ignition HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 97 of 1413

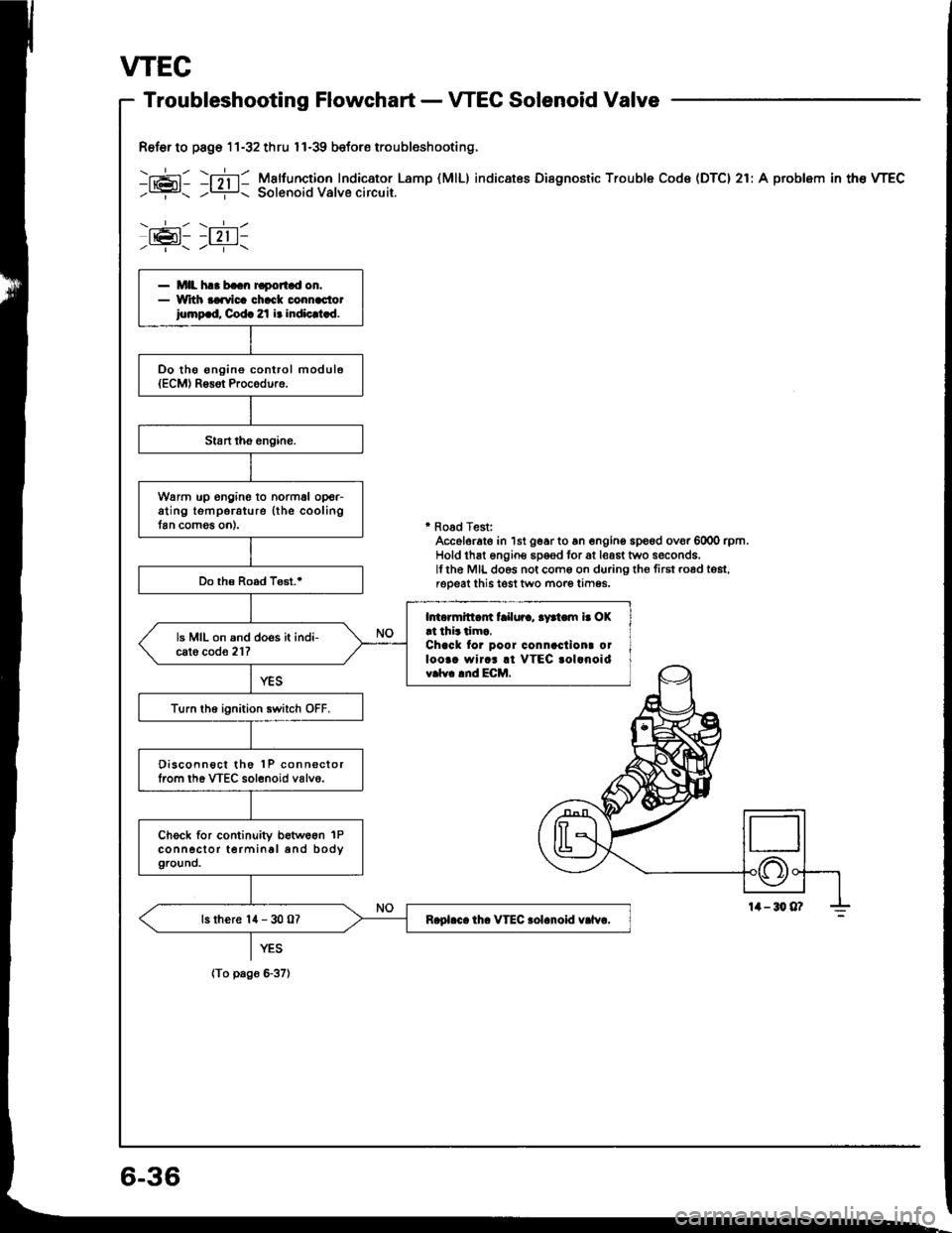

VTEC

Ref€r to page 11-32 thru I l-39 beforo troubleshooting.

-g: -mi !5*3ij'i:,*o:",,XTl.Lamp

(MlL) indicates Disenostic rrouble code (Drc) 2r:A problem in the wEc

\,__-:-/ \.---l-l

Iel- -l 2,1 l-

MIL h.. b..n Fport d on.Wrth aaavica chack connac,tot

iomp.d, Codc 2l i. indic.t.d.

Oo tho ongino control module(ECM) Rg3ot Procgduro.

w6rrn up engine to normal op€r-ating tsmporature (the coolingfan comog on).

Do th€ Road Test.'

lmormitt.m t ilur., .yrtom i. OK!t thi.tim..Chacl tor poor connactiont otloo.. wircr !l VTEC .ol.noidv.lv. lnd ECM.

ls MIL on and does it indi-cato cod€ 21?

Turn tho ignition switch OFF.

Oisconnect tho 1P connsctorlrom the VTEC solenoid valvo.

Chock for continuity betw66n 1Pconn6clor terminal and body

9rcUnO.

ls there '14 - 30 07R.pl.c. th. VTEC rolonoid v.lvr,

' Road Test:Accelerate in 1st gear to 6n engino spood ovor 6000 rpm.Hold thst engine sp€ed tor at least two seconds.lflhe MIL do6s not coms on during th€ first road tost,reoeat this test two more tim95.

YES

(To pago G37l

6-36

Page 99 of 1413

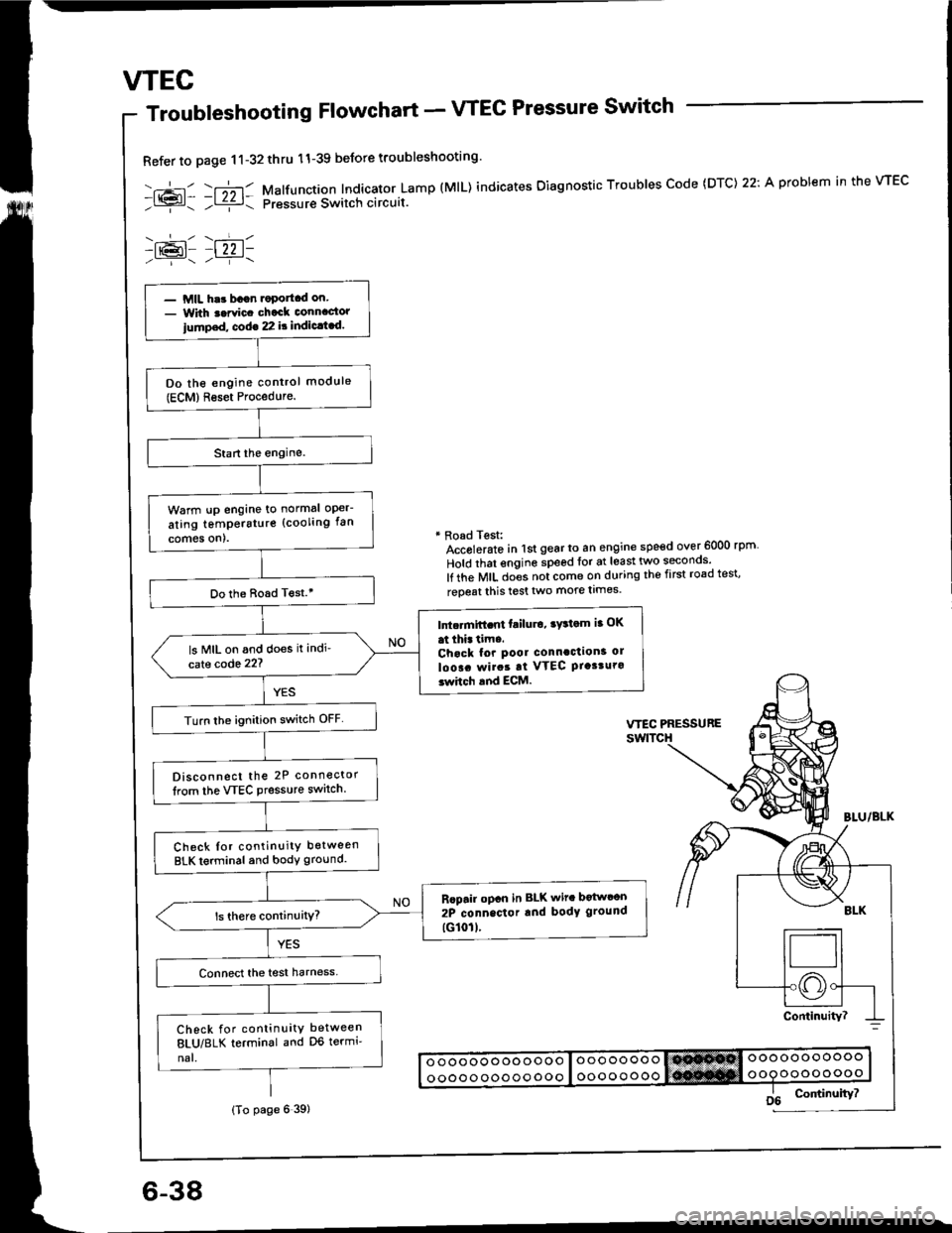

wEc

6-38

Troubleshooting Flowchart - VTEC Pressure Switch

Refer to page 11-32thru 11-39 beJore troubleshooting'

-.+- -r";-r- Malfunction Indicator Lamp (MlL) indicates Oiagnostic Troubles Code (DTC) 22: A problem in the VTEC- l{{?l- ;l ziz r: pressur€ Switch circuit.

-lr@l- |22 1-

* Road Test:Accolerato in lst gear to an engine speed over 6000 rpm

Hold that engine speed for at least two seconos'

lf the MIL does not come on during the first road test'

reoeat this test two more limes.

- MIL har bagn.oportcd on.- With t.rvic. chack connactor

iump.d, cod€ 22 it indic.t.d.

Do the engine control module(ECM)Reset Procedure.

Warm !p engine to normal oper-

ating temperstur€ (cooling fan

comes on).

Do the Boad T€st.'

Intc.mift.nt failu.o, ry3tom ia OK

at thi. tim..Chack for pool connaction3 ol

loo!. rvirat at VTEC Ptasturo3whch and ECM.

ls MIL on and does it indi'

cate code 22?

Turn lhe ignition switch OFF

Disconnect the 2P connector

lrom the VTEC Pressure switch.

Check Ior continuity between

BLK terminal and body ground.

Rcpair opcn in BLK wit. botwcon

2P connector rnd body ground

tG101l.

Check for continuity between

8LU/8LK terminal and D6 termi'

nal.

(To page 6 39)

Page 103 of 1413

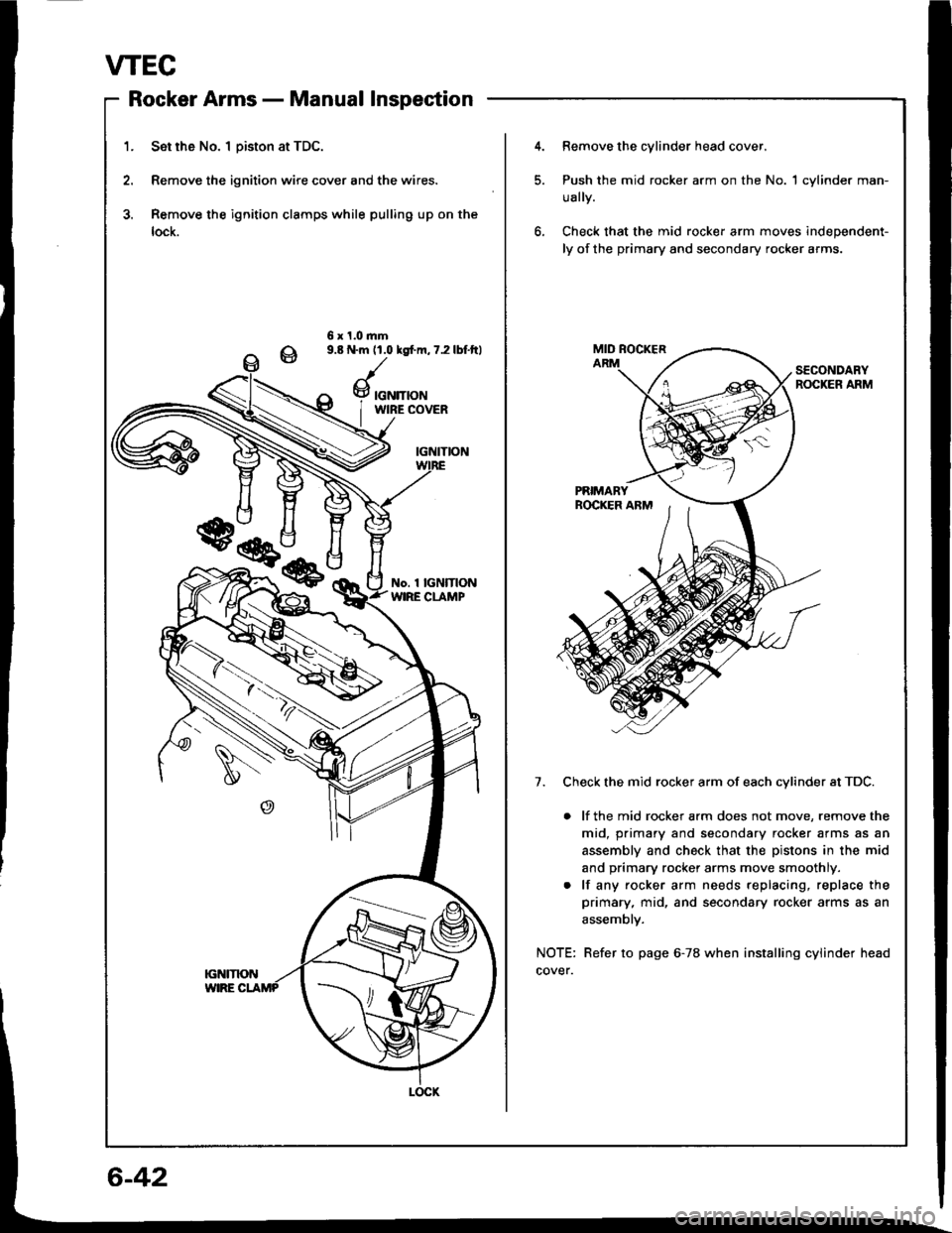

VTEC

Rocker Armsnlrungf rtrrrri' - rYrorrtrcr rrrDPEUtrl,rl

1. Set rh6 No. I Diston at TDC.

2. Remove the ignition wire cover and the wires.

3. Remove the ignition clamps while pulling up on the

lock.

4.Remove the cylinder head cover.

Push the mid rocker arm on the No. 1 cylinder man-

ually.

Check that the mid rocker arm moves independent-

ly of the primary and secondary rocker arms.

6 x 1.0.nm9.8 N.m 11.0 lgfm, 7.2 lbf.ftl

SECONDARYROCKER ARM

7. Check the mid rocker arm of each cvlinder at TDC.

. lf the mid rocker arm does not move, remove the

mid, primary and secondary rocker arms as an

assembly and check that the pistons in the mid

and primary rocker arms move smoothly.

. lf any rocker arm needs replacing, replace the

primary, mid, and secondary rocker arms as an

assemblv.

NOTE: Refer to page 6-78 when installing cylinder head

cover.

w

Page 196 of 1413

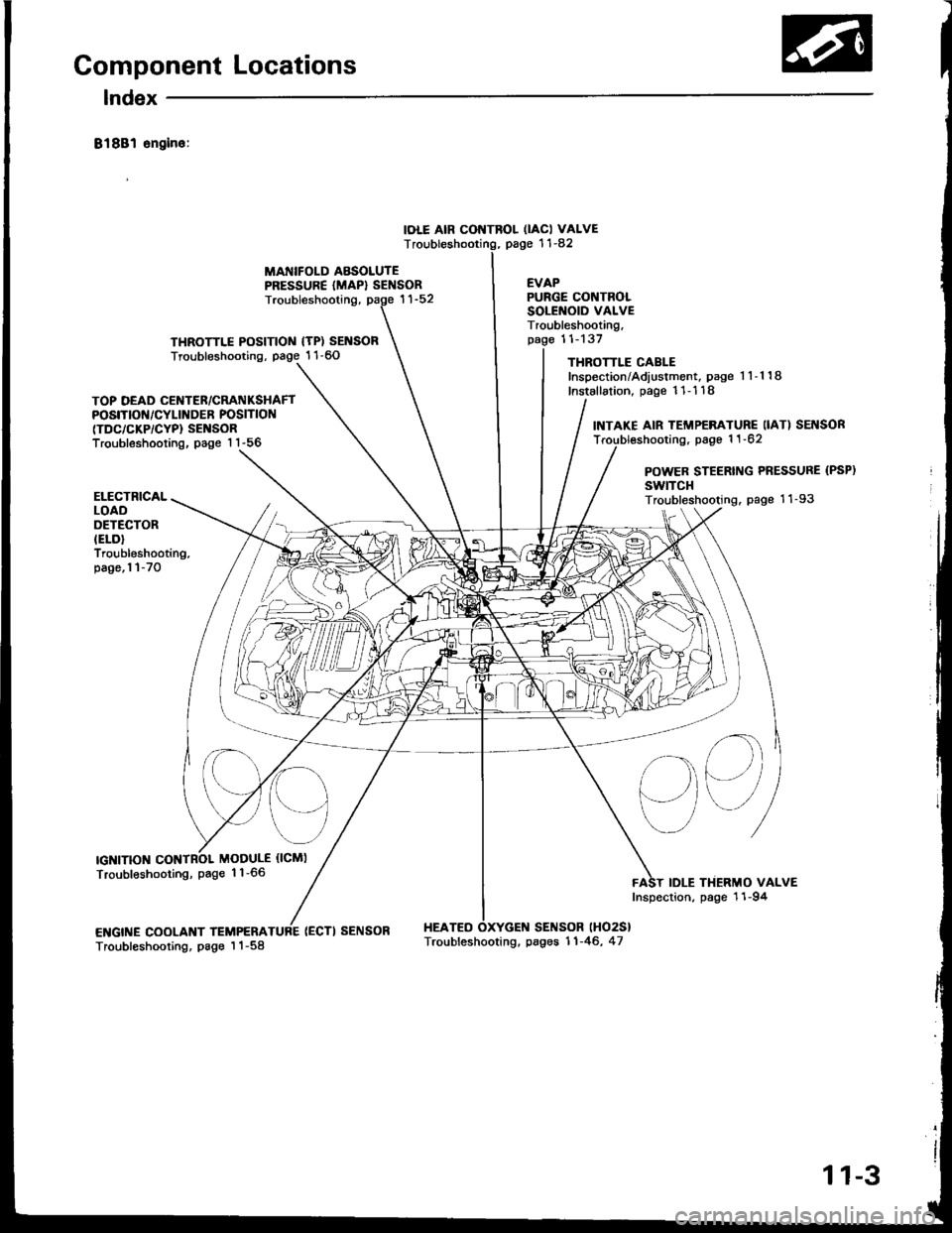

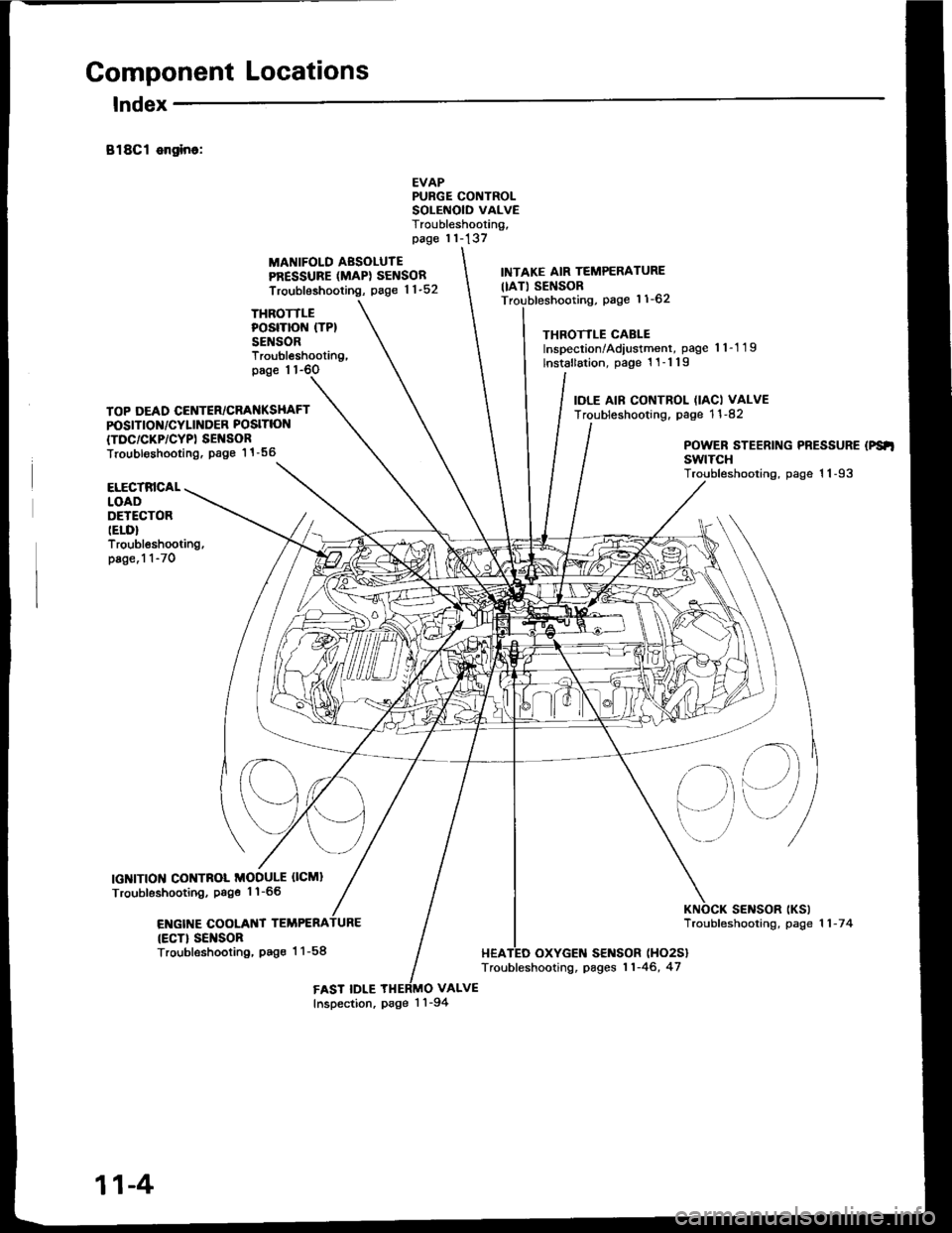

Component Locations

lndex

81881 sngin6:

IOLE AIR CONTROL OACI VALVEpage '11-82T

MANIFOLD ABSOLUTEPRESSURE {MAP} SENSOREVAP

THROTTLE POSITIOIII {TP) SENSORTroubleshooting, page 1 1-60

Troubleshooting,

(ECTI SENSOR HEATEO

PURGE CONTROLSOLENOID VALVETroubleshooting,11-137

THROTTLE CABLEInspection/Adiustment, page 1 1-1 18

Installation, page 11- 1 18

SENSOR lHO2S}

TOP DEAD CENTER/CRATIIKSHAFTPOSITIOf{/CYLINDER POSITION(TDC/CKP/CYP} SENSORTroubleshooting, page 1 1-56

INTAKE AIR TEMP€RATURE IIAT) SEI{SORTroubl€shooting, page 1 1 -62

POWER STEERING PRESSURE (PSP)

swtTcHTroubleshooting. page 11-93

sq

IDLE THERMO VALVEInspection, page 11-94

ELECTRICALLOADOETECTORIELD}Troubleshooting.page,l l-70

IGNITIONMODULE {ICMI

Troubleshooting, page 1 1-66

ENGINE COOLANT TEMPERATroubleshooting, page I 1-58Troubleshooting. pages 11-46, 47

11-3

Page 197 of 1413

Component Locations

lndex

B18Cl ongino:

THROTTLEPOSITION (TP}

SENSOR

MANIFOLD AESOLUTEPRESSURE (MAPI SENSOR

Troubleshooting, page 1 1-52

EVAPPURGE CONTROLSOLEiIOID VALVETroubleshooting,page 11-137

VALVE

INTAKE AIR TEMPERATURE

IIAT) SENSORpage 11-62

THROTTLE CABLEInspection/Adiustment, page 'l 1-1 19

lnstallation, page 1 1-1 19

IOLE AIF CONTROL (IACI VALVETroubleshooting. page 1 1 -82

Troubleshooting,page 1 1-6O

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION

{TDC/CKP/CYPI SEI{SORTroubl€shooting. Page 1 1 -56POWER STEERING PRESSURE (PS'I

swtTcHTroubleshooting, page 1 1-93ELECTRICALLOADDETECTORIELD}Troubleshooting,page.1 1-70

IGNITION CONTNOL MODULE OCMI

Troubleshooting, Psge 1'l-66

ENGIT{E COOLANT TEMPERA

{ECT} SEI{SORTroubleshooting, Pag€ 1 1-58

sElrlsoR tKslTroubfeshooting, page 1 1 -7 4

HEATED OXYGEN SENSOR (HO2S}

Troubleshooting, pages 11-46, 47

FAST IDLEInspection, page 1 'l -94

11-4

Page 224 of 1413

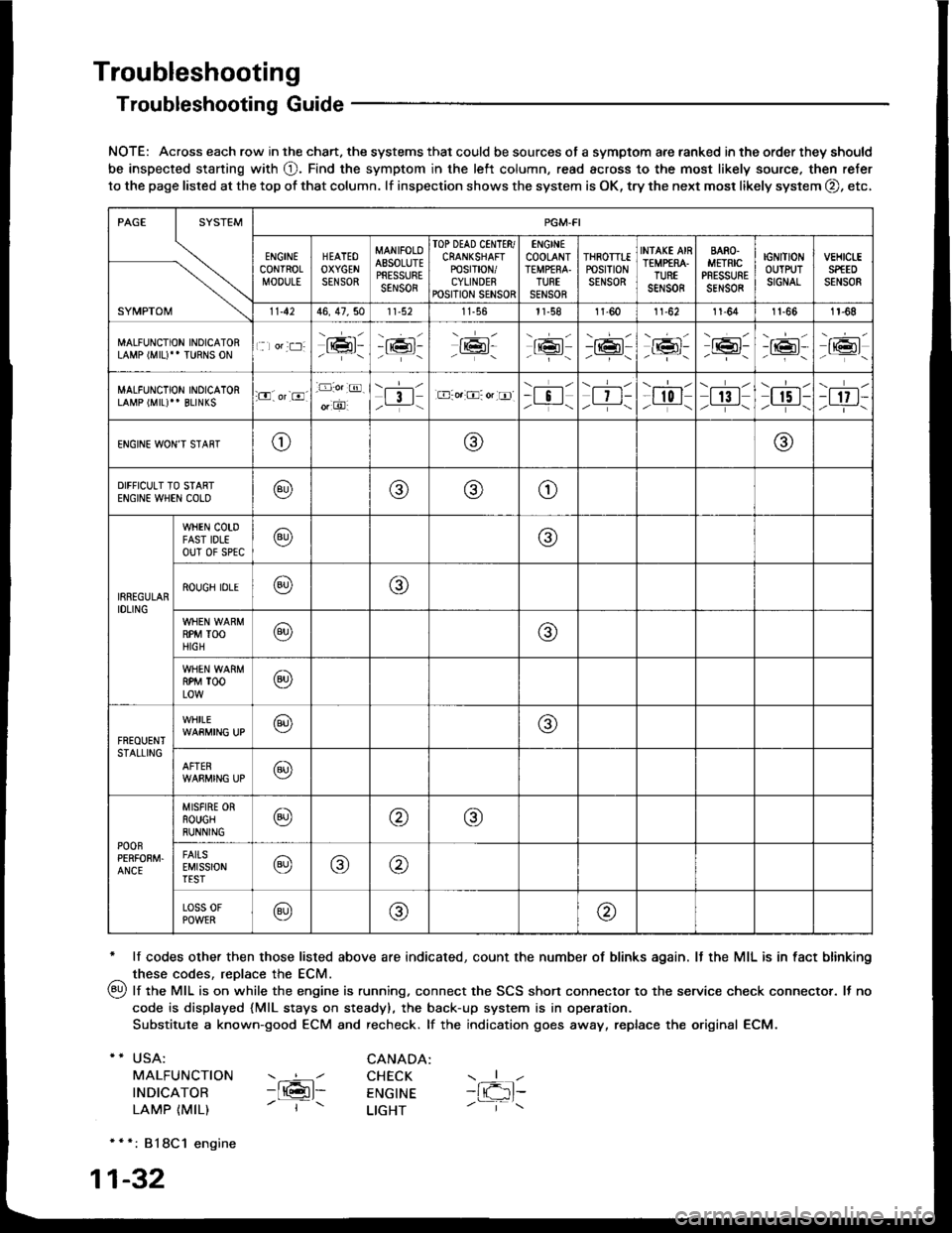

Troubleshooting

Troubleshooting Guide

NOTE: Across each row in the chart. the systems that could be sources of a symptom are ranked in the order they should

be inspected staning with O. Find the symptom in the left column, read across to the most likely source. then refer

to the page listed at the top of that column. lf inspection shows the system is OK, try the next mosr likely system O, etc,

* lf codes other then those listed above are indicated, count the number of blinks again. It the MIL is in fact blinking

^ these codes, replace the ECM.

qy, lf the MIL is on while the engine is running. connect the SCS shon connector to the service check connector. It no

code is displayed {MlL stays on steady), the back-up system is in operation.

Substitute a known-good ECM and recheck. lf the indication goes away, replace the original ECM.

USA:

MALFUNCTION

INDICATOR

LAMP {MIL)

CANADA: ----l CHECK-ltGl- ENGTNE- | - LTGHT

- { -1t-

* * *: 818C1 engine

1-32

SYMPTOM

PGM.FI

ENGINECONTROLMOOULE

HEATEOOXYGENSENSOR

MANIFOLOAESOLUTEPRESSURESENSOR

TOP DEAD CINTTR/CRANKSHAFTPOSTT|ON/CYLINDERPOSITION SENSOR

ENGINECOOLANTTEMPfRA.TURTSENSOR

THROTTTEPOStTtONSENSOR

INfAKE AIRTEMP€RA.TUREsar,rs0R

BARO.METRICPRESSURESENSOR

IGNITIONOUTPUTSIGNAL

vEHtct-ESPfEDSENSOR

11.4246, 47,5011-56l1-581l-6011-6211-641t-661r-68

MALFUNCTION INOICATORLAMP (MIU" TURNS ON1 lor:t:]:lrmr:- i;:i'-tK3t-16l-16l'-\-16l/-----\

-r:+r-

-{"Pr:-o_-16l-.z-\r6t/_-\

MALFUNCTION INOICATORLAMP (MIL)'' BLINKS:O. or-8.-D:o.:@.

o, O'l3l/__-\.E-o.:O: or tr]--i !l/ -i-\| 7 t-/__-\

--l-l-l r0 I/----\| 13 |z_---\

\.--r--l

I r5 t-/.---\-t 17 t-/-]-\

ENGINE WON'T STAffTo@@

DIFFICULT TO STARTENGIN€ WHEN COLO@@(9)o

IRREGULARIDLING

WHEN COTDFAST IDLEouT 0f sPtc@@

ROUGH IDLE@o

RPM TOOHIGH@@

RPM TOOLOW@

FREOUENTSTALLING

WHILE@@

AFTER@

POOnPERFOEM.ANCE

MISFIRE ORROUGHRUNNING@@@

FAITSEMISSIONTEST@@@

Loss 0FPOWER@@@

Page 226 of 1413

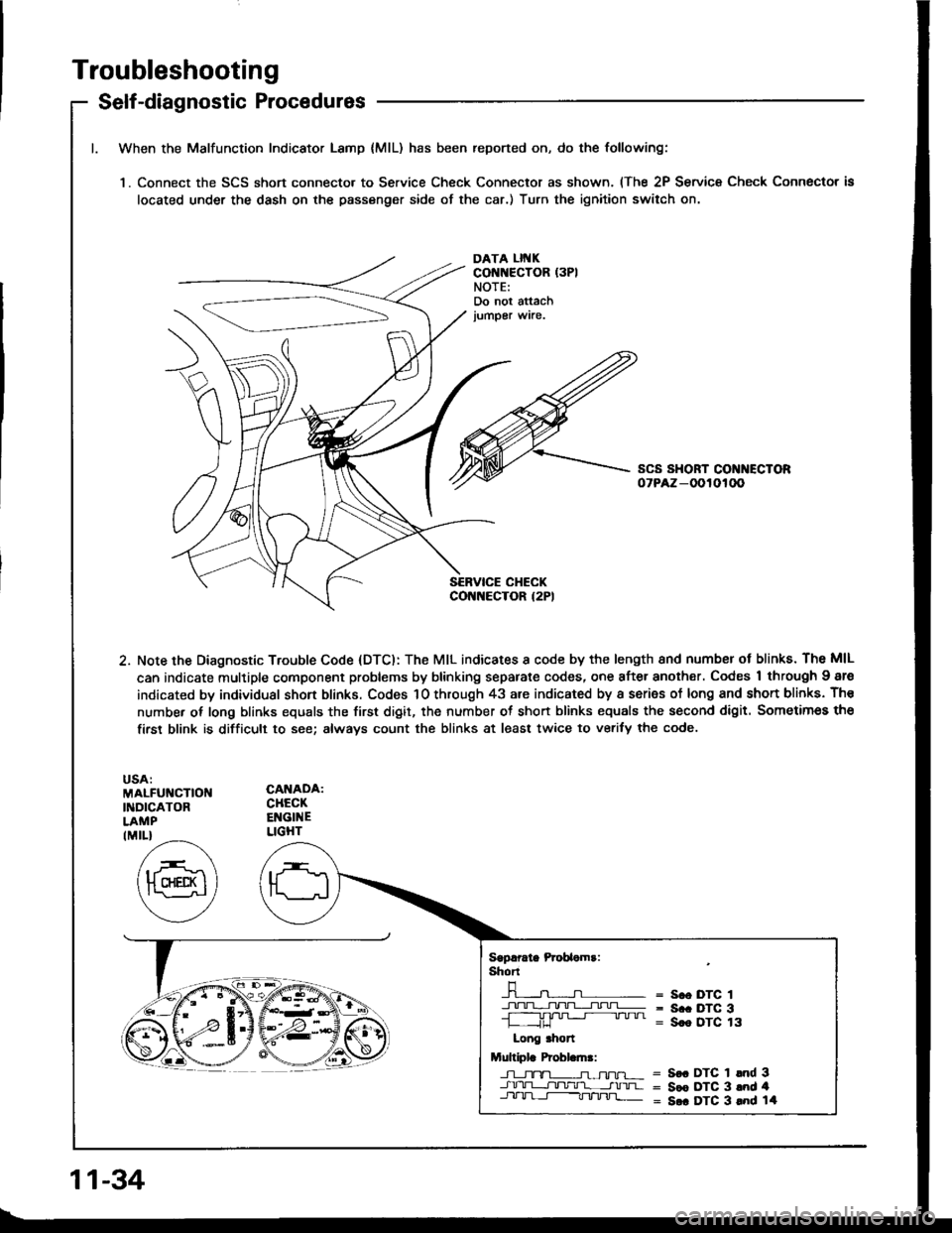

Troubleshooting

Self-diagnostic Procedures

When the Malfunction Indicator Lamp {MlL) has been reported on, do the following:

'1. Connect the SCS short connecto. to Service Check Connector as shown. (The 2P Service Check Connector is

located under the dash on the passenger side of the car.) Turn the ignition switch on.

DATA LII{KCONNECTOR (3PI

NOTE:Do not attachjumper wire.

2. Note the Diagnostic Trouble Code (DTC): The MIL indicates I code by the length 8nd numbsr ot blinks. The MIL

can indicate multiple component problems by blinking separate codes, one after another. Codes 1 through Igre

indicated by individual shon blinks. Codes 1O through 43 are indicated by a series of long and shon blinks. Th€

number of long blinks equals the first digit, the number ot short blinks equals the second digit. Sometimes the

firsr blink is difficult to see; always count the blinks at least twice to verify the code.

MALFUNCTIOI{INDICATORLAMP

CANADA:CHECKENGINELIGHTIMIL}

Sgprrate Prcbaomr:shT

-n-----n- =n- = s.o DTc 1

+!+1].TL;I!!=- = s.. Drc 3-L ,JU '" " " = Sce DTC 13

Long .hon

Multiplr Probl.ln.:

J-l_tx-TL-n-ffu-r- = S€. DTC 1 lnd 3-J.rrU-L-r]tltlr'l- __-tnrua = Sce DTC 3 and 4Jll-lrl-t-----Tt/'tnj]_ = S.. DTC 3 lnd 14

11-34

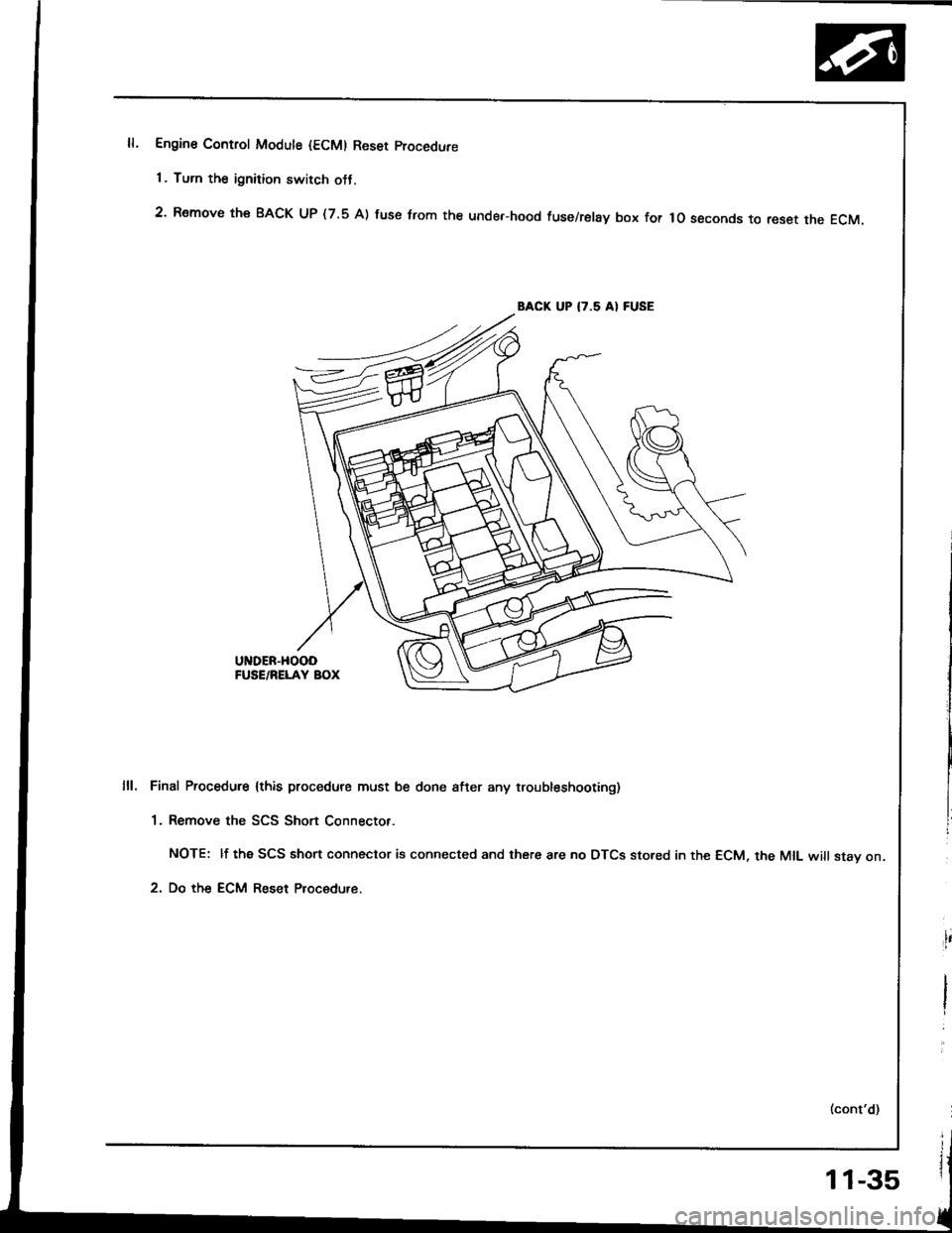

Page 227 of 1413

Engine Control Modute {ECM) Reset procedure

1 . Turn the ignition switch otJ.

2' Remove th€ BACK UP (7.5 A) fuse trom the unde.-hood fuse/relay box for lo seconds to reset the EcM.

BACK UP I7.5 AI FUSE

UNDER-HOOOFUSE/RELAY BOX

Final Procedure lthis procedure must be done after any troubleshooting)

1. Remove the SCS Short Connector.

NOTE: lf the SCS short connector is connected and there are no DTCS sto.ed in the ECM, the MIL will stav on.

2. Do the ECM Reset Procedure.

11-35

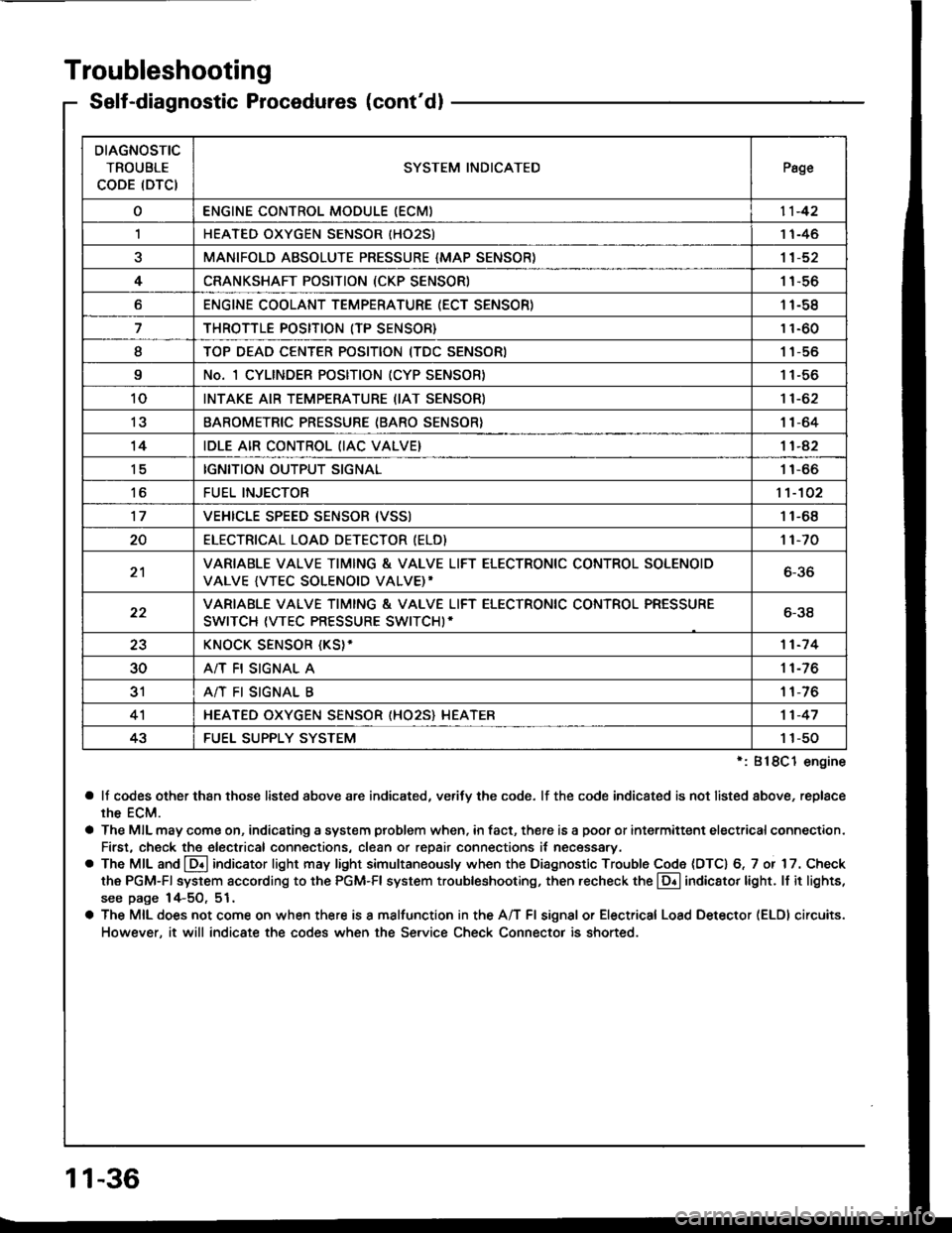

Page 228 of 1413

Troubleshooting

Self-diagnostic Procedures (cont'dl

':818C1 engine

a lf codes other than those listed above are indicated, verifv the code. lf the code indicated is not listed above, replace

rhe ECM.

a The MIL may come on, indicating a system problem when, in fact, there is a poor or intermittent electricalconnection.

First, check the electrical connections, clean or repair connections it necessary.

o The MIL and @ indicator light may light simultaneously when the Diagnostic Trouble Code (DTC) 6, 7 or 17. Check

the PGM-Fl system according to the PGM-Fl system troubleshooting, then recheck the l!! indicator light. ll it lights,

see page 14-5O, 51.

a The MIL does not come on when there is a malfunction in the A/T Fl signal or Electrical Load Detector (ELDI circuits.

However, it will indicate the codes when the Service Check Connector is shorted.

DIAGNOSTIC

TROUBLE

CODE (DTCISYSTEM INDICATEDPsge

oENGINE CONTROL MODULE IECM)11-42

,lHEATED OXYGEN SENSOR IHO25)1 1-46

aMANIFOLD ABSOLUTE PRESSURE {MAP SENSOR)11-52

4CRANKSHAFT POSITION (CKP SENSOR)1 1-56

oENGINE COOLANT TEMPERATURE (ECT SENSOR)11-58

THROTTLE POSITION (TP SENSOR}11-60

ITOP DEAD CENTER POSITION (TDC SENSORI1 1-56

9No. 1 CYLINDER POSITION (CYP SENSOR)1 1-56

10INTAKE AIR TEMPERATURE (IAT SENSOR)11-62

13BAROMETRIC PRESSURE (BARO SENSOR}1|-64

14IDLE AIR CONTROL (IAC VALVE}11-42

tcIGNITION OUTPUT SIGNAL11-66

toFUEL INJECTOR1't-102

17VEHICLE SPEED SENSOR {VSSI11-68

20ELECTRICAT LOAD DETECTOR (ELD)'t 1-70

21VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL SOLENOID

VALVE {VTEC SOLENOID VALVE)'6-36

22VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL PRESSURE

SWITCH (VTEC PRESSURE SWITCHI-6-38

23KNOCK SENSOR {KS}-11-7 4

30A/T FI SIGNAL A11-76

3'rA/T FI SIGNAL B1 1-76

4'lHEATED OXYGEN SENSOR (HO25} HEATER11-47

43FUEL SUPPLY SYSTEM1 1-50

11-36

Page 229 of 1413

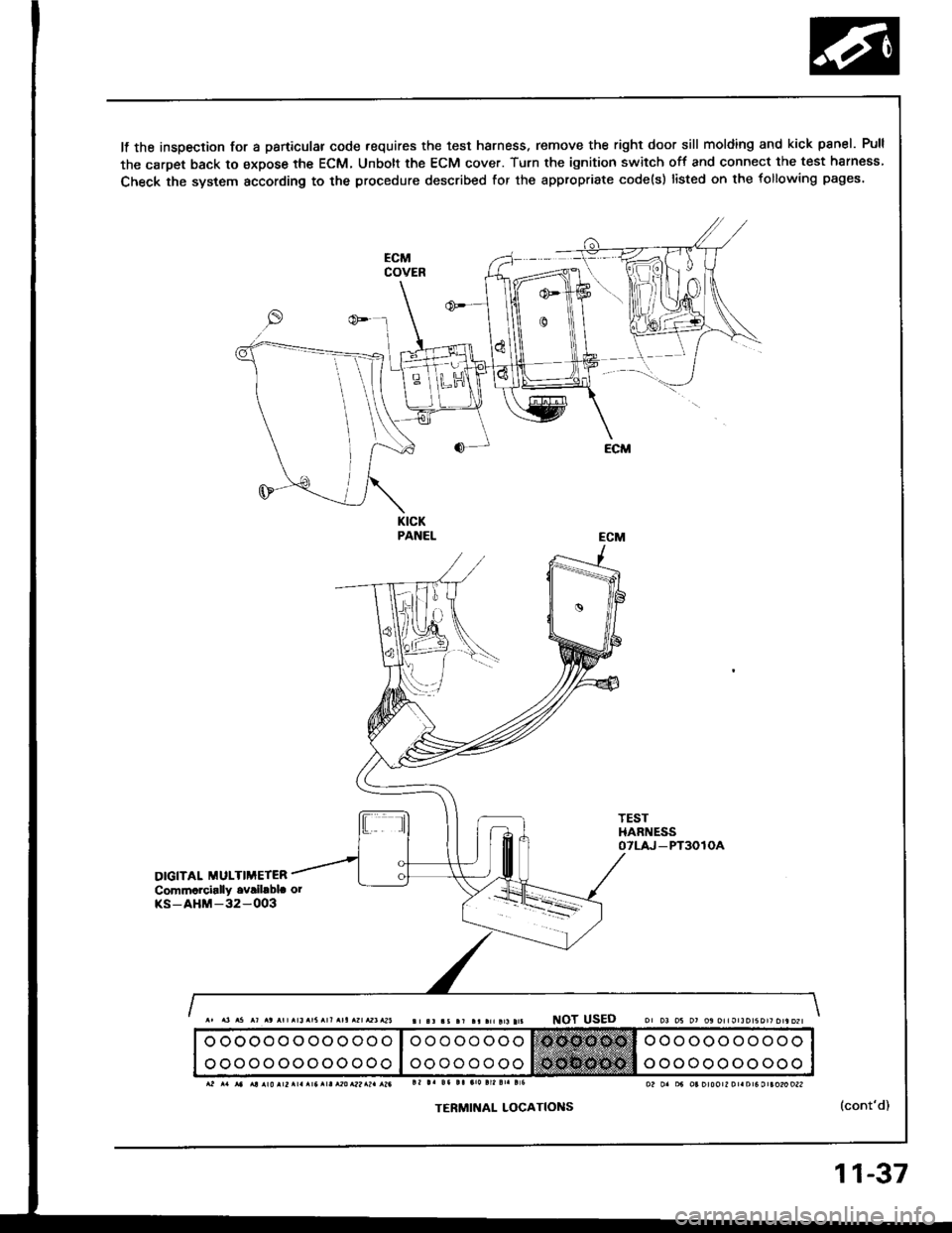

It the inspection for a particular code requires the test harness. remove the right door sill molding and kick panel. Pull

the carpet back to expose the ECM, Unbott the ECM cover. Turn the ignition switch off and connect the test harness

Check the system according to the procedure described for the appropriate code(s) listed on the following pages.

KICKPANEL

TESTHARNESSOTLAJ _PT3OlOA

DIGITAL MULTIMETERCommarcially ovribbla orKS-AHM-32-OO3

NOT USED

TERMINAL LOCATIONS(cont'd)

o oooooooooooo

ooooooooooooo

oo o oo ooo

oooooooo

ooooooooooo

ooooooooooo

11-37