Automatic shift selector HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 26 of 1413

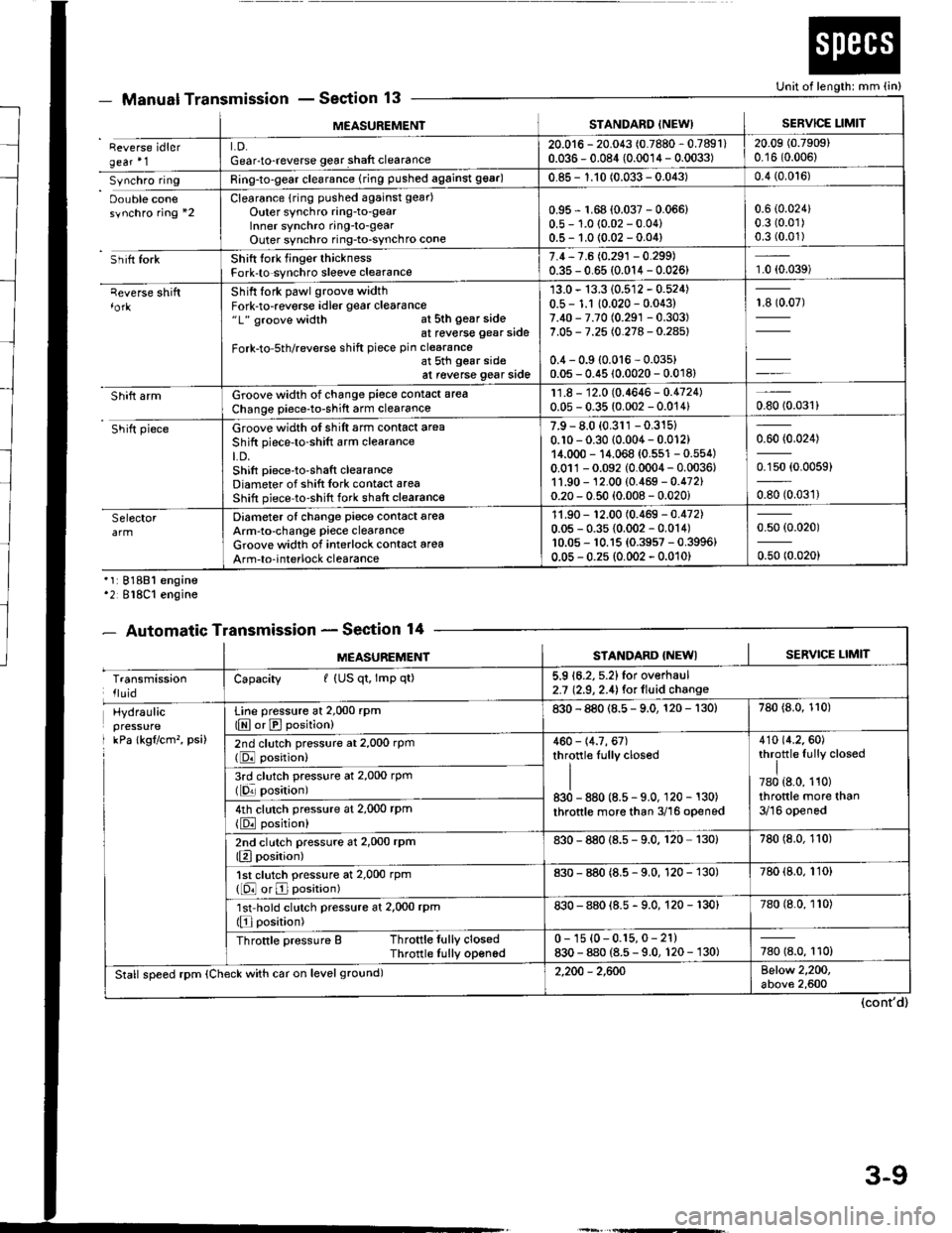

MEASUREMENISTANDARD INEW)SERVICE LIMIT

Reverse idlergear'1LD.Gear-to-reverse gear shaft clearance20.016 - 20.043 (0.7880 - 0.7891)0.036 - 0.084 (0.0014 - 0.0033)20.09 (0.7909)

0.16 (0.006)

Synchro ringRing-to-gear clearance (ring pushed against 99ar)0.85 - 1.10 (0.033 - 0.043)0.4 (0.0't6)

Oouble conesynchro ring *2Clearance {rin9 pushed against gear)

Outer synchro ring-to-gearlnner synchro ring-to-gearOuter synchro ring-to-synchro cone

0.95 r 1.68 (0.037 - 0.066)0.5 - 1.0 (0.02 - 0.04)0.5- 1.0 {0.02 -0.04)

0.6 (0.024)

0.3 (0.01)

0.3 (0.01)

Sh itt forkShift tork finger thicknessFork-to synchro sleeve clearance7.4,7.6 (0.291 - 0.299)0.35 - 0.65 (0.014 - 0.026)1.0 (0.039)

qeverse shiftShift fork pawl groove widthFork-to-reverse idler gear clearance"1" groove width at sth gear sideat reverse gear side

Fork-to-5th/reverse shift piece pin clearanceat 5th gear sideat reverse gear side

13.0 - 13.3 (0.512 - 0.524)0.5 - 1.1 10.020 - 0.043)7.40 - 7.70 (0.291 -0.303)

7.05 - 7.25 (0.278 - 0.28s)

0.4 - 0.9 {0.016 - 0.03s)0.05 - 0.45 (0.0020 - 0.018)

13907)

Shift armGroove width of change piece contact area

Change piece-to-shift arm clearance11.8 - 12.0 (0.4646- 0.4724)0.05 - 0.35 (0.002 - 0.014)0.8010.031)

Shift pieceGroove width of shift arm contact area

Shift piece'to-shift arm clearanceLD.Shift piece-to-shaft clearanceDiameter of shift Iork cont6ct areaShift piece-to-shift fork shaft clearance

7.9 - 8.0 (0.311 -0.315)

0.10 - 0.30 (0.004 - 0.012)14.000 - 14.068 {0.551 - 0.554)0.011-0.092 (0.0004 - 0.0036,1'1.90 - 12.00 (0.469 - 0.472)0.20 - 0.50 (0.008 - 0.020i

0.60 (0.024)

0.150 (0.0059)

oso to.oart

SelectorDiameter of change piece contact areaArm-to-change piece clearanceGroove widlh of interlock contact area

Arm-to-interlock clearance

11.90 - '�t2.00 (0.469 - 0.472)0.05 - 0.35 {0.002 - 0.014)10.05 - 10.15 {0.3957 - 0.3996}0.05 - 0.2s (0.002 - 0.010)

0.50 (0.020)

0.50 (0.020)

Manual TransmissionSection 13

'1:81881 engine'2 818C1 engine

- Automatic TransmissionSection 14

Unit of length: mm (in)

(cont'd)

- oEutrlrrl rr

MEASUREMENTSTANDARD {NEWISERVICE LIMIT

TransmissionlluidCapacity I (US qt, lmp qt)5.9 16.2, 5.2)for overhaul2.7 (2.9, 2.4) for lluid change

Hydraulicpressure

I kPa lkgflcm'�, psi)

Line pressure at 2,000 rpm(E or E position)830 - 880 (8.5 - 9.0, 120 - 130)780 {8.0, 110)

2nd clutch pressure at 2,000 rpm(DJ position)460 - 14.7, 67)throttle Iully closed

II830 - 880 (8.5 - 9.0, 120 - 130)

throttle more than 3/16 opened

410 {4.2.60)throttle fully closed

I780 {8.0, 110)throttle more than3/16 opened

3rd clutch pressure at 2,000 rpm(lqr posirion)

4th clutch pressure at 2,000 rPm

{E position)

2nd clutch pressure at 2,000 rPm(Elposition)830 - 880 {8.s - 9.0. 120 130)780 (8.0, 110)

1st clutch pressure at 2,000 rpm([O or E position)830 - 880 (8.5 - 9.0, 120 - 130)780 (8.0, 110)

'lst'hold clutch pressure at 2,000 rpm(Elposition)830 - 880 {8.5 - 9.0, 120 - 130}780 (8.0, 110)

Throttle pressure B Throttle fully closedThrotlle Iully opened0 - 1s {0-0.15,0- 21)830 - 880 (8.5 - 9.0, 120 - 130)780 18.0, 110)

Stall speed rpm (Check with car on level ground)2,200 - 2,600Below 2,200,above 2,600

3-9

Page 393 of 1413

Automatic Transmission

'l4-2

14-3't 4-6

14-8

14-14

14-23

Hvdraulic Flow ...--...... 14-24

Lock-up System ........ 14-38

Eloctrical Systom

Component Location ............,...,................ I 4-45

Circuit Diagram ............. 14-46'Troubleshooting Procedures ........,..........., l4-48

Symptom-to-Component Chart

Electrical System ...... 14-50

Electrical Troubleshooting

Troubleshooting Flowchart .................... 14-52

Lock-uo Control Solenoid Valve A/8

Test .................. --.... \4-82

ReDlacement ,...,...,..,. 14-82

Shift Control Solenoid Vslve A/B

Test .................. ...... 14-83

Reolacement .............. 14-83

Transmission Control Module (TCM)*ReDlacement ........... 14-84

Mainshalt/CountershaJt SDeed Sensors

Reolacement ............. 14-85

Hydraulic Systom

Symptom-to-Component Chart

Hydraulic System

Road Test

Slall Speed

Test ..................

Fluid Level

Checking/Changing

Pressu.e Testing

Transmission

Transmission

Removal ............. ...... 14-99

lllustrated Index

Right Side Cover .................................. 1 4- 1 04

Transmission Housin9 ..................,,....... I 4-1 06

Torque Converter HousingNalve

Body .................. ... 14- 1O8

Right Side Cover

Removal ............. ...... 14-110

Transmission Housing

Removal ............. .-..-. 14-112

Torque Convener HousingNalve Body

Removal ............. ...... 14-114

Valve Caps

Description ................ 14-116

Valve Body

Repair ................ ...-.. 14-117

Valve

Assembly ...........

Oil Pump

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly .......

Secondary Valve Body

Disassembly/lnspection/Reassembly .......

Servo Body

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Covet

Oisassembly/lnspection/Reassembly .,..,..

Mainshaft

Disassembly/lnspection/Reassembly -.. -... 1 4- 1 29

lnsDection ................. 14- 130

Countershaft

Disassembly/lnspection/Reassembly ....... 14-132

Disassembly/Reassembly ....................... 1 4-1 33

lnsDection ................. 14-134

One-way Clutch/Parking Gear

Disassembly/lnspection .................... -.. -. 1 4-137

Sub-shaft

Disassembly/lnspection/Reassembly ....... 14-138

Disassemblv/Reassemblv ....................... 1 4-1 39

Sub-shaft Bearings

Replacement ............. l4-140

Clutch

fllustrated lndex ................. -..-...-.......... 14-1 41

Disassembly ,,,.,,........ 14-144

Reassembly .............. 14-146

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Reolacement ......... 14-1 50

Countershaft Bearing Replacement .......,, 14-1 5l

Transmission Housing Bearings

Mainshsft/Countershaft Bearing

Repfacement ...-..-..14-152

Sub-shaft Bearing Replacement .............. 1 4-1 53

Reve.se ldler Gear

lnstallation ................ 14-154

Parking Brake Stopper

lnspection/Adjustment ..........................'14-'154

Transmission

Reassemblv .............,. .14_156

Toroue Converter/Drive Plate ..,..,............... 1 4- 1 63

Transmission

14-120

14-122

14-123

14-124

14-126

14-124

14-86

14-90

't4-92

14-93

14-94

lnstallation

Cooler Flushing'Shitt Cable

Removal/lnstallation ..............................

Adiustment ...-..-......-. 14-'171*Gearshift Selector

Disassembly/Reassembly .....................,. 1 4-17 2*Shift Indicator Panel

Adjustment -..........-...14-173

Throttle Control Cable

fnspection .......,..,...... 14-17 4

Adjustment .............. 14-176

14-164

14-168

14-'t 7 0

Inspection

Page 395 of 1413

The Automatic Transmission is a combination of a 3-e,ement torque convefter and triple-shaft electfonically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator assembly in a single unit, The torque converter is connected

to the engine crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter

is a ring gear which meshes with the starter pinion when the engine is being staned. The entire torque converter assem-

bly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft. countershaft and sub-shaft. The mainshatt is in line with the

engine crankshaft.

The mainshaft includes the clutches for 1 st, and 2ndl4th, and gears for 3rd. 2nd, 4th, reverse and l st (3rd gear is in-

tegral with the mainshaft, while reverse gear is integral with the 4th gear).

The countershaft includes the 3rd clutch and gears Ior 3rd, 2nd,4th, reverse, lst and parking. Reverse and 4th gears

can be locked to the countershaft at its center, providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the lst-hold clutch and gears for 1st and 4th

The gears on the mainshait are in constant mesh with those on the countershaft and sub-shaft. When certain combina-

tions of gears in the transmission are engaged by the clutches, power is transmitted from the mainshaft to the counter-

shaft via the sub-shatt to provide @, E, tr. tr and @ position.

Electronic Control

The electronic control system consists of the Transmission Control Module {TCM), sensors, and 4 solenoid valves. Shift-

ing and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the left side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, regulator valve body. servo body, and lock-up valve

body throuqh the respective separator plates.

They are bolted on the torque converter housing.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, Clutch Pressure Cont.ol (CPC) valve,

4th exhaust valve, relief valve, and oil pump gears.

The secondary valve body contains the 4-3 kick-down valve,3-2 kick-down valve,2-3 orifice cont.ol valve, 3-4 shitt

valve, orifice control valve. modulator valve, and servo control valve

The regulator valve body contains the pressure regulator valve. lock-up control valve, torque converter check valve, and

cooler check valve.

The servo bodv contains the servo valve which is integrated with the reverse shift fork, throttle valve B, and accumulators.

The lock-ug valve bodv contains the lock-up shift valve and lock-up timing B valve. and is bolted on the secondary valve

body.

Fluid from the regulator passes through the manual valve to the various control valves.

Shitt Control Mochanism

Input to the TCM i.om various sensors located throughout the car determines which shift control solenoid valve should

be activated.

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear.

Lock-up Mechanism

In @ position. in 2nd, 3rd and 4th, and E position in 3rd, pressurized tluid can be drained from the back of the tor-

que converter through an oil passage, causing the lock-up piston to be held against the torque converter cover. As this

takes Dlace, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM

optimizes the timing ol the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

14-3

Page 396 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Description

(contd)

Gear Selection

The selector lever has seven posirions; E PARK, E REVERSE, N NEUTRAL, @ 1st through 4th positions. E 1st

through 3rd positions, Ql2nd gear and [] 1st gear.

Starting HONDA INTEGRA 1994 4.G Workshop Manual Description

(contd)

Gear Selection

The selector lever has seven posirions; E PARK, E REVERSE, N NEUTRAL, @ 1st through 4th positions. E 1st

through 3rd positions, Ql2nd gear and [] 1st gear.

Starting](/img/13/6067/w960_6067-395.png)

Description

(cont'd)

Gear Selection

The selector lever has seven posirions; E PARK, E REVERSE, N NEUTRAL, @ 1st through 4th positions. E 1st

through 3rd positions, Ql2nd gear and [] 1st gear.

Starting is possible only in @ and I Oosition through use ot a slide-type, neutral-safety switch.

Automatic Tlansaxle {A/T) Gear Position Indicatol

A/T gear pos;tion indicator in the instrumenl panel shows what gear has been selected without having look down at

the console.

Position Description

l3?]] PARK Front wheels locked; parking pawl engaged with parking gear on countershatt. All clutches

reteaseo,

[R] REVERSE Reverse; reverse selector engaged with countershalt reverse gear and 4th clutch locked.

N NEUTRAL All clurches released.

D+l DRIVE General driving; starts off in 'lst, shifts automatically to 2nd, 3rd, then 4th, depending on vehicle

('lst through 4th) speed and throttle position. Do'vnshifts through 3rd, 2nd and 1st on deceleration to stop.

The lock-up mechanism comes into operation in 2nd, 3rd and 4th when the transmission in lDtposrtron.

Dgi DRIVE For rapid acceleration at highway speeds and general driving; starts off in 1st. shifts automatical-(1st through 3rd) ly to 2nd then 3rd, depending on vehicle speed and throttle position. Downshifts through lower

gears on deceleration to stop. The lock-up mechanism comes into operation in 3rd.

El SECOND Driving in 2nd geari stays in 2nd gear, does not shift up and down.

For engine braking or better traction starting off on loose or slippery surfece.

L]l FIRST Driving in 1st gear; stays in lst gear, does not shilt up.

For engine braking.

14-4

Page 561 of 1413

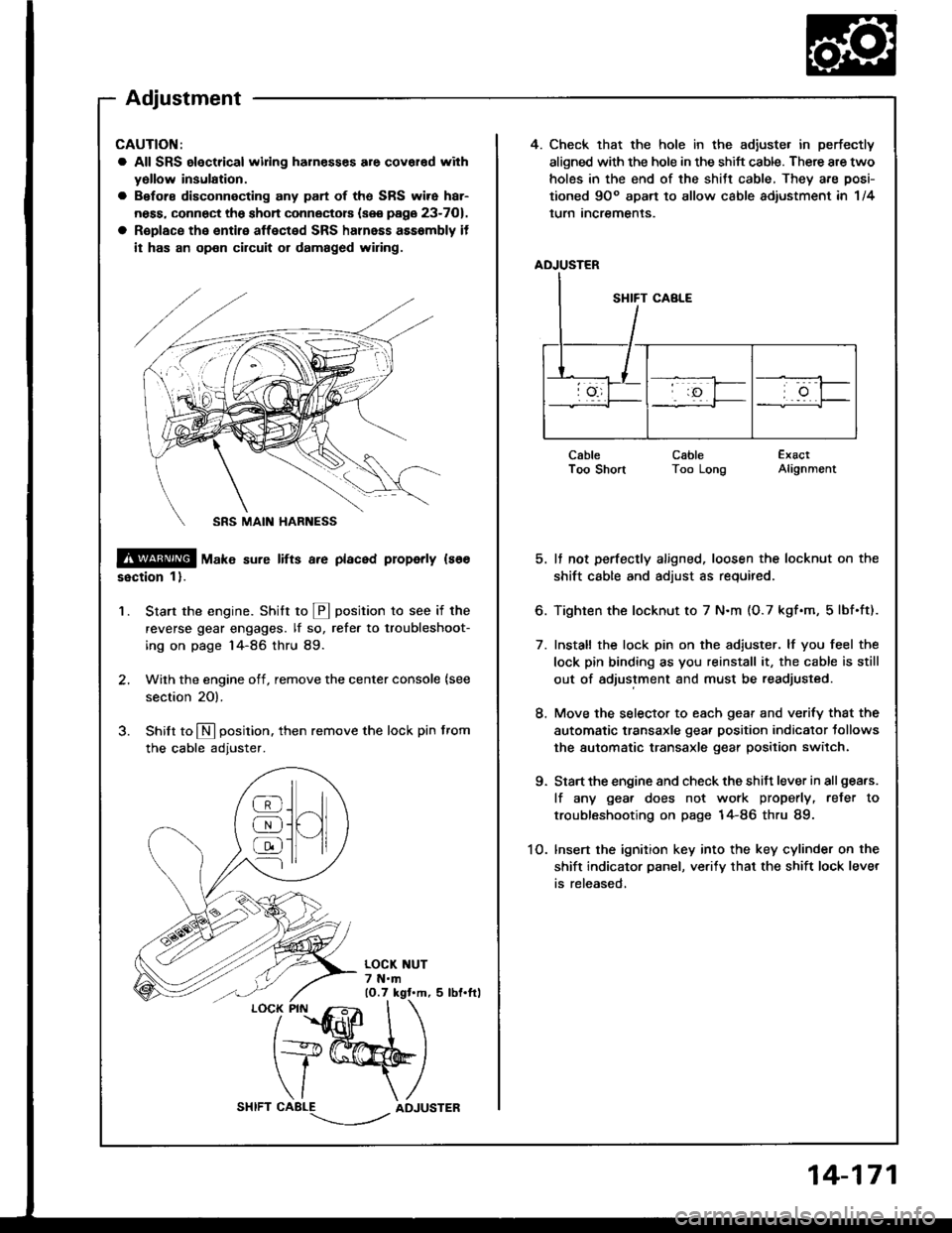

4. Check that the hole in the adiuste. in perfectly

aligned with the hole in the shift cable. There are two

holes in the end of the shitt cable, They are posi-

tioned 9Oo apart to allow cable adiustment in 1/4

lurn Incremenls.

ADJUSTER

CableI oo snonCableToo LongExactAlignment

5. It not perfectly aligned, loosen the locknut on the

shift cable and adjust as required.

6. Tighten the locknut to 7 N.m (O.7 kgf.m, 5lbf.ft).

7. Install the lock pin on the adiuster. lf you feel the

lock pin binding as you reinstall it, the cable is still

out of adjustment and must be readjusted.

8. Move the selector to each gear and verify that the

automatic transaxle gear position indicator tollows

the automatic transaxle gear position switch.

9. Start the engine and check the shift lever in all gea.s.

lf any gea. does not work properly, refer to

troubleshooting on page 14-86 thru 89.

1O. lnsert the ignition key into the key cylinder on the

shift indicator panel, ve.ify that the shift lock lever

is released,

CAUTION:

a All SRS electrical widng harn€sses are covar€d with

yollow insulation.

a Before disconnecting any part of ths SRS wire har-

ness, connect the shon connectors (see page 23-701.

a R€place the entire affected SRS halnass asssmbly it

it has an op€n circuit or damaged wiring.

@ tu"t" sure lifts a.e placed properly ls66

ssction 1).

Start the engine. Stritt to @ position to see if the

reverse gear engages. lf so, refer to troubleshoot-

ing on page 14-86 thru 89.

Wilh the engine off, remove the center console {see

section 20).

Shilt to N position. then remove the lock pin from

the cable adjuster.

'1.

/

''fidlfr

I

t+@

\/ \

CABLE-.'.-_--l../ADJUSTER

]H

@

@

@

Adjustment

14-171

Page 562 of 1413

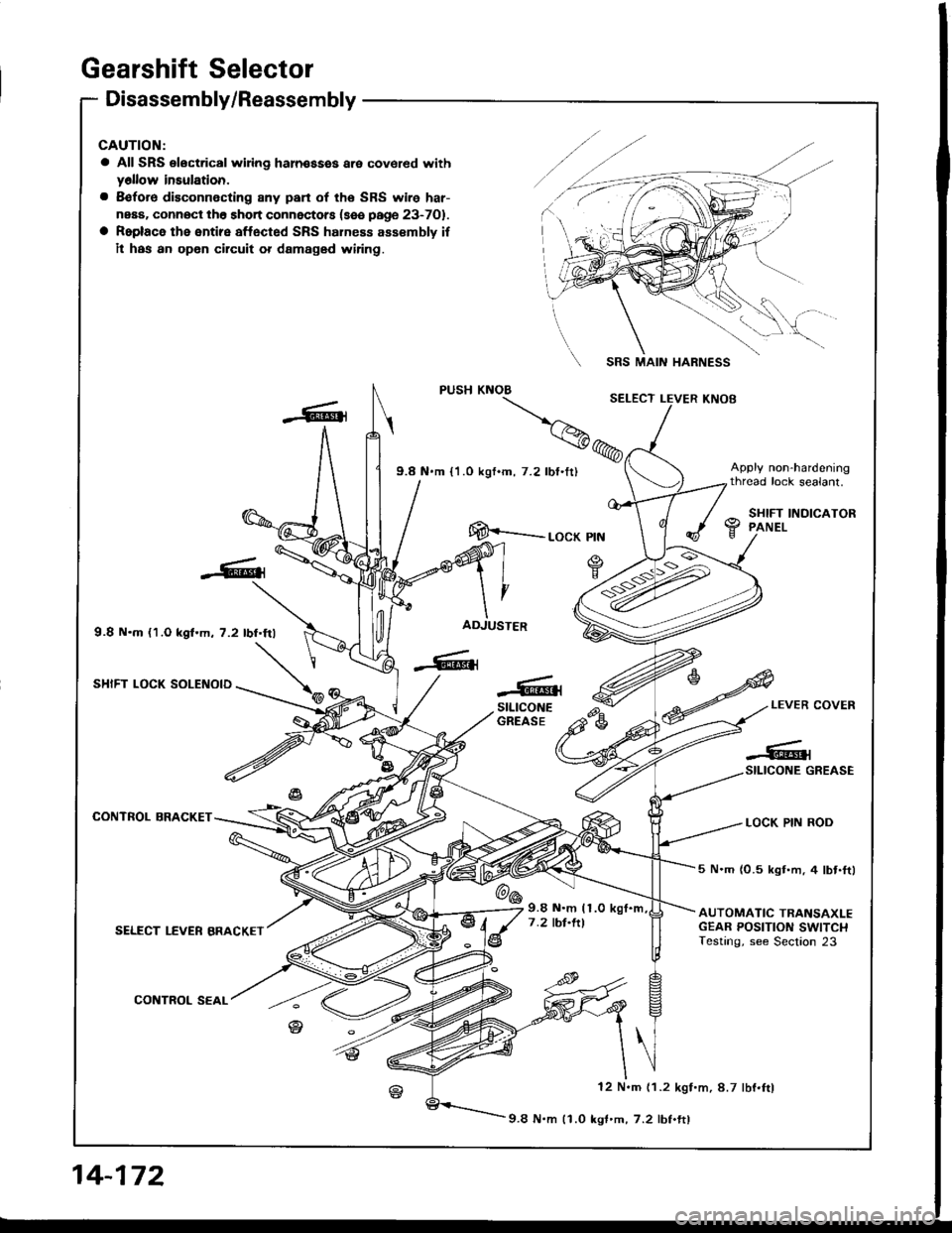

Gearshift Selector

Disassembly/Reassembly

CAUTION:

a All SRS electrical wiing haln€ssss are covered withy6llow insulation.

a 8€fore disconnecting 8ny pan of the SRS wire har-

neaa. connOct th6 short connectors (sse page 23-701.

a Roplace the entire affected SRS hahess assembly if

il has an opon circuit or damaged wiring.

9.8 N.m {1.O kgf.m, 7.2 lbf.frl

SHIFT LOCK SOLENOID

CONTROL BRACKET

SELECT LEVER BRACKET

CONTROL SEAL

SRS MAIN HARNESS

[E--__ rocK ptN

ADJUSTER

-6{stLtcoNEGREASEe-LEVER COVER

LOCK PIN ROD

-#qSILICONE GREASE

@6

5 N.m (0.5 kgt.m, 4 lbt.ftl

AUTOMATIC TRANSAXLEGEAR POSITION SWITCHTesting, see Section 23

9.8 N.m (1.0

7 .2 tbt.ltl

12 N.m (1.2 kgf.m, 8.7 lbf.ftl

9.8 N.m 11.0 kgf'm,7.2 lbf.ftl

14-172