driveshaft HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 31 of 1413

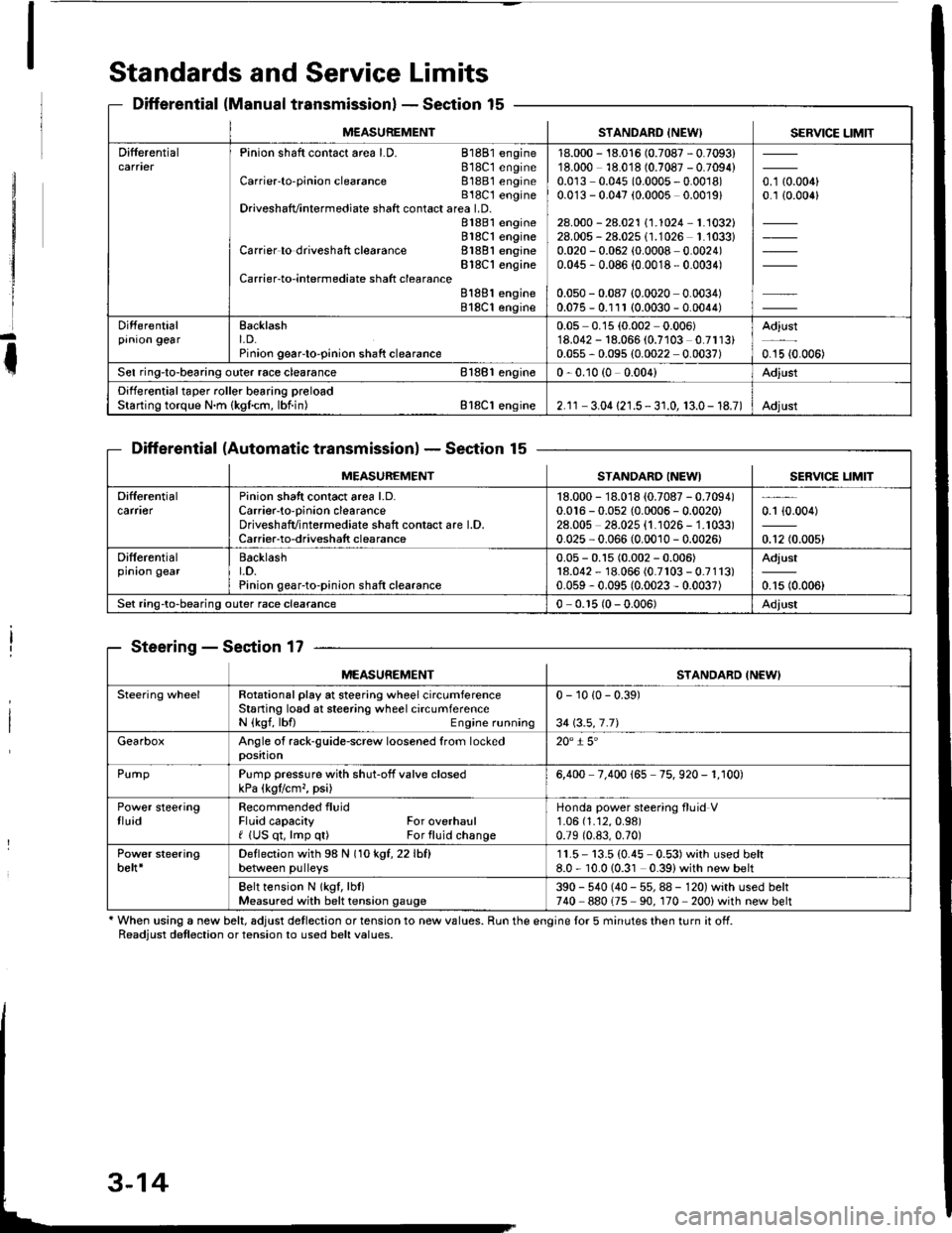

Standards and Service Limits

Differential (Manual transmissionlSection 15

Differential (Automatic transmissionlSection 15

Steering - Section 17

' When using a new belt, adjust detlection or tension to new values. Run the engine lor 5 minutes then turn it off.Readiust detlection or tension to used belt values.

M€ASUREMENTSTANDARD INEW) SERVICE LIMIT

DifferentialPinion shaft contact area LD. 81881 engine818C1 engineCarrier'to-pinion clearance 81881 engineB18C t engineDriveshafvintermediate shaft contact area LD.81881 engine818C1 engineCarrier to driveshaft clearance 81881 engineBlSC'l engineCarrier-to-intermediate shatt clearanceB188l engine818C1 engine

18.000 - 18.016 (0.7087 - 0.7093)18.000 18.018 (0.7087 - 0.7094)0.0r3 0.045 (0.0005 - 0.0018)0.0'13 - 0.047 (0.0005 0.0019)

28.000 - 28.021 \1.1024-1.1032128.005 - 28.025 (1.1026 1.'1033)0.020 - 0.062 (0.0008 0.0024)0.045 , 0.086 {0.0018 - 0.0034)

0.050 - 0.087 (0.0020 0.0034)0.075 - 0.111 (0.0030 - 0.0044)

o. t aron,0.1 {0.006}

Differentialprnron gearEacklasht. D.Pinion geaFto-pinion shaft clearance

0.05 0.15 (0.002 0.006)'18.042 - 18.066 (0.7103 0.7113)0.055 - 0.095 (0.0022 0.0037)

Adjust

0.15 {0.006)

Sel ring-to-bearing outer race clearance 81881 engin€0 - 0.10 (0 0.004)Adjust

Differential taper roller bearing preloadStarting torque N.m {kgfcm, lbf.in) Bl8Cl engine2.1r - 3.04 {21.5 - 3 r.0, 13.0- 18.7)Adjust

MEASUREMENTSTANDARO INEWISERVICE LIM]T

Difterentialcarfl€rPinion shatt contact area l.D.Carrier-to-oinion clearanceDriveshafvintermediate shaft contact are l.D.Carrier-to-driveshatt clearance

18.000 - 18.018 {0.7087 - 0.7094)0.016 - 0.052 {0.0006 - 0.0020)28.00s 28.025 {1.1026 - 1.1033)0.025 - 0.066 (0.0010 - 0.0026)

0.1 {0.004)

0.12 (0.005)

Differentialprnron gearBacklasht.D.Pinion gear-to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.042 - 18.066 (0.7r03 - 0.7113)0.059 - 0.095 (0.0023 - 0.0037)

Adjust

0.15 (0.006)

Set ring-to-bearing outer race clearance0 - 0.r5 (0 - 0.006)Adjust

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning losd at steering wheel circumferenceN {kgf, lbfl Engine running

0 - 10 {0 - 0.39)

34 \3.5,7.71

GearboxAngle of rack-guide-screw loosened from lockedposition20" i 5'

PurnpPump pressure with shut-off valve closedkPa (kgtlcm,, psi)6,400 7.400 165 75. 920 - 1. r00)

Power steeringtluidRecommended fluidFluid capacity For overhaulf (US qt, lmp q0 For fluid change

Honda power steering fluid V1.06 (1.12,0.98)

0.79 (0.83,0.70)

Power steeringbelt*Deflection with 98 N (1okgt,22lhfl

between pulleys11.5- 13.5 (0.45 0.53)with used belt8.0 - 10.010.31 0.39)with new belt

Belt tension N lkgf, lbl)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 880175 90. 170 200) with new belt

Page 54 of 1413

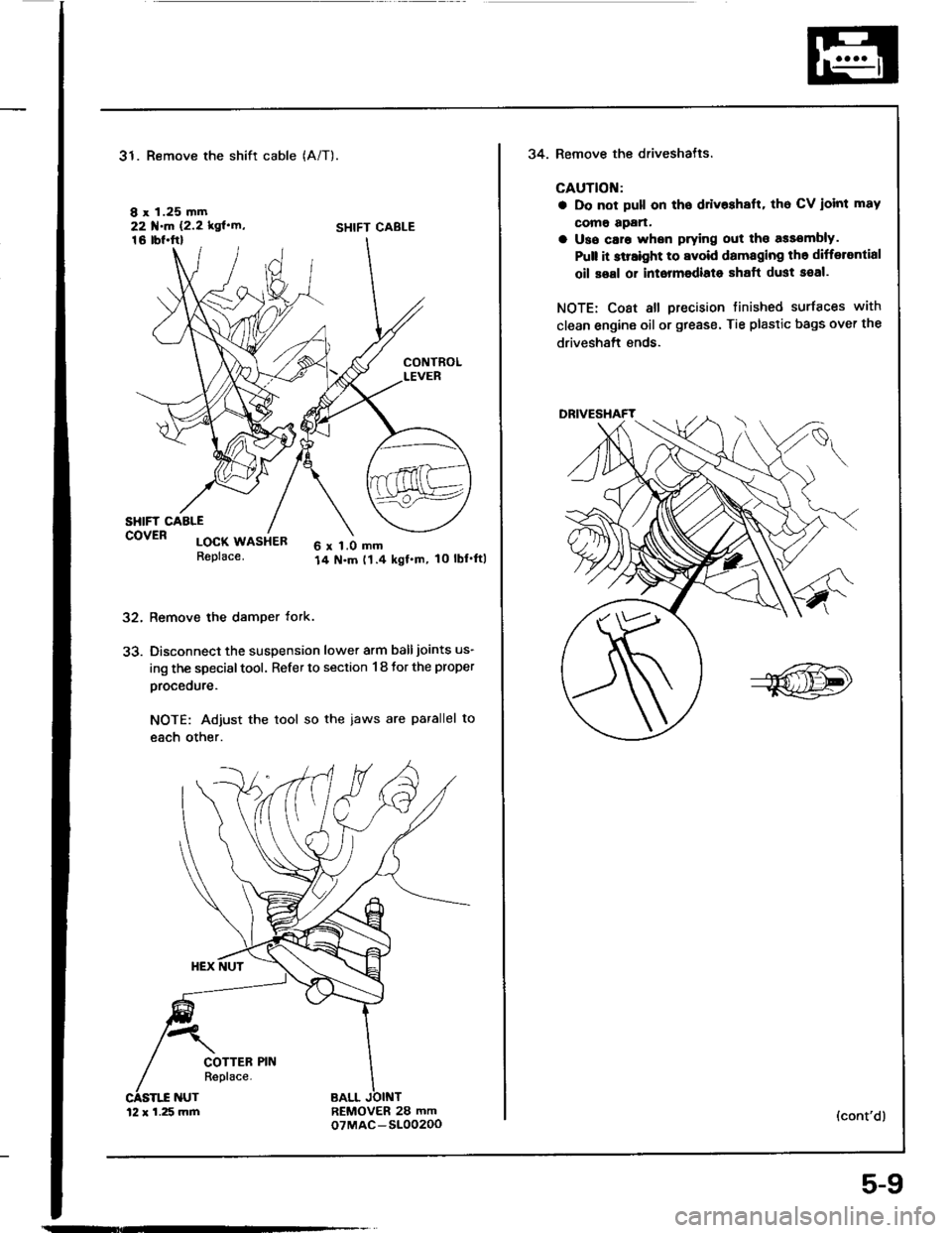

31. Remove the shift cable

I x 1.25 mm22 f.m 12.2 kgl'rn'16 tbl.ftl

(A/T).

SHIFT CABLE

32.

33.

CONTROLLEVER

SHIFT CAALEcovER locx usiea6 x 1.0 mm14 N.m t1.4 kgf.m, 10 lbl'ftlReplace.

Remove the damper tork.

Disconnect the suspension lower arm balljoints us-

ing the special tool. Refer to section 1 8 tor the proper

procedure.

NOTE: Adjust the tool so the iaws are parallel to

each other.

REMOVER 28 mmoTMAC-S10020012 x 1.25 mm

5-9

34. Remove the driveshatls.

CAUTION:

a Do not pull on tho ddv$halt, tho CV ioint mav

como apan.

a Uso caro whsn prying out tho assombly.

Pult it slraight to avoid damaging th6 differantial

oil soal or intormodiato shaft dust seal.

NOTE: Coat all precision tinished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends.

(cont'd)

Page 60 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Insrall the left front mount, then tighten the bolts in

the numbered sequence as shown (O-@),

O 12 x 1.25 ]n]n83 N.m 18.5 kst.m,61 lbt.ftlReplace.

@ 12 r 1.25 mm59 N.m {6.0 kgl.n,43 tb{.ftlReplace.

@ HONDA INTEGRA 1994 4.G Workshop Manual Insrall the left front mount, then tighten the bolts in

the numbered sequence as shown (O-@),

O 12 x 1.25 ]n]n83 N.m 18.5 kst.m,61 lbt.ftlReplace.

@ 12 r 1.25 mm59 N.m {6.0 kgl.n,43 tb{.ftlReplace.

@](/img/13/6067/w960_6067-59.png)

Insrall the left front mount, then tighten the bolts in

the numbered sequence as shown (O-@),

O 12 x 1.25 ]n]n83 N.m 18.5 kst.m,61 lbt.ftlReplace.

@ 12 r 1.25 mm59 N.m {6.0 kgl.n,43 tb{.ftlReplace.

@ 10 r 1.25 mm44 N.m (4.5 kgf.m, 33 lbt.ftl

k-

5-15

a Check that the sp.ing clip on the end of each

driveshaft clicks into place.

GAUTION: Uso oow spring clips.

a Bleed air trom the cooling system at the bleed bolt

with the heater valve open (see page 10-5).

a Adjust the th.ottle cable (see section 1 1).

a Check the clutch pedal tree play lsee section 12).

a Check that the transmission shifts into gear

smoothlv,

a Adiust the tension of the following drive belts.

Alternator belt {s€e section 23).

P/S pump belt {see section 17).

A/C comoressor belt (see section 22).

a Inspect tor fuel leakage (see section 1 1).

. After assembling fuel line parts, turn on the ig-

nition switch (do not operate th€ starter) so

that the Juel pump operates for approximat€-

lV two seconds and the tuel line pressurizes.

Repeat this operation two or three times and

check for fuel leakage at any point in the fuel

line.

(cont'd)

Page 330 of 1413

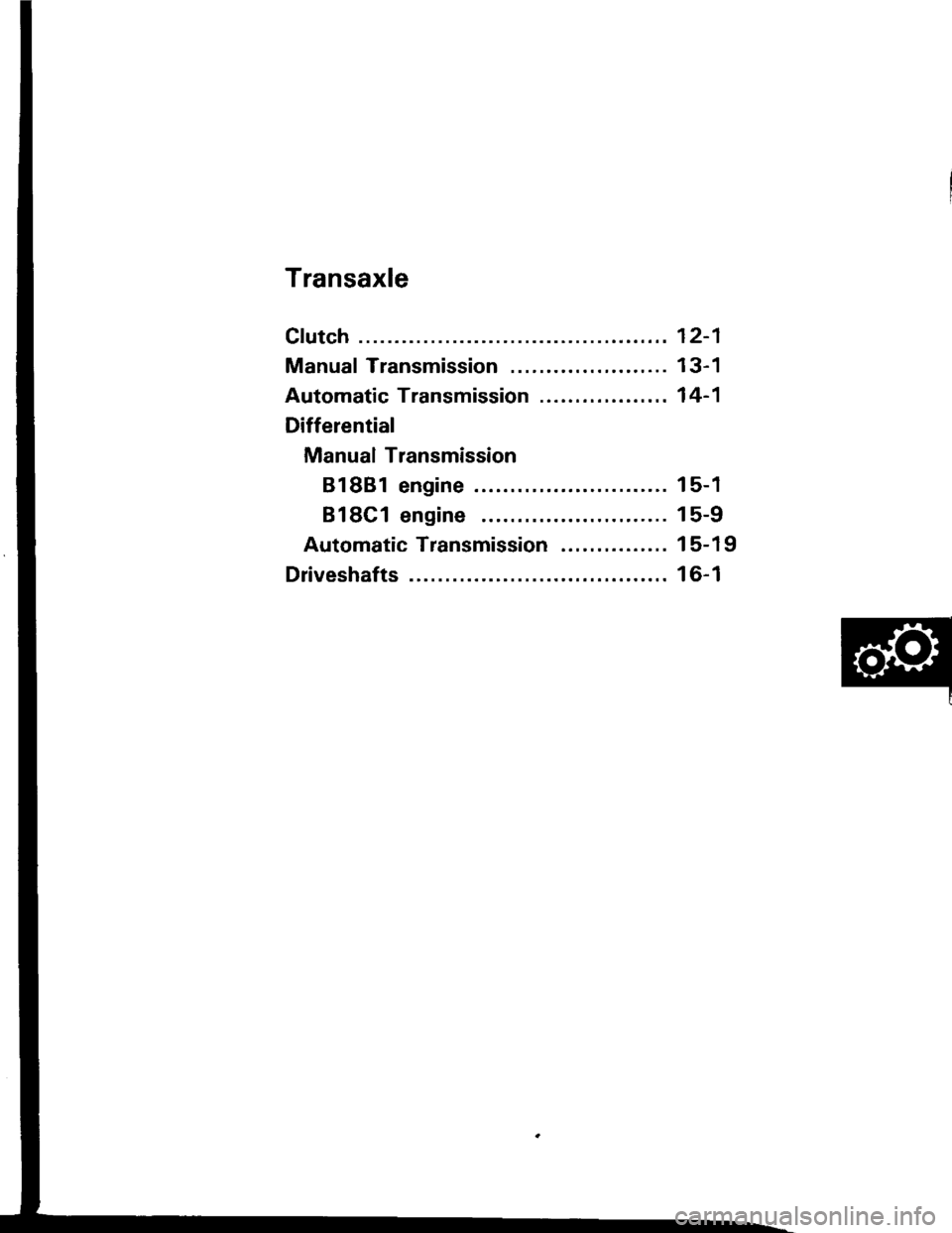

Transaxle

Clutch

Manual Transmission ......................

Automatic Transmission ..................

Differential

Manual Transmission

81881 engine

818C1 engine

Automatic Transmission ...............

Driveshafts

12-1

13-1

14-1

15-1

15-9

15-19

16-1

Page 390 of 1413

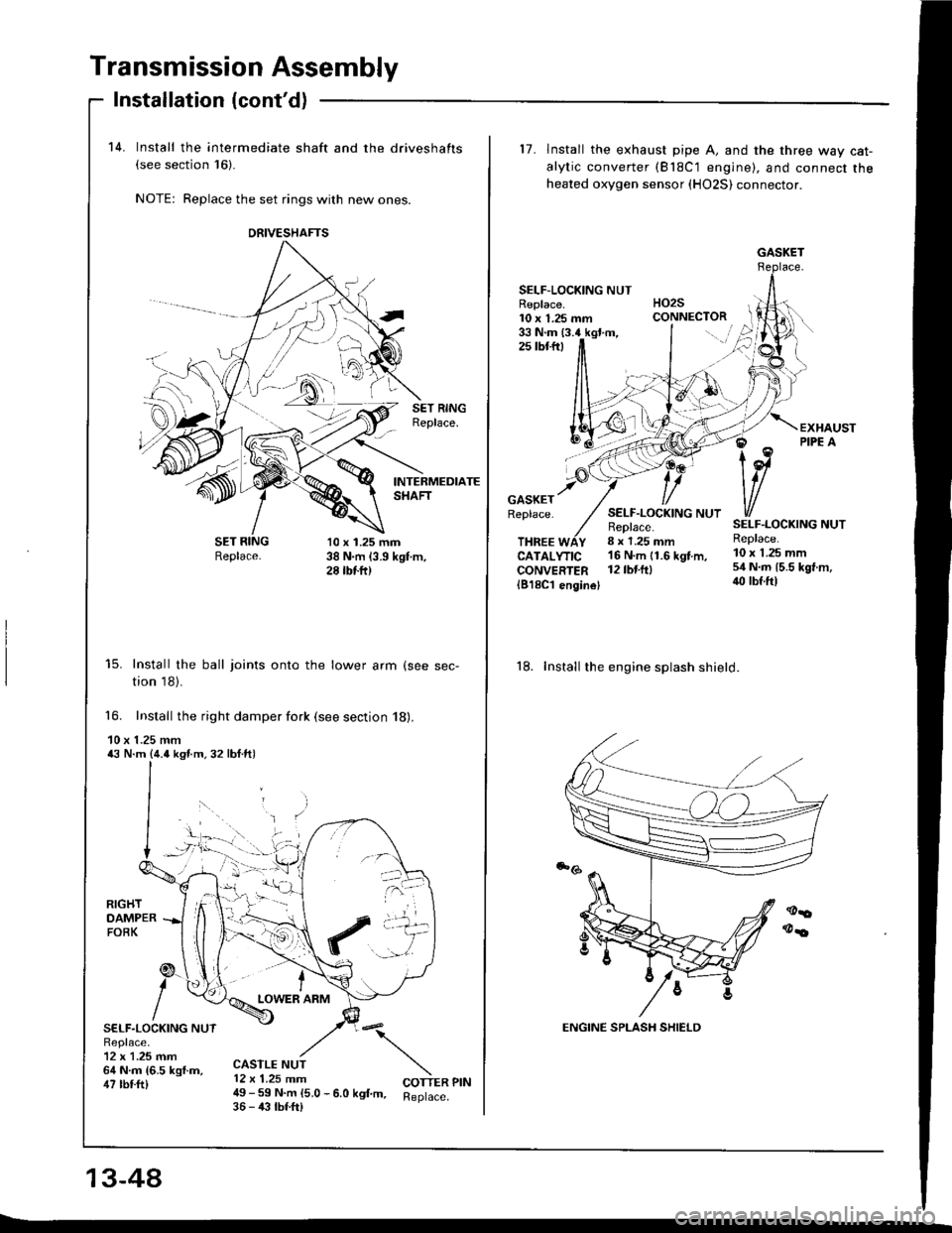

Transmission Assembly

14. Install the intermediate shaft and the driveshafts(see section 16)-

NOTE: Replace the set rings with new ones.

Installation (cont'd)

-Sl

SET RINGReplace.

INTERMEDIATESHAFT

Replace.10 x 1.25 mm38 N.m (3.9 kgt m,28 tbtft)

15. Install the ball joints onto the lower arm (see sec-

tion 18).

16. Install the right damper fork (see section 18).

10 x 1.25 mm43 N.m {4.o ksf.m.32 lbf.ft)

RIGHTDAMPERFOBK

SELF.LOCKING NUTReplace.12 x 1.25 mm64 N.m {6.5 kgf.m,47 tbtft)

tLOWER ARM

:\

COTTER PIN

CASTLE NUT12 x 1.25 mm49 - 59 N.m 15.0 - 6.0 kgf m. Reptace.36 - 43 tbf.frl

13-44

DNIVESHAFTS

::.t

L

17. lnstall the exhaust pipe A, and the three way cat-

alytic converter (Bl8C'1 engine), and connect theheated oxygen sensor (HO2S) connector.

SELF-LOCKING NUTHO2SCONNECTORReplace.10 x 1.25 mm33 N.m (3.4 kgt.m,2s tbtftt

GASKETReplace.SELF.LOCKING NUTReplace.8 x 1.25 mm

SELF.LOCKING NUTReplace.THREE WAYCATALYTICCONVERTER1818C'l enginel

16 N'm 11.6 kgt m, 10 x 1 25 mm

l2tbt.ftl 54 N.m 15.5 kgt m,iro lbf.ftl

18. Install the engine splash shield.

GASKET

Page 493 of 1413

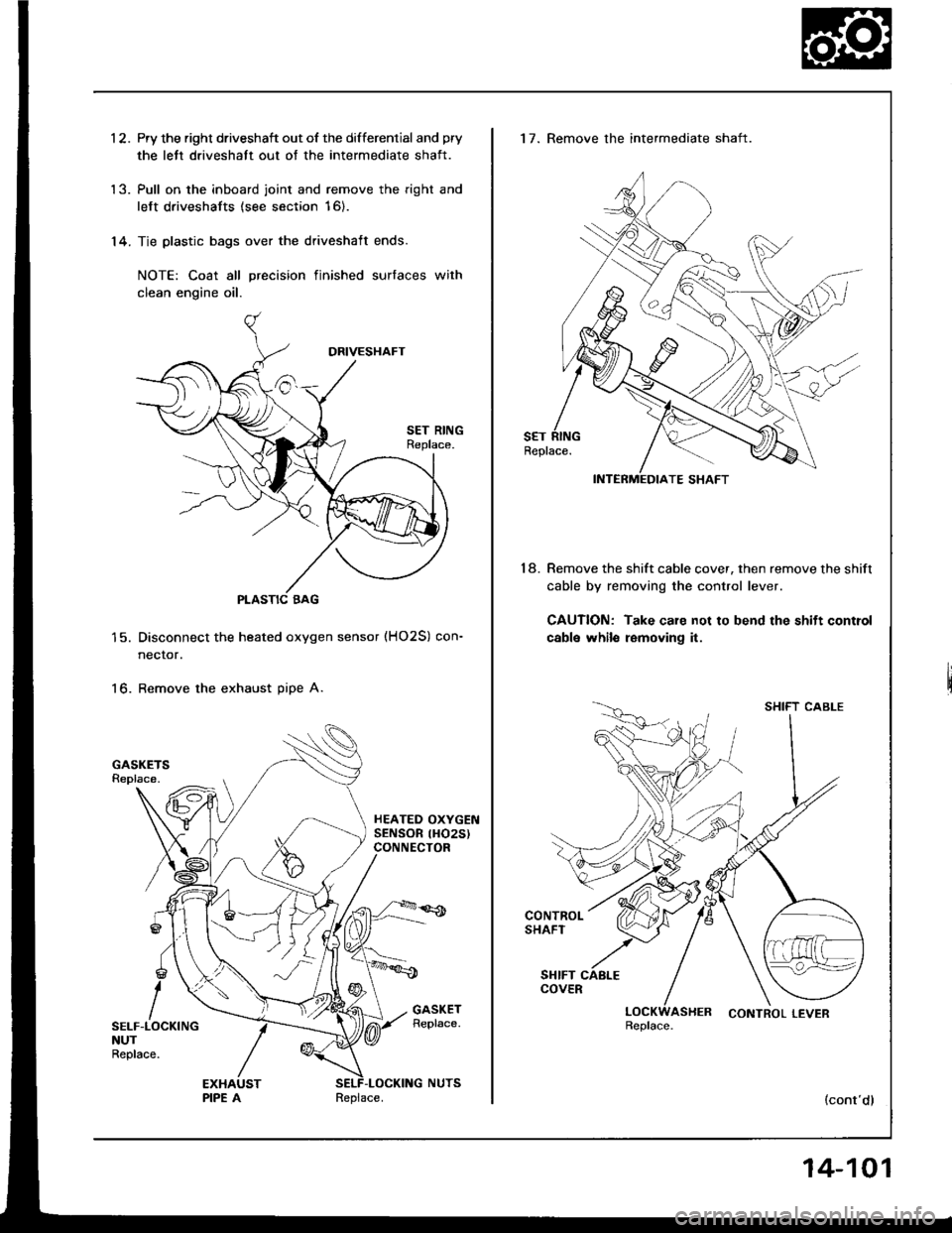

1 2. Pry the right driveshaft out of the differential and pry

the lett driveshatt out of the intermediate shaft.

'13. Pull on the inboard joint and remove the right and

left driveshafts (see section 16).

'14. Tie plastic bags over the driveshaft ends.

NOTE: Coat all precision finished surfaces with

clean engine oil.

PLASTIC BAG

Disconnect the heated oxygen sensor (HO2S) con-

necror.

Remove the exhaust pipe A.16.

SELF-LOCKINGNUTReplace.

Replace.

14-101

17. Remove the intermediate shaft.

Remove the shift cable cover, then remove the shift

cable by removing the control lever.

CAUTION: Take care not to bend the shift control

cabls whilo removing it.

18.

SHIFT CABLE

LOCKWASHER CONTROLLEVERReplace.

(cont'dl

Page 556 of 1413

Transmission

Installation {cont'd)

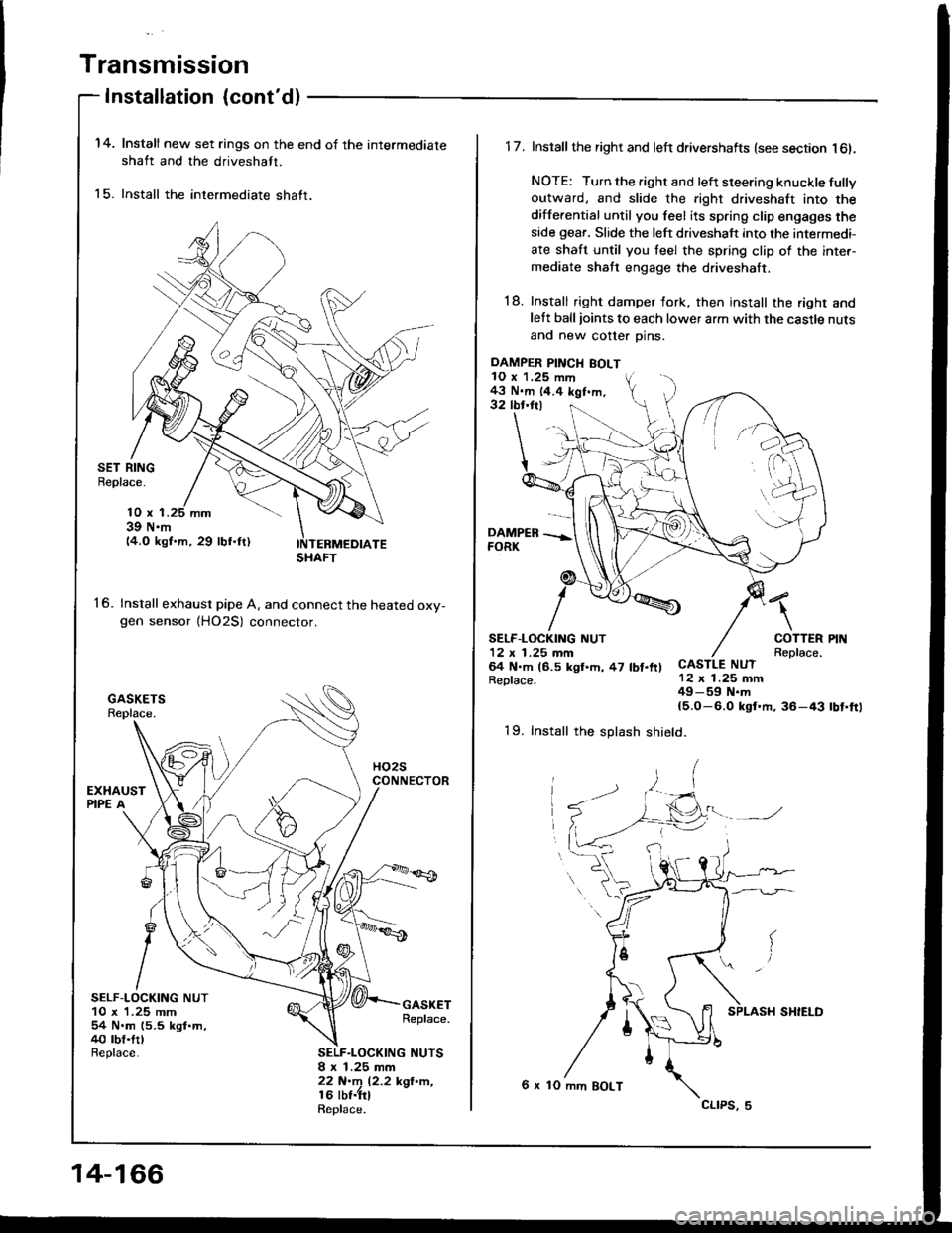

14.

15.

Install new set rings on the end of the intermediate

shaft and the driveshaft.

Install the intermediate shaft.

SET RINGBeplace.

16.

10 x 139 N.m14.O kgf.m, 29 lbf.ftl

Install exhaust pipe A. and connect the heated oxv-gen sensor {HO2S) connector.

SELF-LOCKING NUT10 x 1.25 mm54 N.m (5.5 kgl.m,40 rbt.trlReplace.

GASKETReplace.

SELF.LOCKING NUTSI x 1.25 mm22 N.m 12.2 kgl'n,16 lbt.trlRepl6ce.

SHAFT

14-166

DAMPER PINCH BOLT10 x 1.25 mm43 N.m 14.4 kgf.m,32 tbr.ftl

1 7. Install the right and left drivershafts (see section l6l.

NOTE: Turn the right and left steering knuckle fullyoutward, and slide the right driveshaft into the

differential until you feel its spring clip engages theside geaf. Slide the left driveshaft into the intermedi-

ate shaft until you teel the spring clip of the inter-mediate shaft engage the driveshaft.

18. Install right damper fork, then install the right andlett balljoints to each lower arm with the castle nuts

and new cotter Dins.

\

COTTERReplace.CASTLE NUT12 x 1.25 mm49-59 N.m{5.O-6.0 ksf.m, 36-43

SELF.LOCKING NUT12 x 1 .25 mm64 N.m (6.5 kgl.h, 47 lbt.ftlReplace.

rbt'ft1

19. Install the splash shield.

6 x 10 mm BOLT

cltPs, 5

Page 595 of 1413

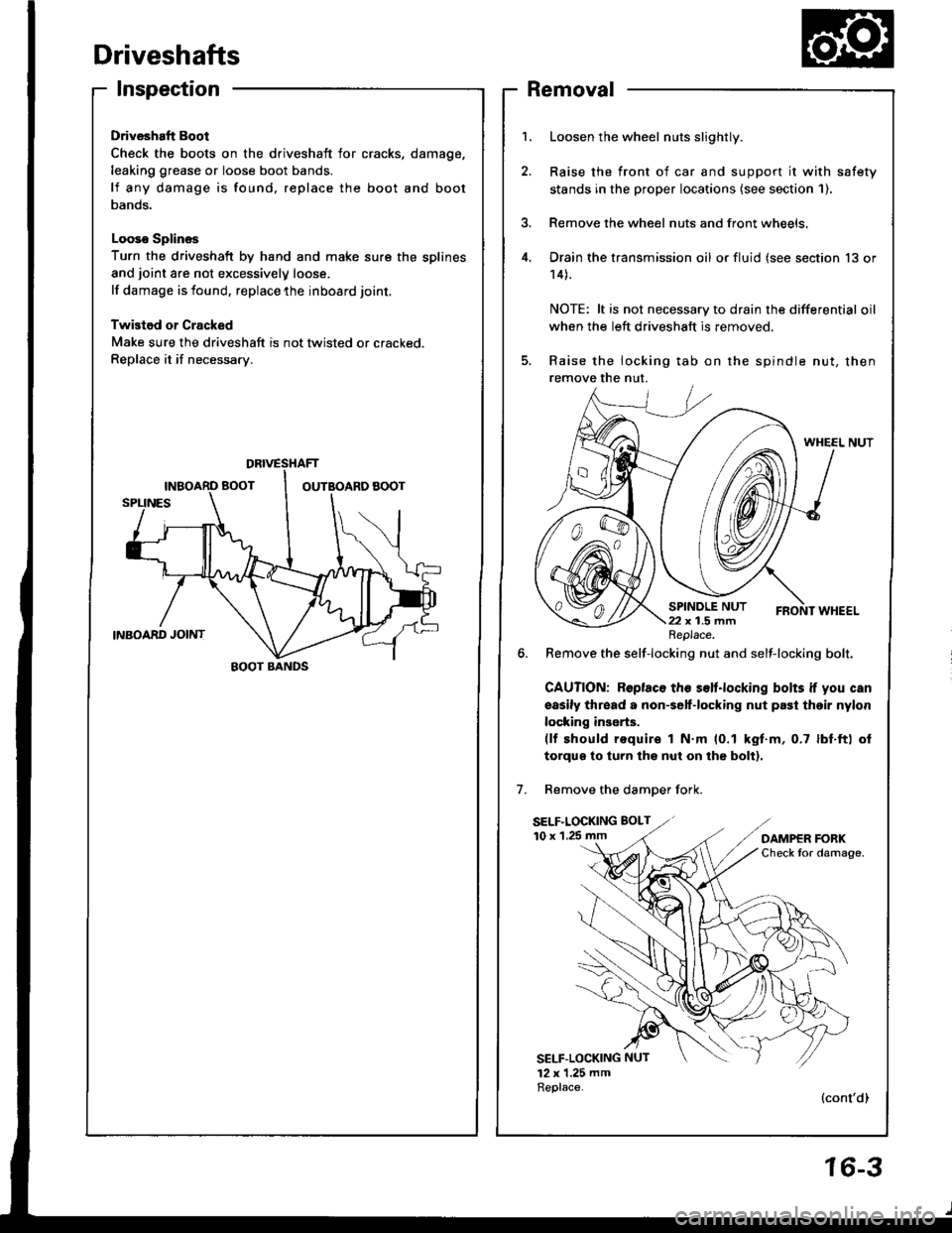

Driveshafts

Inspection

Driveshaft Boot

Check the boots on the driveshaft for cracks,

leaking grease or loose boot bands.

lf any damage is found, replace the boot

Danos.

Looso Splines

Turn the driveshaft by hand and make sure the splines

and joint are not excessivelV loose.

lf damage is found, replace the inboard joint,

Twistod or Cracked

Make sure the driveshaft is not twisted or cracked.

Replace it if necessarv.

damage,

and boot

Removal

Loosen the wheel nuts slightly.

Raise the front of car and support it with safety

stands in the proper locataons (see section 1),

Remove the wheel nuts and front wheels,

Drain the transmission oil or fluid (see section 13 or

14).

NOTE: lt is not necessary to drain the differential oil

when the left driveshaft is removed.

Raise the locking tab on the spindle nut, then

remove the nut.

WHEEL NUT

6. Remove the self-locking nut and self-locking bolt.

GAUTION: Roplaco th€ s€lt.locking bolts if you can

sasily thread a non€elf-locking nut prst thoir nylon

locking inserts.(lf should require I N.m (0.1 kgt.m, 0.7 lbf.ft) ol

torqus to turn lhs nut on the bolt).

Remove the damDer fork.

SELF.LOCKING BOLT

10 x 1.25 mm

SELF-LOCKING NUT

12 x 1.25 mmReplace.(cont'dl

DBIVESTIAFT

EOOT BANDS

Replace.

16-3

Page 596 of 1413

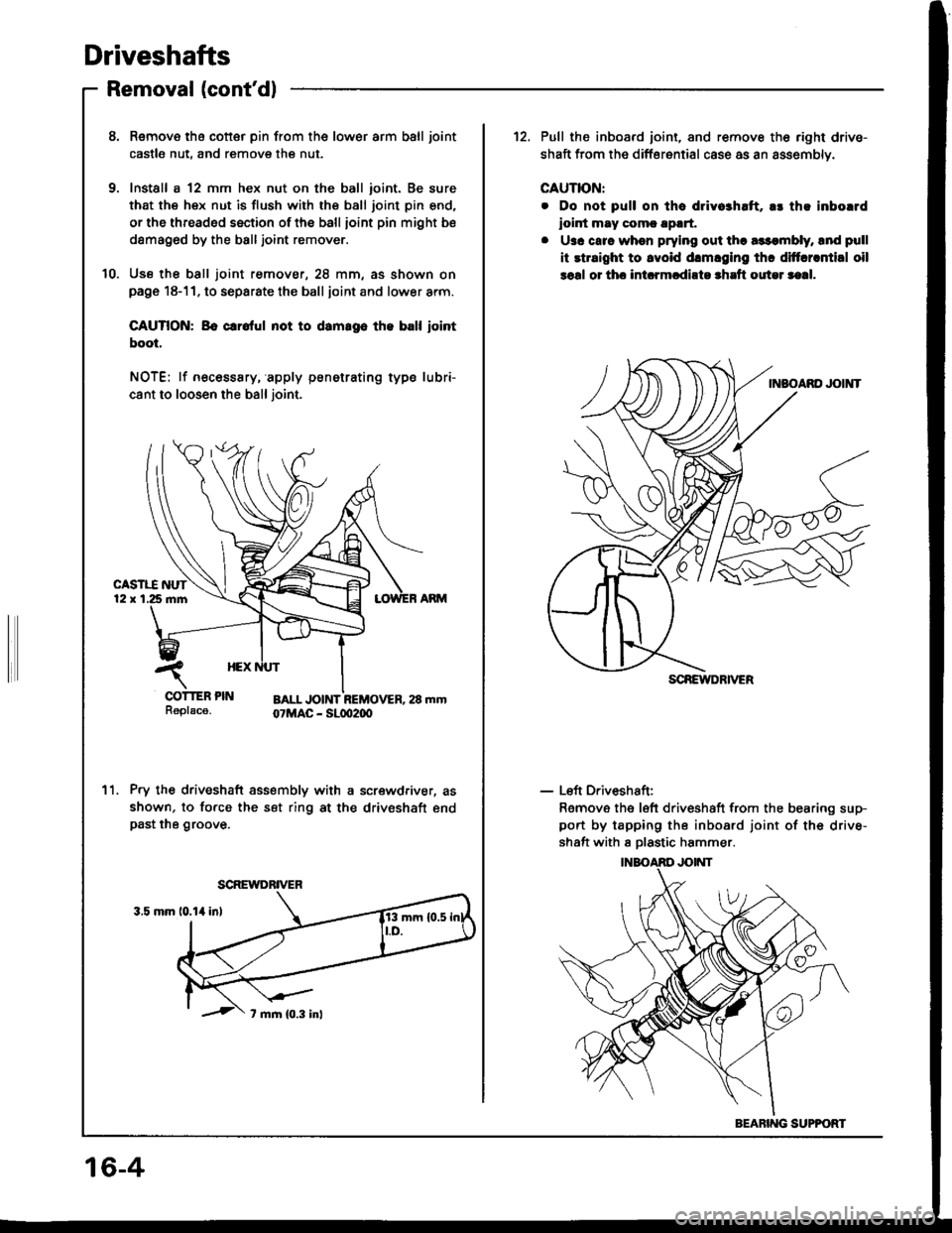

Driveshafts

Removal (cont'dl

8. Remove tha cotter pin from the lower arm ball joint

castle nut, and remove the nut.

9. Install a 12 mm hex nut on the ball ioint. Be sure

that the hex nut is flush with the ball joint pin end,

or the threaded section of the ball ioint pin might be

damag6d by the balljoint remover.

10. Use th€ ball joint remover, 28 mm, as shown onpage 18-11. to separate the ball joint and lower arm.

CAUTION: Bo crrolul not to damrgo th. ball iointboot.

NOTE: lf necesssry, apply penetrating type lubri-

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft endpast the groove.

11.

SCREWDRIVER

12. Pull the inboard joint, and remove th6 right drive-

shaft from the differential case as an assemblv.

CAUTION:

. Do not pull on tha dlivo3haft, a! th! inborrd

ioint may comc !p!rt,

. U3c carc when prying out tha a$qnbly, lnd pull

it rtraight to lvoid drmlging thc diftcrrntial oil

soal or thc int.rmcdirto shrft outel saal.

- Left Driveshaft:

Remove the left driveshaft from the bearing sup-

port by tapping the inboard joint of the drive-

shaft with I Dlastic hammer.

SCREIYDRIVER

BEARING SUPPOFT

16-4

Page 597 of 1413

KNUCKLE

DRIVESHAFT

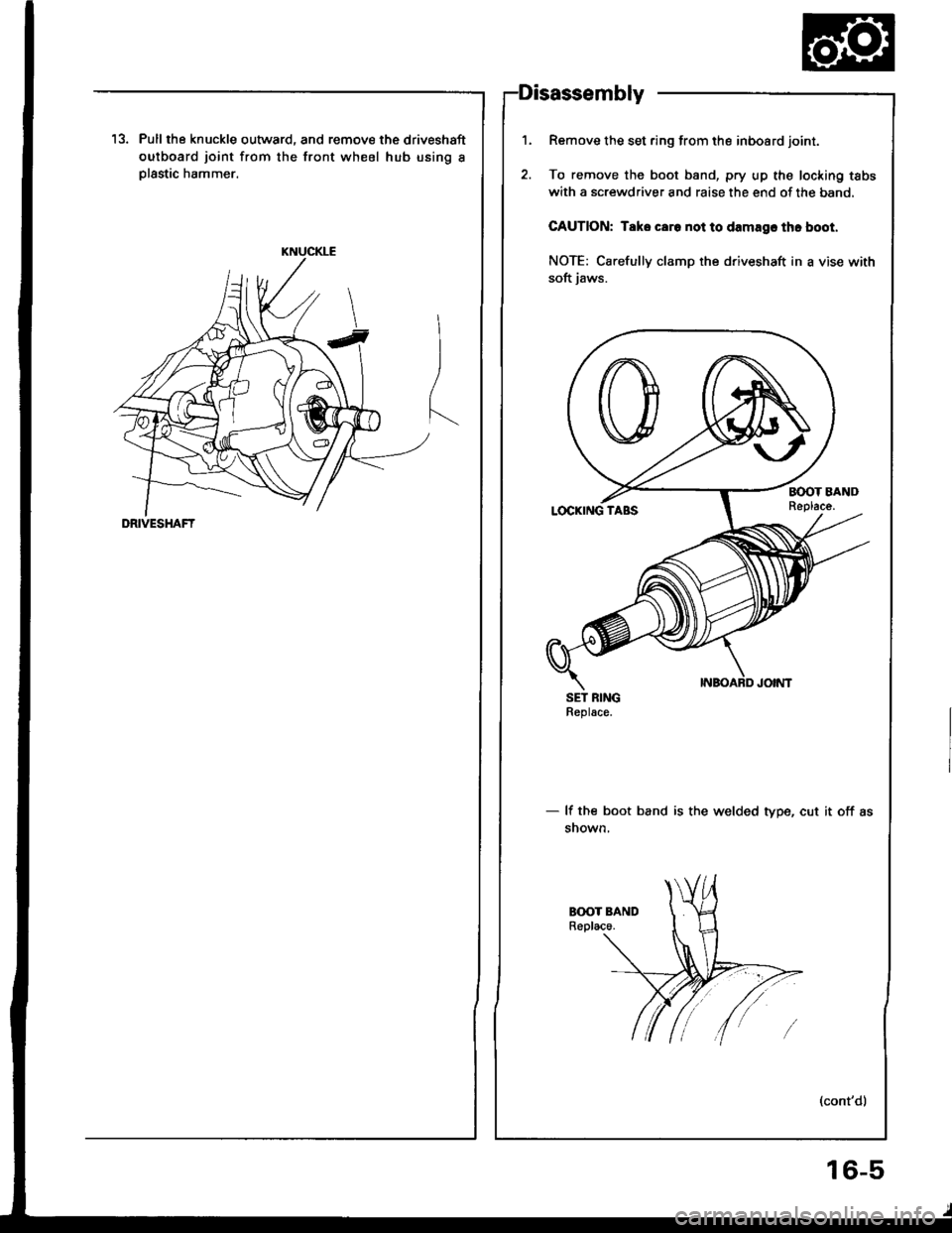

13. Pull the knuckle outward, and remove the driveshaft

outboard joint from the front wheel hub using I

Dlastic hammer.

Remove the set ring from the inboard joint.

To remove the boot band, pry up the locking tabs

with a screwdriver and raise the end of the band,

CAUTION: Taks caro not to damagc thc boot.

NOTE: Carefully clamp the driveshaft in a vise with

soft iaws.

SET RINGReplace.

- lf the boot band is the welded type, cut it off as

snown,

1.

16-5