main wire harness HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1178 of 1413

lgnition Switch

Steering Lock Replacement

CAUTION:

a All SRS electrical wiring harnesses ale covsred with

yellow insulation.

a Belore disconnecting any parl ot the SRS wir€ hal-

ness, connecl the short connector{s).

a Replace the entire alfected SRS harness a$6mbly il

it has an open circuit or damaged wiring.

NOTE: The original radio has a coded thett protection

circuit. Be sure to get the customer's code number betore

- disconnecting the batterY.

- removing the No. 32 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative cable from the battery.

2. Remove the dashboald lower cover and knee bolster

(see page 23-7'l ).

3. Disconnect the 5-P connector from the under-dash

fuse/relay box and the 7-P connector trom the main

wire harness {see page 23-71).

4. Remove the steering column covers (see page

23-711.

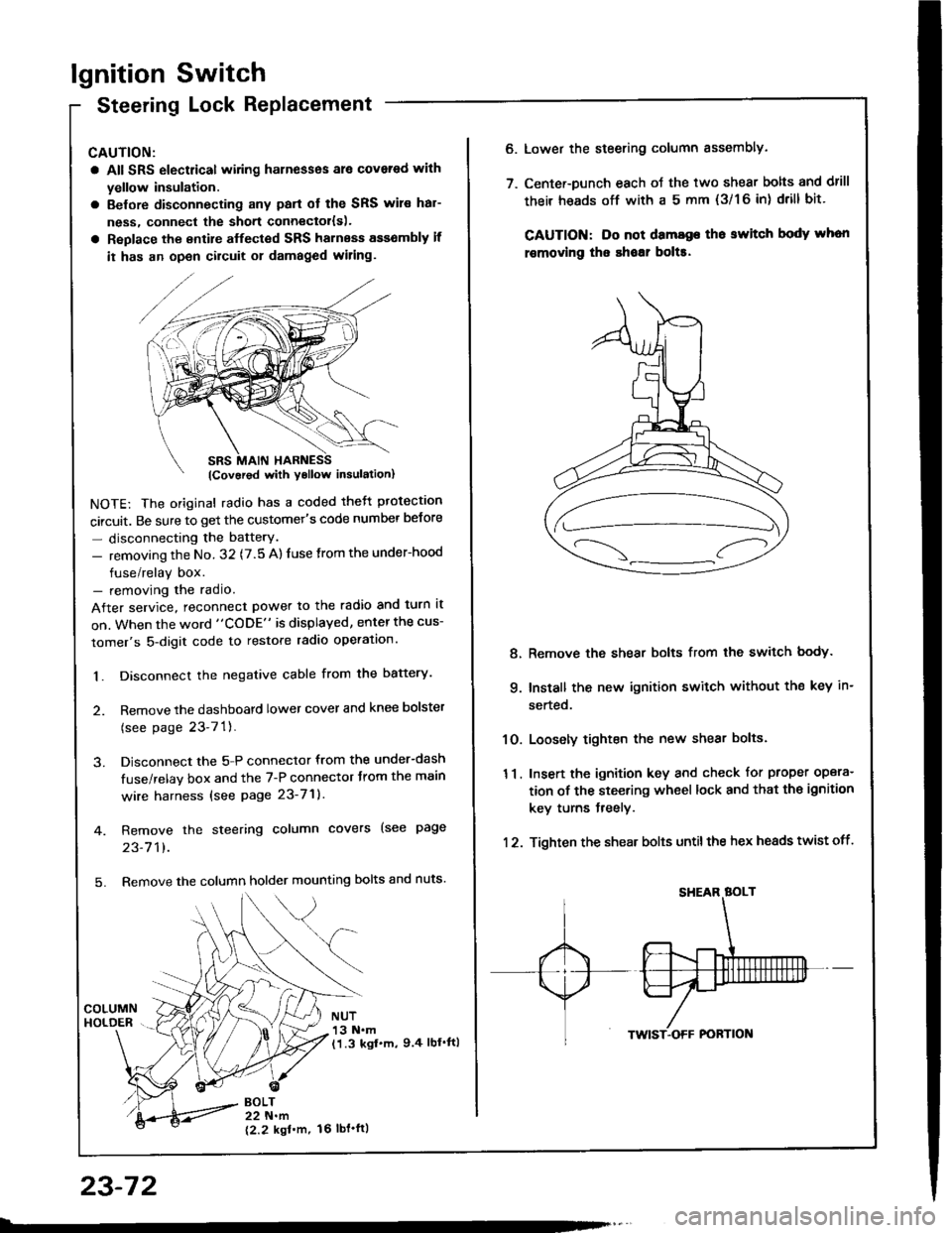

5. Remove the column holder mounting bolts and nuts'

BOLT22 N.m

12.2 kgl'm.

NUT13 N.m(1.3 kgf.m, 9.4 lbl'ftl

23-72

16 tbt.ftl

6. Lower the steering column sssembly.

7. Center-Dunch each oJ the two shear bolts and drill

their heads off with a 5 mm {3/1 6 in) drill bit'

CAUTION: Do not dama96 tho switch body whon

r€movlng the shoar bol$.

Remove the shear bolts from the switch body.

Install the new ignition switch without the key in-

serted.

Loosely tighten the new shear bolts.

Insert the ignition key and check for proper opera-

tion of the steering wheel lock and that th€ ignition

key turns freely.

Tighten the shear bolts untilthe hex heads twist off.

8.

q

10.

11.

12.

Page 1219 of 1413

Gauge Assembly

Component Location Index

CAUTION:

a All SRS electrical wiring harnosses are cov€rod withyellow insulation.

a Bofore disconnecting any prn ot th€ SRS wire har-ness, connect tho short connector(sl.a R€place th6 entirs affGcted SRS halne$ assembly ifit has an open circuit o? damaged wiring.

SRS MAIN HARNESS{Cov.r6d with yollow inrularionl

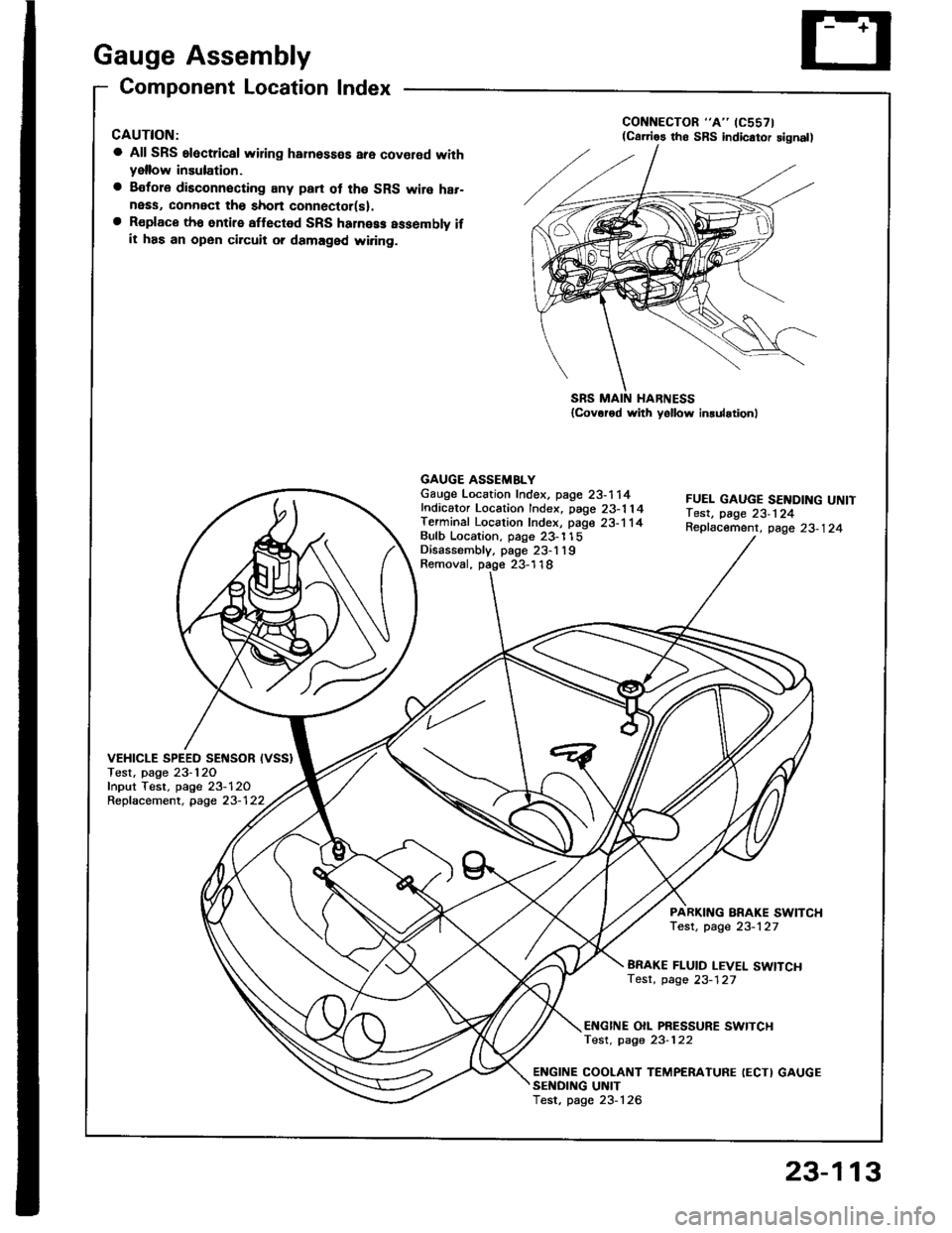

GAUGE ASSEMBLYGauge Location Index, page 23-114Indicator Location Index, page 23-1 14Terminal Location Index, page 23-114Bulb Location. page 23-'l 15Disassembly. page 23-1 19Removal, page 23-118

FUEL GAUGE SENDING UNtTTest, page 23'124Repfacemenr, page 23-124

VEHICLE SPEEO SENSOB IVSS}Test, page 23-120fnput Test. page 23-120Repfacement, page 23-122

PARKITTG BRAKE SWITCHTest, page 23-127

BRAKE FLUID LEVEL SWITCHTesr, page 23-127

EI{GINE OIL PBESSURE SWITCHTest, page 23-122

ENGINE COOLANT TEMPERATURE IECTI GAUGESENOING UNITTest, page 23-126

(C61'ios tho SBS indicator signal)

23-113

Page 1248 of 1413

Interlock System

Kev Interlock SolenoidTestKey IntenocK Dorenoro I esr -

CAUTION:

a All SRS electrical wiring harnesses ar€ covered rYith

yollow insulation.

a 8eforc disconnecting any pan of the SRS wire har-

ness. connecl tha short connoclol{s|.

a Raplace the ontire affected SRS harness assembly if

it has an opon circuit or damaged wiring,

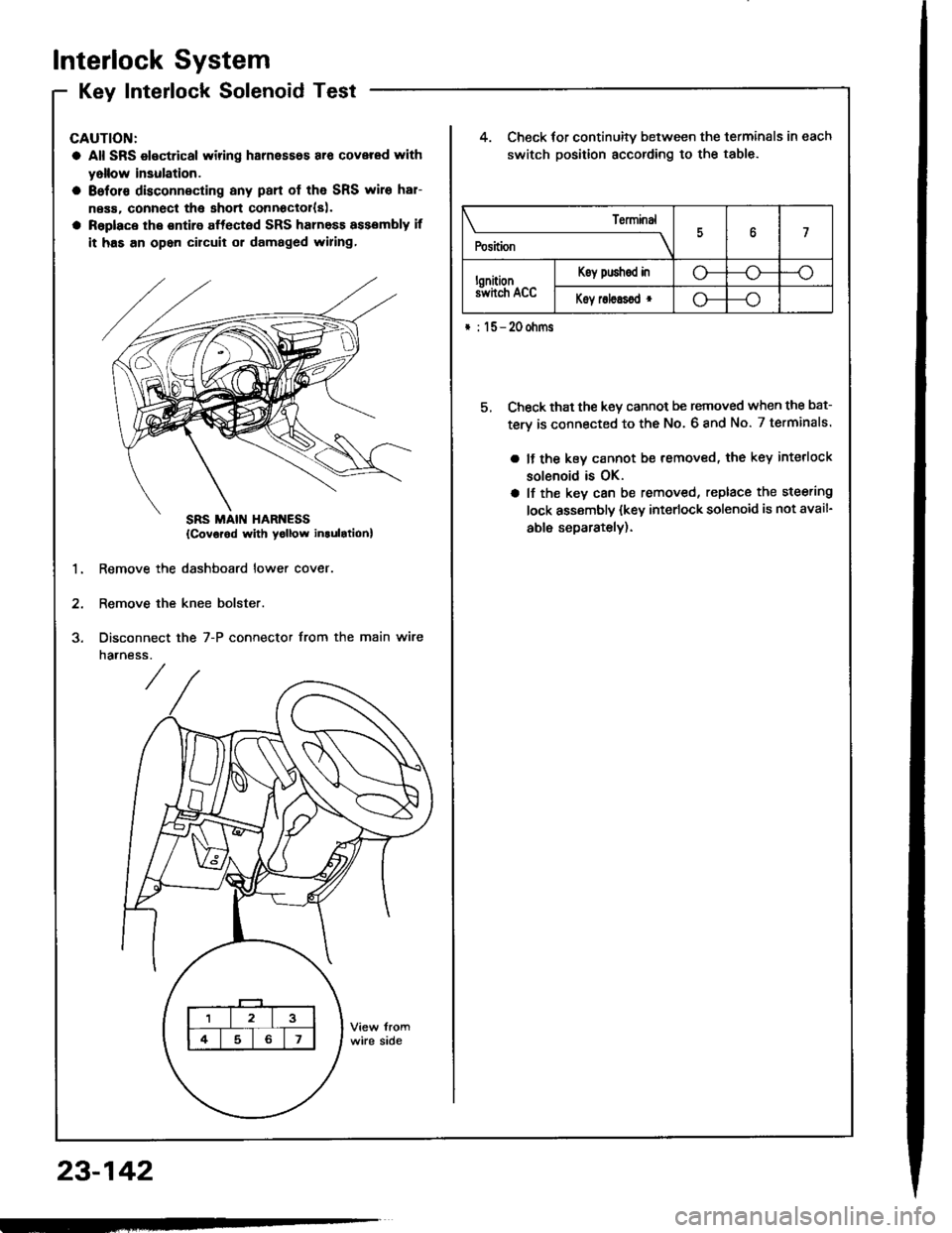

4. Check for continuitv between the terminals in each

switch position according to the table.

5, Check that the key cannot be removed when the bat-

tery is connected to the No. 6 8nd No. 7 terminals.

a It the kev cannot be removed, the key interlock

solenoid is OK.

a lf the key can be removed, replace the steering

lock assembly (key interlock solenoid is not avail-

able separately).

1.Remove the dashboard lower cover

Remove the knee bolster.

Disconnect

narness.

the 7-P connector from the main wire

\______________rry

Position7

lonitionS hch Acc

Koy push€d ino---o

Koy roleEsod r--o

* : l5-20ohms

{Covorod with yollow inlulrtionl

23-142

Page 1249 of 1413

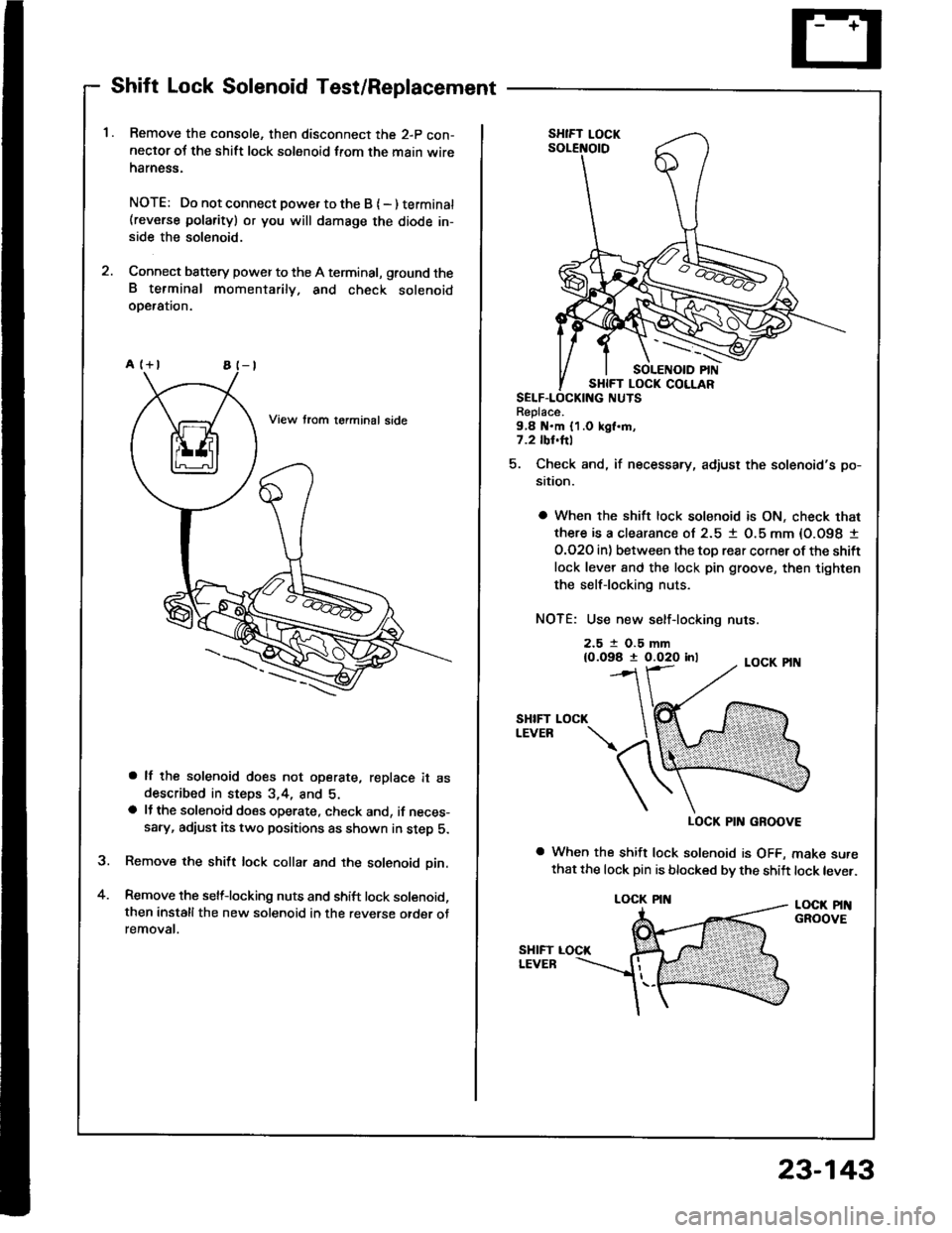

Shift Lock Solenoid Test/Replacement

Remove the console, then disconnect the 2-p con-neclor oJ the shift lock solenoid from the main wireharness.

NOTE: Do not connect powe. to the B { - ) terminat(reverse polarity) or you will damsge the diode in-side the solenoid.

Connect battery power to the A terminal, ground theB terminal momentarily. and check solenoidoDeralron.

a lf the solenoid does not operate, replace it asdescribed in steps 3,4, and 5.a lJ the solenoid does operate, check and, if neces-sary, adiust its two positions as shown in step 5.

Remove the shift lock collar and the solenoid pin.

Remove the selflocking nuts and shift lock solenoid,then installthe new solenoid in the reverse otder otremovat.

a

Replace.9,8 N.m {1.0 kgl.m,7.2 tbl.hl

5. Check and, if necessary, adjust the solenoid's po-

sition.

a When the shift lock solenoid is ON, check that

there is a clearance ol 2.5 1 O.5 mm {O.O98 I

O.O2O in) between the toD rear corner ot the shift

lock lever 8nd the lock pin groove, then tighten

the selflocking nuts.

NOTE: Use new self-locking nuts.

2.5 t O.5 mm{0.098 t 0.020 inl

SHIFTLEVEB

LOCK PIN GROOVE

a When the shift lock solenoid is OFF, make surethat the lock pin is blocked bv the shift lock lever.

LOCK PINGROOVE

LOCK

LOCK PIN

23-143

Page 1256 of 1413

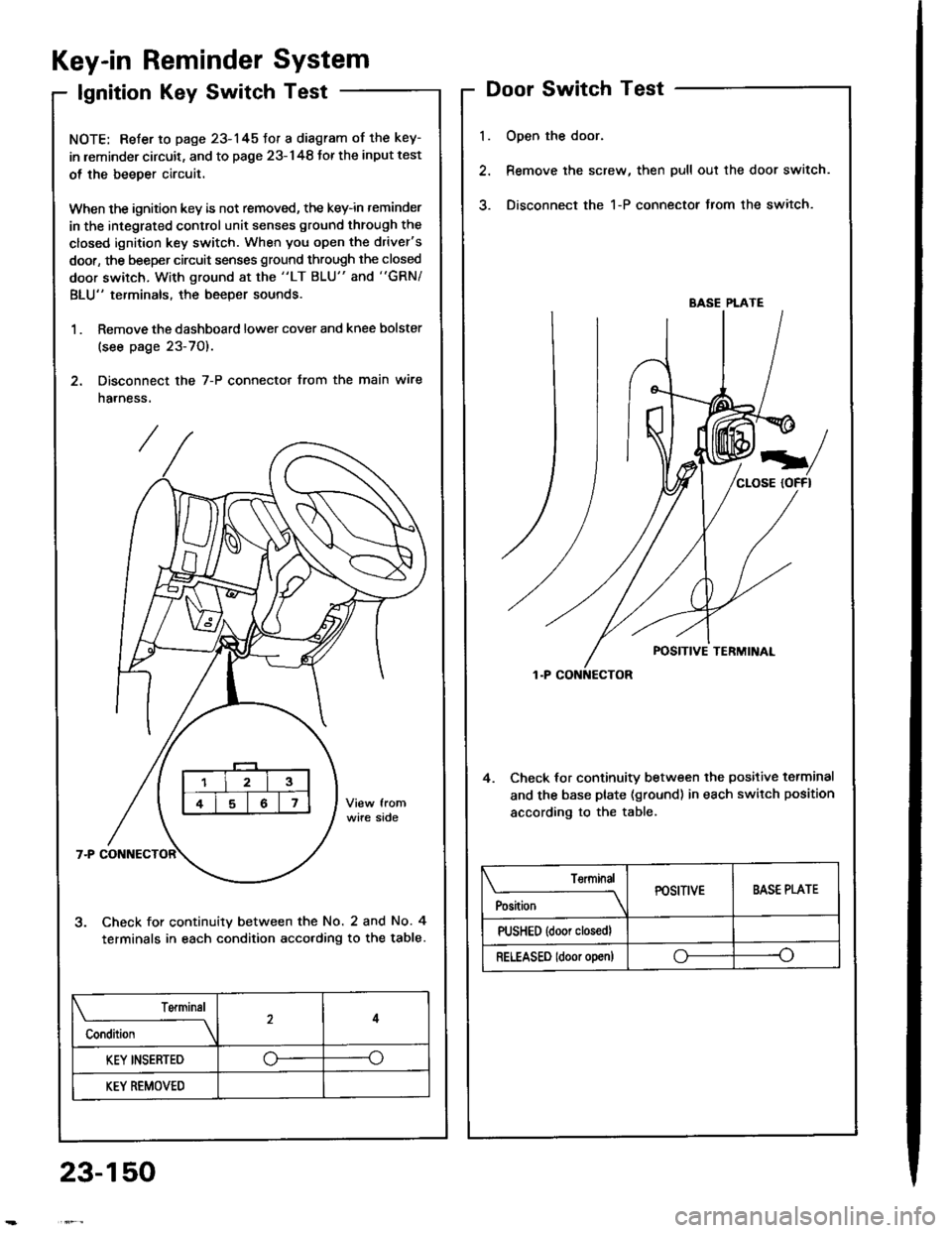

Key-in Reminder System

lgnition Key Switch Test

NOTE: Refer to page 23-145fot a diagram of the key-

in leminder circuit, and to page 23-148 Jor the input test

ol the beeper circuit.

When the ignition key is not removed, the key-in reminder

in the integrated control unit senses ground through the

closed ignition key switch. When you open the driver's

door, the beeper circuit senses ground through the closed

door switch, With ground at the "LT BLU" and "GRN/

BLU" terminals, the beeper sounds.

1 . Remove the dashboard lower cover and knee bolster

(see page 23-70).

2. Disconnect the 7-P connector from the main wire

harness.

Check for continuity between the No. 2 and No. 4

terminals in each condition acco.ding to the table.

l.

Door Switch Test

Open the door.

Remove the screw, then pull out the door switch.

Disconnect the 1-P connector from the switch.

4. Check lor continuity between the positive terminal

and the base plate (ground) in each switch position

according to the table.

BASE PLATE

Position

TerminalPOSITIVEBASE PLATE

PUSHED {door closedl

RELEASED ldoor o!en)oo

Terminal

Condition

4

KEY INSERTED--o

KEY REMOVED

23-150

Page 1264 of 1413

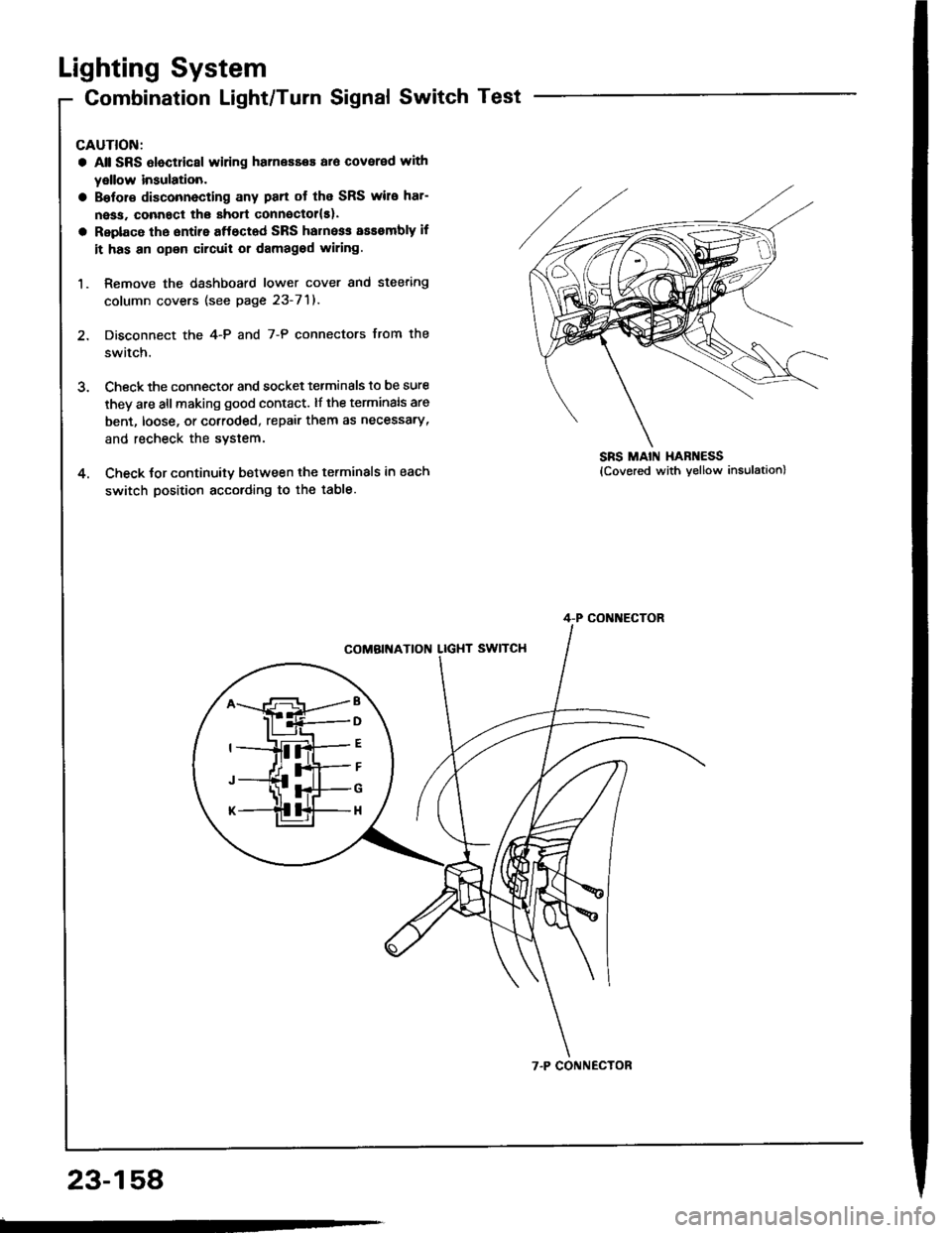

Lighting System

Combination Light/Turn Signal Switch Test

CAUTION:

a Atl SRS Oloctricsl wiring harnesses ar6 covered with

yellow insulation.

a Bslor€ disconnecting any pan ot the SRS wire har-

ness, connact the short connsctollsl.

a Replace the sntire aftectad SRS harne$ assembly if

it has an opon circuit or damagod wiring.

1. Remove the dashboard lower cover and steering

column covers (see page 23-71).

2. Disconnect the 4-P and 7-P connectors from the

switch.

3. Check the connector and socket tetminals to be sure

they are all making good contact. lf the terminals are

bent, loose, or cotroded, repair them as necessary,

and recheck the system.

4. Check tor continuitv between the terminals in each

switch position according to the table.

SRS MAIN HAR ESS

B

D

G

H

4-P CONI{ECTOR

7.P CONNECTOR

23-158

Page 1290 of 1413

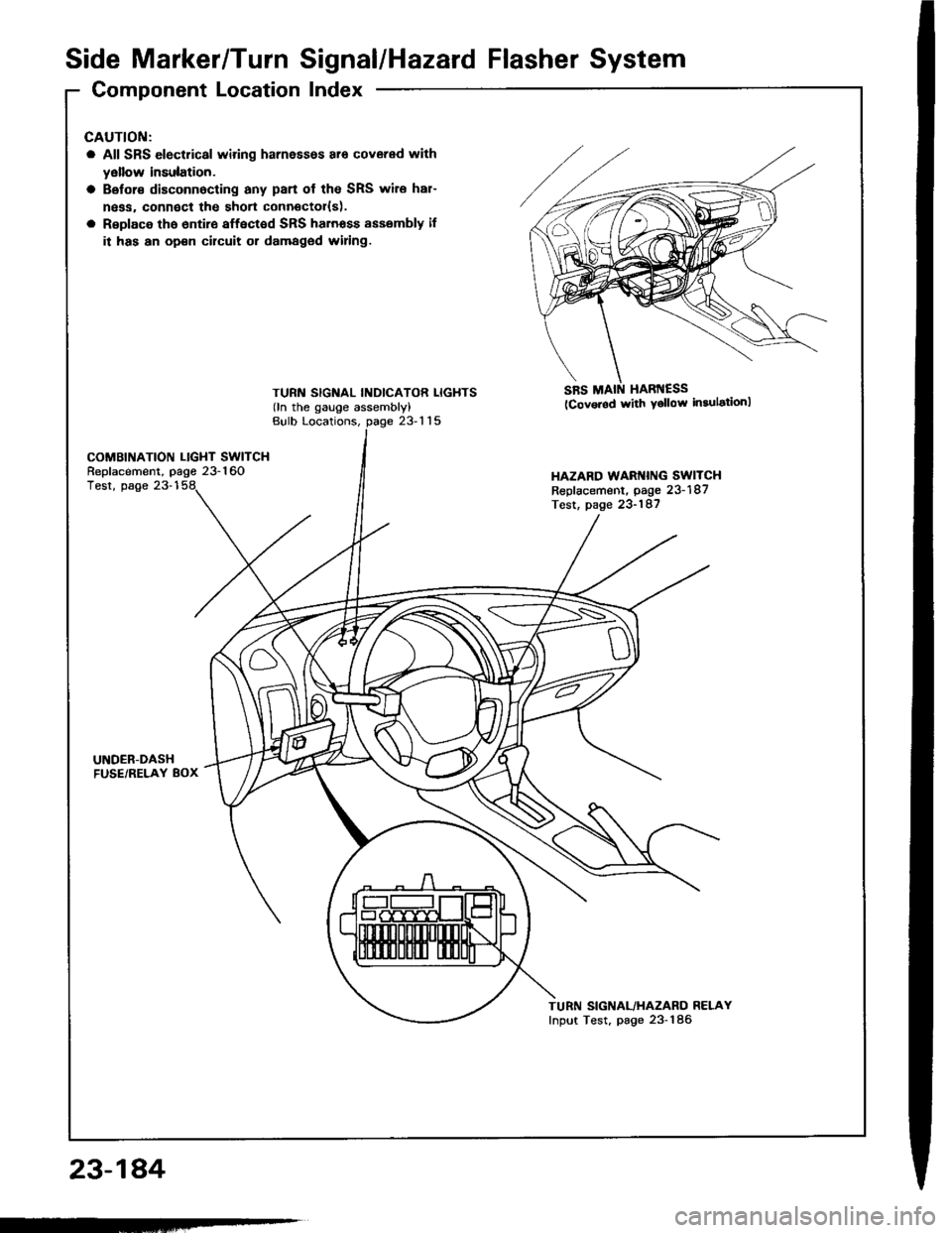

Side Marker/TurnSignal/Hazard Flasher System

Component LocationIndex

23-184

GAUTION:

a All SRS electrical wiring harnessos ar6 covered with

yellow insulation.

a Belor€ disconnocting any pan of the SRS wire har-

ngss, connoct the short connector{s).

a Rsplace tho 6ntir€ affect€d SRS harnoss sssembly il

it has an op€n cilcuit or damaged widng.

TURN SIGNAL INDICATOR LIGHTS(ln the gauge assembly)

SRS MAIN HARI{ESS(Cov.rod with Ysllow in3ulationl

Bulb Locations,23-115

COMBINATION LIGHT SWITCHReplacement, page 23-160HAZARD WARI{ING SWITCHReplacement, page 23-187Test, page 23-187

Test, page 23-1

UNDER-DASHFUSE/RELAY 8OX

TURN SIGNAL/HAZARO RELAYInput Test, page 23-186

-

Page 1292 of 1413

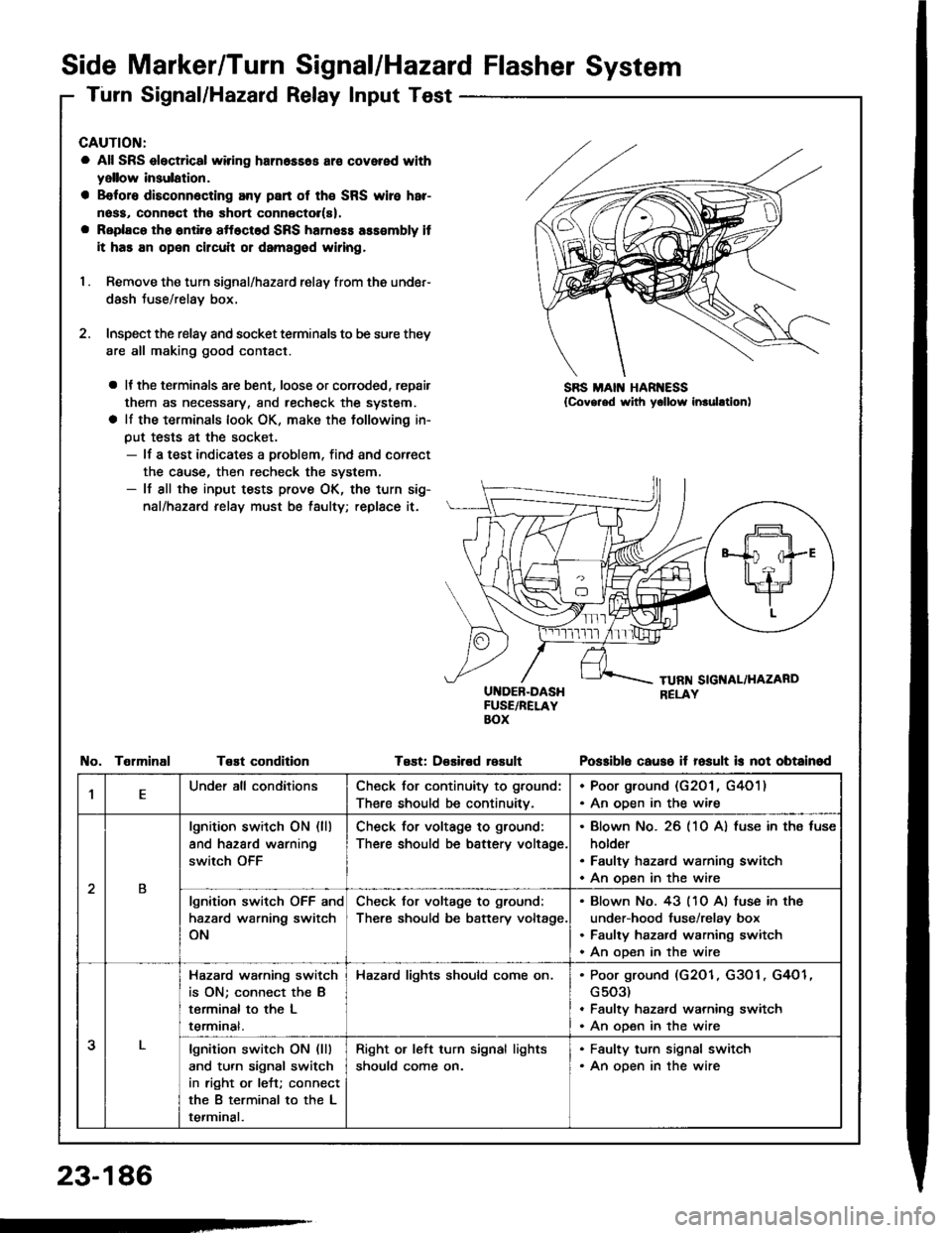

Side Marker/Turn Signal/Hazard Flasher System

Turn Signal/Hazard Relay Input Test

CAUTION:

a All SRS electrical wiring harn6ss6s ar€ covered with

yellow insulation.

a B€foro disconn6cting any part of th€ SRS wire har-

noss, connoct tho short connector(s).

a Replaco tho ontiro sftoctod SRS harness ass€mbly it

it has an open circuit or damagod wiring,

I . Remove the turn signal/hazard relay from ths under-

dash Juse/relay box.

2. Inspect the relay and socket terminals to be sure they

are all making good contact.

a It the terminals are bent, loose or coroded, repair

them as necessary, and recheck the system.

a lf the terminals look OK, make the tollowing in-

put tests at the socket.- lf a test indicates a problem, find and correct

the cause, then recheck the system.- lf all the input tests prove OK, the turn sig-

nal/hazard relay must be taulty; replace it.

UI{DEB-DASHFUSE/RELAYBOX

Test: D€sired rosult

SBS MAIN HAR ESS{Covg.ed with yollow inrulltion)

TelminalTeEt conditionPo$iblo causo it fosult is not obtainod

,lEUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G201 , G4O1). An oDen in the wire

2B

lgnition switch ON (ll)

and hazard warning

switch OFF

Check for voltage to ground:

There should be battery voltage.

Blown No. 26 (10 A) fuse in ths fuse

holder

Faulty hazard warning switch

An open in the wire

lgnition switch OFF and

hazard warning switch

ON

Check for voltage to ground:

There should be battery voltage.

Blown No. 43 (10 Al fuse in the

under-hood fuse/relay box

Faulty hazard warning switch

An ooen in the wire

3

Hazard wa.ning switch

is ON; connect the B

terminal to the L

termrnat.

Hazard lights should come on.Poor ground (G2O1, G3O1, G4O1

G503)

Faulty hazard warning switch

An open in the wire

lgnition switch ON (lll

and turn signal switch

in right or left; connect

the B terminal to the L

terminal.

Right or left turn signal lights

should come on.

. Faulty turn signal switch. An open in the wire

23-186

-

Page 1307 of 1413

Switch Test

CAUTION:

a All SRS el6ctrical wiring harnossos are covarod withyellow inaulation.

a Beforo disconnecting any pan ot the SRS wire har-neaa, connoct ths short connector(s).a Roplace the entil€ afloctod SRS harne$ a$6mbly ifit has an open circuit or dsmagad wlring.

NOTE; The original radio has a coded theft protection

circuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 32 {7.5 A) fuse lrom the under-hoodtuse/relav box.- removing the radio.

After service, reconnect power to the radio and turn iton. When the word "CODE" is displayed, enter the cus-tomer's 5-digit code to restore radio operation.

1. Disconnect the battery negative cable, then discon-nect the positive cable.

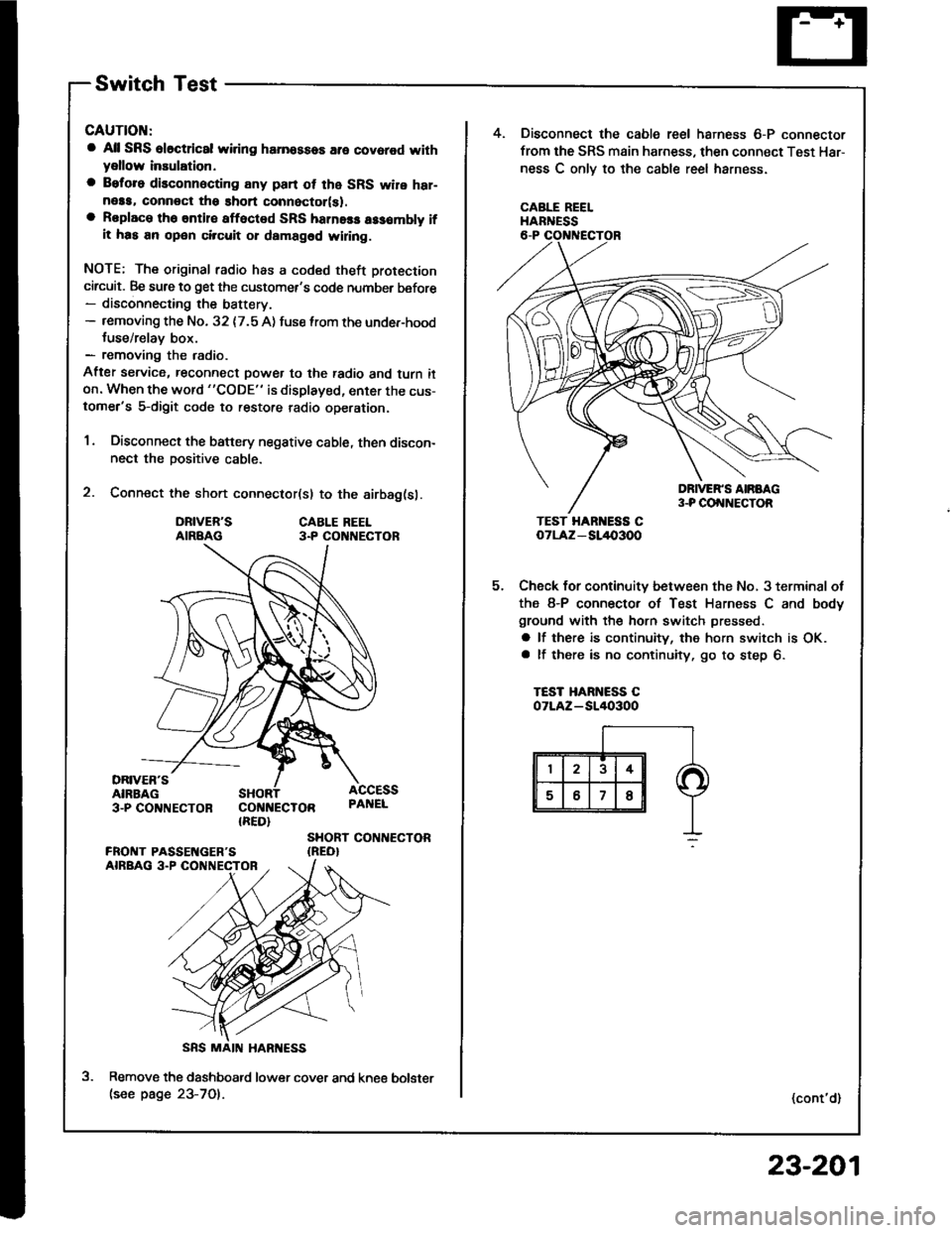

2. Connect the short connector(sl to the airbag(sl.

DRIVER'SAIRBAGCABLE REEL3.P CO NECTOR

DRIVER'SAIRBAG3-PCO'TNECTOR COI{NECTOR{RED}

ACCESSPAI{EL

SHORT CONTIECTOR{REO}

Remove the dashboatd lower cover and kne€(see page 23-701.

5.

4. Disconnect the cable reel harness 6-P connector

from the SRS main harness, then connect Test Har-

ness C onlv to the cable reel harness.

CABLE REELHARNESS

TEST HAR ESS CoTLAz - SL/l{,3OO

Check for continuity between the No, 3 terminal ot

the 8-P connector of Test Harness C and body

ground with the horn switch pressed.

a lf there is continuity, the horn switch is OK.a lf there is no continuity, go to step 6.

TEST HARNESS COTLAZ-SI/I()3OO

(cont'd)

bolster

23-201

Page 1317 of 1413

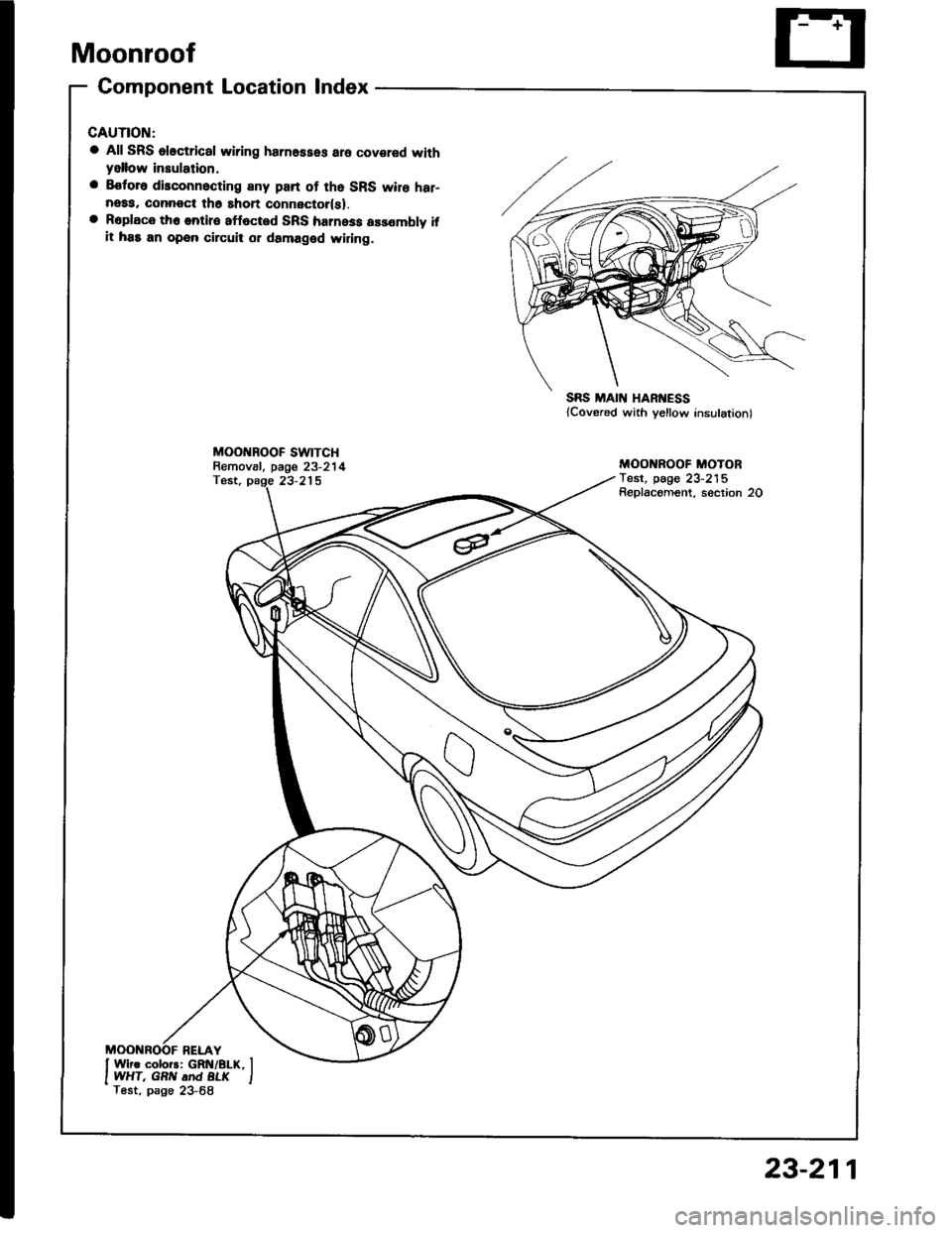

Moonroof

Gomponent Location lndex

a All SRS oloctrical wiring harnesses aro covared withyellow insulation,

a Eoforo disconnocting any part of tho SRS wire har-neaa, connoct th6 shon connector(sl.a Roplace th6 entire 8ff6cted SRS harness assombly ifit has an open circuit or damaged widng.

MOO BOOF SWTTCHRemov8l, page 23-214Test, page 23-215

SRS MAIN HARI{ESS{Covered with yellow insulation)

MOO ROOF MOTORTest, pag€ 23-215Replacoment, section 20

23-211