coolant temperature HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 23 of 1413

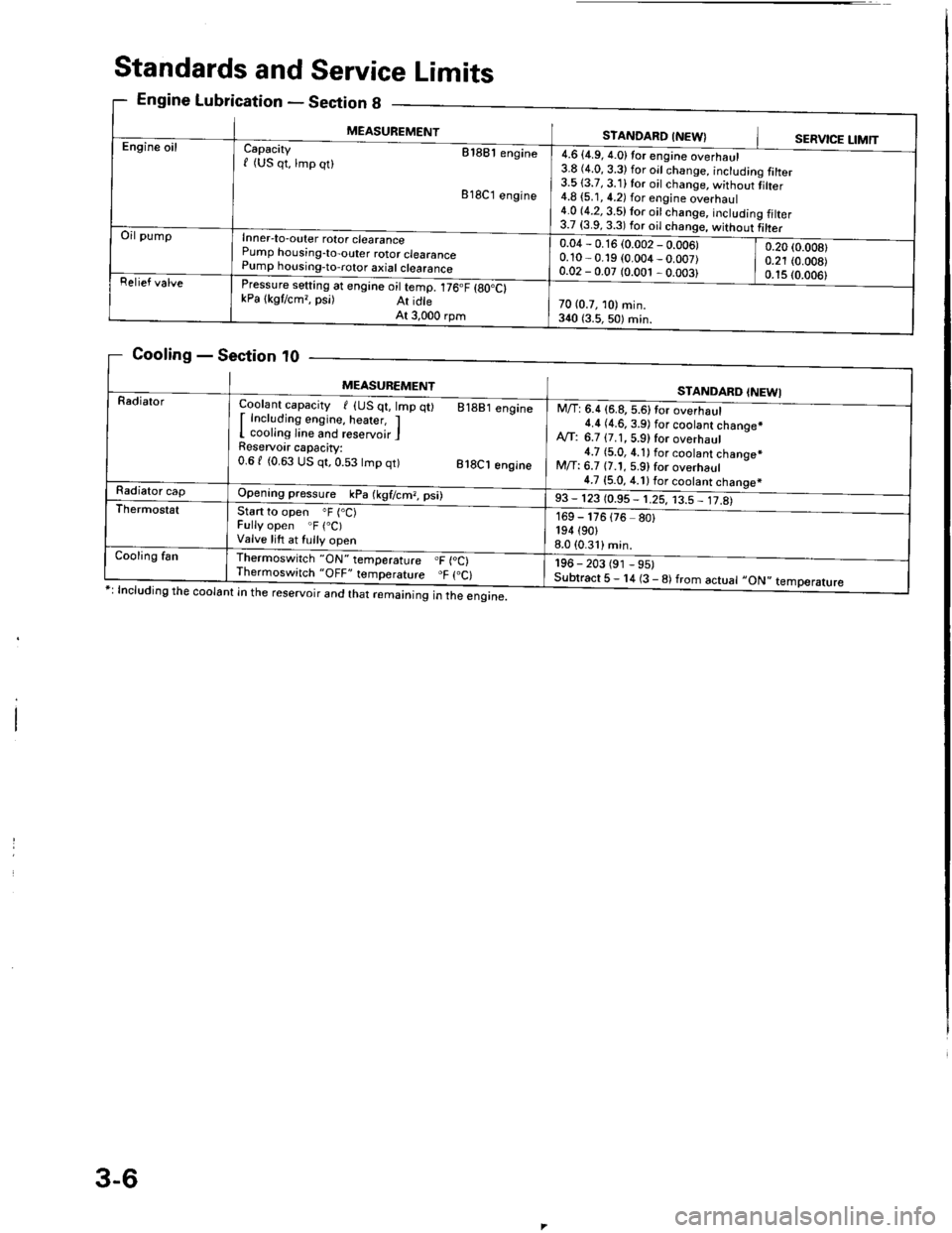

Standards and Service Limits

Engine Lubrication - Section g

Cooling - Section t0

ng the coolant in the reservoir and that remaining in the engine.

eclton u _

MEASUREMENTSTANDARD INEW}SERVICE LIMTT

g talter

tiher

g filter

Engine oilCapacity etaet engine

f (US qt, lmp qt)

818C1 engine

Inner-to-outer rotor clearance

Pump horising-to-outer rotor clearance

Pump housing-to,rotor axial clearance

rressure setting at engine oil temp. 176.F {gO.Ct

kPa lkgtcm,, psi) At idte

At 3,000 rpm

4.6 {4.9, 4.0}tor engine overhaul

3.8 (4.0, 3.3) for oil change, inctudin

3.513.7, 3.11 for oil change, without

4.8 {5.1, 4.2) for engine overhaul

4.0 (4.2, 3.5) lor oit change, includin

3.7 i3.9 3 3l fdr ^il .hi

Oil pump

0.04 - 0.16 (0.002 - 0.006)

0.10 - 0.19 (0.004 _ 0.007)

0.02 - 0.07 (0.001 , 0.003)

0.20 (0.008)

0.21 (0.008)

0.1s (0.006)

Relief valve

70 (0.7, 10) min.

3{0 {3.5,50) min.

MEASUBEMENTSTANDARD INEWI

RadialorCoolant capacity I {US qt, lmp

I Including engine, heater, I

I cooling line and reservoir I

Reservoir capacity:

0.61 (0.63 US qt,0.53 tmp qt)

q0 81881 engine

818C1 engine

Opening pressure kPa (kgf/cm?, psi)

start to open oF (.C)

Fully open .F (.C)

Valve lift at fully open

lhermoswitch "ON" temperature .F {oC)

Thermoswitch "OFF" temporature "F (.C)

M/T: 6.4 (6.8, 5.6)tor overhaul

4.4 (4.6.3.9) f6r s66lsn1gh66q.*

A,rf: 6.7 {7.1, 5.9) for overhaul

4.7 {5.0, 4.1) for coolant chanoe*

M/T: 6.7 {7.1, 5.9} for overhaul

4.7 {5.0, 4.1) for coolant chanoe*

,3 - 113 toss - trs, r3= Jt&

-

196 - 203 (91 - 95)

Subtract 5 - 14 (3 - 8) from actuat -ON',

169 - 176

194 (90,

8.0 (0.31)

{76 80}

temperature

Radiator cap

Thermostst

Cooling fan

3-6

Page 79 of 1413

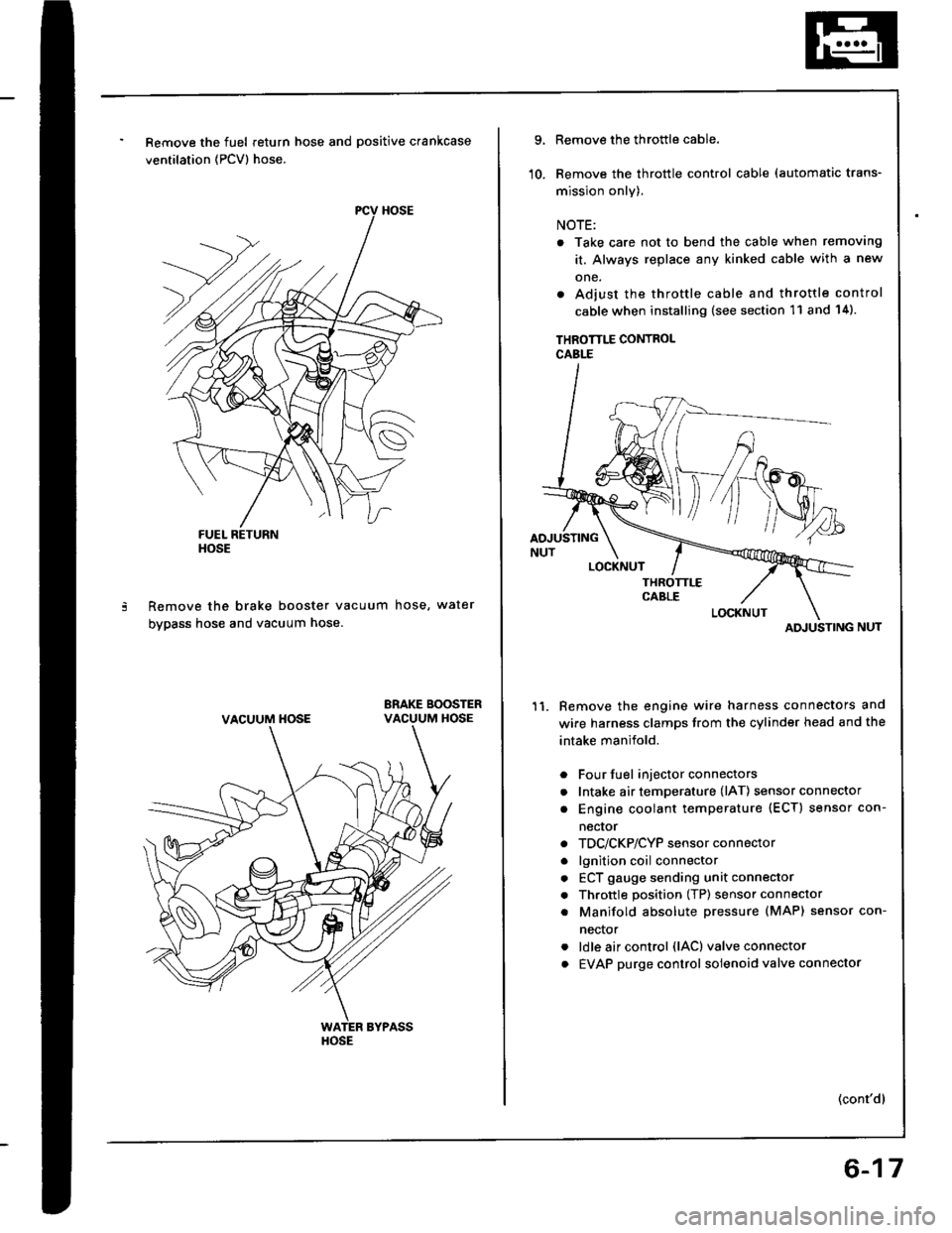

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 118 of 1413

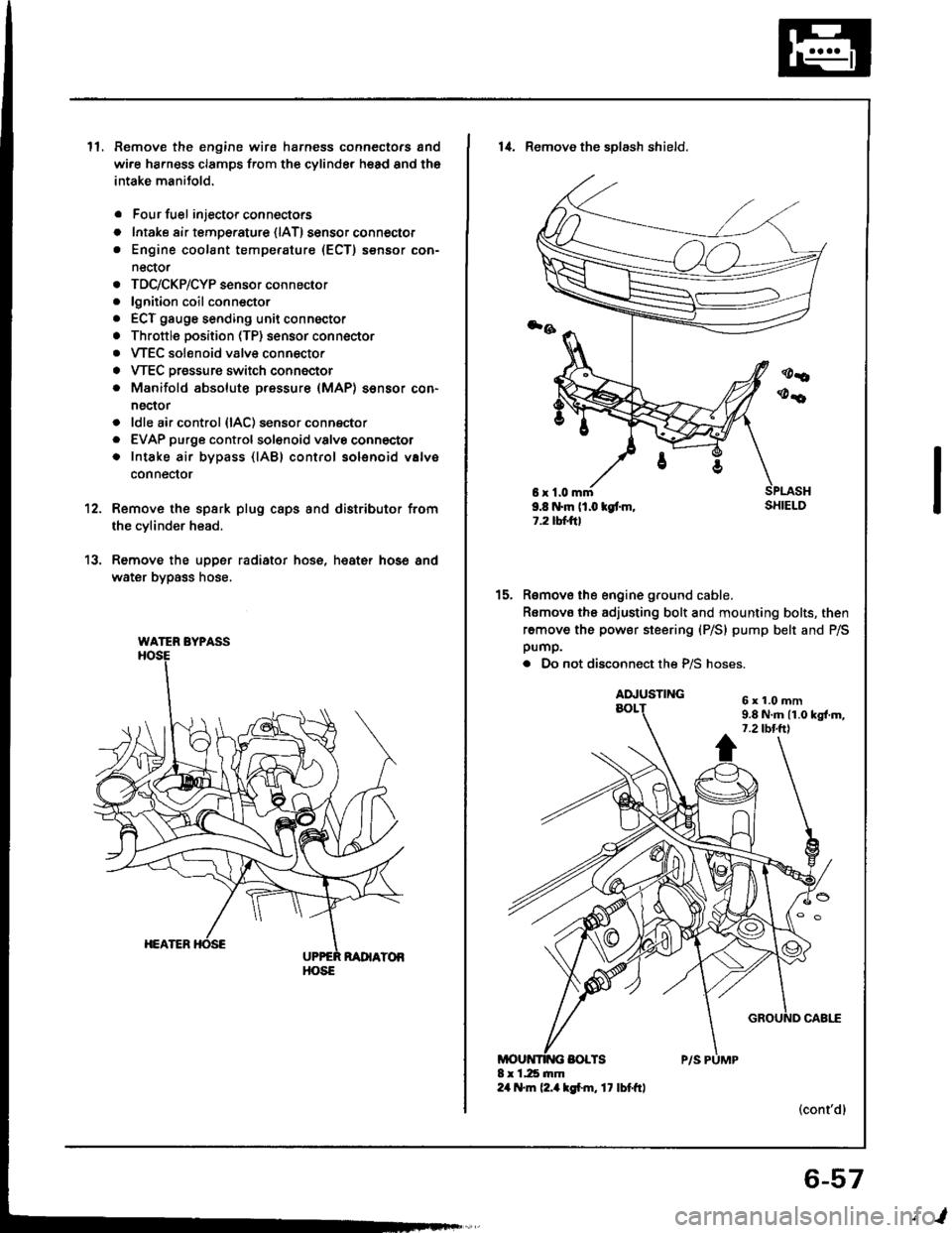

ll.Remove the engine wire harness connectors and

wi.e ha.ness clamps from the cylinder head and the

intake manitold.

Four fuel injector connectors

Intake air tempe.ature {lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

nector

TDC/CKP/CYP sensor connector

lgnition coil conn€ctor

ECT gauge sending unit connector

Throttle position (TP) sensor connector

VTEC solenoid valve connector

VTEC Dressure switch connector

Manifold absolute pressure (MAP) sensor con-

nector

ldle air control {lAC) sensor connector

EVAP purge controlsol€noid valvo connector

Intake air bypass {lABl control solenoid valve

conneclor

a

o

a

o

a

a

a

a

a

a

a

a

a

12.

13.

Remove the spsrk plug caps and distributor from

the cylinder head.

Remove the upper radiator hose, heat€r hose and

water bypass hose.

WATER BYPASS

HOSE

6r1.0mm9.8 N.m (1.0 kgt m,1.2 tbtftl

14. Remove the sDlash shield.

Remove the engine ground cable.

Romovo the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt and P/Spump.

. Do not disconnect the P/S hoses.

(cont'dl

15.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 tbt.ttl

6-57

,l

Page 189 of 1413

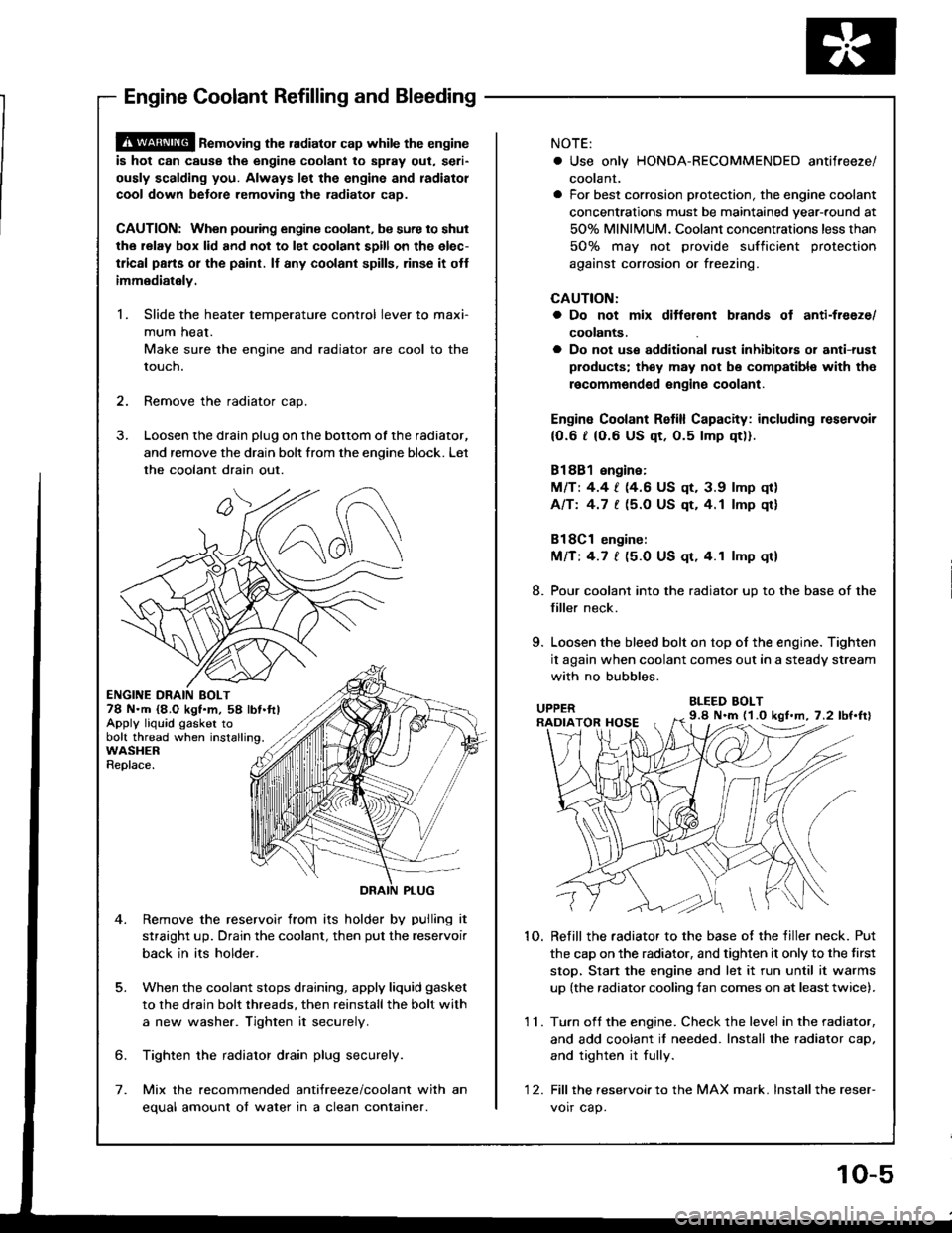

@ ne-oving the radiator cap while the engine

is hot can cause the engine coolant to splay out, seri-

ously scalding you. Always let the engine and radiatol

cool down betore removing the radiator cap.

CAUTION: When poudng engine coolant, be sure to shut

the relay box lid and not to let coolant spill on the elec-

tlical pans or the paint. ll any coolant spills, rinse it otf

immediately.

1. Slide the heater temperature control lever to maxi-

mum heat.

Make sure the engine and radiator are cool to the

touch.

2. Remove the radiator cao.

3. Loosen the drain plug on the bottom of the radiator,

and remove the drain bolt from the enoine block. Let

the coolant drain out.

ENGINE DRAIN BOLT78 N.m {8,O kgt.m, 58 lbt.ftlApply liquid gasker tobolt thread when installing.WASHERReplace.

5.

Remove the reservoir from its holder by pulling it

straight up. Drain the coolant, then put the reservoir

back in its holder.

When the coolant stops draining, apply liquid gasket

to the drain bolt threads, then reinstallthe bolt with

a new washer. Tighten it securely

6. Tighten the radiator drain plug securely.

7. Mix the recommended antifreeze/coolant with an

equal amount of water in a clean container.

NOTE:

. Use only HONDA-RECOMMENOED antifreeze/

coolant.

a For best corrosion protection, the engine coolant

concentrations must be maintained year-round at

50% MINIMUM. Coolant concentrations less than

50% may not provide sufficient protection

against corrosion or freezing.

CAUTION:

a Do not mix ditterent blands ot anti-freeze/

coolants.

a Do not use additional rust inhibitois or anti-rust

products; they may not bs compatibl€ with the

recommgndsd engins coolant.

Engin€ Coolant Retill Capacity: including reservoir

{0.6 t (0.6 US qt, 0.5 lmp qt)).

81881 engine:

MlTt 4.4 | (4.6 US qt, 3.9 lmp qr)

Afft 4.7 [ (5.O US qt,4.1 lmp qt]

Bl8Cl engine:

Mnt 4.7 | (5.0 US qt.4.1 lmp qt)

8. Pour coolant into the radiator up to the base of the

filler neck.

9. Loosen the bleed bolt on top of the engine. Tighten

it again when coolant comes out in a steady stream

with no bubbles.

BLEED BOLT

1O. Refill the radiator to the base of the tiller neck. Put

the cap on the radiator. and tighten it only to the tirst

stop, Stan the engine and let it run until it warms

up (the radiator cooling fan comes on at leasttwice).

11. Turn oft the engine. Check the level in the radiator,

and add coolant it needed. Install the radiator caD,

and tighten it fully.

'1 2. Fill thereservoirto the MAX mark. lnstallthe reser-

voir cap.

9.8 N.m (1.O kgl.m, 7.2 lbf.ftl

Engine Coolant Refilling and Bleeding

10-5

Page 197 of 1413

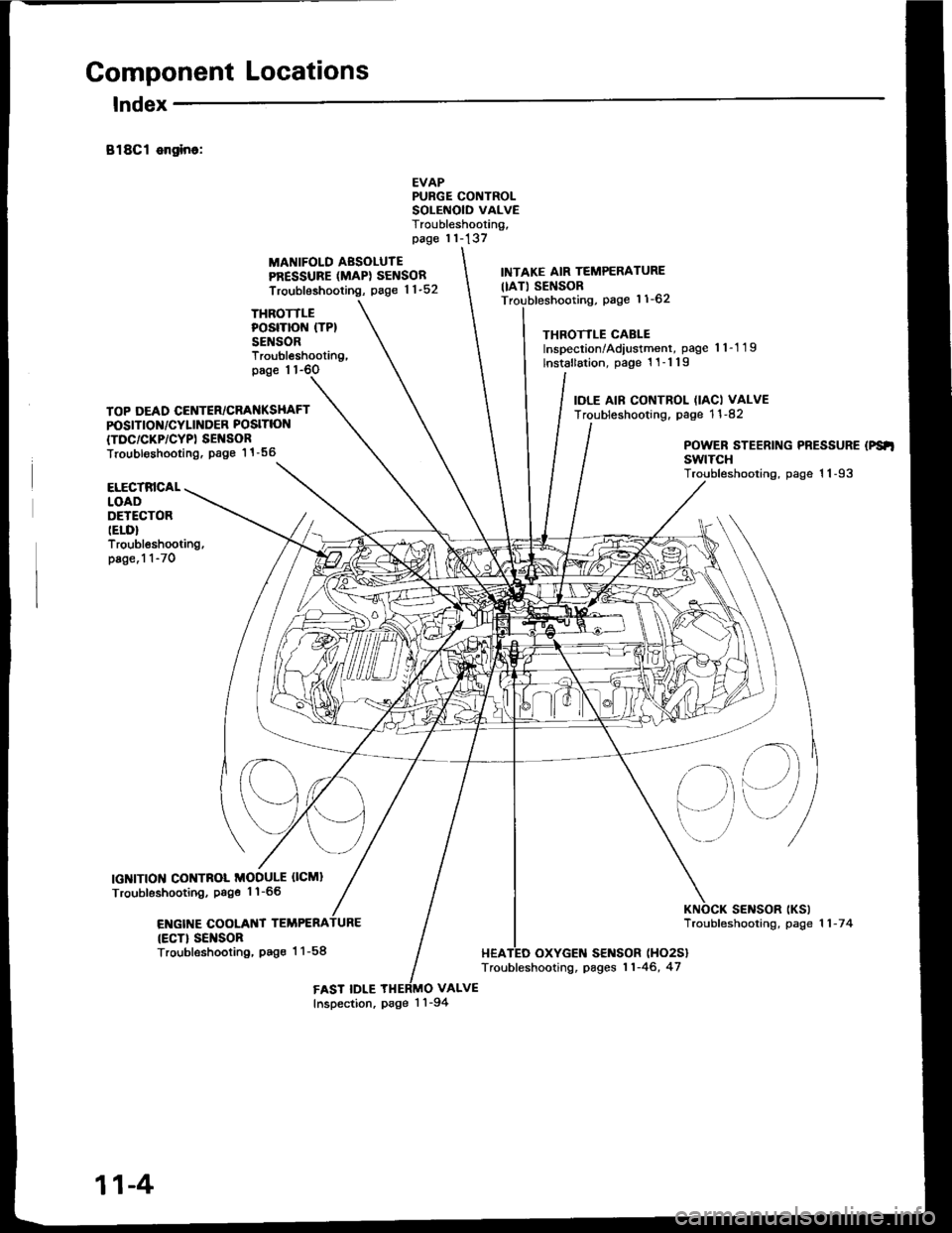

Component Locations

lndex

B18Cl ongino:

THROTTLEPOSITION (TP}

SENSOR

MANIFOLD AESOLUTEPRESSURE (MAPI SENSOR

Troubleshooting, page 1 1-52

EVAPPURGE CONTROLSOLEiIOID VALVETroubleshooting,page 11-137

VALVE

INTAKE AIR TEMPERATURE

IIAT) SENSORpage 11-62

THROTTLE CABLEInspection/Adiustment, page 'l 1-1 19

lnstallation, page 1 1-1 19

IOLE AIF CONTROL (IACI VALVETroubleshooting. page 1 1 -82

Troubleshooting,page 1 1-6O

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION

{TDC/CKP/CYPI SEI{SORTroubl€shooting. Page 1 1 -56POWER STEERING PRESSURE (PS'I

swtTcHTroubleshooting, page 1 1-93ELECTRICALLOADDETECTORIELD}Troubleshooting,page.1 1-70

IGNITION CONTNOL MODULE OCMI

Troubleshooting, Psge 1'l-66

ENGIT{E COOLANT TEMPERA

{ECT} SEI{SORTroubleshooting, Pag€ 1 1-58

sElrlsoR tKslTroubfeshooting, page 1 1 -7 4

HEATED OXYGEN SENSOR (HO2S}

Troubleshooting, pages 11-46, 47

FAST IDLEInspection, page 1 'l -94

11-4

Page 201 of 1413

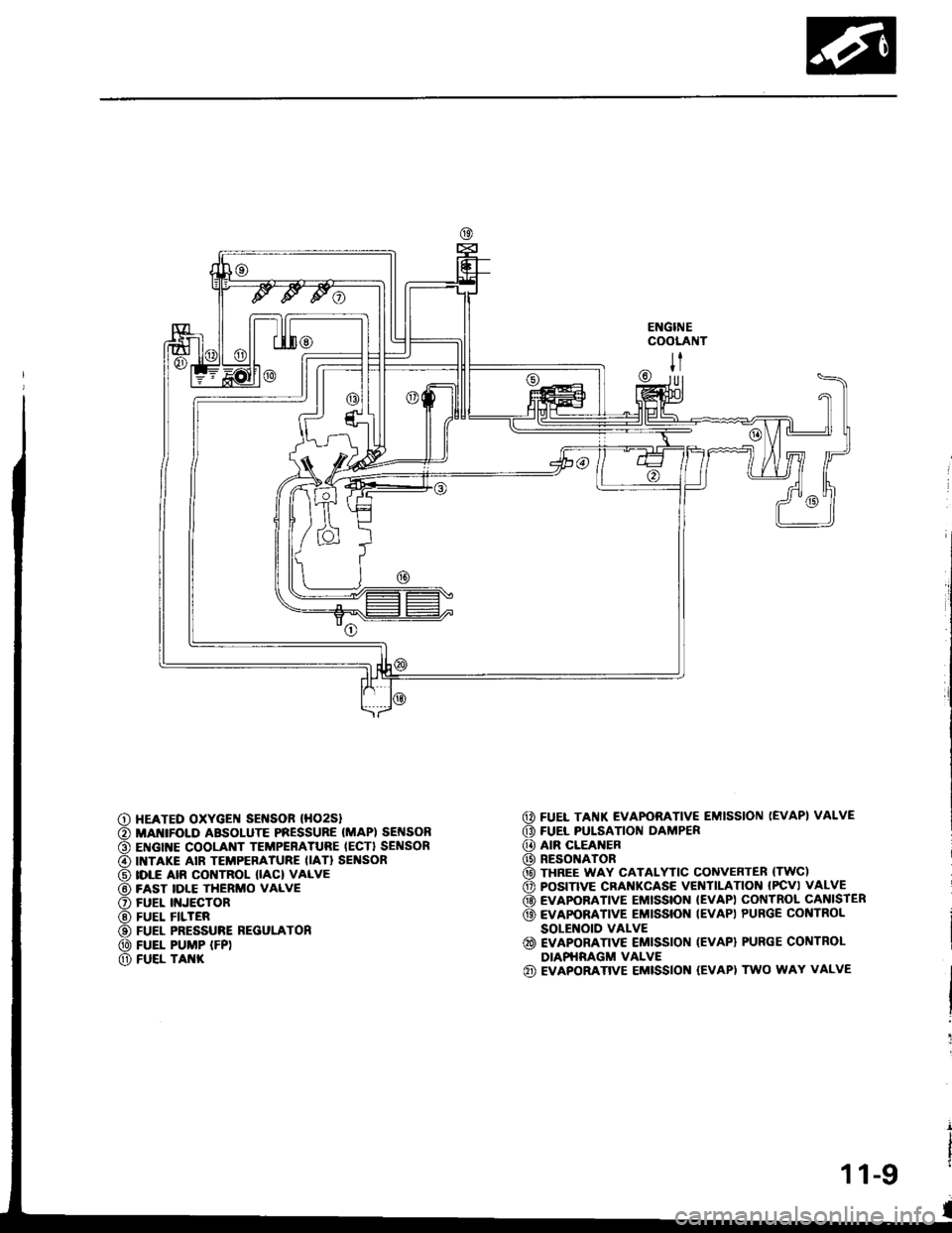

ENGINECOOLANT

@ FUEL TAI{K EVAPORATIVE EMISSION (EVAP} VALVE

G) FUEL PULSATION DAMPER

@ AIR CLEANER

@) RESONATOR

@ THREE WAY CATALYTIC CONVEnTER (TWC)

o POS|TIVE CRANKCASE VEITITILAT|ON IPCV) VALVE

@ EVAPOBATIVE EMISSION IEVAP) COI{TROL CANISIER

@ EvApoRATrvE EMrssroN IEVAP) PURGE coNTRoL

SOLENOID VALVE

@ EVAPORATTVE EMISSION (EVAP) PURGE CONTROL

DIAPHRAGM VALVE(iD EVAPORATIVE EMISSION (EVAPI TWO WAY VALVE

|l

U]

HEATED OXYGEI{ SEI{SOF (HO2S}

MANIFOI.D ABSOLUTE PRESSURE (MAP) SEI{SONENGINE COOLANT TEMPERATURE IECT} SENSORINTAKE AIR TEMPERATURE IIAT} SEI'ISORIDLE AIR CONTROL IIAC) VALVEFAST IDLE THERMO VALVEFUEL II{JECTORFUEL FILTERFUEL PRESSURE REGULATONFUEL PUMP IFP)FUEL TAI{K

11-9

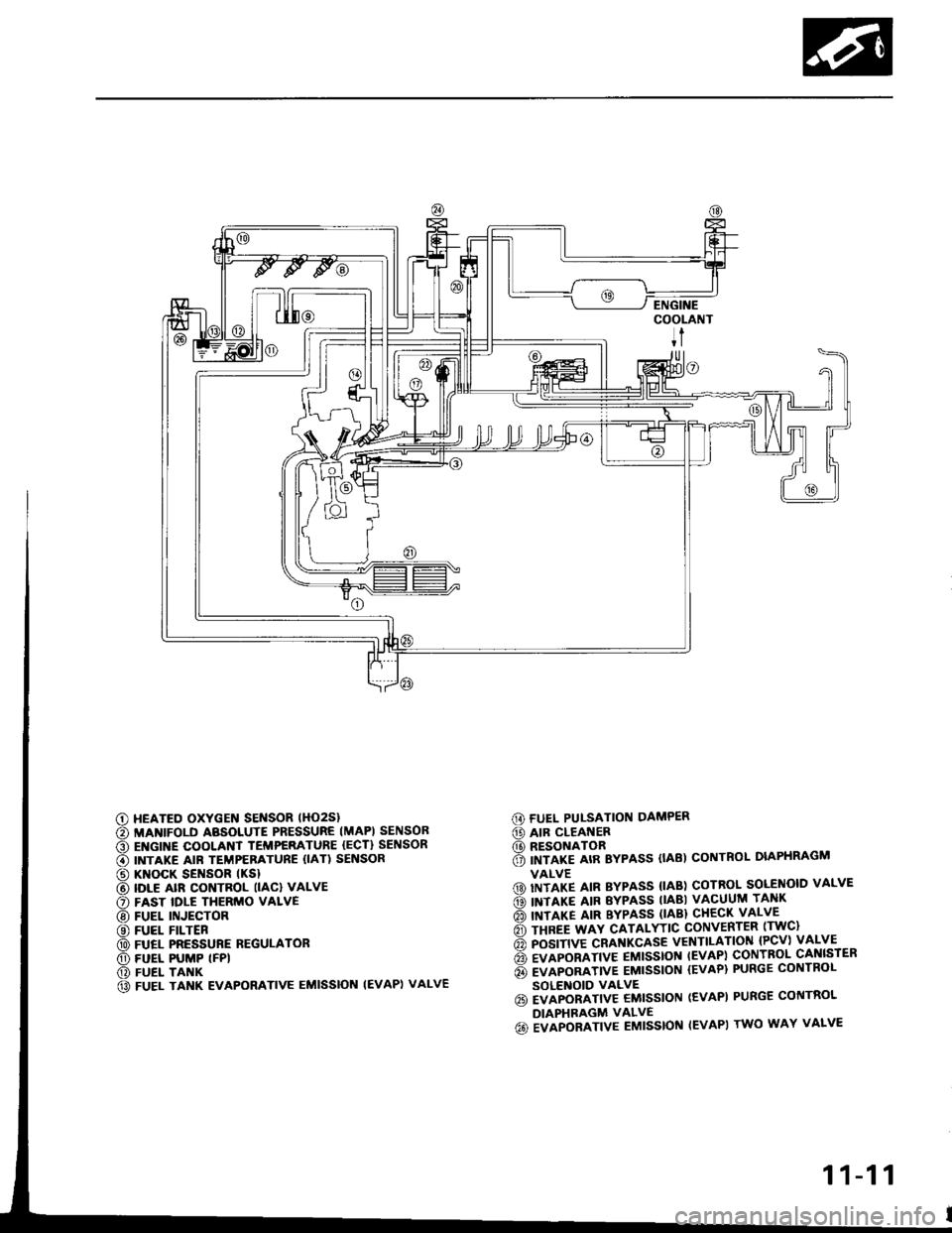

Page 203 of 1413

G) FUEL PUI-SATION DAMPER

@ AIR CLEANER(D RESONATOR6 imrlre arR Bypass (tAB) coNTRoL DIAPHRAGM

VALVE(D) IITITP IIN BYPASS {IAB) COTROL SOLENOID VALVE

ds) INTIXT AIR EYPASS TIABI VACUUM TANK

rio'l rnrarg ltn BYPASS (lABl cHEcK vALvE

6 rsnee wav cATALYTtc coNvERTER lrwc)

6 posrnve cRAf{KcAsE vENTILATIoN {Pcv) vALVE

6 evlponlrtve EMtsstot{ tEvAPl coNTBoL cANlsrER

6 evlponltvE EMtssloN {EvAP} PURGE coNTRoL

SOLENOID VALVE6i EVAPORATIV€ EMISSION (EVAPI PURGE CONTROL

DIAPHRAGM VALVE

6o ivlpoalrtve Eutsstof{ IEVAPI rwo wAY vALvE

c) HEATED OXYGEN SENSOR lHO2Sl

€) MANIFOLD ABSOLUTE PRESSURE IMAPI SENSOB

O EI{GINE COOLANT TEMPERATURE {ECT} SENSOR

€) INTAKE AIR TEMPERATURE {IAT) SENSOR

@ KNOCK SENSOR tKSl

@ IDLE alR coNTRoL llAcl vALvE

O FAST IDLE THERMO VALVE

@ FUEL INJECTOR

@ FUEL FILTER

@ FUEL PRESSURE REGULATOR

O) FUEL PUMP (FPI

@) FUEL TANK

@ FUEL TANK EVAPORATIVE EMISSION IEVAPI VALVE

11-11

Page 228 of 1413

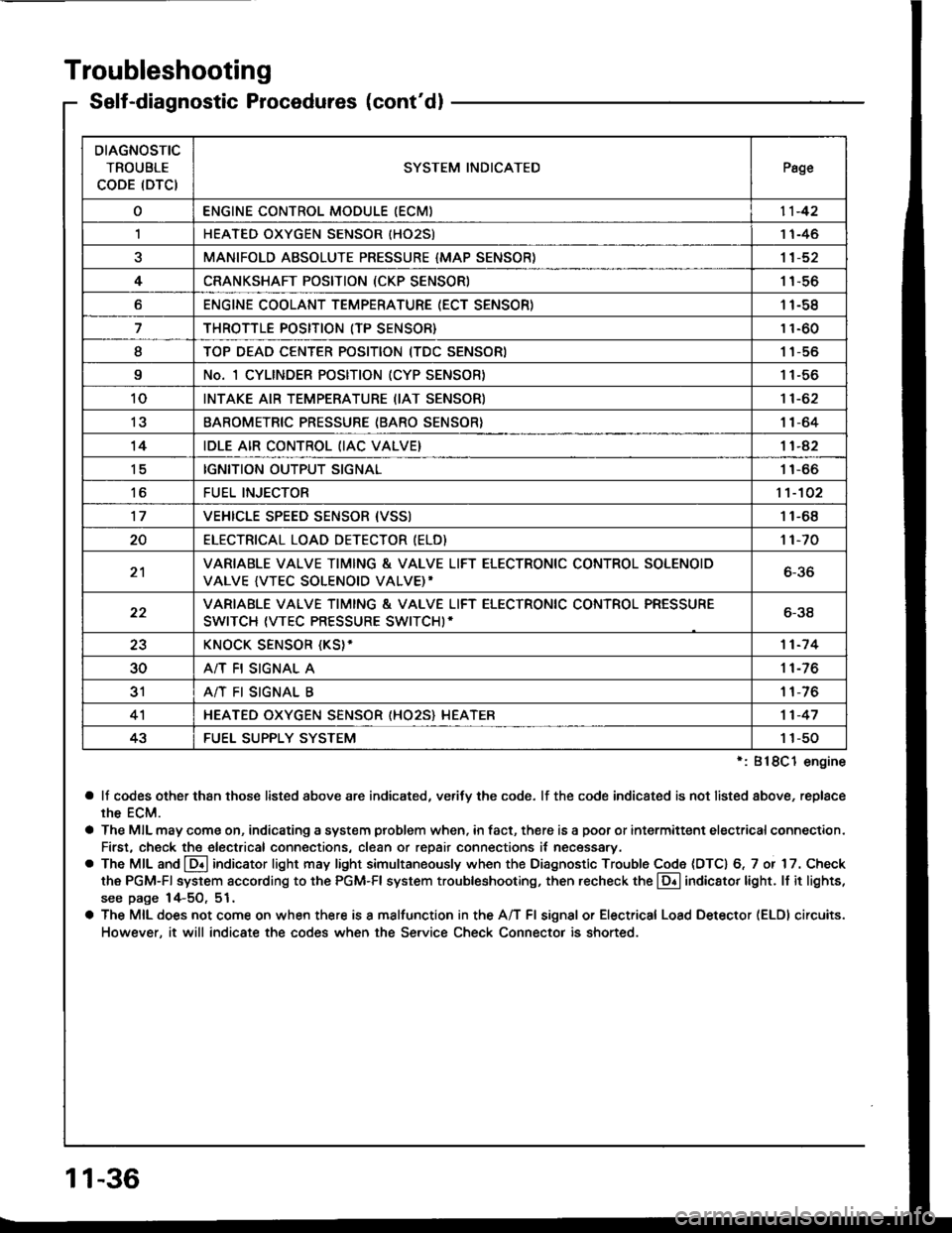

Troubleshooting

Self-diagnostic Procedures (cont'dl

':818C1 engine

a lf codes other than those listed above are indicated, verifv the code. lf the code indicated is not listed above, replace

rhe ECM.

a The MIL may come on, indicating a system problem when, in fact, there is a poor or intermittent electricalconnection.

First, check the electrical connections, clean or repair connections it necessary.

o The MIL and @ indicator light may light simultaneously when the Diagnostic Trouble Code (DTC) 6, 7 or 17. Check

the PGM-Fl system according to the PGM-Fl system troubleshooting, then recheck the l!! indicator light. ll it lights,

see page 14-5O, 51.

a The MIL does not come on when there is a malfunction in the A/T Fl signal or Electrical Load Detector (ELDI circuits.

However, it will indicate the codes when the Service Check Connector is shorted.

DIAGNOSTIC

TROUBLE

CODE (DTCISYSTEM INDICATEDPsge

oENGINE CONTROL MODULE IECM)11-42

,lHEATED OXYGEN SENSOR IHO25)1 1-46

aMANIFOLD ABSOLUTE PRESSURE {MAP SENSOR)11-52

4CRANKSHAFT POSITION (CKP SENSOR)1 1-56

oENGINE COOLANT TEMPERATURE (ECT SENSOR)11-58

THROTTLE POSITION (TP SENSOR}11-60

ITOP DEAD CENTER POSITION (TDC SENSORI1 1-56

9No. 1 CYLINDER POSITION (CYP SENSOR)1 1-56

10INTAKE AIR TEMPERATURE (IAT SENSOR)11-62

13BAROMETRIC PRESSURE (BARO SENSOR}1|-64

14IDLE AIR CONTROL (IAC VALVE}11-42

tcIGNITION OUTPUT SIGNAL11-66

toFUEL INJECTOR1't-102

17VEHICLE SPEED SENSOR {VSSI11-68

20ELECTRICAT LOAD DETECTOR (ELD)'t 1-70

21VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL SOLENOID

VALVE {VTEC SOLENOID VALVE)'6-36

22VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL PRESSURE

SWITCH (VTEC PRESSURE SWITCHI-6-38

23KNOCK SENSOR {KS}-11-7 4

30A/T FI SIGNAL A11-76

3'rA/T FI SIGNAL B1 1-76

4'lHEATED OXYGEN SENSOR (HO25} HEATER11-47

43FUEL SUPPLY SYSTEM1 1-50

11-36

Page 232 of 1413

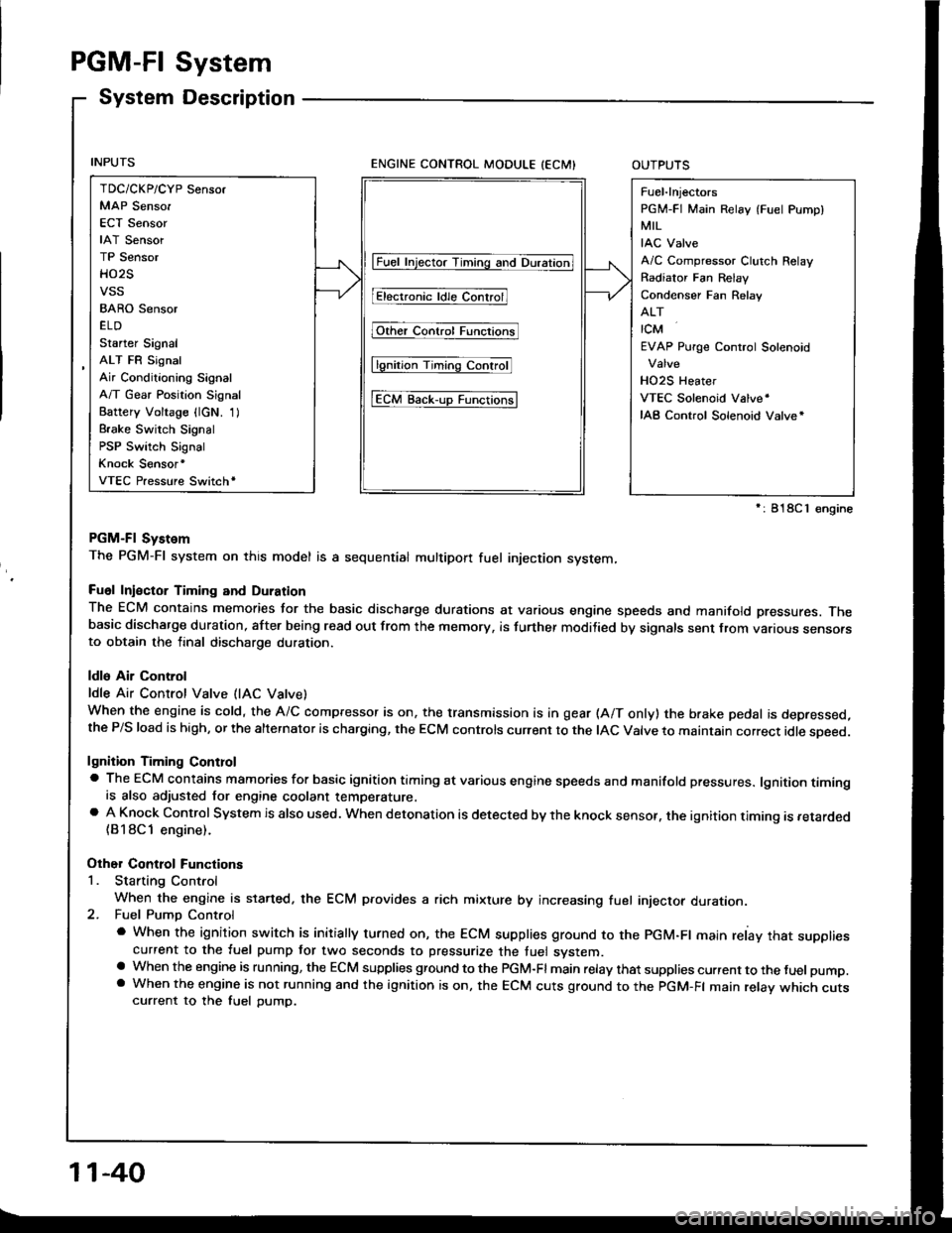

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECMIOUTPUTS

PGM-Fl System

The PGM-Fl system on this model is a sequential multipon fuel injection system,

Fuol Iniector Timing and Duration

The ECM contains memories tor the basic discharge durations at various engine speeds and manifold pressures. Thebasic discharge duration, after being read out from the memory, is turther modilied by signals sent from vanous sensofsto obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Vatve)

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) the brake pedal is depressed,the P/S load is high, or the alternalor is charging, the ECM controls current to the IAC Valve to maintain correct idle soeed.

lgnition Timing Controla The ECM contains mamories for basic ignition timing at various engine speeds and manifold pressures. lgnition timingis also adjusted for engine coolant temperature.a A Knock Control System is also used. when detonation is detected by the knock sensof. the ignition timing is retarded(B18Cl engine).

Other Control Functions

1. Starting Control

When the engine is started. the ECM provides a rich mixture by increasing fuel injector duration.2. Fuel Pump Control

a When the ignition switch is initially turned on, the ECM supplies ground to the PGM-Fl main relay that suppliescurrent to the fuel pump tor two seconds to pressurize the tuel system.a When the engine is running, the ECM supplies gfound to the PGM-Fl main relay that supplies current to the fuel pump.a When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relav which cutscurrent to the fuel pump.

TDC/CKP/CYP Sensor

MAP Senso.

ECT Sensor

IAT Sensor

TP Sensor

HO2S

vss

BARO Sensor

ELD

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Signal

Battery Voltage {lcN. 1)

Brake Switch Signal

PSP Switch Signal

Knock Sensor'

VTEC Pressure Switchr

Fuel-lnjectors

PGM-FI Main Relay (Fuel Pump)

MIL

IAC Valve

A/C Compressor Clutch Relay

Radiator Fan Relav

Condenser Fan Relav

ALT

rcM

EVAP Purge Control Solenoid

HO2S Heater

VTEC Solenoid Valve'

IAB Control Solenoid Valve*

lFuet tnjector Timing and Duration]

I Electr..l"ldle Contr;il

Fit'e' contr; Funcrfit

l6tio; Ttntrlg c..trol

tEcM aack-,rp Functiorlsl

': 818C 1 €ngine

11-40

Page 249 of 1413

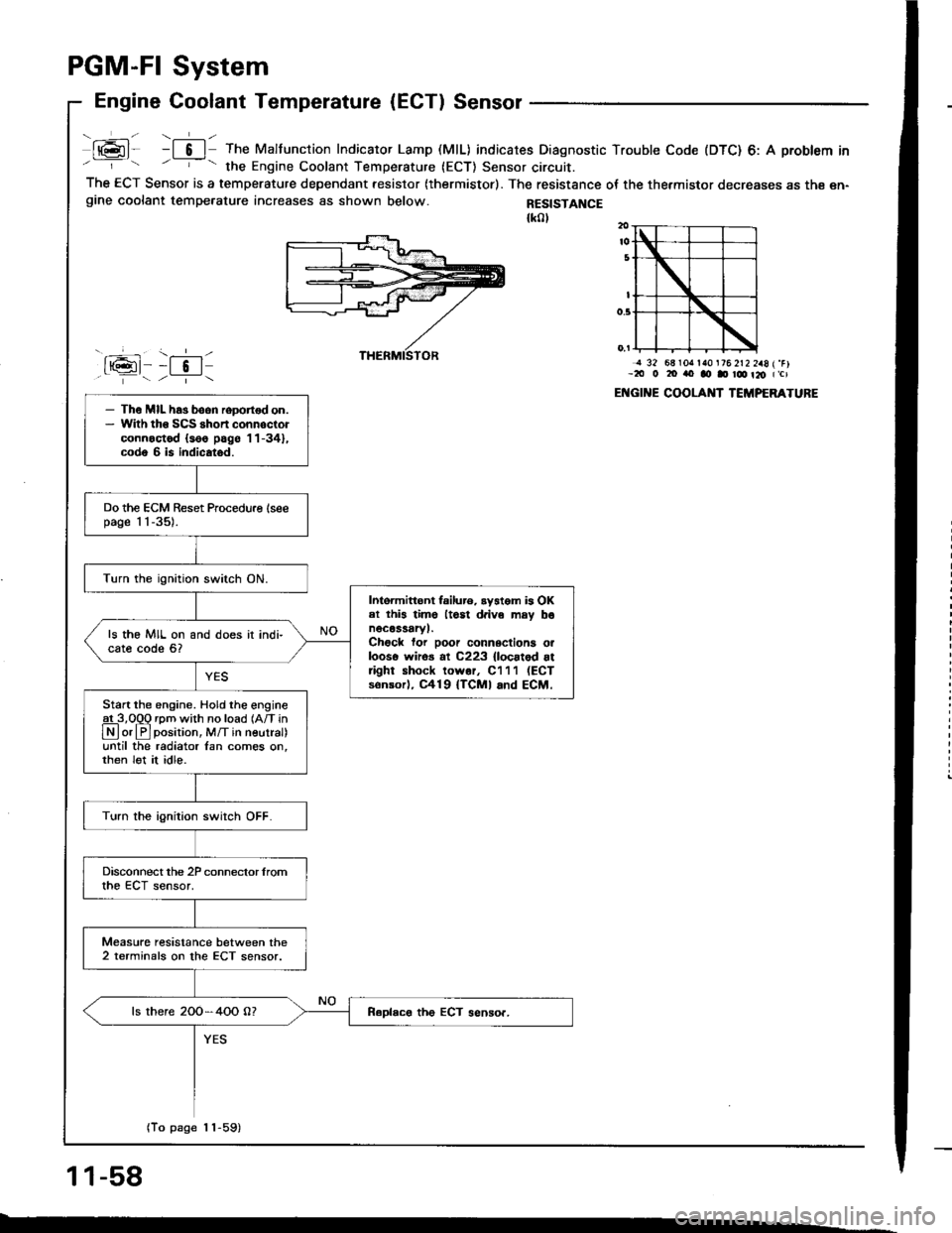

PGM-FI System

Engine Coolant Temperature (ECT) Sensor

- ,-!-- ---1- -

t@l- -l 6 | The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 6: A problem in- - the Engine Coolant Temperature (ECT) Sensor circuit.The ECT Sensor is a temperature dependant resistor (thermistor). The resistance oI the thermistor decreases as th€ en-gine coolant tempe.ature increases as shown below.

J rsG-11

RESISTANCE{k0l

- \.--r-l--t 5 | /--i- \

j 32 68lOrr la0 t76 2t2 2a8 (.Fl-2tt 0 20 rto ao D r@ t20 (,cl

ENGII{E COOLAI{T TCMPERATURE- Th€ MIL has boon roDortod on.- Wlth tho SCS shon connoctorconnoctod {s66 pag6 '11-34},

code 6 is indicatod.

Do the ECM Reset Procedu.e lseepage 1 1-35).

Turn the ignition switch ON.

Intoimittont failur6. ryatom is OKel this lime ltosl d.ive may bonocassaryl.Chock for poor connsctiona orlooso wiros al C223 {locatod attight shock lowor, C111 (ECT

sonsorl, C419 {TCMI and ECM.

ls the MIL on and does it indi-cate code 6?

Start the engine. Hold the engineat 3,O0O rom with no load {Afi in

N or lF]position, M/T in neutral)until the radiator lan comes on,then lot it idle.

Turn the ignition swirch OFF.

Disconnect the 2P conneclor lromthe ECT sensor.

Measure resistance between the2 terminals on the ECT sensor.

ls there 2OO-4OO O?

(To page 1 1-59)

11-58

--