brace HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 48 of 1413

Engine Removal/lnstallation

@a Make sure jacks and safety stands aro placed ploper-

ly and hoisl brackots arg attachod to the correct po-

sitions on tho engine (se€ ssction 1).

a Mak€ sure tho car willnot roll off stands and tallwhile

you are wotking under it'

CAUTION:

a Use fendet covals to avoid damaging painted

sudaces.

r Unspecified itsms alo common

a Unplug tho widng connectots carefully while holding

the couplor and tha connector portion to avoid

oamage.

a Mark all wiring and hoses to avoid misconnection.

Also, be sulo that thsy do not contact other wiring

or hoses, or interfere with oth€l parts.

NOTE: Anti-theft radios have a coded theft ptotection

circuit. Be sure to get the customer's code number beJore

- Disconnecting the batterY.

- Removing the No. 32 (7.5 A) fuse from the under-

hood tuse/relay box.- Removing the radio

Atter service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operataon.

1. Remove the hood (see section 2O).

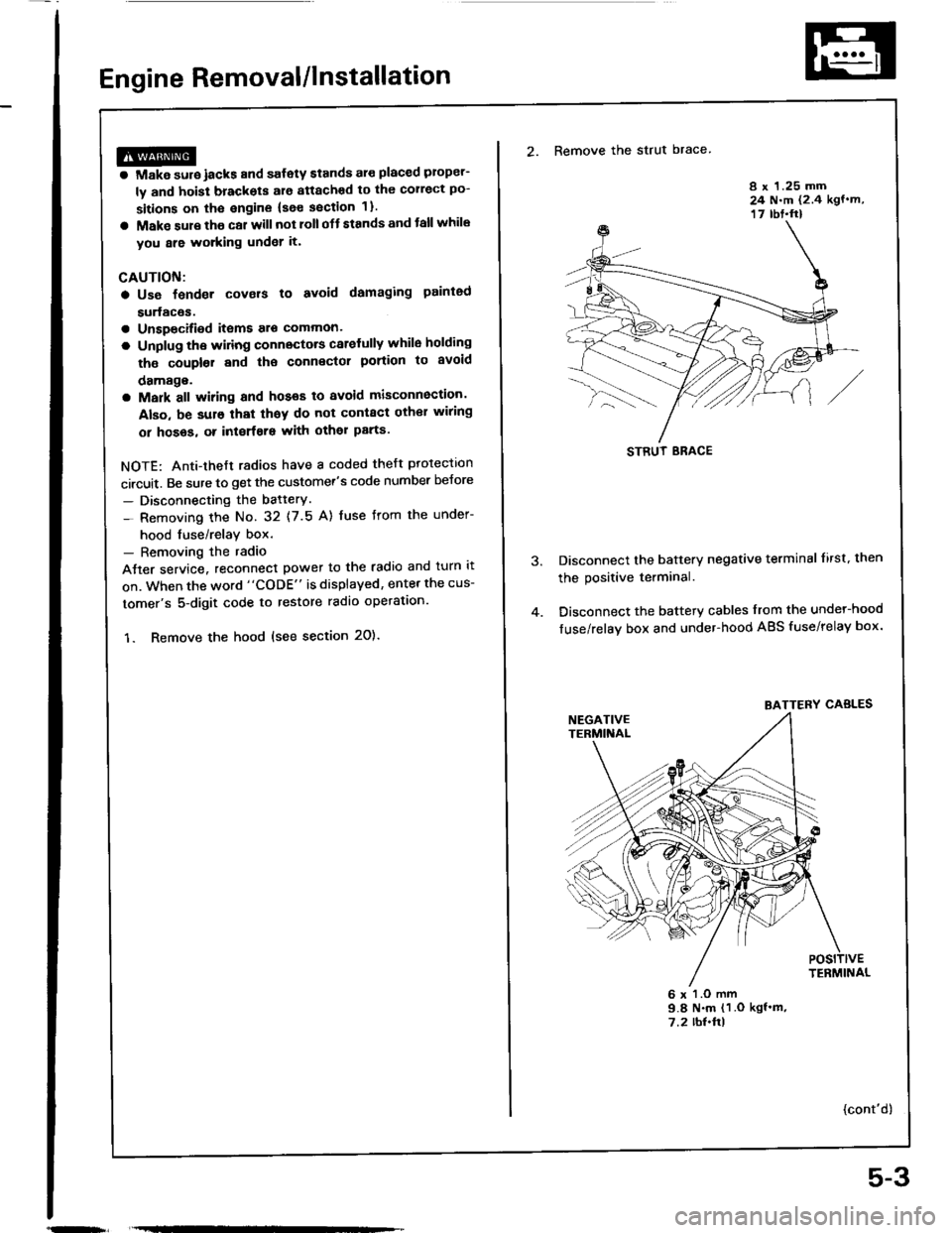

2. Remove the strut brace

8 x 1.25 mm24 N.m (2.4 kgf.m,17 rbt.ft)

Disconnect the battery negative terminal lirst. then

the positive terminal.

Disconnect the battery cables from the undel-hood

fuse/relay box and under-hood ABS fuse/relay box.

6 x l.O mm9.8 N.m (1 .O kgf'm,7.2 rbl.ftl

{cont'd)

STRUT ERACE

BATTERY CABLES

5-3

Page 116 of 1413

Cylinder Head

Removal

Engine removal is not required or this procedure.

CAUTION: To avoid damaging tho cylinder head, wail

u[tilths.nginc coolant tsmperaturo drops bolow 100"F(38'Cl bafore loos6ning tho retaining bolts.

NOTE;

. Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDc) {page 6-51).

Mark all emissions hoses betore disconnecting them.

Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before- Disconnecting the battery.- Removing the No.32 (7.5 A) fuse trom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect power to the radio 8nd turn it

on.

When the word "CODE" is displaved. enter the cus-

tomer's 5-digit code to restore radio operation,

Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

Relieve fuel pressure (see section 111.

l@ Do not 3moke whilo working on fuel

a

a

'1.

systgm. ko6p opon tlamo ot Spark away trom work

aroa. Drain fugl only into an approved containsr,

4. Disconnect the fuel feed hose.

SERVIC€ BOLT15 N.m (1.5 kgtm, rl bf.tt)WASHERSReplace.

BANJO BOLT

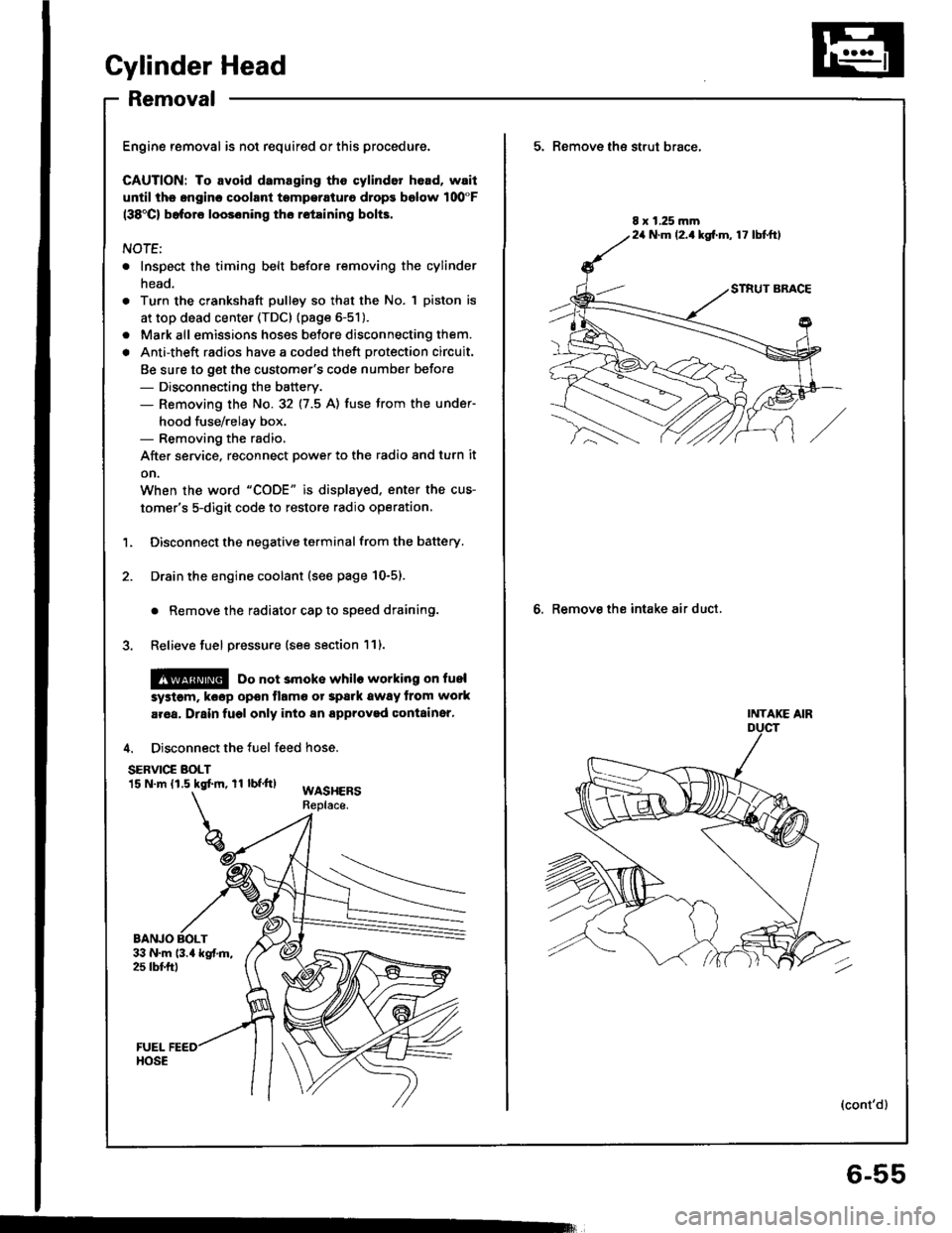

5. Remove th€ strut brace,

6. Remove the intake air duct.

8 x 1.25 mm24 N.m (2.1kg[.m, 17 lbtftl

INTAKE AIR

(cont'd)

6-55

Page 653 of 1413

Steering Gearbox

Removal (cont'dl

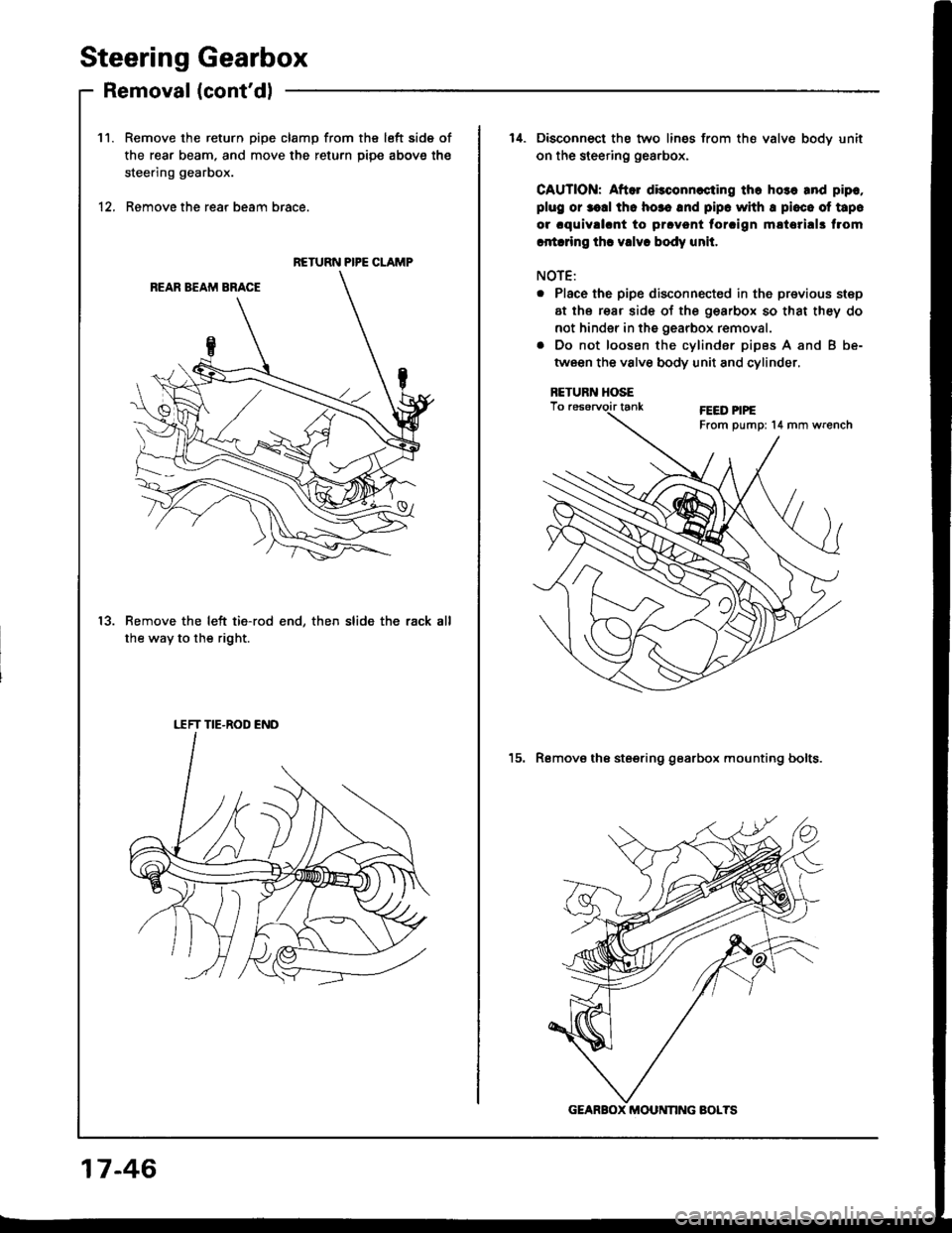

Remove the return pipe clamp from the left side of

the rear beam. and move the return piDe above the

steering gearbox.

Remove the rear beam brace.

Remove the left tie-rod end, then slide the rack

the way to the right.

11.

12.

RETURN PIPE CLAMP

13.

I.TFT TIE-ROD END

14. Disconnect the two lines from th€ valve bodv unit

on the steering gea.box.

CAUTION: Aftor dkconnccting tho ho3o and pip.,

plug or r.d thc ho3. rnd pipc whh I pioco of tapo

or .quivll.nt to prcvont torcign m!tori!|3 f.om

ritrdng thc vdv. body unit.

NOTE:

. Place the pipe disconnected in the previous step

at the rear side of the gearbox so that they do

not hinder in the gearbox removal.

. Do not loosen the cylinder pipes A and B be-

tween the valve body unit and cylinder,

RETUR]T HOSE

15. Remove the steering gearbox mounting bolts.

GEARBOX MOU NNG BOLTS

17-46

Page 671 of 1413

Steering Gearbox

Installation (cont'd)

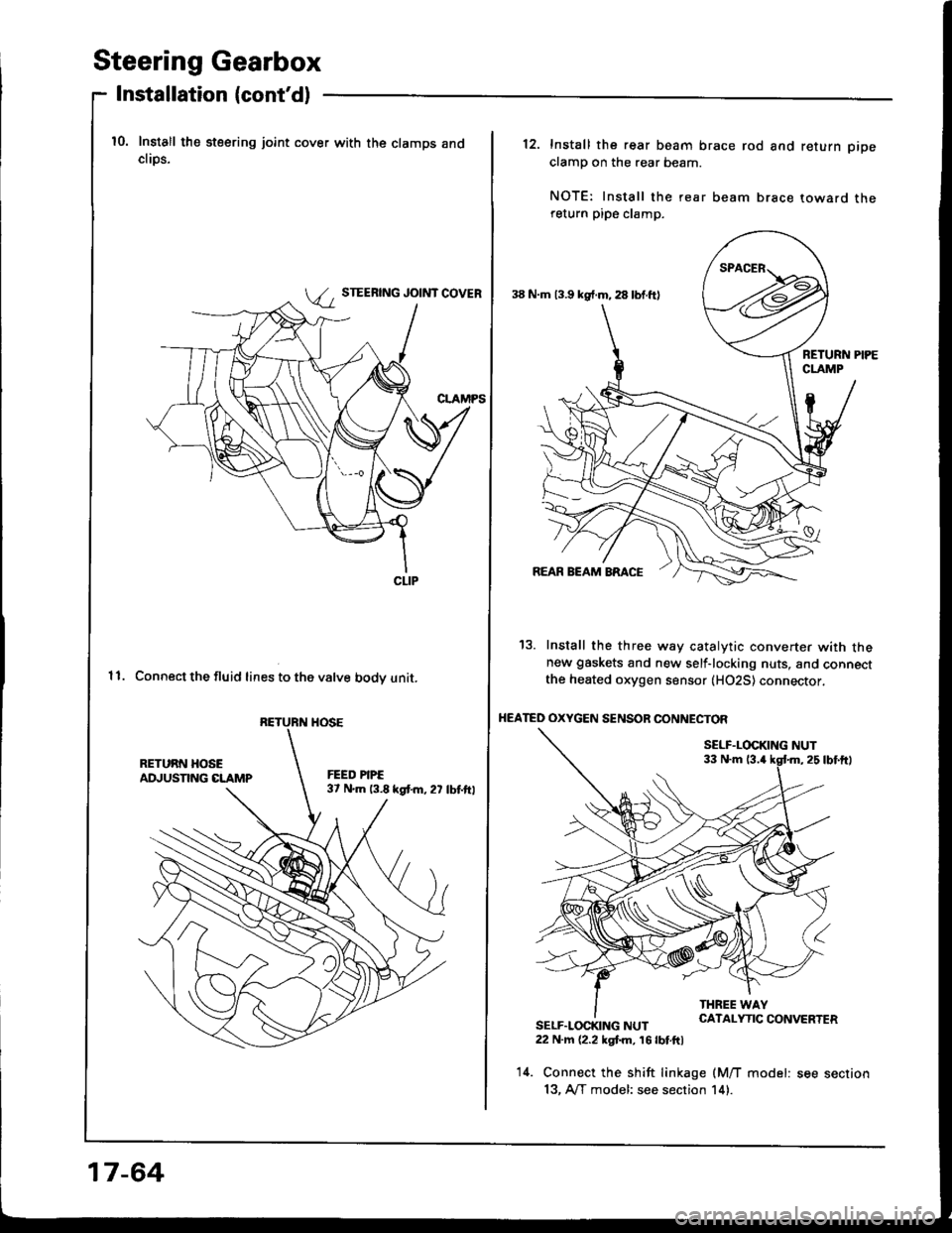

10. Install the steering joint cover with the clamps andcliDs.

STEERING JOINT COVER

11. Connect the fluid lines to the valve bodv unit.

CLIP

RETURN HOSE

17-64

38 N.m 13.9 kg{.m, 28 lbf.ft)

12. Install the rear beam brace rod and return pipe

clamp on the rear beam.

NOTE: Install the rear beam brace toward thereturn pipe clamp.

13. Install the three way catalytic converter with thenew gaskets and new self-locking nuts, and connectthe heated oxygen sensor (H02S) connector,

HEATED OXYGEN SENSOR CONNECTOF

SELF.LOCKING NUT33 N.m 13.4

SELF.LOCKING NUT22 N.m (2.2 kgt m, 16 lbt.ftl

14. Connect the shift linkage (M/T model: see section

13, A/T model: see section 14).