Iac valve HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 180 of 1413

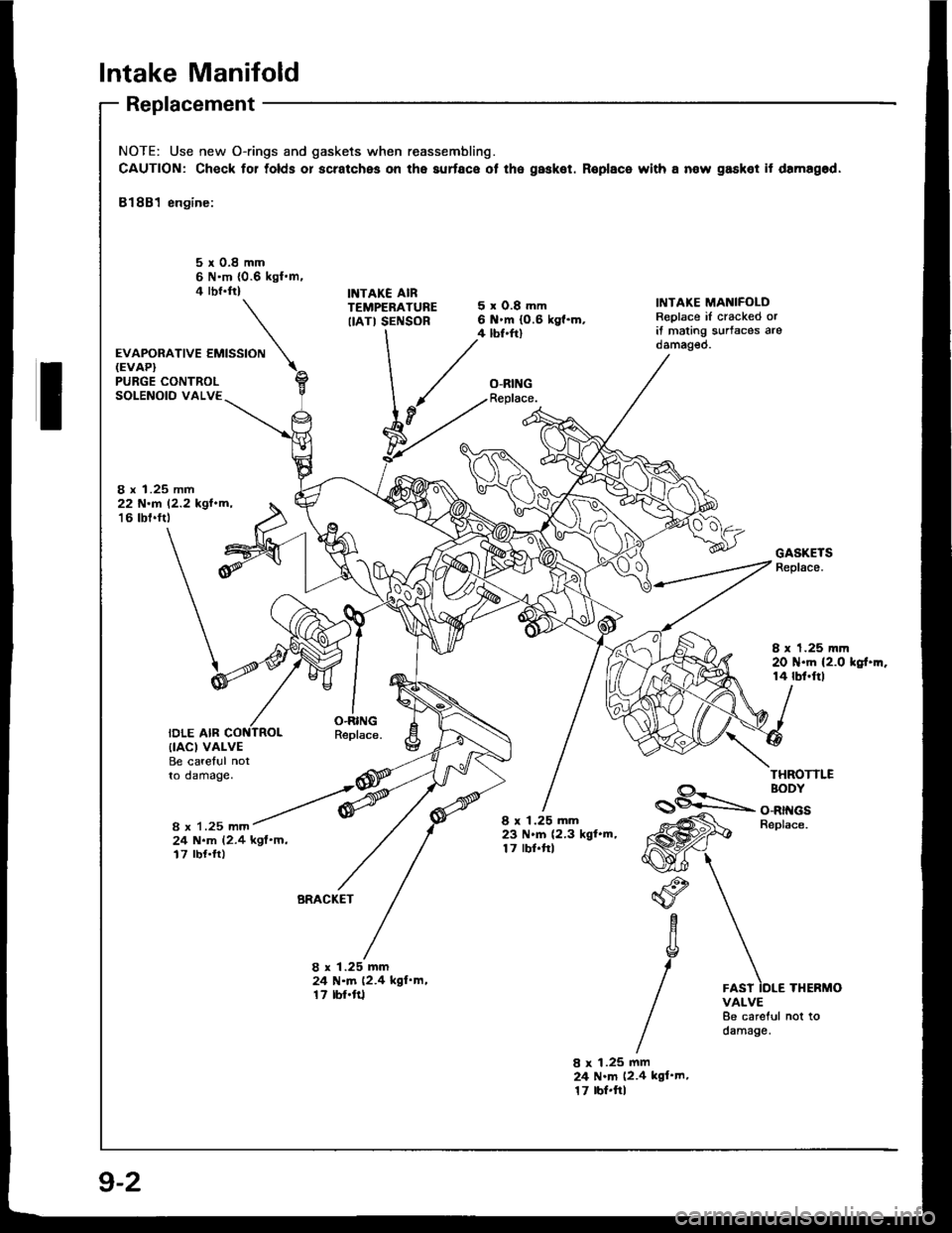

Intake Manifold

Replacement

NOTE: Use new O-rings and gaskets when reassembling.

CAUTION: Check for tolds or scratches on the aurface ot the gasket. Roplace with a now gasket it damagod,

81881 engine:

5r0.8mm6 N'm {0.6 kgl.m.4 rbr.ftlINTAKE AIRTEMPERATUREIIATI SENSOR

'*o*ot'u""'""N

5xO.8mm6 .m (0.6 kg{.m.4 tbf.ftl

O-RINGReplace.

IiITAKE MANIFOLDReplace iI cracked orit mating s!rtaces arodamag€o.

PURGE CONTROLSOLENOID VALVE

8 x 1.25 mm22 N.r 12.2 kgl.m,'16 tbt.ftt

IDLE AIR

GASKETSReplace.

I x 1.25 mm20 N.m (2.0 kgt.m.14 rbf.ftl

O.RINGReplace.{IACI VALVEBe careful notto damage.THROTTLE

8 x 1.25 mm

BODY

O-RINGSBeplace.

24 N.m (2.4 kgf'm,17 rbf.ft)

8 x 1.25 mm23 N.m (2.3 kgl.m,17 lbf.frl

BRACKET"o

aYc

g

/

1.25 mmN.m (2.4 kgl'm,rbf'ft1

8x2417

8 x 1.25 mm24 N.m (2.4 kgl'm.17 tbr.ftlTHERMOVALVE8e careful not todamage.

9-2

Page 181 of 1413

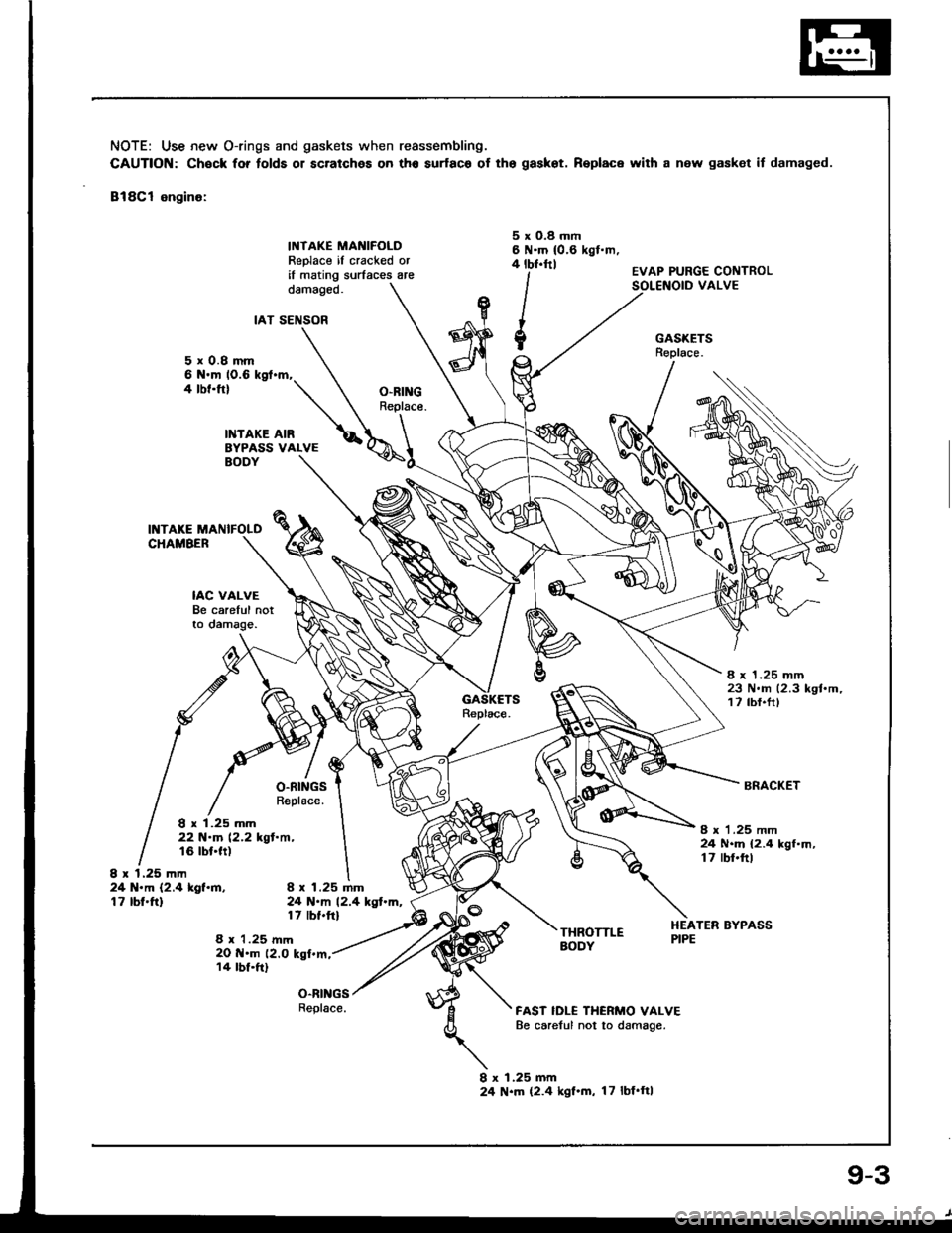

NOTE: Use new O-rings and gaskets when reassembling.

CAUTION: Chock for folds 01 scratches on th6 surfac6 of tho gaskot. Replace wilh a new gasket if damaged.

818C1 engino:

INTAKE MANIFOLDReplace il cracked oril mating surfaces are

5 x O.8 rnm6 N.m 10.6 kgl.m,4 tbt.ttl

lI

{,/

?,/

EVAP PURGE CONTROLVALVEdamageo.

IAT SENSOR

5xO.8mm6 N.m 10.6 kgf.m,4 tbf.ftl

INTAKE AIRBYPASS VALVE

IAC VALVEBe carelul notlo oamage.

O.RINGSReplace.

GASKETSReplace.

O.BI GReplace.

BODY

INTAKE MANIFOLDCHAMBER

8 x 1.25 mm23 N.rn 12.3 kgt'm,17 tbf.frl

I x 1.25 mm22 N.m 12.2 kgl.ft,t6 tbt.tt)

BRACKET

8 r 1.25 mm24 N.m {2.4 kgf.h,t7 rbr.ftl

8 x t.25 mfi24 N.m (2.4 lgf.m.17 tbt.ft)I r 1.25 lnm24 N.m 12.4 kgt.m,17 tbt.ftl

8 x 1.25 mm20 .m (2.0 kgt.m,14 tbf.ftl

THROTTLEAODY

FAST IDL€ THERMO VALVEBe carelul not to damage.

HEATER BYPASSPIPE

o-Rt GsReplace.

I x 1.25 mm24 N.m (2.4 kgl.m, 17lbf'ft|

9-3

Page 187 of 1413

ENGINE COMPARTMENT HOSE CONNECTIONS:

Bl88l engine:FAST IDLETHERMOVALVE

THERMOSTATHOUSIITGIDLE AIR CONTROLIIAC} VALVE

O'RINGReplace.

BREATHER PIPE

O-RINGReplace.

HEATER HOSES

818C1 engine:

ENGINE OILCOOLER

IAC VALVE

HEATER BYPASSPIPE

FAST IDLETHERMOVALVE

THERMOSTATHOUSING

BREATHER PIPE

HEATEB HOSES

10-3

Page 197 of 1413

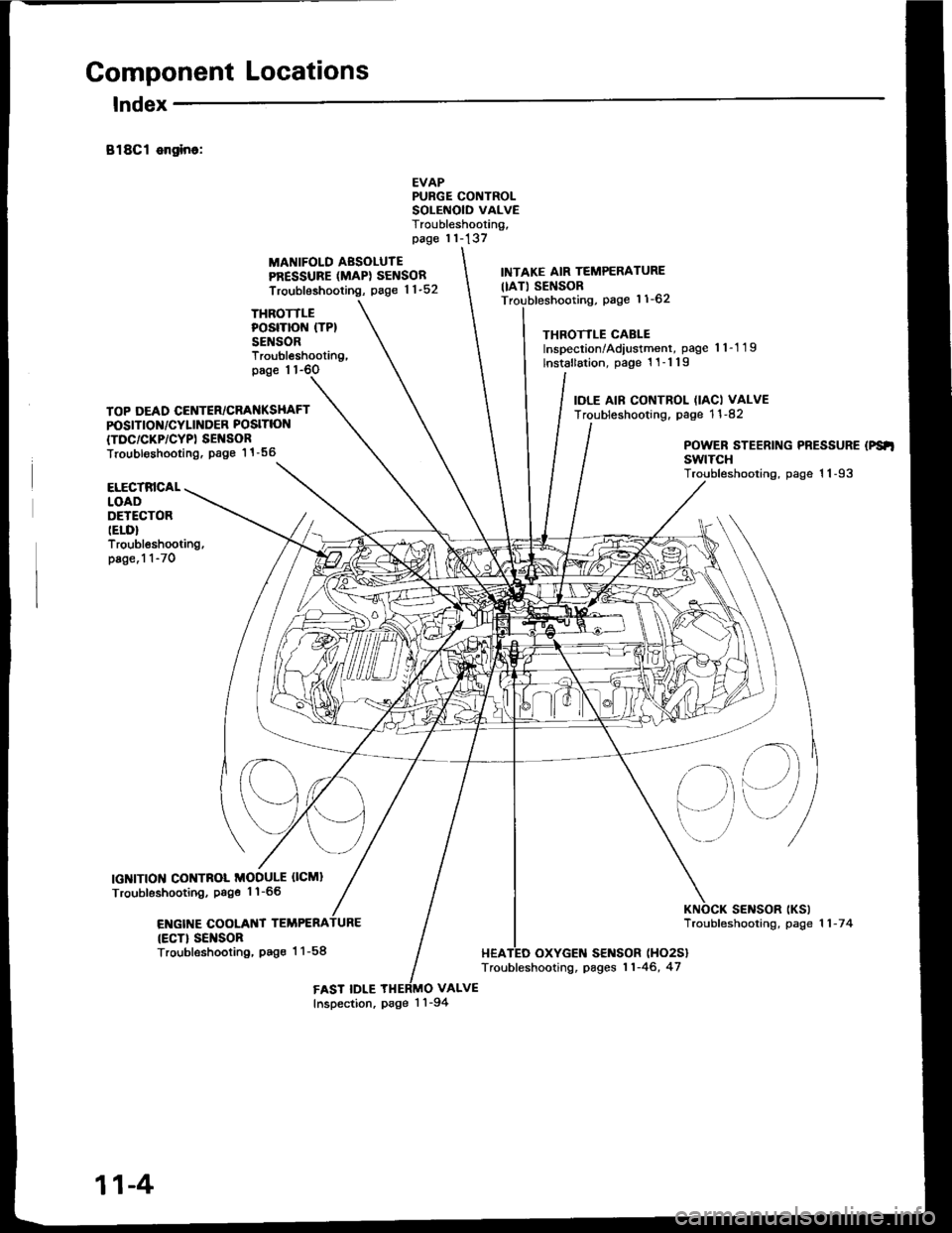

Component Locations

lndex

B18Cl ongino:

THROTTLEPOSITION (TP}

SENSOR

MANIFOLD AESOLUTEPRESSURE (MAPI SENSOR

Troubleshooting, page 1 1-52

EVAPPURGE CONTROLSOLEiIOID VALVETroubleshooting,page 11-137

VALVE

INTAKE AIR TEMPERATURE

IIAT) SENSORpage 11-62

THROTTLE CABLEInspection/Adiustment, page 'l 1-1 19

lnstallation, page 1 1-1 19

IOLE AIF CONTROL (IACI VALVETroubleshooting. page 1 1 -82

Troubleshooting,page 1 1-6O

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION

{TDC/CKP/CYPI SEI{SORTroubl€shooting. Page 1 1 -56POWER STEERING PRESSURE (PS'I

swtTcHTroubleshooting, page 1 1-93ELECTRICALLOADDETECTORIELD}Troubleshooting,page.1 1-70

IGNITION CONTNOL MODULE OCMI

Troubleshooting, Psge 1'l-66

ENGIT{E COOLANT TEMPERA

{ECT} SEI{SORTroubleshooting, Pag€ 1 1-58

sElrlsoR tKslTroubfeshooting, page 1 1 -7 4

HEATED OXYGEN SENSOR (HO2S}

Troubleshooting, pages 11-46, 47

FAST IDLEInspection, page 1 'l -94

11-4

Page 198 of 1413

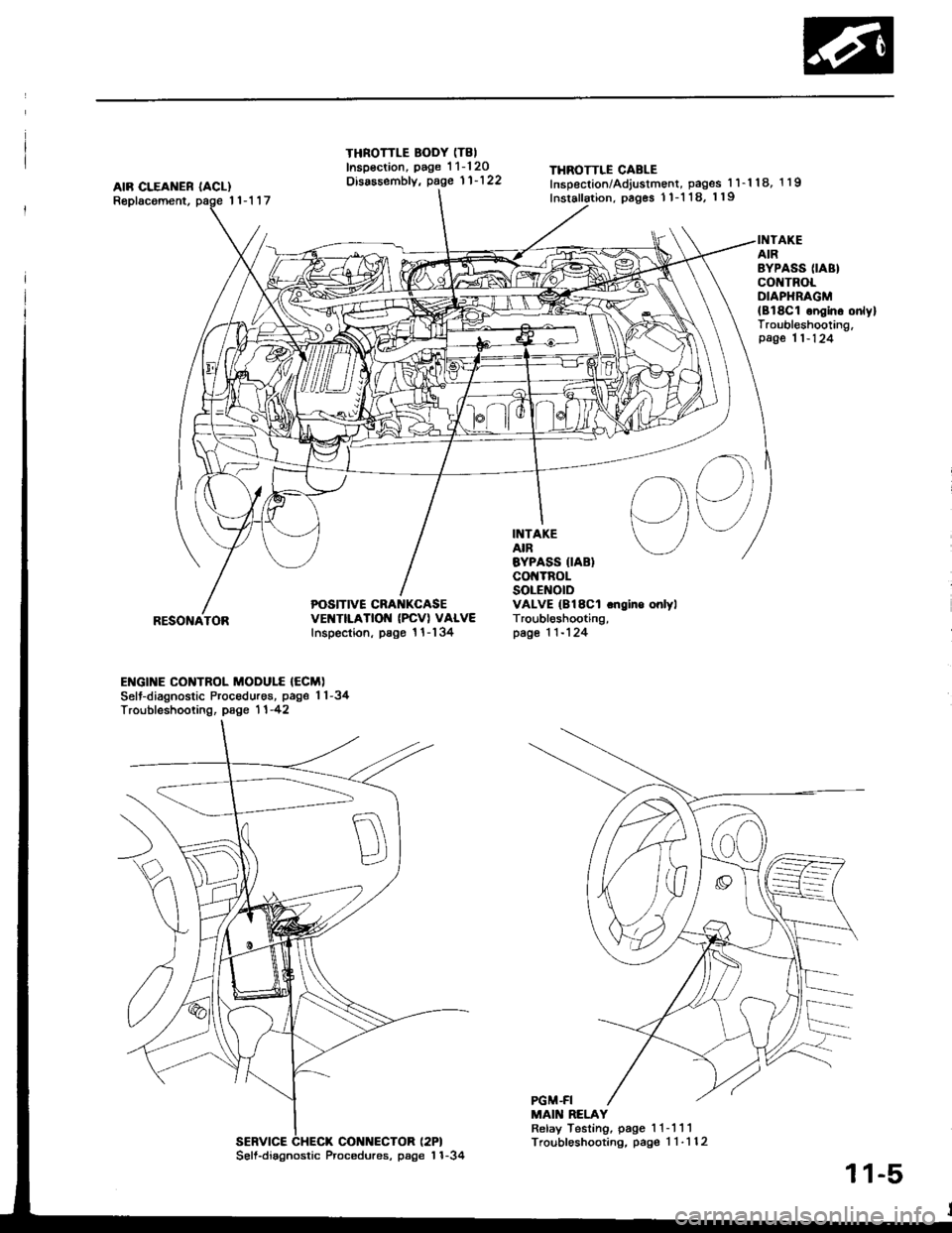

AIR CLEAI{ER IACL)Replacoment,11-117

THROTTLE BODY (T8I

Inspsction, page 1 1-120Disassembfy, page 11'122THROTTLE CABLEInsDection/Adjustment, pages 1 l-'l 18, 1 19

Inslallation, pages 1 1-1 18, 119

POSITIVE CRA KCASEvEt{TtLATtOt{ (PcVl VALVEInspection, psgo 1 l-134

INTAKEAIREYPASS IIABIco TnoLSOLENOIDVALVE (B18Cl .ngino onlylTroubl6shooting,page 1 1-124

INTAKEAIRBYPASS (IABI

co TROLOIAPHRAGM{Bl8C1 ongino onlylTroubleshooting,page 11-124

I

RESONATOR

ENGI]TE CONTROL MODULE {ECM)Selt-diagnostic Procedures, page 1 1-34Troubfeshooting, page 1 1 -42

MAIN RELAYRelay Testing, page 1 1- 111Troubleshooting, pag€ 1 1-112SERVICE CHECX CONNECTOR (2PI

56ll.diagnostic Procedures, page'l 1-34

11-5

Page 201 of 1413

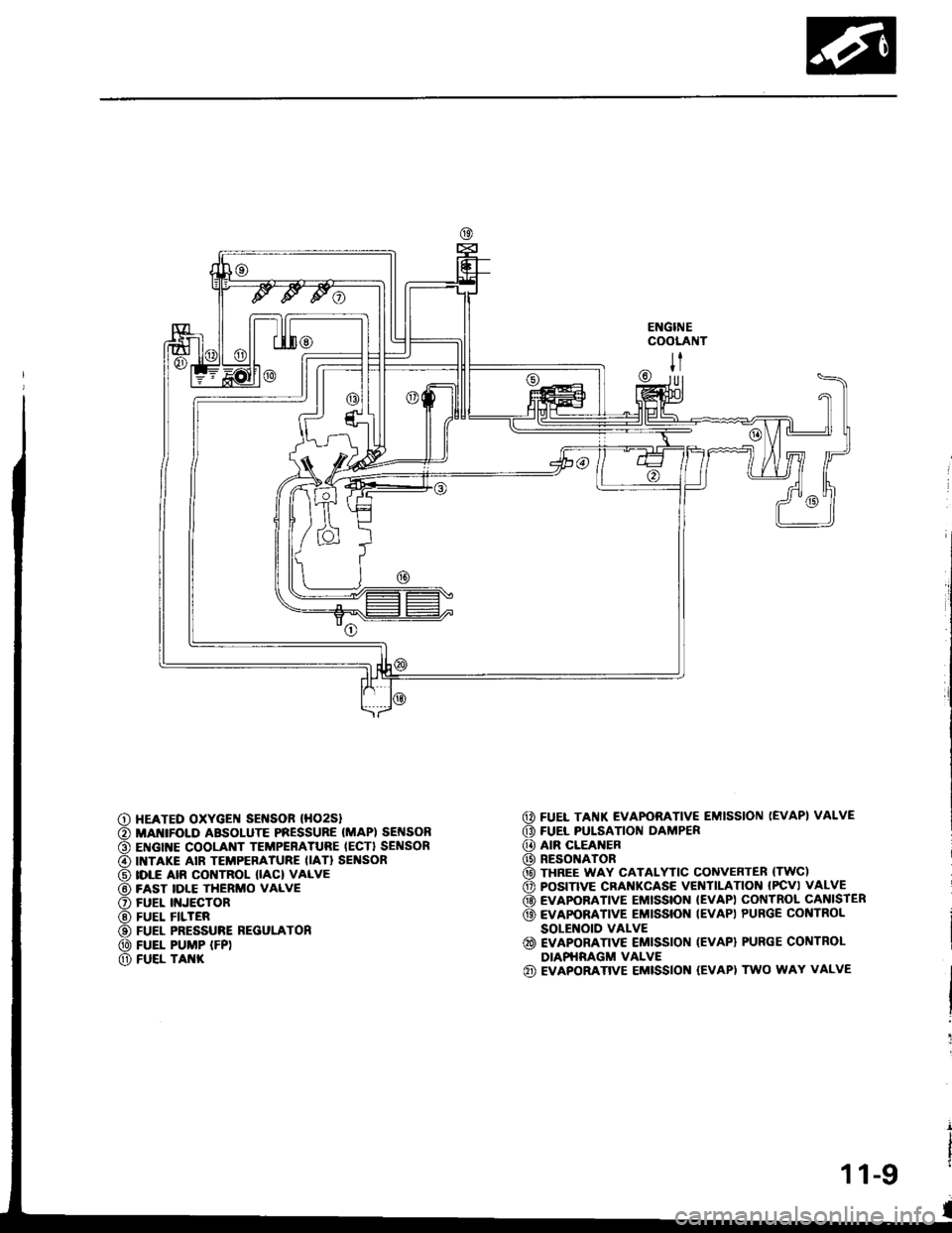

ENGINECOOLANT

@ FUEL TAI{K EVAPORATIVE EMISSION (EVAP} VALVE

G) FUEL PULSATION DAMPER

@ AIR CLEANER

@) RESONATOR

@ THREE WAY CATALYTIC CONVEnTER (TWC)

o POS|TIVE CRANKCASE VEITITILAT|ON IPCV) VALVE

@ EVAPOBATIVE EMISSION IEVAP) COI{TROL CANISIER

@ EvApoRATrvE EMrssroN IEVAP) PURGE coNTRoL

SOLENOID VALVE

@ EVAPORATTVE EMISSION (EVAP) PURGE CONTROL

DIAPHRAGM VALVE(iD EVAPORATIVE EMISSION (EVAPI TWO WAY VALVE

|l

U]

HEATED OXYGEI{ SEI{SOF (HO2S}

MANIFOI.D ABSOLUTE PRESSURE (MAP) SEI{SONENGINE COOLANT TEMPERATURE IECT} SENSORINTAKE AIR TEMPERATURE IIAT} SEI'ISORIDLE AIR CONTROL IIAC) VALVEFAST IDLE THERMO VALVEFUEL II{JECTORFUEL FILTERFUEL PRESSURE REGULATONFUEL PUMP IFP)FUEL TAI{K

11-9

Page 228 of 1413

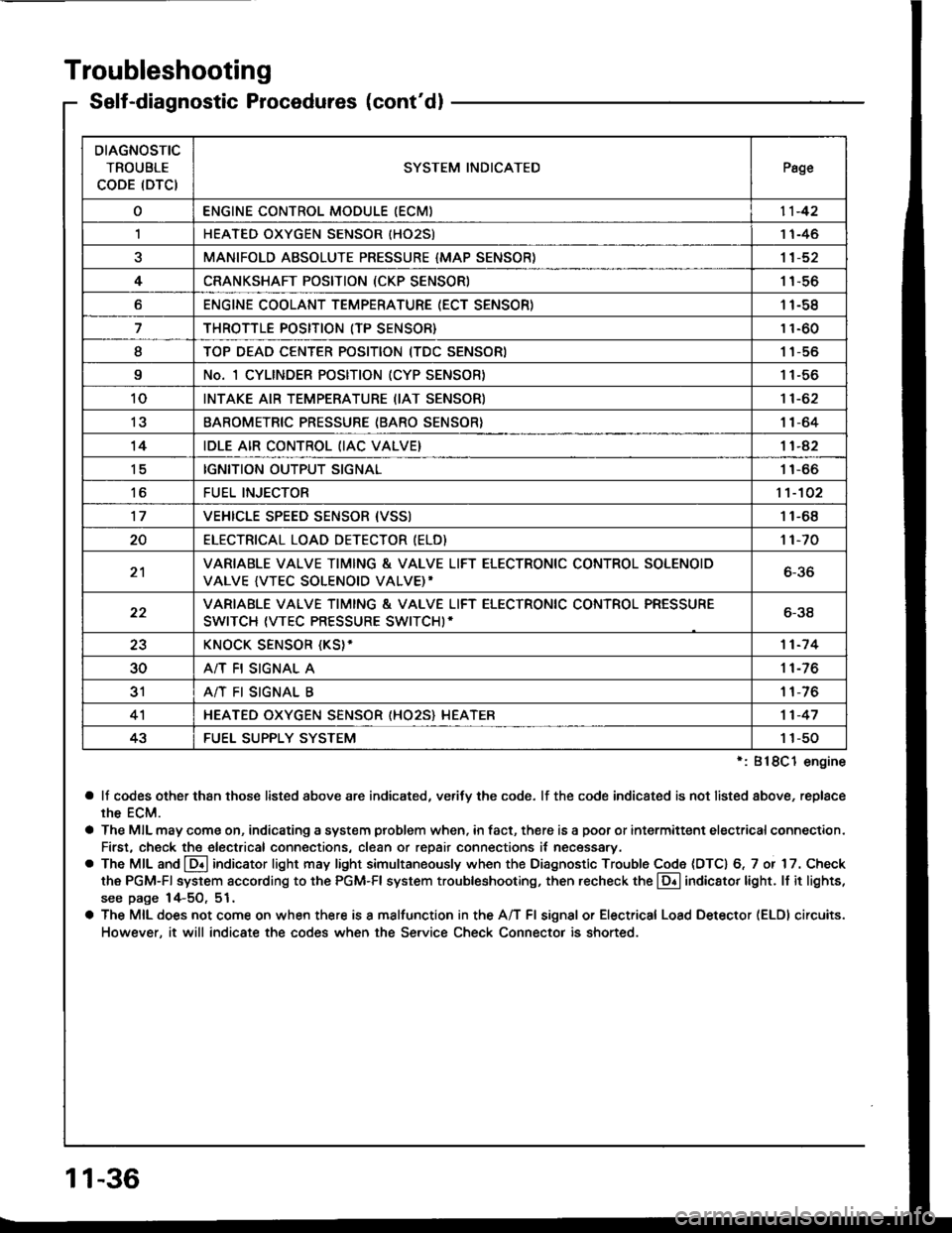

Troubleshooting

Self-diagnostic Procedures (cont'dl

':818C1 engine

a lf codes other than those listed above are indicated, verifv the code. lf the code indicated is not listed above, replace

rhe ECM.

a The MIL may come on, indicating a system problem when, in fact, there is a poor or intermittent electricalconnection.

First, check the electrical connections, clean or repair connections it necessary.

o The MIL and @ indicator light may light simultaneously when the Diagnostic Trouble Code (DTC) 6, 7 or 17. Check

the PGM-Fl system according to the PGM-Fl system troubleshooting, then recheck the l!! indicator light. ll it lights,

see page 14-5O, 51.

a The MIL does not come on when there is a malfunction in the A/T Fl signal or Electrical Load Detector (ELDI circuits.

However, it will indicate the codes when the Service Check Connector is shorted.

DIAGNOSTIC

TROUBLE

CODE (DTCISYSTEM INDICATEDPsge

oENGINE CONTROL MODULE IECM)11-42

,lHEATED OXYGEN SENSOR IHO25)1 1-46

aMANIFOLD ABSOLUTE PRESSURE {MAP SENSOR)11-52

4CRANKSHAFT POSITION (CKP SENSOR)1 1-56

oENGINE COOLANT TEMPERATURE (ECT SENSOR)11-58

THROTTLE POSITION (TP SENSOR}11-60

ITOP DEAD CENTER POSITION (TDC SENSORI1 1-56

9No. 1 CYLINDER POSITION (CYP SENSOR)1 1-56

10INTAKE AIR TEMPERATURE (IAT SENSOR)11-62

13BAROMETRIC PRESSURE (BARO SENSOR}1|-64

14IDLE AIR CONTROL (IAC VALVE}11-42

tcIGNITION OUTPUT SIGNAL11-66

toFUEL INJECTOR1't-102

17VEHICLE SPEED SENSOR {VSSI11-68

20ELECTRICAT LOAD DETECTOR (ELD)'t 1-70

21VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL SOLENOID

VALVE {VTEC SOLENOID VALVE)'6-36

22VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL PRESSURE

SWITCH (VTEC PRESSURE SWITCHI-6-38

23KNOCK SENSOR {KS}-11-7 4

30A/T FI SIGNAL A11-76

3'rA/T FI SIGNAL B1 1-76

4'lHEATED OXYGEN SENSOR (HO25} HEATER11-47

43FUEL SUPPLY SYSTEM1 1-50

11-36

Page 232 of 1413

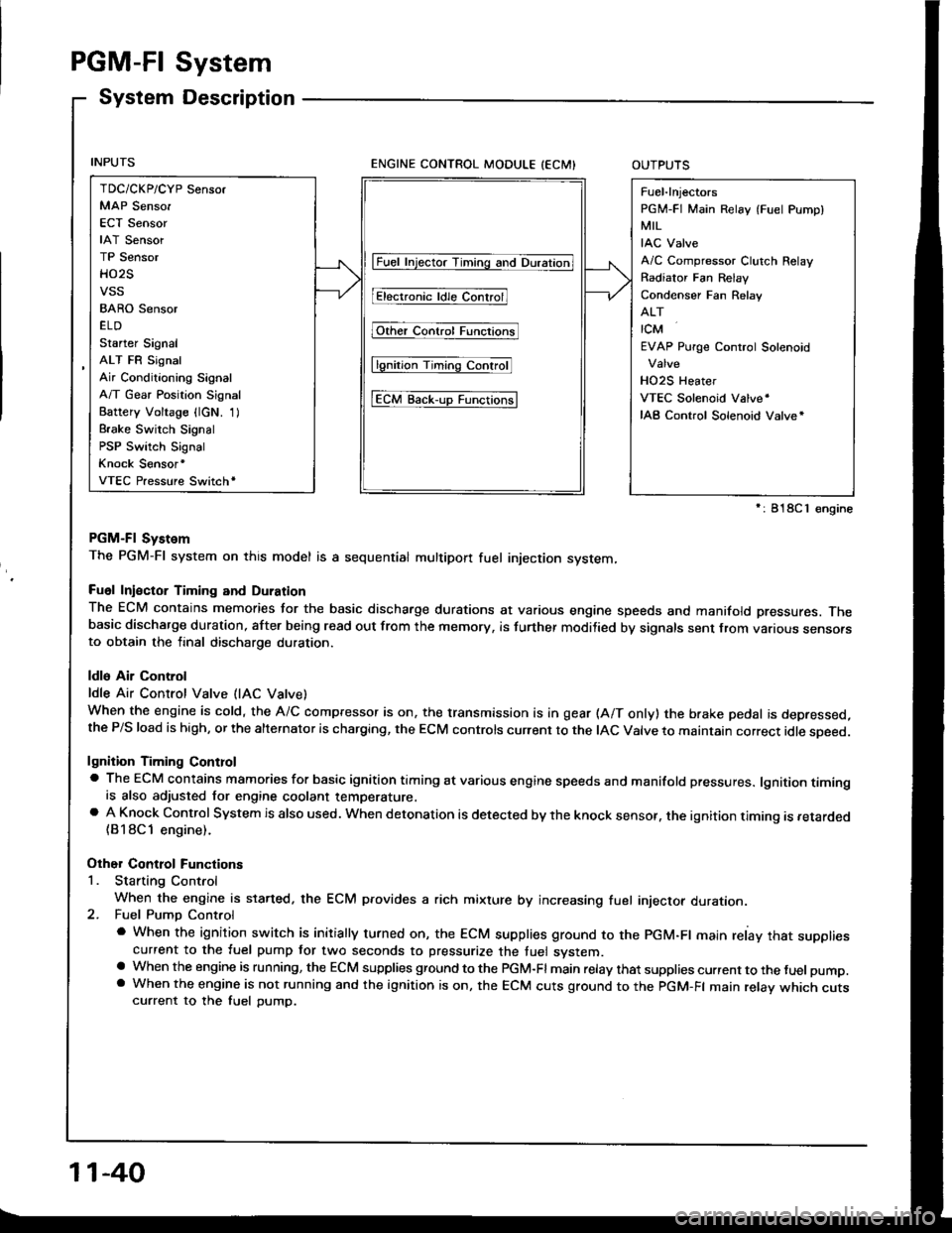

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECMIOUTPUTS

PGM-Fl System

The PGM-Fl system on this model is a sequential multipon fuel injection system,

Fuol Iniector Timing and Duration

The ECM contains memories tor the basic discharge durations at various engine speeds and manifold pressures. Thebasic discharge duration, after being read out from the memory, is turther modilied by signals sent from vanous sensofsto obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Vatve)

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) the brake pedal is depressed,the P/S load is high, or the alternalor is charging, the ECM controls current to the IAC Valve to maintain correct idle soeed.

lgnition Timing Controla The ECM contains mamories for basic ignition timing at various engine speeds and manifold pressures. lgnition timingis also adjusted for engine coolant temperature.a A Knock Control System is also used. when detonation is detected by the knock sensof. the ignition timing is retarded(B18Cl engine).

Other Control Functions

1. Starting Control

When the engine is started. the ECM provides a rich mixture by increasing fuel injector duration.2. Fuel Pump Control

a When the ignition switch is initially turned on, the ECM supplies ground to the PGM-Fl main relay that suppliescurrent to the fuel pump tor two seconds to pressurize the tuel system.a When the engine is running, the ECM supplies gfound to the PGM-Fl main relay that supplies current to the fuel pump.a When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relav which cutscurrent to the fuel pump.

TDC/CKP/CYP Sensor

MAP Senso.

ECT Sensor

IAT Sensor

TP Sensor

HO2S

vss

BARO Sensor

ELD

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Signal

Battery Voltage {lcN. 1)

Brake Switch Signal

PSP Switch Signal

Knock Sensor'

VTEC Pressure Switchr

Fuel-lnjectors

PGM-FI Main Relay (Fuel Pump)

MIL

IAC Valve

A/C Compressor Clutch Relay

Radiator Fan Relav

Condenser Fan Relav

ALT

rcM

EVAP Purge Control Solenoid

HO2S Heater

VTEC Solenoid Valve'

IAB Control Solenoid Valve*

lFuet tnjector Timing and Duration]

I Electr..l"ldle Contr;il

Fit'e' contr; Funcrfit

l6tio; Ttntrlg c..trol

tEcM aack-,rp Functiorlsl

': 818C 1 €ngine

11-40

Page 268 of 1413

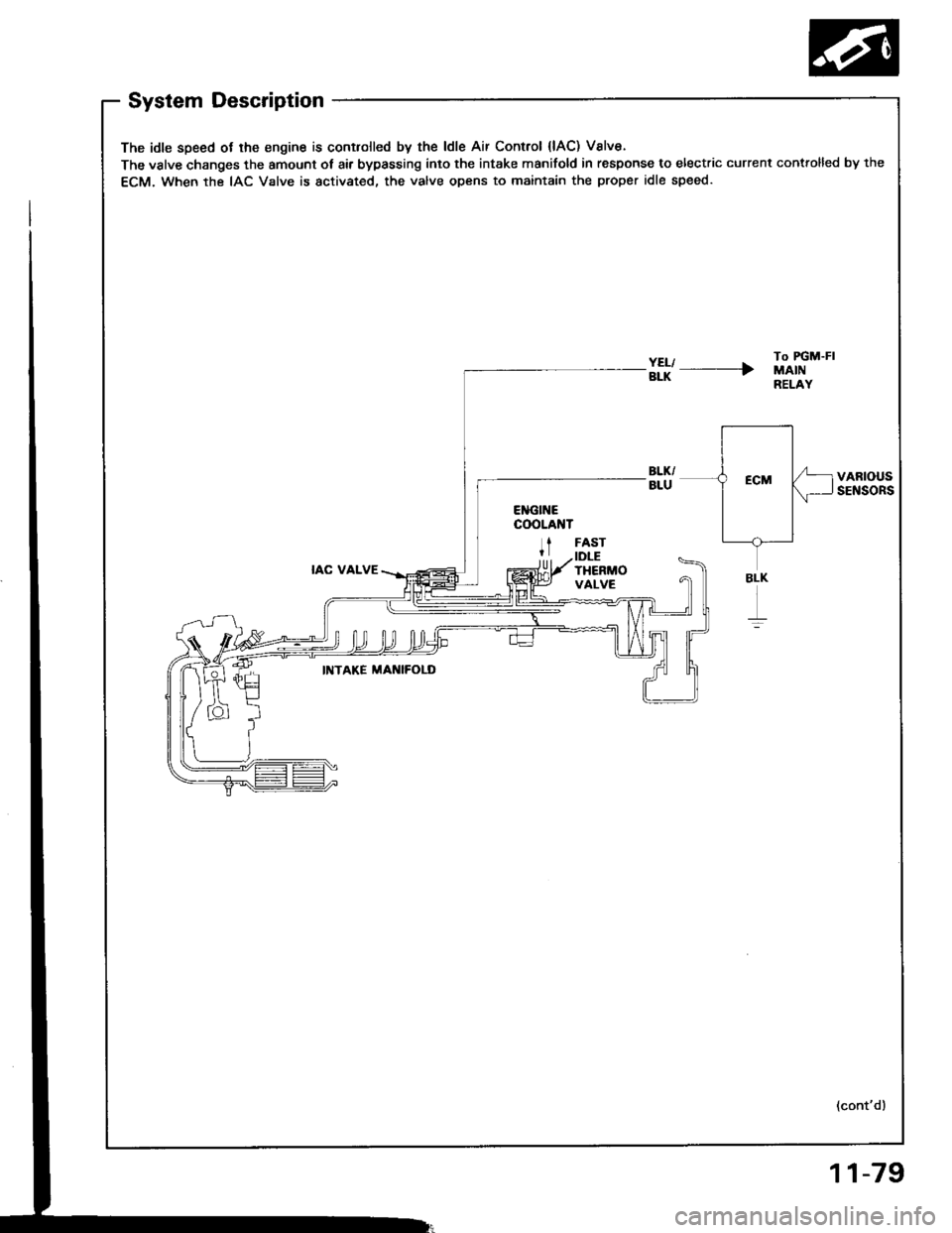

System Description

The idle speed ot lhe engine is controlled by the ldle Air Control {lAC) Valve.

The valve changes the amount ot air bypassing into the intake manifold in response to electric current controlled by the

ECM. When the IAC Valve is activated, the valve opens to maintain the proper idle speed.

#l' ----rTo FGM-FIMAINRELAY

VARIOUSSENSORS

IAC VALVE

FASTIDLETHERMOVALVE

INTAKE MAI{IFOLD

(cont'd)

BLK

r

11-79

Page 269 of 1413

ldle Control System

System Description (cont'd)

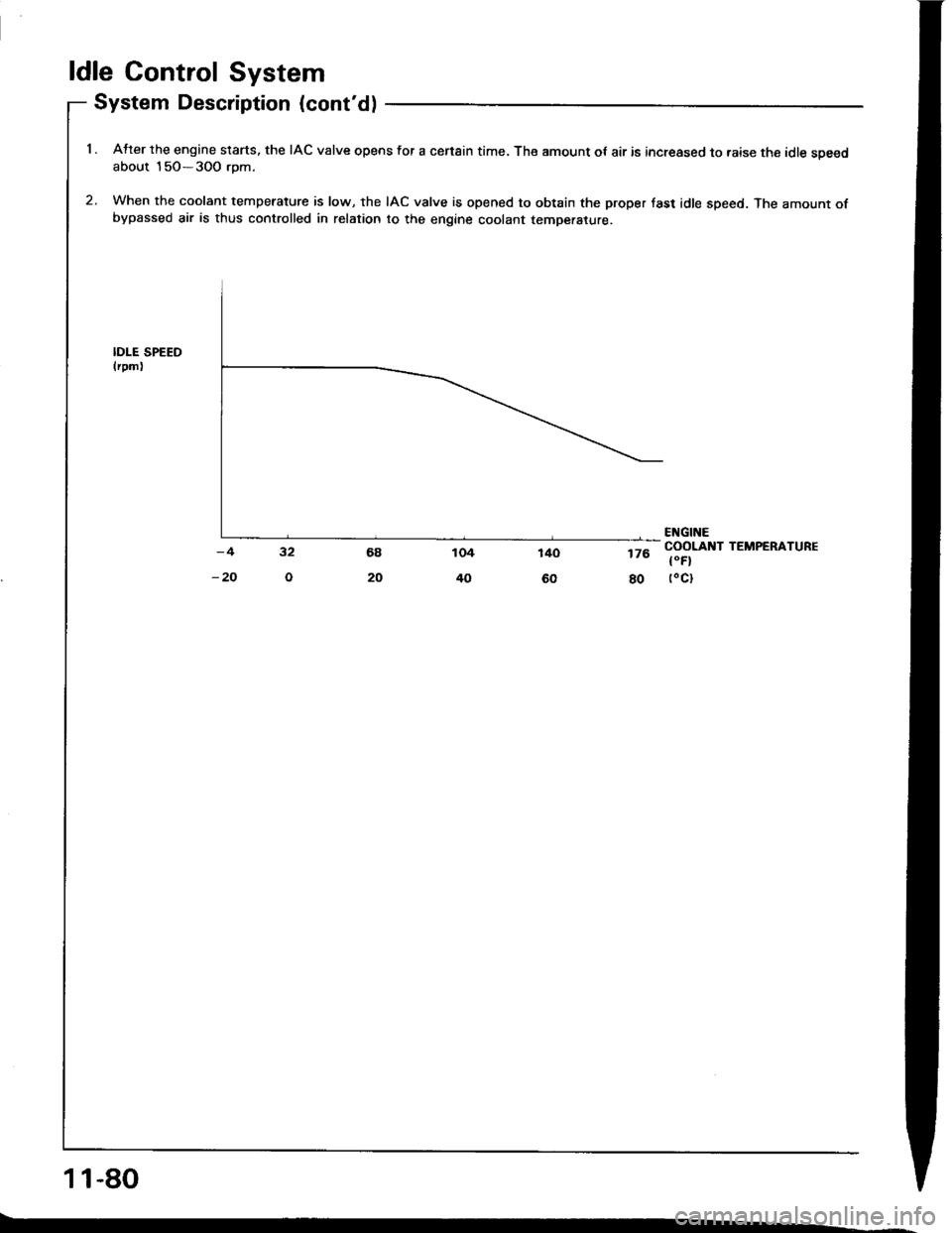

1 . Atter the engine slarts. the IAC valve opens for a censin time, The amount ot air is increased to raise the idle soeedabout 15O-3OO rom.

2. When the coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. The amount ofbypassed air is thus controlled in relation to the engine coolant temperature.

IDI-E SPEEDlrpm)

176

80

ENGINECOOLANT TEMPERATURE

t"Fl(oct

11-80