

ifuitle cable adjustment is essential for proper operation of the transmission. Not only does it affect

the shift points if misad,usted, but also the shift quality and lock-up clutch operation'

A cable adjusted too long will result in throttle pressure being too low for the amount of engine torque

input into ihe trsnsmission and may cause clutch slippage. A cable adjusted too short will result in too

hi;h throttle pressure which may cause harsh shitts, erratic shrfts and torque con

14-89

Page 486 of 1413

Pressure Testing

a While testing, be caretul of the rotating flont wheels.a Make aura litts, jacks, and sat€ty stands alo placedplop6rly {see section 1}.

CAUTION: Betore t€sting, be sure the transmission fluidis tilled to rh6 ploper l€vet.

1. Raise the car (see section i),

2. Warm up the engine {the cooling fan comes onl, thenstop the engine and connect a tachometer.

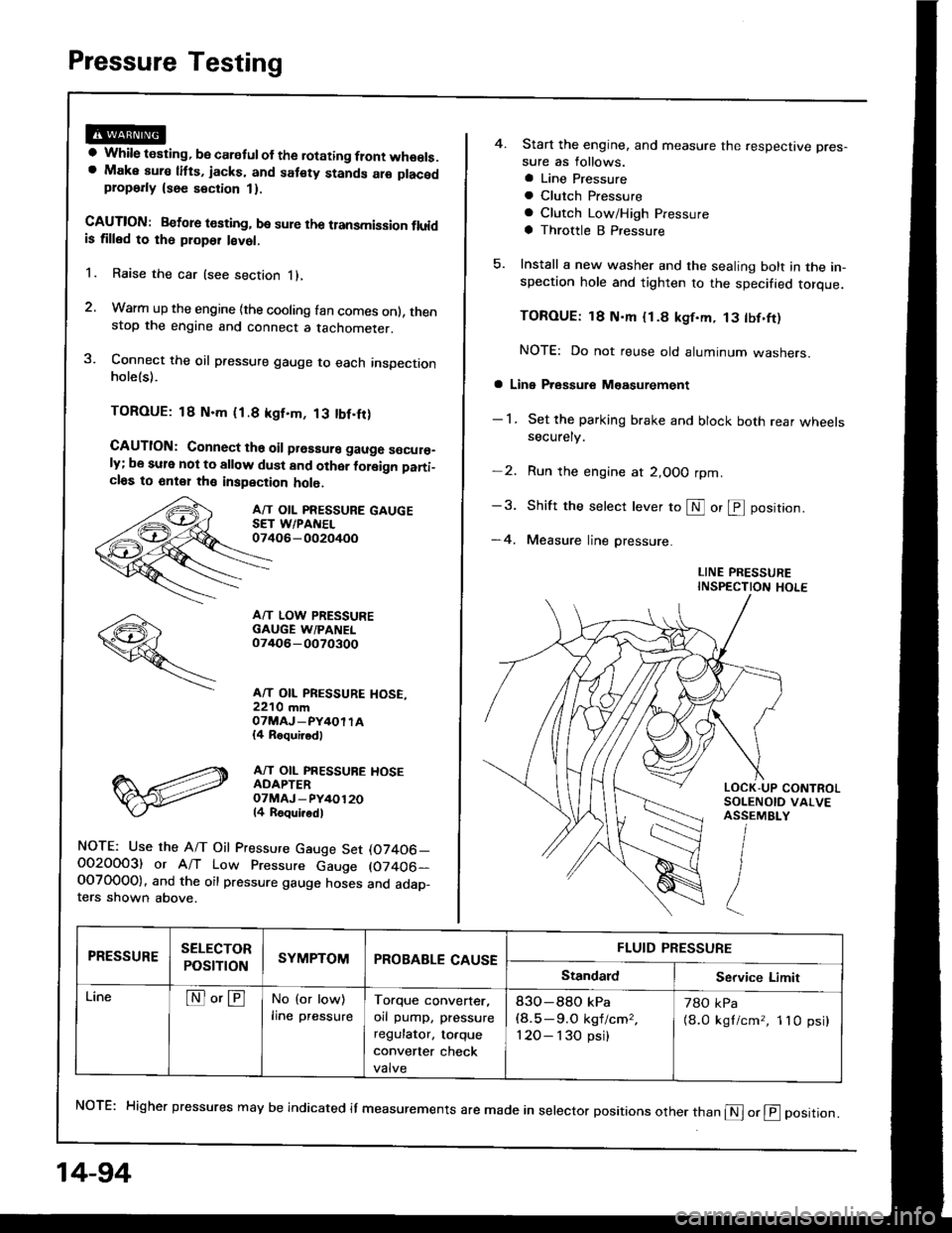

3. Connect the oil pressure gauge to each inspectionholels).

TOROUE: 18 N.m (1.8 kgf.m, 13 tbf.fr)

CAUTION: Connect ths oil prsssure gauge s€cur€_ly; be sule not to allow dust and other foleign pani_cl6s to 6nt€1 th€ inspection holo.

A/T OIL PRESSURE GAUGESET WPANEL07406-002oi+oo

A/T LOW PRESSUREGAUGE W/PANEL07/rO6-0O70300

A/T OIL PRESSURE HOSE,22'10 mmOTMAJ_PY4OI TA{4 Roquirod)

A/T OIL PRESSUBE HOSEADAPTEROTMAJ - PY/+O12014 Roqui.odl

NOTE: Use the A/T Oil Pressure Gauge Set (07406_O02OOO3) or A/T Low Pressure Gauge (07406-OOTO0OO). and the oil pressure gauge hoses and adap_ters shown above.

14-94

4. Start the engine, and measure the respective pres-

sure as follows.

a Line Pressure

a Clutch Pfessure

a Clutch Low/High Pressure

a Throttle B Pressure

5. Install a new washer and the sealing bolt in the in-spection hole and tighten to the specified torque.

TOROUE: 18 N'm {1.8 kgf.m, 13 tbf.ft)

NOTE: Do not reuse old aluminum washers.

a Line Pressure M€asurement

- 1 . Set the parking brake and block both rear wheelssecurely.

-2. Run the engine at 2,OOO rpm

-3. Shift the selecr lever to S or @ position.

-4. Measure line pressure.

LINE PRESSUREINSPECTION HOLE

NoTE: Higher pressures may be indicated it measurements are made in selector positions other than @ or @ position.

PRESSURESELECTOR

POStTTONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandardService Limit

LineNo'ENo (or low)

lrne pressureTorque converter,

orl pump, pressure

regulator, to.que

convener check

valve

83O-88O kPa(8.5-9.O kgf/cm,,

120- I 30 psi)

78O kPa

{8.0 kgl/cm,, 1lO psi}

Page 500 of 1413

OIL FEED PIPE

ACCUMULATOR COVER

O-RING Replace.

OIL FEED PIPE

OIL FEED PIPE

SERVO OETENT EASE

LOCN WASHER Feplace.

ATF STRAINER

SUCTION PIPE COLLAR

SERVO BOOY

THROTTLE CONTROL SHAFT

E RING

SERVO SEPARATOR PLATE

1ST ACCUMULATOR CHOKE

CHECK BALL

STOPPER SHAFT STAY

SECONDARY VALVE BODY

DOWEL PIN

SECONDARY SEPARATOR PLATE

LUBRICATOR PLATE

OIL FEED PIPE

LOCK.UP VALVE BODY

DOWEL PIN

LOCK-UP SEPARATOR PLATE

TOROUE CONVERTER CHECK VALVE SPRING

TOROUE CONVERTER CHECK VALVE

COOLER CHECK VALVE SPRING

COOLER CHECK VALVE

TOROUE SPECIFICATIONS

@ REGULAToR vALvE BoDY

@ STOPPER SHAFT

@ O-RING Reptace.

@ STATOR SHAFT

@ otl FEED PIPE

@ MAIN vALvE BoDY

@ CHECK EALL

@ DowEL PIN

@ oIL PUMP DRIVE GEAR

@ OIL PUMP DRIVEN GEAR SHAFT

Q9 OIL PUMP DRIVEN GEAR

@ MAIN SEPARAToR PLATE

@ DowEL PrN

@ coNTBoL sHAFT

@ DETENT SPRING

@ DETENT ARM SHAFT

@) DETENT ARM

@ ATF MAGNET

@ COUNTEBSHAFT TOROUE CONVERTER HOUSING

NEEDLE BEANING

@ oIL GUIDE PLATE

@ TOROUE CONVERTER HoUSING

@) MAINSHAFT TOROUE CONVERTER HOUSING BEARING

@ oll SEAL Reptace.

@ LocK-up coNTRoL soLENotD vALvE A/B

@ coNNECTOR STAY

@ LOCK-UP CONTROL SOLENOTD VALVE A/B

FILTER/GASKET Replace.

ReI No.Torque ValueBolt SizeRemarks

12 N.m (1 .2 kgf.m, 8.7 lbf.ft)6 x 1.O mm

14-109

Page 506 of 1413

NOTE:

a Clean all parts thoroughly in solvent or carbuetor

cleaner and dry with compressed air.a Blow out all passages.

a When removing the valve body replace the following:. O-rings. Lock wsshers

1 . Remove the oil feed pipes from the servo body, s€r-

vo detent base, accumulatof cover, lock-uD valve

body and main valve body.

2, Remove the three bolts securing the ATF strainer and

servo detent base, then remove them.

3. Remove the three bolts securing the accumulator

cover. then remove the accumulator cover.

4. Remove the six bolts secu.ing the servo body, then

remove the servo body and separator plate.

5. Remove the bolt securing the secondary valve body,

then remove the secondary valve body and separa-

tor plate.

6. Remove the eight bolts securing the lubricator plate

and lock-up valve body, then remove the lubricatorplate, lock-up valve body and separator plate.

7. Femove the bolt securing the.egulator valve body,

then.emove the regulator valve body.

8. Remove the stator shaft and stopper shaft.

9. Remove the detent spring t,om the detent arm. thenremove the control shaft from the torque convenerhousing.

1O. Remove the detent arm and detent afm shaft t.om

the main valve bodv.

1 1 . Remove the four bolts secu.ing the main valve body,then remove the main valve body.

12. Remove the oil pump driven gear shaft, then remove

the oil pump gears.

'13. Remove the main separator plate with two dowelDtns.

14, Remove and clean the ATF magnet.

15.Clean the inlet opsning of the ATF strainer thorough-

ly with compressed air, then check that it is in good

condition, and the inlet opening is not clogged.

II{LET OPENING

Replace the ATF strainer it it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is notclo9ged.

16.

14-115

Page 513 of 1413

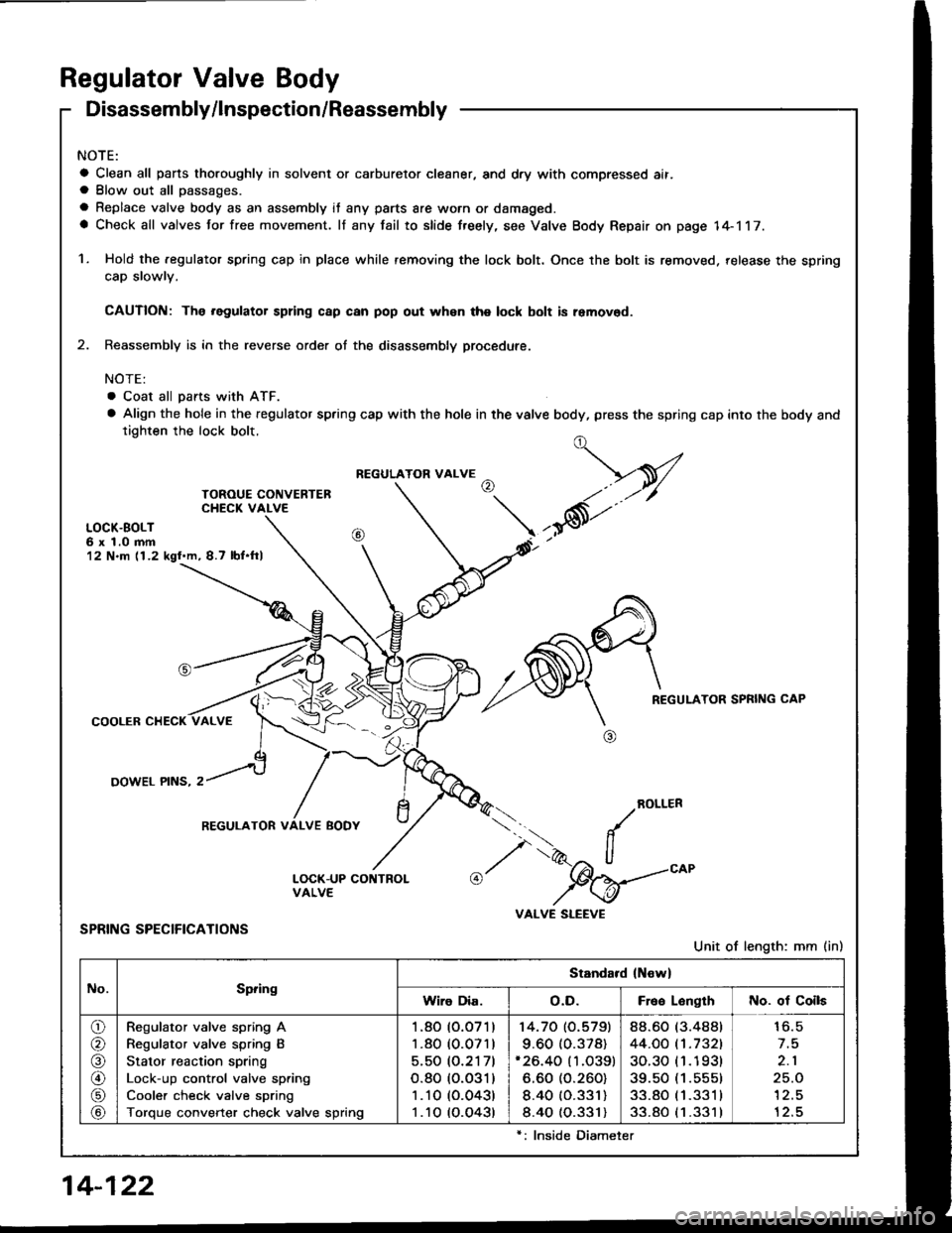

Regulator Valve Body

Disassembly/lnspection/Reassembly

NOTE:

a Clean all pans thoroughly in solvent or carburetor cleaner, and dry with compressed ait.a Blow out all passages.

a Replace valve body as an assembly it any parts are worn or damaged.a Check all valves for free movement. lf any fail to slide freely, see Valve Body Repair on page 14-117.

1. Hold the .egulator spring cap in place while removing the lock bolt. Once the bolt is removed. release the spring

cap slowlv.

CAUTION: The .egulator spring c8p can pop out whsn the lock bolt is removod.

2. Reassembly is in the reverse order of the disassembly procedute.

NOTE:

. Coat all pans with ATF.

a Align the hole in the regulator spring cap with the hole in the valve body, press the spring cap into the body andtighten the lock bolt.

LOCK.BOLT6 x 1.0 mm12 N.m (1.2 kgl.m, 8.7 lbf.ftl

REGULATOR SPRING CAP

COOLER CHECK

OOWEL PINS, 2

ROLLER

SPRING SPECIFICATIONS

Unit of length: mm (in)

../

I',.-2" ll"%=

VALVE SLEEVE

t,-V

,*6t'"

REGULATOR VALVE

REGULATOR VALVE BODY

No.Spring

Standard (New)

Wiro Dia.o.D.Free LonglhNo. of Coils

o/a

@

\9/

Regulator valve spring A

Regulator valve spring B

Stator reaction spring

Lock-up control valve spring

Cooler check valve spring

Torque converter check valve spring

1.80 (O.O71)

1.80 (0.071)

5.50 (O.2171

o.80 (o.o31)

1 .10 (0.043)

1 .10 (O.O43t

14.70 (O.5791

9.60 (0.378)'26.40 (1.O39)

6.60 (O.260)

8.40 (O.331)

8.40 (0.331)

88.60 (3.488t

44.OO t't.7321

30.30 (1 .1 93t

39.50 (1.555)

33.80 (1 .331 I

33.80 (1 .331 )

16.5

2.1

25.O'l2.5

12.5

14-122

lnside Diameter

Page 514 of 1413

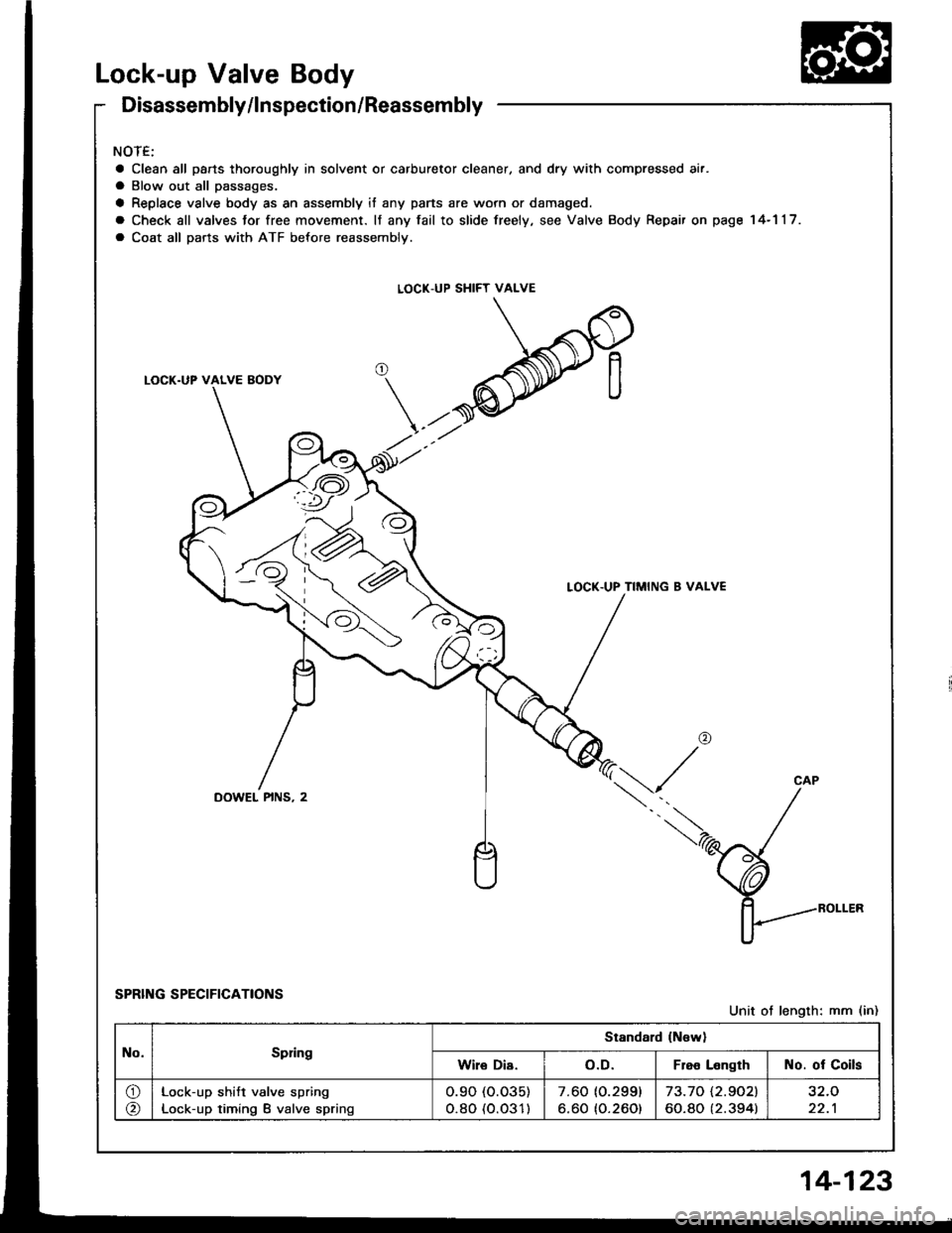

NOTE:

a Clean all paris thoroughly in solvent or carburetor cleaner, and dry with compressed air.

a Blow out all passages.

a Replace valve body as an assembly it any parts are worn or damaged.

a Check all valves tor free movement. lf any fail to slide fre€ly, see Valve Body Repair on page 14-117.

a Coat all parts with ATF before reassembly.

LOCK-UP SHIFT VALVE

LOCK.UP TIMING 8 VALVE

,ar

\,/

SPRING SPECIFICATIONS

CAP

Unit ot length; mm (in)

No.Spring

Standard {Nsw}

Wile Di8.o.D.Flee LengthNo. of Coils

o

@

Lock-up shift valve spring

Lock-up timing B valve spring

o.90 (o.035)

o.80 (o.031)7.60 (0.299)

6.60 {O.260)

73.70 i.2.9021

60.80 (2.394)32.O

22.1

Disassembly/lnspection/Reassembly

14-123

Page 516 of 1413

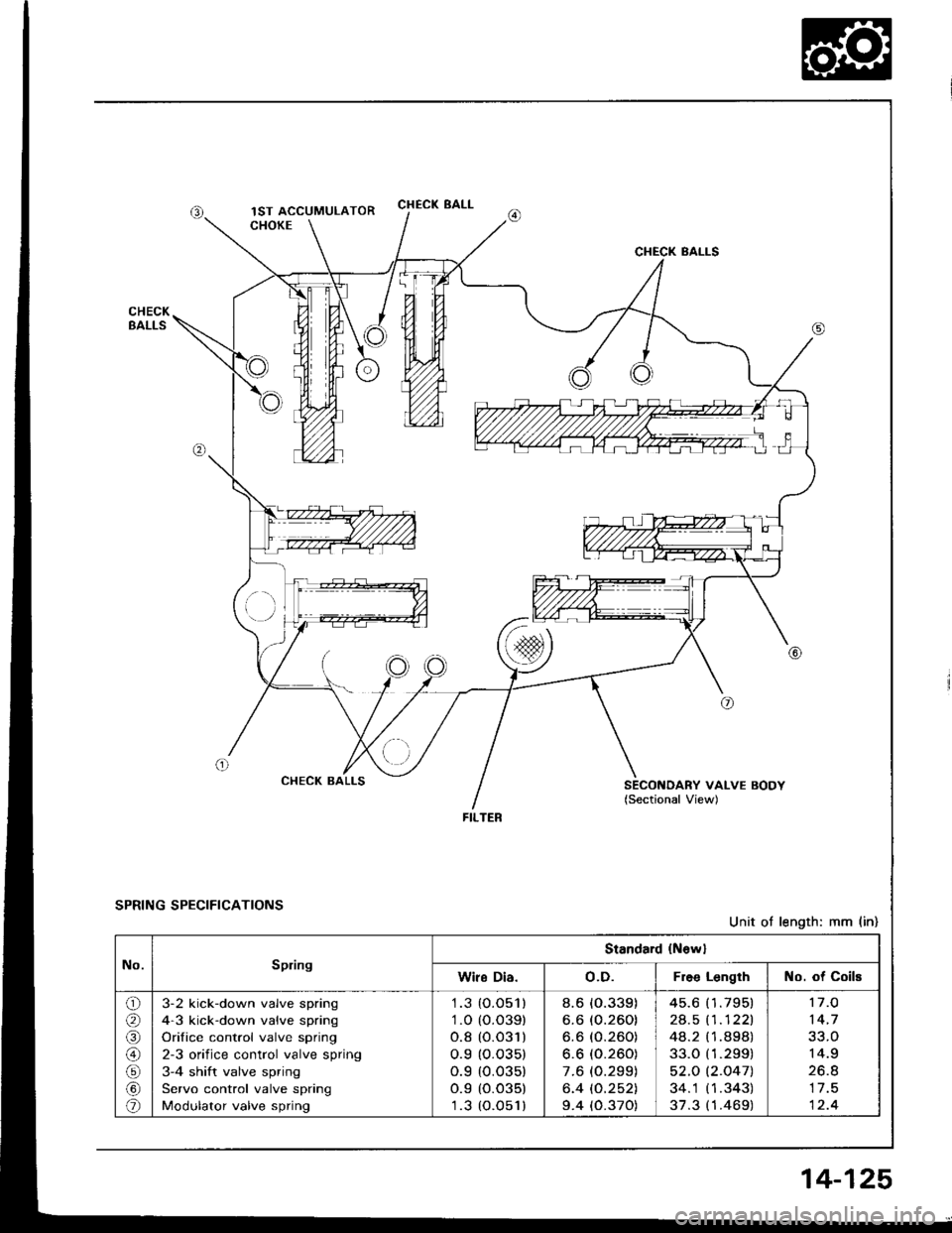

CHECK BALL

CHECK BALLS

FILTER

SPRING SPECIFICATIONS

Unit ot length: mm (in)

No.Spring

Standard (N€wl

Wire Dia.o.D.Free LengthNo. of Coils

o

@

tcl

\9

@

3-2 kick-down valve spring

4-3 kick-down valve spring

Orifice control valve spring

2-3 orifjce control valve spring

3-4 shift valve spring

Servo control valve spring

Modulator valve spring

1 .3 {O.051)

1 .O (O.O39)

o.8 (o.031)

o.9 (o.03s)

0.9 {0.035)

o.9 (o.o35)

1.3 (O.O51)

8.6 tO.339)

6.6 (O.260)

6.6 (0.260)

6.6 (0.260)

7.6 (O.299)

6.4 lO.252l

9.4 (O.370)

45.6

28.5

48.2

33.O

52.O

34.1

37.3

1.795)

1 .1221

1.898)

1.299)

2.O47l�

1.343)

1 .469)

17 .O

14.7

33.O

14.9

26.8

12.4

14-125

Page 529 of 1413

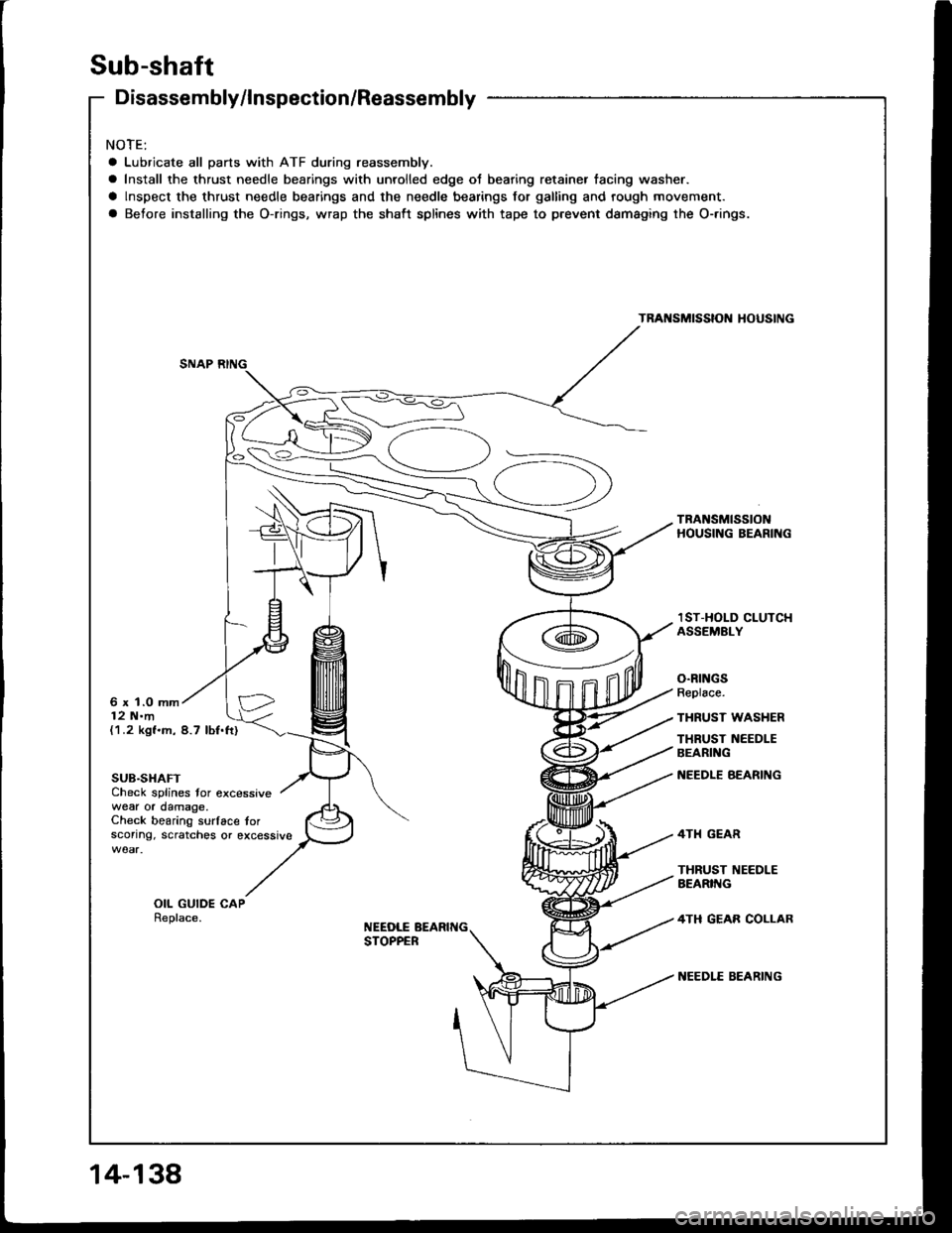

Sub-shaft

Disassembly/lnspection/Reassembly

NOTE:

a Lubricate all parts with ATF during reassembly.

a Install the thrust needle bearings with unrolled edge ot bearing retainer tacing washer.

a lnspect the thrust needle bearings and the needle bearings for galling and rough movement.

a Before installing the O-rings, wrap the shaft splines with tape to prevent dsmaging the O-.ings.

TRANSMISSIOI{ HOUSING

TRANSMISSIONHOUSING BEARING

6 x 1.0 mm12 N.m

lST-HOLD CLUTCHASSEMELY

O.RINGSReplace.

THRUST WASHER

THRUST NEEDLEBEARING

NEEDLE BEARING

4TH GEAR

THRUST I{EEDLEAEARIIIG

4TH GEAB COLLAR

NEEDLE EEARING

(1.2 kgf.m, 8.7 lbf.ft)

SUB.SHAFTCheck splines tor excessivewear or damage.Check bearing surlace torsconng. scratches or excessive

OIL GUIDE CAPReplace.NEEDLE BEARIT{GSTOPPER

Page 546 of 1413

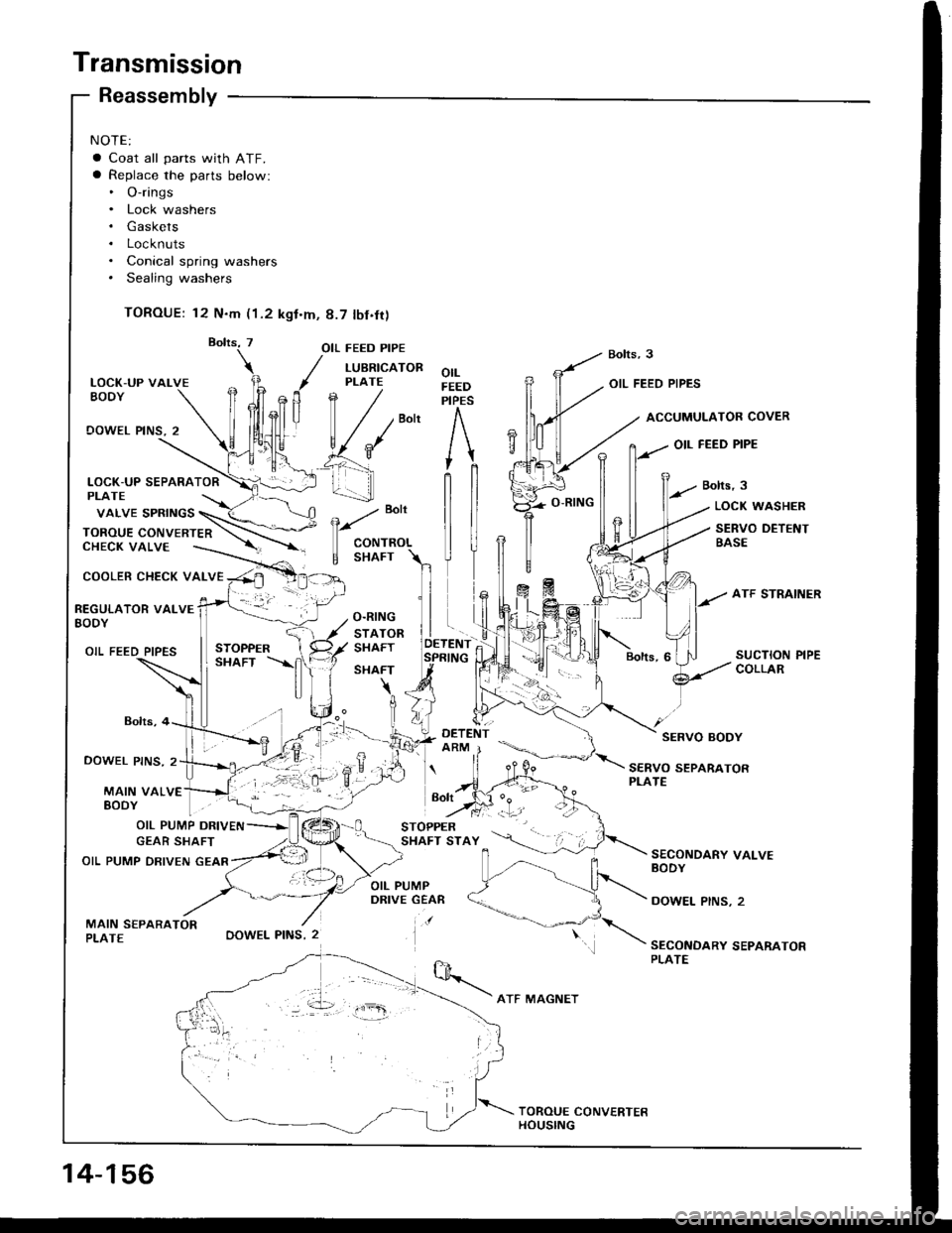

Transmission

NOTE:

a Coat all parts with ATF.a Replace the parts below:. O-rings. Lock washers. Gaskets. Locknuts. Conical spring washers. Sealing washers

TOROUE: 12 N.m (1.2 kgt.m, 8.7 tbf.fr)

LOCK-UP VALVEEODY

OOWEL PINS, 2

COOLER CHECK VALVE

Reassembly

Bolts,4

DOWEL PINS. 2

MAIN VALVE

OIL FEED PIPE

/ LUBRTcAToR

, PLATE

fln /

| / /""n

v{*' e'f _\

_! 1.-...-]]

-. :-,.

OOWEL PINS, 2

orLFEEDPIPES

OIL FEED PIPES

ACCUMULATOB COVER

OIL FEED PIPE

Bolts,3

e

"o't

CONTROL

E SHAFT

LOCK WASHER

SERVO DETENTBASE

REGULATOR VALVEBODY

OIL FEED PIPES

SERVO BODY

SERVO SEPARATORPLATE

EoDY | . "1-

OIL PUMP DRIVEN

GEAR SHAFT

OIL PUMP DRIVEN GEAR

MAIN S€PARATORPLATE

SECONDARY VALVEBODY

DOWEL PINS, 2

SECONDARY SEPARATORPLATE

vaLVE spRtNGS \_(< \

ToRou E coN vE RTE n \-\.--CHECK VALVE ----.-. --'r -

Bolt

14-156

ATF MAGNET

Page 547 of 1413

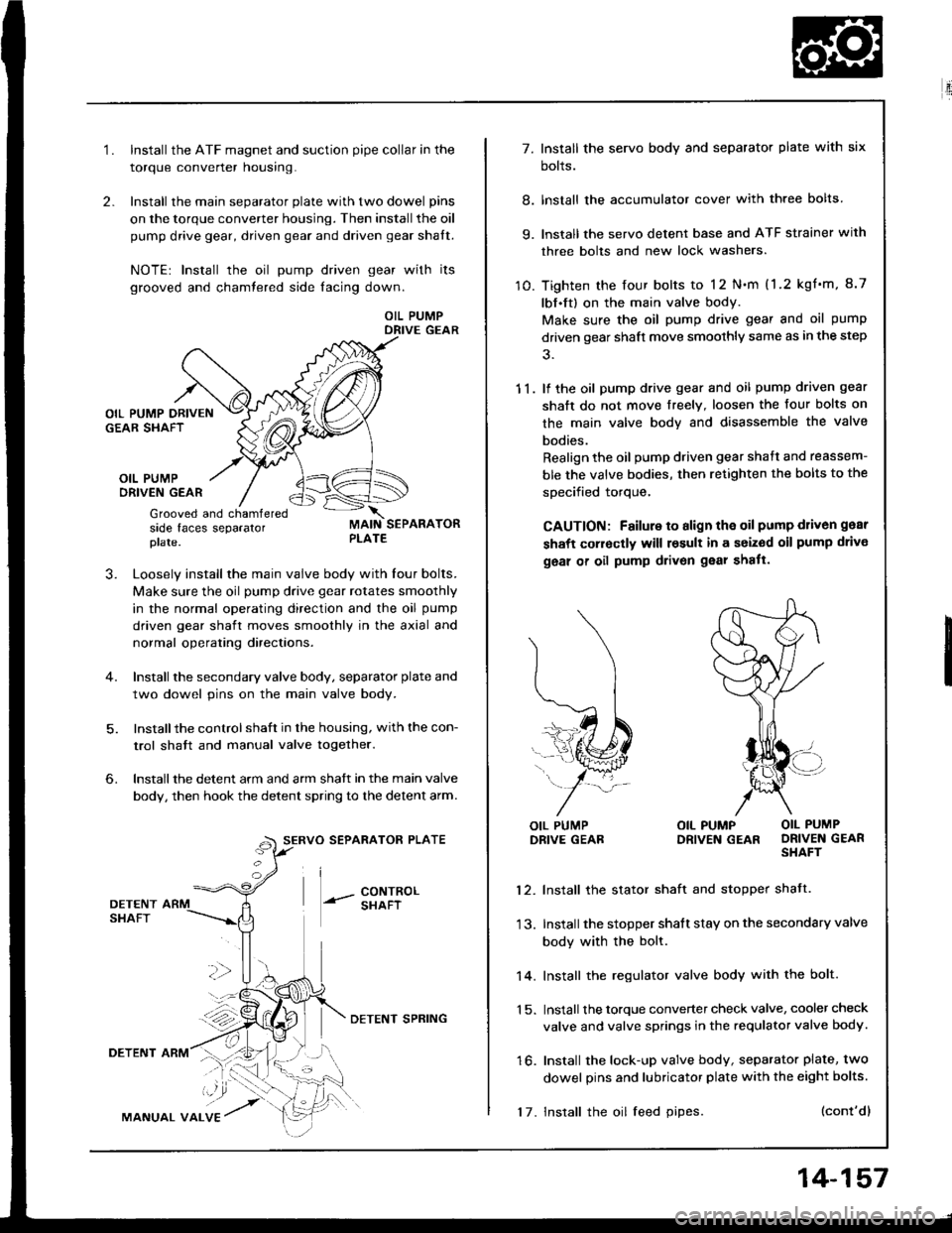

2.

1.Install the ATF magnet and suction pipe collar in the

torque converter nousrng.

Install the main separator plate with two dowel pins

on the torque converter housing. Then install the oil

pump drive gear, driven gear and driven gear shalt.

NOTE| Install the oil pump driven gear with its

grooved and chamtered side facing down.

OIL PUMPDRIVE GEAR

OIL PUMPORIVEN GEAR

Grooved and chamferedside faces separatorplate.

J.Loosely install the main valve body with Iour bolts.

Make sure the oil pump drive gear rotates smoothly

in the normal operating direction and the oil pump

driven gear shaft moves smoothly in the axial and

normal operating directaons.

Install the secondary valve body, separator plate and

two dowel pins on the main valve body.

Installthe control shaft in the housing, with the con-

trol shatt and manual valve togelher.

Install the detent arm and arm shatt in the main valve

body, then hook the detent spring to the detent arm.

SERVO SEPARATOR PLATE

--- 8ixli"'

6.

36

DETENTSHAFT

DETENT ARM

MANUAL VALVE

DETENI SPRING

17. Install the oil feed pipes.

14-157

E'.:

7. Install the servo body and separator plate with six

bolts.

8. lnstall the accumulator cover with three bolts

9. lnstall the servo detent base and ATF strainer with

three bolts and new lock washers.

10. Tighten the four bolts to 12 N.m (1.2 kgf'm, 8.7

lbf.ft) on the main valve body.

Make sure the oil pump drive gear and oil pump

driven gear shaft move smoothly same as in the step

11. lf the oil pump drive gear and oil pump driven gear

shaft do not move freelY. loosen the four bolts on

the main valve body and disassemble the valve

bodies.

Realign the oil pump driven gear shaft and reassem-

ble the valve bodies, then retighten the bolts to the

specified torque,

CAUTION: Failure to align the oil pump d1iv6n gear

shaft corroctly will result in a seized oil pump drivo

geal of oil pump drivon gear shatt.

l\

(...l

=..�N

L,1ffi#

j-*/:

OIL PUMPDRIVE GEABOIL PUMP OIL PUMPDRIVEN GEAR DRIVEN GEARSHAFT

12. Install the stator shaft and stopper shatt.

13. Install the stopper shatt stay on the secondary valve

body with the bolt.

14. Install the regulator valve body with the bolt.

1 5. Install the torque converter check valve, cooler check

valve and valve springs in the requlator valve body.

16. Install the lock-up valve body, separator plate, two

dowel pins and lubricator plate with the eight bolts.

(cont'dl