cylinder head HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 139 of 1413

11.

12.

13.

Cylinder Head

Installation lcont'd)

lnstallthe timing belt lsee page 6-51).

Adjust the valve clearance (see page 6-44).

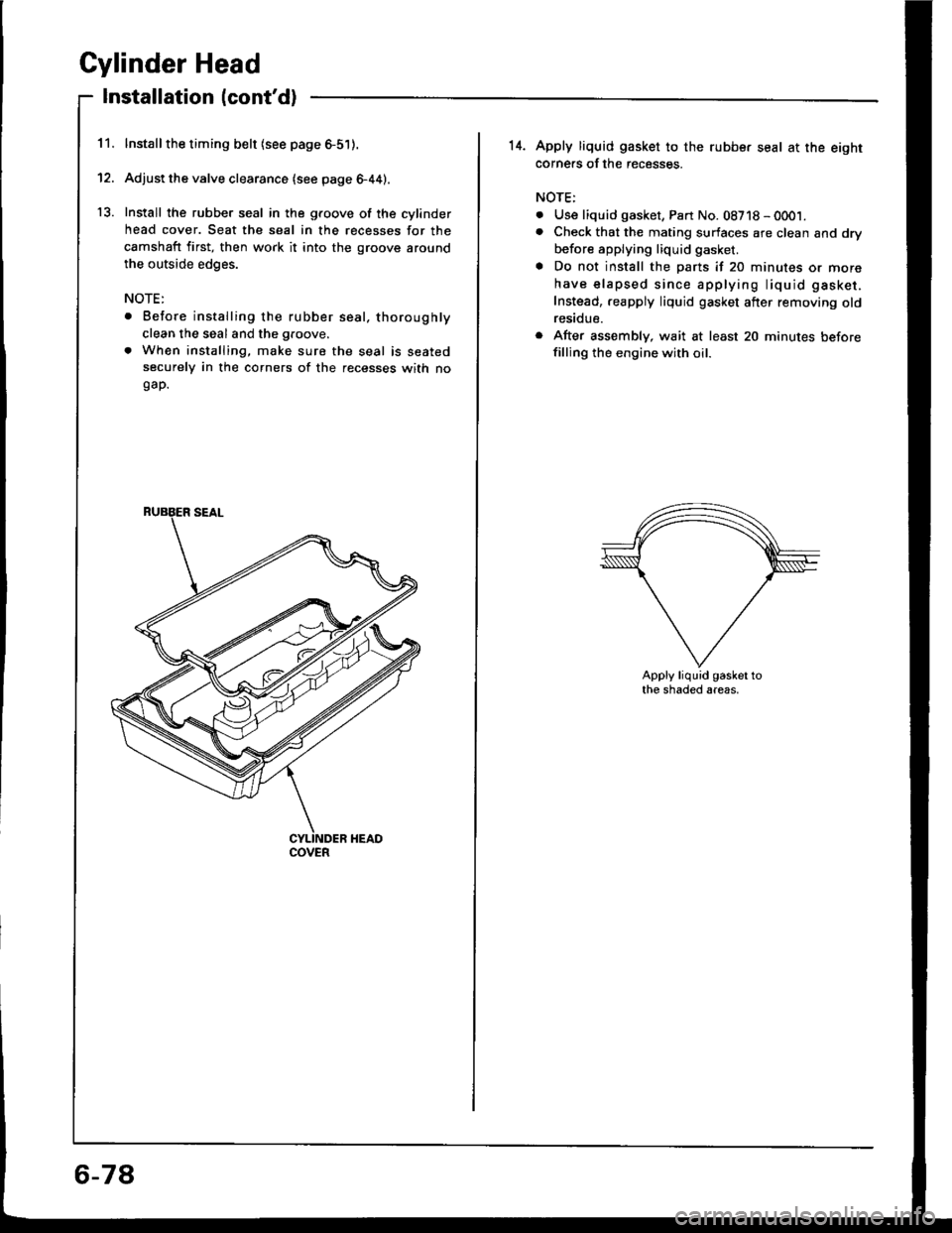

Install the rubber seal in the groove of the cylinder

head cover. Seat the seal in the recesses for the

camshaft first, then work it into the groove around

the outside edges.

NOTE:

. Before installing the rubber seal. thoroughly

clean the seal and the groove.

. When installing, make sure the seal is seatedsecurely in the corners of the recesses with nogap.

COVER

6-78

14. Apply liquid gasket to the rubbe. seal at the eightcorne.s of the recesses.

NOTE:

. Use liquid gasket, Part No. 08718 - 0001.. Check that the mating surfaces are clean and dry

before applying liquid gasket.

a Do not install the parts if 20 minutes or more

have elapsed since applying liquid gasket.

Instead,.eapply liquid gasket after removing oldresidue.

r After assembly, wait at least 20 minutes beforefilling the engine with oil.

Apply liquid gasket tothe shaded areas.

Page 140 of 1413

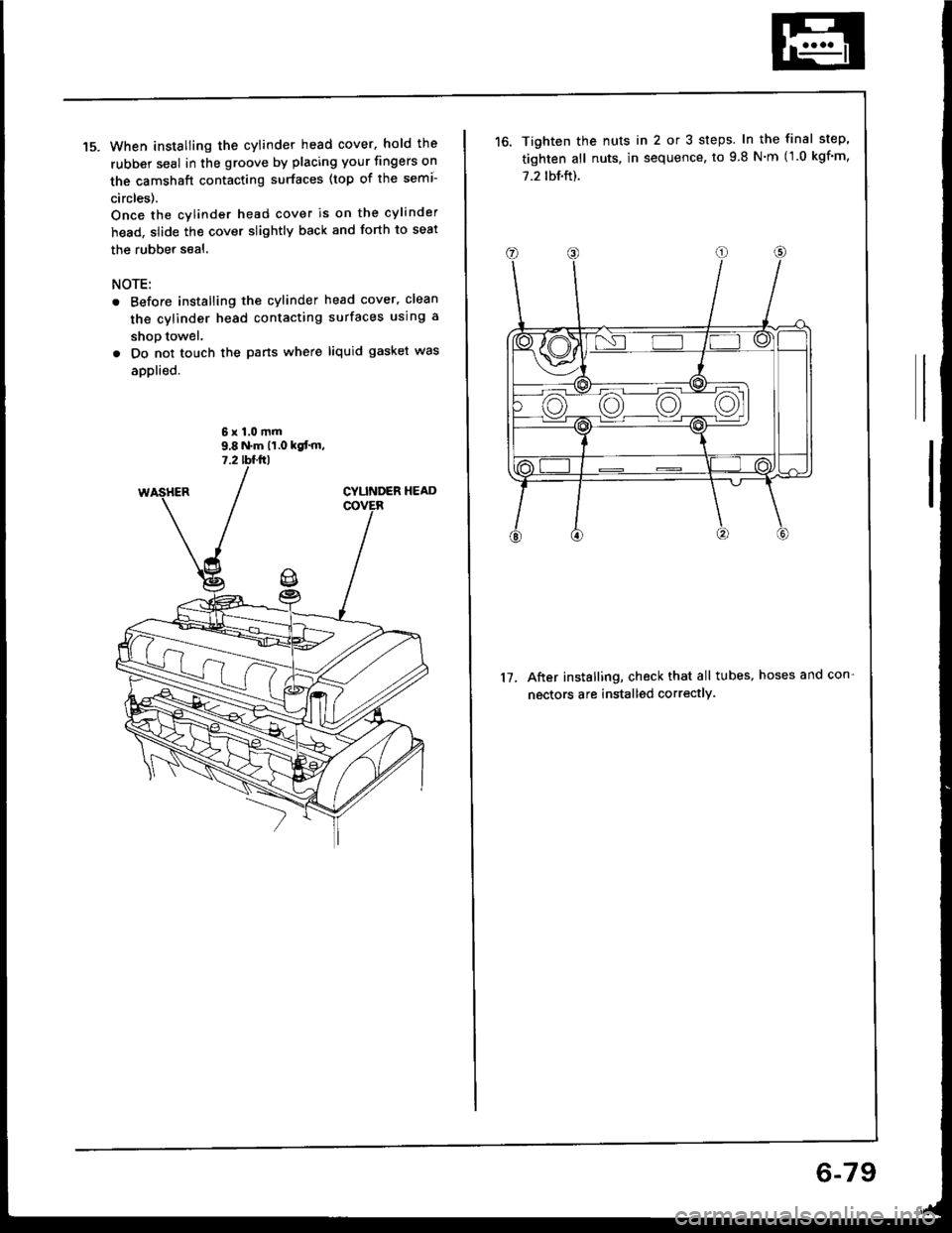

When installing the cylinder head cover. hold the

rubber seal in the groove by placing your fingers on

the camshaft contacting surfaces (top of the semi-

circles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the rubber seal.

NOTE:

Before installing the cylinder head cover, clean

the cylinder head contacting surfaces using a

shop towel.

Do not touch the pans where liquid gasket was

applied.

6x1.0mm9,8 N.m 11.0 kgt'm,7.2 tffirl

Tighten the nuts in 2 or 3 steps. In the final step'

tighten all nuts, in sequence, to 9.8 N'm (1.0 kgf'm,

7.2 tbf.ft).

After installing, check that all tubes, hoses and con-

nectors are installed correctly.

17.

6-79

Page 176 of 1413

Oil Pump

5.

4.

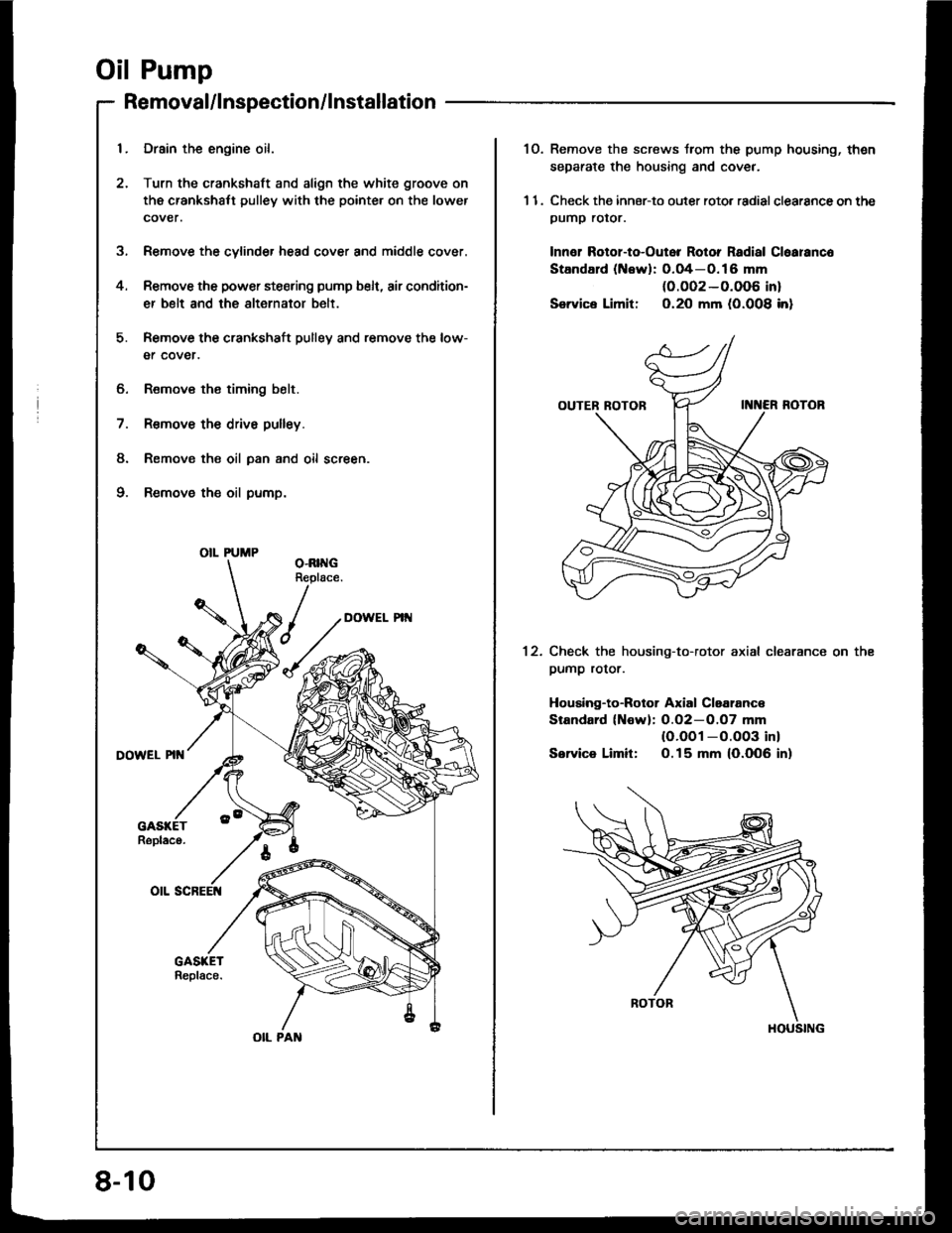

Removal/lnspection/lnstallation

6. Remov€ the timing belt.

7. R€move the drive pulley.

8. Remov€ the oil pan and oil screen.

9. Remove the oil pump.

Drain the engine oil.

Turn the crankshatt and align the white groove on

the crankshalt pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condition-

er belt and the alternator belt.

Remove the crankshaft pulley and remove the low-

er cover.

OIL PUMP

OIL PAN

8-10

1O. Remove the screws trom the pump housing, thsn

separate the housing and coveJ.

1 1. Check the inner-to outer roto. radial clearance on thepumP rotor.

Innor Rotol-to-Outor Rotor Radial Cloaranco

StandErd (Newl: O.O4-O.16 mm(0.O02-0.006 in)

Service Limit: O.2O mm (0.008 inl

Check the housing-to-rotor axial clearance

pump rotor.

Housing-to-Botor Axial Claalanc€

Standard (Nowl: O.O2-O.O7 mm(O.OO1 -O.OO3 inl

Service Limit: O.15 mm (0.006 in)

on the12.

HOUSING

Page 309 of 1413

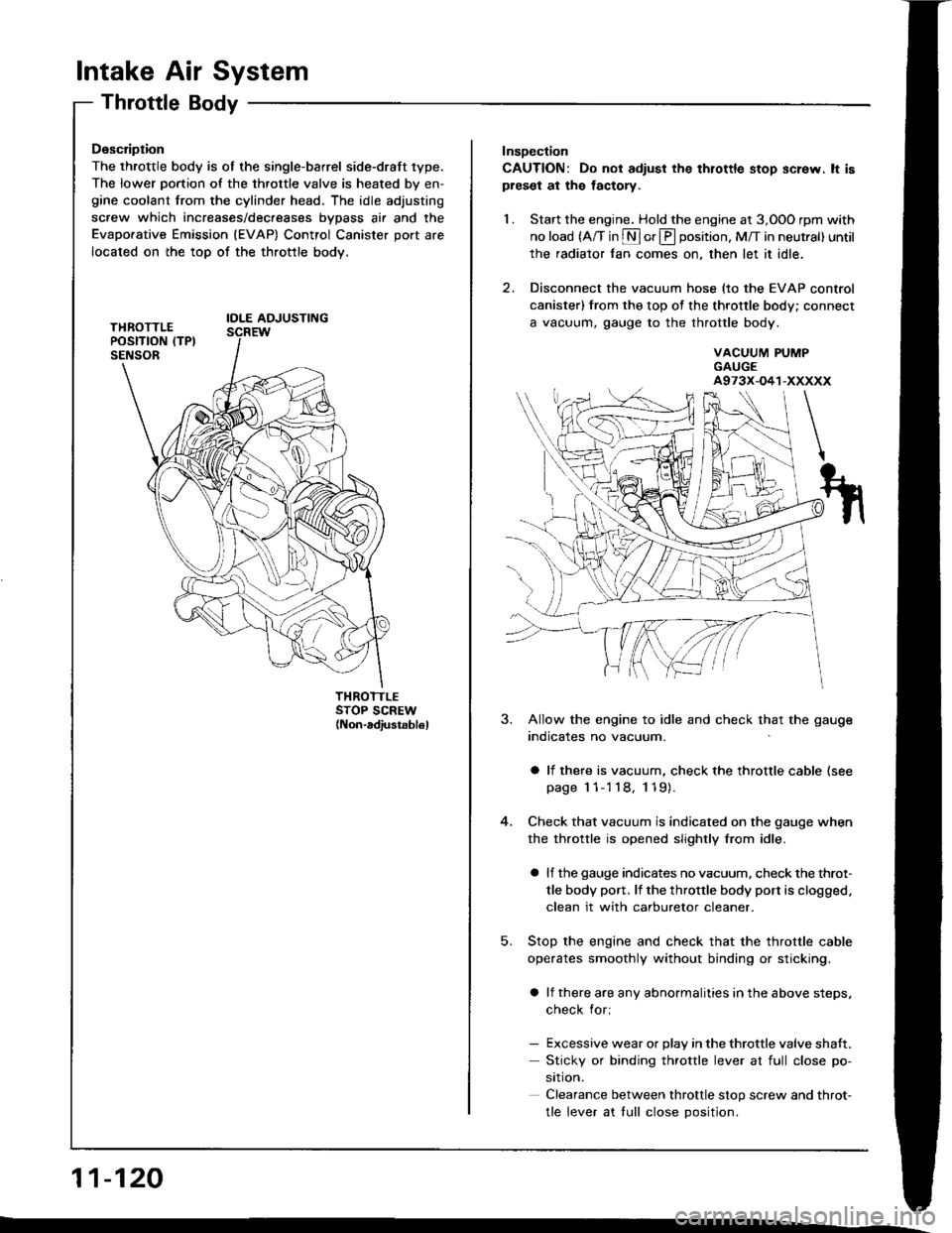

lntake Air System

Throttle Body

Description

The throttle body is ot the single-barrel side-draft 1ype.

The lower portion of the throttle valve is heated by en-gine coolant from the cylinder head. The idle adjusting

screw which increases/dec.eases bvDass air and the

Evaporative Emission (EVAP) Control Canister port are

located on the top of the throttle body.

IOLE AOJUSTING

THROTTLESTOP SCREW(Non-adiustsb16l

11-120

Insoection

CAUTION: Do not adiust the thlottle stop screw. lt ispreset at the lactory.

1. Start the engine. Hold the engine at 3,OOO rpm with

no load (A/T in S or E position, M/T in neutral) until

the radiator fan comes on, then let it idle.

2. Disconnect the vacuum hose (to the EVAP control

canister) from the top of the throttle body; connect

a vacuum, gauge to the throttle body.

VACUUM PUMPGAUGEA973X-O41-XXXXX

5.

3. Allow the engine to idle and check that the gauge

indicates no vacuum.

a li there is vacuum, check the throttle cable (see

page 1 1-'l 18, 119).

Check that vacuum is indicated on the gauge when

the throttle is opened slightly from idle.

a lf the gauge indicates no vacuum, check the throt-

tle body port. lf the throttle body port is clogged.

clean it with carburetor cleaner.

Stop the engine and check that the throttle cable

operates smoothly without binding or sticking.

a lf there are any abnormalities in the above steps,

check for:

- Excessive wear or Dlav in the throttle valve shaft.

Sticky or binding throttle lever at full close po-

srtron.

Clearance between throttle stop screw and throt-

tle lever at tull close Dosition.

Page 616 of 1413

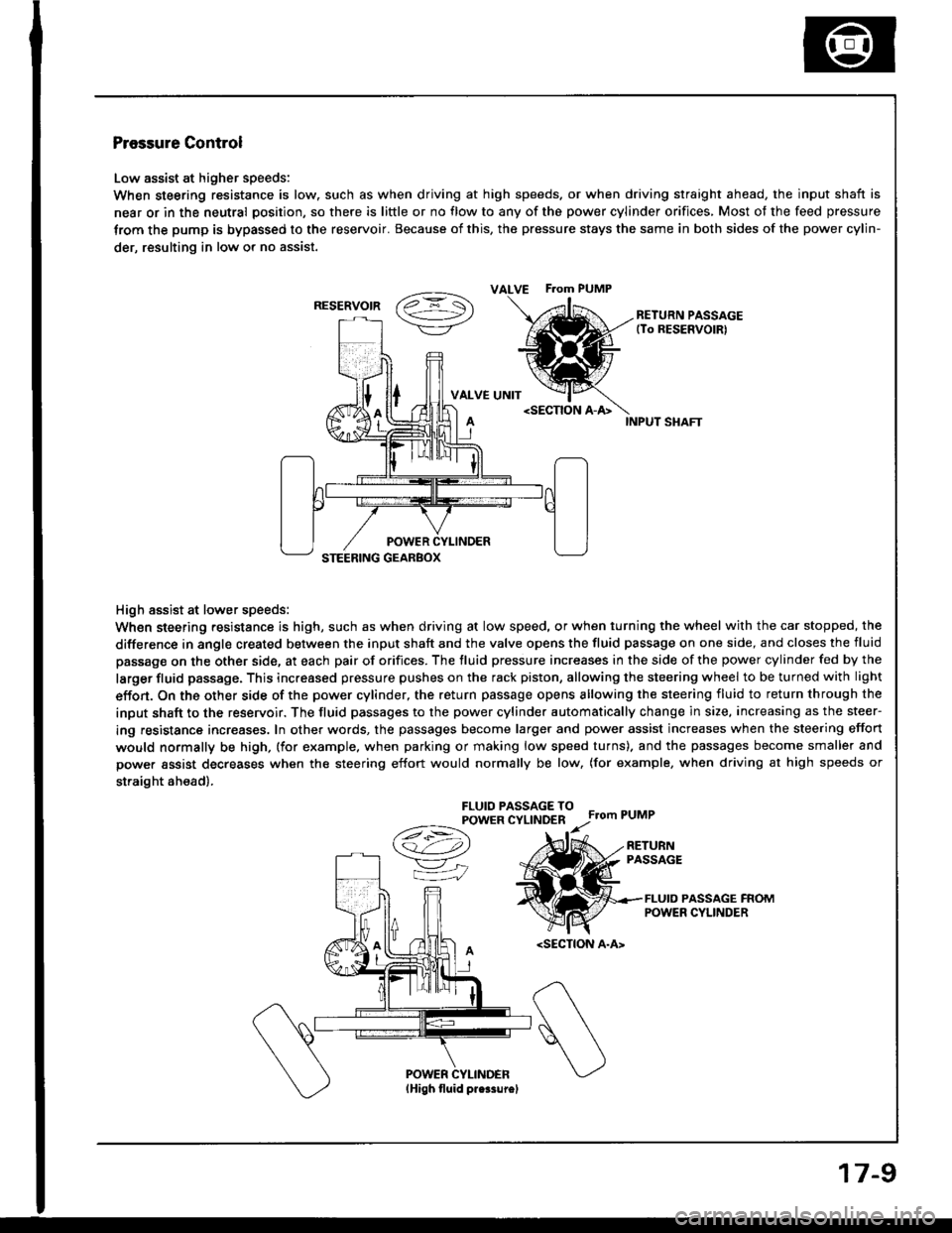

Pressure Control

Low assist at higher speeds:

When steering resistance is low. such as when driving at high speeds. or when driving straight ahead, the input shaft is

near or in the neutral position, so there is little or no flow to any of the power cylinder orifices, Most of the feed pressure

trom the pump is bypassed to the reservoir. Because of this, the pressure stays the same in both sides of the power cylin-

der, resulting in low or no assist.

vaz =- S\->/-\7/RETURN PASSAGE(To RESERVOIRI

VALVE UNIT

High assist at lower speeds:

When steering resistance is high, such as when driving at low speed, or when turning the wheel with the car stopped, the

difference in angle created between the input shaft and the valve opens the fluid passage on one side, and closes the fluid

passage on the other side, at each pair of orifices. The fluid pressure increases in the side of the power cylinder fed by the

larger fluid passage. This increased pressure pushes on the rack piston, allowing the steering wheel to be turned with light

effon. On the other side of the power cylinder, the return passage opens allowing the steering fluid to return through the

input shaft to the reservoir. The fluid passages to the power cylinder automatically change in size, increasing as the steer-

ing resistance increases. In other words, the passages become larger and power assist increases when the steering effort

would normally be high, (for example. when parking or making low speed turns). and the passages become smaller and

power assist decreases when the steering effort would normally be low, (for example, when driving at high speeds or

straight ah€ad).

FLUIO PASSAGE TOPOWER CYLINDERFrom PUMP

A

/t-:\

v"

=iJ

RETURNPASSAGE

FLUID PASSAGE FROMPOWER CYLINDER

ALVE F.om PUMP

RESERVOIR

17-9

Page 619 of 1413

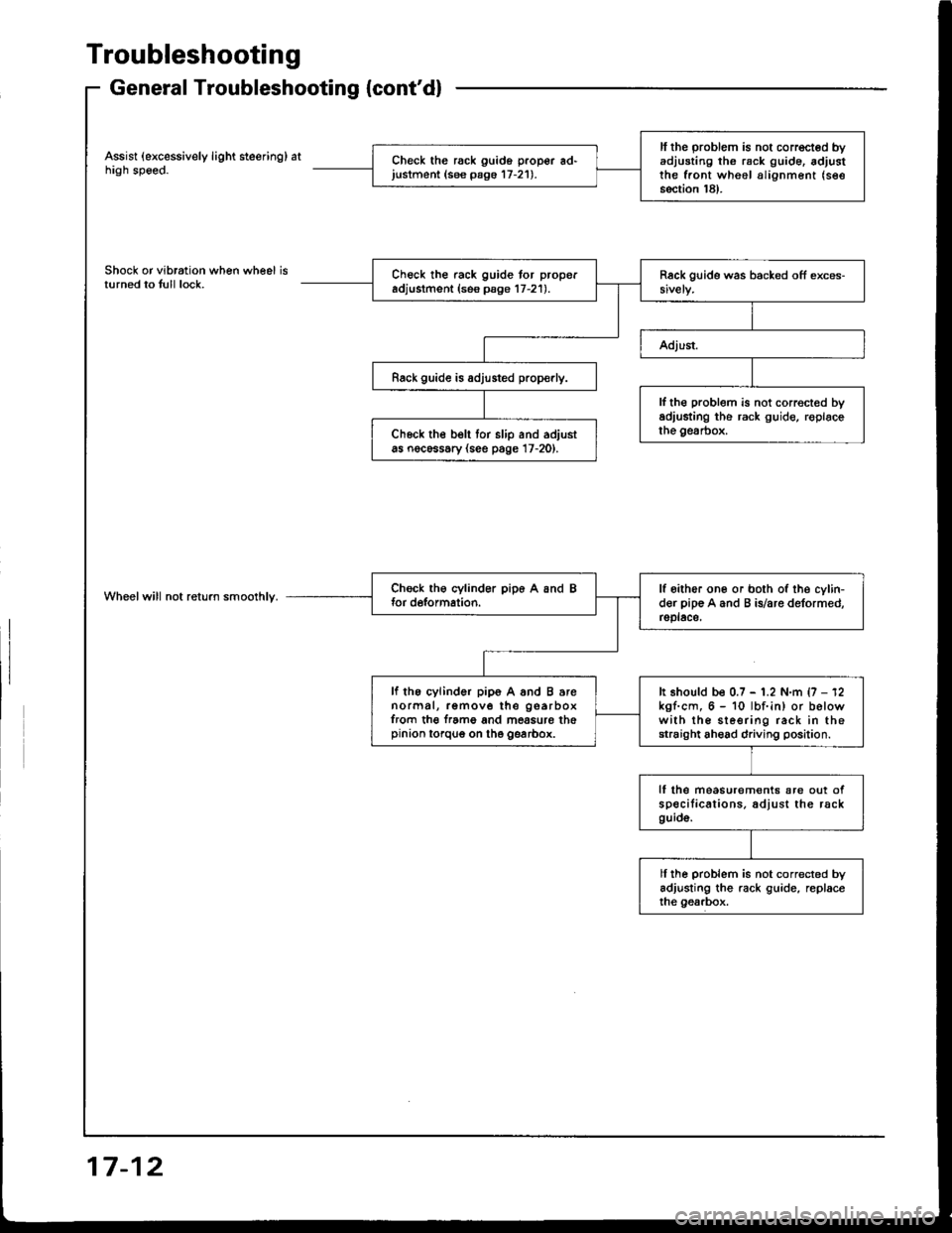

Troubleshooting

General Troubleshooting {cont'd}

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to tull lock.

Wheelwill not return smoolhly.

ll the problem is not corrected byadjusting th6 rack g!ide. adjustthe front wheel alignment (see

section 18).

Check the rack guido proper ad'justment (see pago 17-21).

Check the rack guide tor properadjustment (ses psge 17-21).

Rack guide is adjusted prop€rly.

lf th€ problem is not correct€d byadiusting the rack guide, roplacethe gesrbox.Ch6ck the belt tor slip and adjustas nocessary (see page 17-20).

lf oither one or both of the cylin-der pip€ A and B is/are deformed,rsplace,

lf the cylinder pip6 A and B arenormal, remove the gearboxfrom th€ f.ame and mossure thepinion torqug on the gearbox.

It should be 0.7 - 1.2 N.m {7 - 12kgf.cm, 6 - 10 lbf.in) or belowwith the sleering rack in thestraight ahead driving position.

lf lhe measurem€nts are out ofspecilications. adjust the rackguid6.

ll ihe problem is not corrected byadjusting the rack guide, replaceihe gearbox.

17-12

Page 1203 of 1413

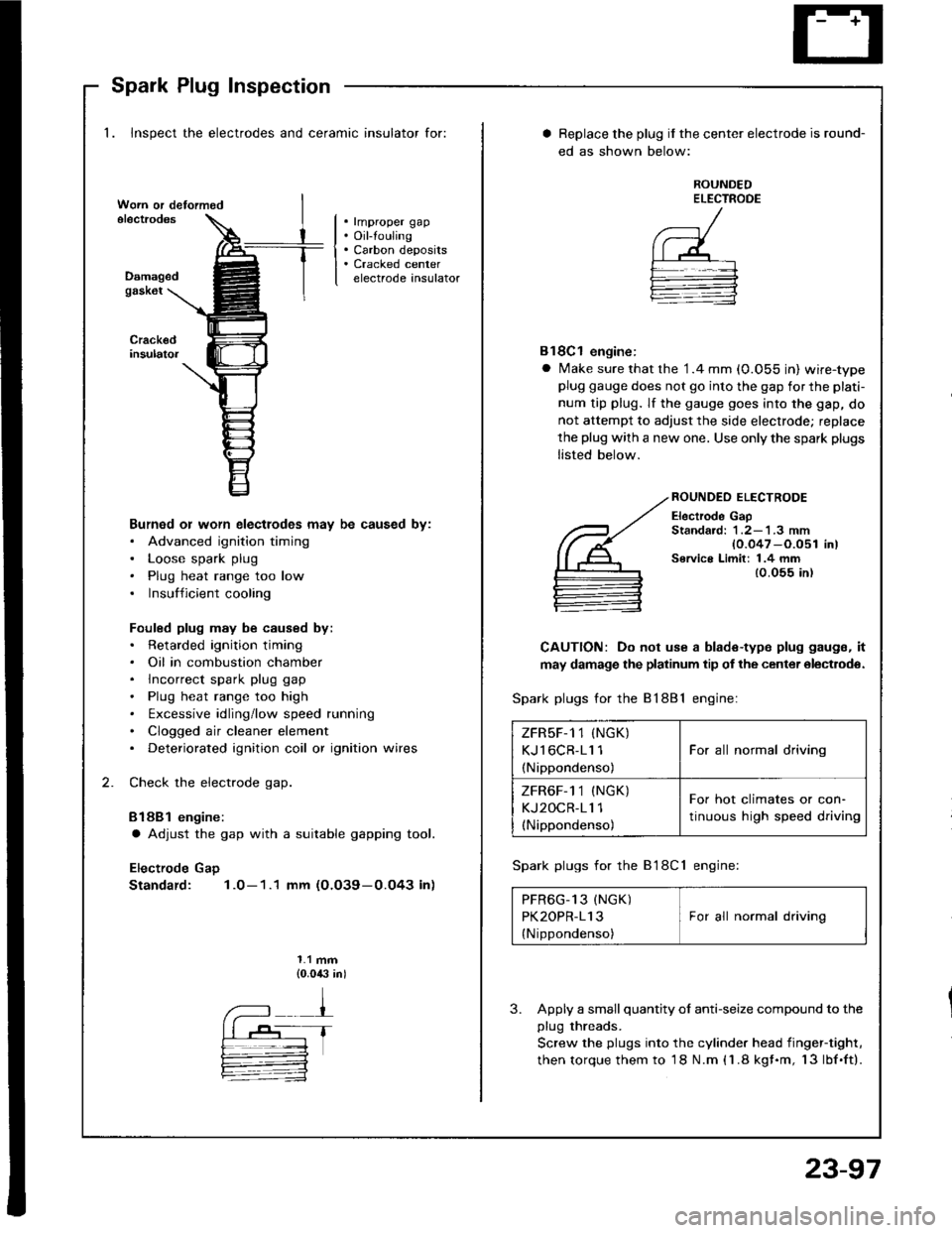

Spark Plug Inspection

1. Inspect the electrodes and ceramic insulator for:

. rmproper gap. Oil-touling. Carbon deposits. Cracked centerelectrode insulatorDamagedgask6t

Burned or worn electlodes may be caused by:. Advanced ignition timing. Loose spark plug. Plug heat range too low. Insufficient cooling

Fouled plug may be caused by:. Retarded ignition timing. Oil in combustion chamber. lncorrect spark plug gap. Plug heat range too high. txcessive idling/low speed running. Clogged air cleaner element. Deteriorated ignition coil or ignition wires

Check the electrode gap.

Bl88l engine:

a Adjust the gap with a suitable gapping tool.

Electrode Gap

Standard: 1.0-1.1 mm (O.O39-0.O43 in)

1.1 mm{0.0,$ in)

Replace the plug if the center electrode is round-

ed as shown below:

ROUNDEDELECTROOE

Bl8Cl engine:

a Make sure that the '1.4 mm (0.055 in) wire-typeplug gauge does not go into the gap for the plati-

num tip plug. lf the gauge goes into the gap, do

not attempt to adjust the side electrode; replace

the plug with a new one. Use only the spark plugs

listed below.

ROUNDEO ELECTRODE

Electrode GapStandard: 1 .2-'l .3 mm{0.047 -O.051 in)Service Limit: 1.4 mm{0.055 in)

CAUTION: Do not use a blade-type plug gaugs, it

may damage the platinum tip of the center olectrodo.

Spark plugs for the 81881 engine:

Spark plugs for the B'l8Cl engine:

PFR6G_13 (NGK) IPK2OPR-113 I For all normal driving

{Nippondenso)

3. Apply a small quantity ol anti-seize compound to the

plug threads.

Screw the plugs into the cylinder head iingef-tight,

then torque them to 18 N.m (1.8 kgf.m, 13lbf.ft).

ZFRsF-1 1 (NGK)

KJl6CR-11 1

(Nippondenso)

For all normal driving

ZFR6F-1 1 (NGK)

KJ2OCR-11 1(Nippondenso)

For hot climates or con-

tinuous high speed driving

23-97