lock HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 13 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Lift and Support Points

Lift

Wh€n heavy 16ar compon€nts such aa susponsion, luel tank, spale tile and hatch ale to

il]iii6iliieigltt in the tuggage area bsfore hoisting. When substantial woight is HONDA INTEGRA 1994 4.G Workshop Manual Lift and Support Points

Lift

Wh€n heavy 16ar compon€nts such aa susponsion, luel tank, spale tile and hatch ale to

il]iii6iliieigltt in the tuggage area bsfore hoisting. When substantial woight is](/img/13/6067/w960_6067-12.png)

Lift and Support Points

Lift

Wh€n heavy 16ar compon€nts such aa susponsion, luel tank, spale tile and hatch ale to

il]iii6iliieigltt in the tuggage area bsfore hoisting. When substantial woight is lemoved from ths

b€ removod, plac6

l€ar ol th€ car, ths

cantor of gravity may chango and can cause the cal to tip folward on the hoist'

NOTE: Since each tire/wheel assembly weighs approximately 14 kg (30 lbs), placing the front wheels in trunk can assist

with the weight distribution.

1. Place the lift blocks as shown

2. Raise the hoist a lew inches (centimeters) and rock the car to be sure it is firmly supported.

3. Raise the hoist to full height and inspect lift points for solid support.

FRONT SUPPORT POINTLIFT BLOCKSBEAR SUPPORT POINT

1-9

Page 14 of 1413

and Support Points

Jack

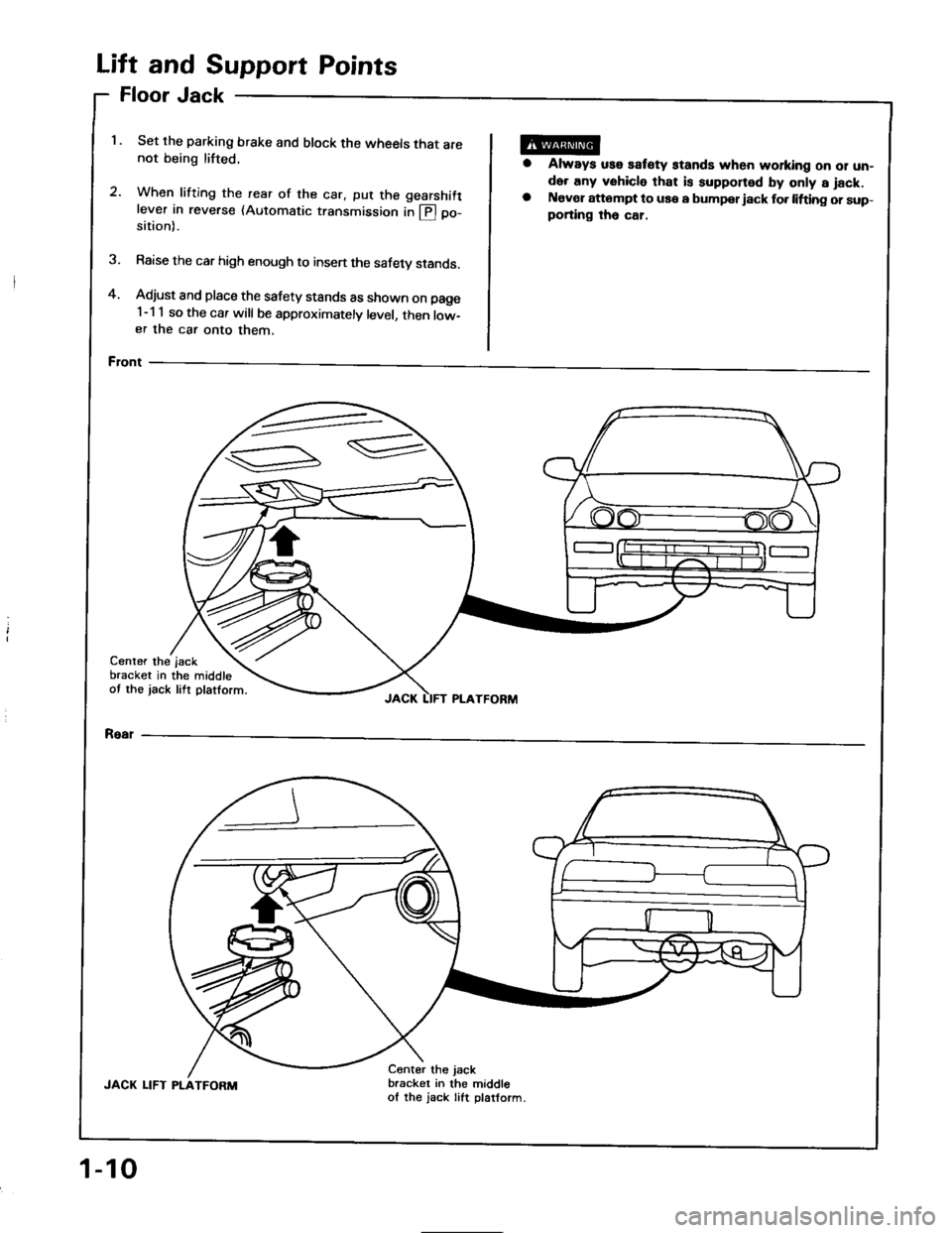

Set the parking brake and block the wheels that are

not being lifted.

2.When lifting the rearwhen tritrng the rear of the car, put the gearshift

lever in reverse (Automatic transmission in @ po-

of

sition).

Raise the car high enough to insen the safety stands.

Adjust and place the safety stands as shown on page

1-1 1 so the car will be approximately level, then low-

er the car onto them.

Front

oor

ft

FI

Li

4.

1.

a

Always uss satety stands when working oo 01 un-

der any vehicle that is supponed by only a jack.

Naver attompt to use a bumpor iack fo. lifting or sup-

porting tho car,

3.

Center the

bracket in

ot the jack

the middle

lift platform.

jsck

JACK LIFT PLATFORM

Rear

JACK LIFT PLATFORM

Center the jack

bracket in the middle

of the jack Iift platform.

1-10

Page 20 of 1413

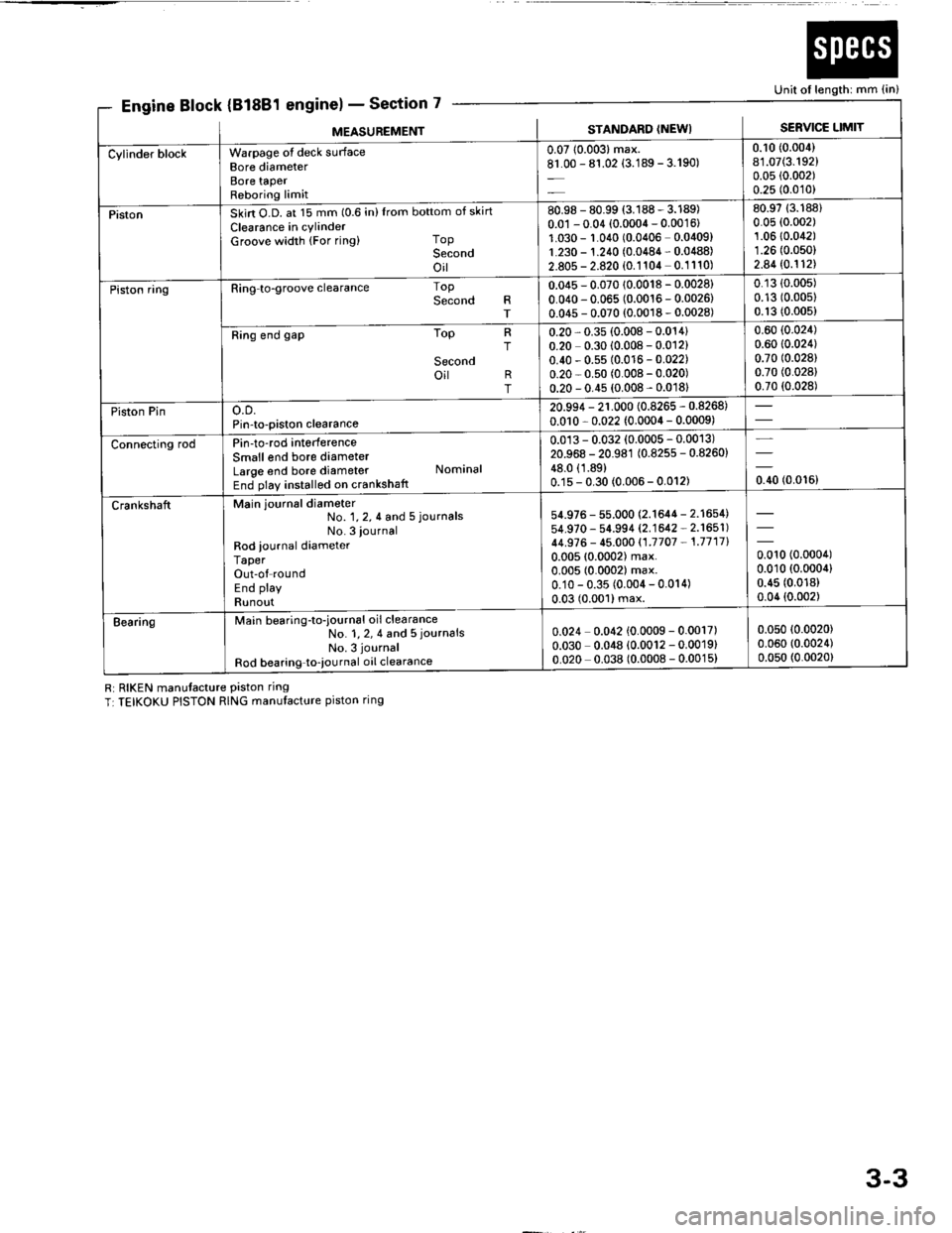

k (81881

Ri RIKEN manutacture Piston ring

T:TEIKOKU PISTON RING manufacture piston ring

7scti

Unit of length: mm {in}

Engine Block {Bl6E1 englnel - sectlon

MEASUNEMENTSTANDARD (NEWI SERVICE LIMIT

bottom of skirt

Top

Second

oil--

top

Second

'....=-

lop

Ring to-groove clearance

Ring end gap

o.D.

Pin-to-piston clearance

Pin-to-rod interference

Smallend bore diameter

Large end bore diameter

End play installed on crankshatt

Main journal diameter

Warpage ot deck sLrrface

Bore diameter

Bore taPer

Reboring limit

Skirt O.D. at 15 mm (0.6 in)Irom

Clearance in cylinder

Groove width (For ring)

R

T

;

T

No. 1, 2, 4 and 5 journals

No. 3 iournal

Rod iournal diameter

Taper

Out-of round

End play

Runout

Main bearing-to-iournal oil clearance

No. 1, 2, 4 and 5 journals

No. 3 journal

Rod bearing to-iournal oil clearance

Second

oit R

T

Nominal

0.0710.003)max.

81.00 - 81.02 {3.189 - 3.190)

0.10 (0.004)

81.07(3.192)

0.05 (0.002)

0.25 (0.010)

Cylinder block

80.98 - 80.99 (3.188 - 3.189)

0.01 - 0.04 (0.0004 - 0.0016)

1.030 - r.010 (0.0406 0.0409)

1.230 - 1.210 (0.0484 - 0.0488)

2.805 - 2.820 (0.1104 0.1110)

80.9713.188)

0.05 (0.002)

1.0610.042)

1.26 (0.050)

2.8410.112\

Piston

0.045 - 0.070 {0.0018 - 0.0028}

0.040 - 0.065 (0.0016 - 0.0026)

0.045 - 0.070 (0.0018 - 0.0028)

0.13 {0.00s)

0.13 (0.00s)

0.13 (0.005)

0.60 {0.024)

0.60 10.024)

0.70 (0.028)

0.70 (0.028)

0.70 (0.028)

Piston ring

0.20 - 0.35 (0.008 - 0.014)

0.20 0.30 (0.008 - 0.012)

0.40 - 0.5s (0.0 r6 - 0.022)

0.20 - 0.s0 (0.008 - 0.020)

0.20 - 0.45 (0.008 - 0.0181

20.994 - 21.000 (0.8265 - 0.8268)

0.0r0 - 0.022 (0.0004 - 0.0009)

rrston rln

0.013 - 0.032 (0.0005 - 0.0013)

20.968 - 20.981 (0.825s - 0.8260)

48.0 (1.89)

0.1s - 0.30 (0.006 - 0.012)

Connecting rod

54.976 - 55.000 (2.1644 - 2.1654)

54.970 - 54.994 (2.1642 - 2.1651)

44.S76 - 45.000 {1.7707 - 1.7717}

0.00510.0002) max.

0.005 (0.0002) max.

0.10 - 0.35 (0.004 - 0.014)

0.03 (0.001) max.

0.010 (0.0004)

0.010 (0.0004)

0.45 (0.018)

0.04 {0.002)

Crankshaft

0.024 0.042 {0.0009 - 0.0017)

0.030 0.048 {0.0012 - 0.0019}

0.020 0.038 (0.0008 - 0.0015)

0.05010.0020)

0.060 (0.0024)

0.050 (0.0020)

Bearing

3-3

Page 22 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual EBIk (818C1Section 7

Unit of length: mm (in)

ngrne ]ocK (ltluur englnel -

MEASUREMENTSTANDARD (NEWI SERVIC€ LIMIT

Cyiinder blockwarpage of deck surlace

Bore diameter

Bore taPer

Reboring limit

0.05 HONDA INTEGRA 1994 4.G Workshop Manual EBIk (818C1Section 7

Unit of length: mm (in)

ngrne ]ocK (ltluur englnel -

MEASUREMENTSTANDARD (NEWI SERVIC€ LIMIT

Cyiinder blockwarpage of deck surlace

Bore diameter

Bore taPer

Reboring limit

0.05](/img/13/6067/w960_6067-21.png)

EBIk (818C1Section 7

Unit of length: mm (in)

ngrne ]'ocK (ltluur englnel -

MEASUREMENTSTANDARD (NEWI SERVIC€ LIMIT

Cyiinder blockwarpage of deck surlace

Bore diameter

Bore taPer

Reboring limit

0.05 (0.002) max.

81.00 - 81.02 {3.189 - 3.190)

0.08 (0.003)

81.0713.192)

0.05 (0.002)

0.25 (0.010)

PistonSkin O.D. ar 15 mm (0.6 in) {rom bottom ot skirt

Clearance in cylinder

Groove width (For ring) ToP

Socond

oil

80.98 - 80.99 13.188 - 3.189)

0.0r - 0.04 {0.0004 - 0.0016}

1.030 - 1.0,r0 {0.0406 - 0.0409)

1.230 - 1.240 (0.0484 - 0.0488)

2.805 - 2.820 (0.1104 - 0.11101

80.97 (3.188)

0.05 (0.002)

1.060 (0.0417)

1.260 (0.0496)

2.840 (0.1118)

Piston ringRing-to-pistongrooveclearance Top

Second

0.045 - 0.070 {0.0018 - 0.0028}

0.010 - 0.065 (0.0016 - 0.0026)

0.13 (0.005)

0.13 (0.005)

Ring end gap I oP

Socond

oil

0.20 - 0.35 {0.008 - 0.014)

0.40 - 0,55 (0.016 - 0.022)

0.20 - 0.s0 {0.008 - 0.020}

0.60 (0.024)

0.70 (0.028)

0.7010.0281

rrston rtno.D.

Pin-to-piston clearance

20.994 - 21.000 (0.8265 - 0.8268)

0.010 - 0.022 {0.0004 - 0.0009)

0.017 - 0.035 (0.0007 - 0.0014)

20.964 - 20.997 (0.8254 - 0.8267)

€.0 (1.89)

0.15 - 0.30 (0.006 - 0.012)

Connecting rodPin to-rod int€rference

Small end bore diameter

Large end bore diameter Nominal

End play installed on crankshaft

crankshatt

No. 1,2,4 and 5 iournals

No. 3 journal

Rod iournal diameter

Taper

Out'ol round

End play

Runout

Msin journal diameter

54.976 - 55.000 (2.1644 - 2.16541

54.974 - 54.998 (2.'�|643 - 2.1553)

44.976 - 45.000 {1.7707 -'�I.7717)

0.005 {0.0002} max.

0.004 {0.0002) max.

0.10 - 0.35 {0.00{ - 0.014)

0.020 (0.0008) max.

-t-oou

lo.ooort

EearingMain bsaring-to-journal oil clearance

No. 1, 2, 4 and 5 journals

No 3 journal

Rod bearing-to-journal oil clearanc€

0.024 - 0.042 (0.0009 - 0.0017)

0.030 - 0.048 (0.0012 - 0.0019)

0.032 - 0.050 (0.0013 - 0.0020)

0.050 (0.0020)

0.060 {0.0024)

0.060 (0.0024)

3-5

Page 26 of 1413

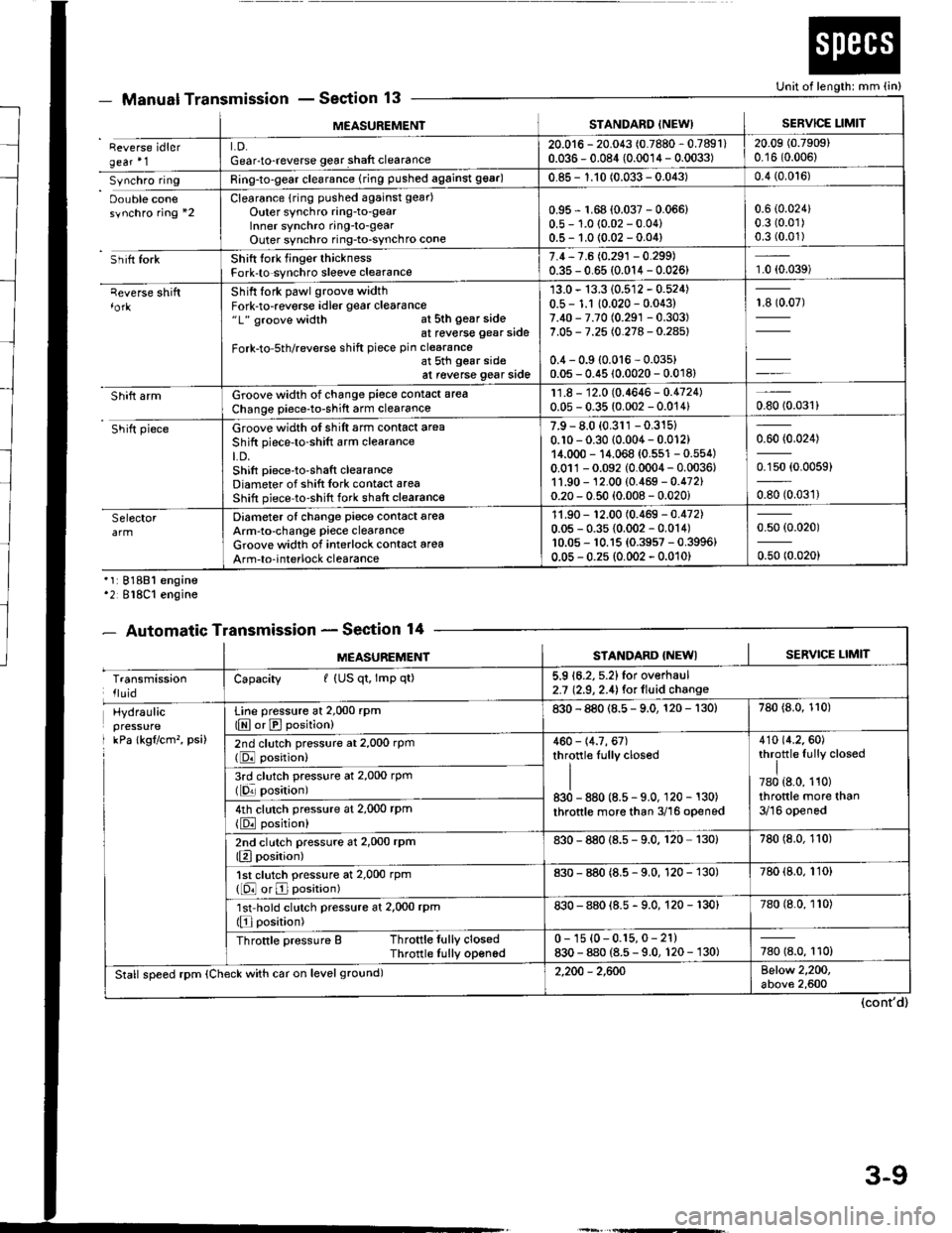

MEASUREMENISTANDARD INEW)SERVICE LIMIT

Reverse idlergear'1LD.Gear-to-reverse gear shaft clearance20.016 - 20.043 (0.7880 - 0.7891)0.036 - 0.084 (0.0014 - 0.0033)20.09 (0.7909)

0.16 (0.006)

Synchro ringRing-to-gear clearance (ring pushed against 99ar)0.85 - 1.10 (0.033 - 0.043)0.4 (0.0't6)

Oouble conesynchro ring *2Clearance {rin9 pushed against gear)

Outer synchro ring-to-gearlnner synchro ring-to-gearOuter synchro ring-to-synchro cone

0.95 r 1.68 (0.037 - 0.066)0.5 - 1.0 (0.02 - 0.04)0.5- 1.0 {0.02 -0.04)

0.6 (0.024)

0.3 (0.01)

0.3 (0.01)

Sh itt forkShift tork finger thicknessFork-to synchro sleeve clearance7.4,7.6 (0.291 - 0.299)0.35 - 0.65 (0.014 - 0.026)1.0 (0.039)

qeverse shiftShift fork pawl groove widthFork-to-reverse idler gear clearance"1" groove width at sth gear sideat reverse gear side

Fork-to-5th/reverse shift piece pin clearanceat 5th gear sideat reverse gear side

13.0 - 13.3 (0.512 - 0.524)0.5 - 1.1 10.020 - 0.043)7.40 - 7.70 (0.291 -0.303)

7.05 - 7.25 (0.278 - 0.28s)

0.4 - 0.9 {0.016 - 0.03s)0.05 - 0.45 (0.0020 - 0.018)

13907)

Shift armGroove width of change piece contact area

Change piece-to-shift arm clearance11.8 - 12.0 (0.4646- 0.4724)0.05 - 0.35 (0.002 - 0.014)0.8010.031)

Shift pieceGroove width of shift arm contact area

Shift piece'to-shift arm clearanceLD.Shift piece-to-shaft clearanceDiameter of shift Iork cont6ct areaShift piece-to-shift fork shaft clearance

7.9 - 8.0 (0.311 -0.315)

0.10 - 0.30 (0.004 - 0.012)14.000 - 14.068 {0.551 - 0.554)0.011-0.092 (0.0004 - 0.0036,1'1.90 - 12.00 (0.469 - 0.472)0.20 - 0.50 (0.008 - 0.020i

0.60 (0.024)

0.150 (0.0059)

oso to.oart

SelectorDiameter of change piece contact areaArm-to-change piece clearanceGroove widlh of interlock contact area

Arm-to-interlock clearance

11.90 - '�t2.00 (0.469 - 0.472)0.05 - 0.35 {0.002 - 0.014)10.05 - 10.15 {0.3957 - 0.3996}0.05 - 0.2s (0.002 - 0.010)

0.50 (0.020)

0.50 (0.020)

Manual TransmissionSection 13

'1:81881 engine'2 818C1 engine

- Automatic TransmissionSection 14

Unit of length: mm (in)

(cont'd)

- oEutrlrrl rr

MEASUREMENTSTANDARD {NEWISERVICE LIMIT

TransmissionlluidCapacity I (US qt, lmp qt)5.9 16.2, 5.2)for overhaul2.7 (2.9, 2.4) for lluid change

Hydraulicpressure

I kPa lkgflcm'�, psi)

Line pressure at 2,000 rpm(E or E position)830 - 880 (8.5 - 9.0, 120 - 130)780 {8.0, 110)

2nd clutch pressure at 2,000 rpm(DJ position)460 - 14.7, 67)throttle Iully closed

II830 - 880 (8.5 - 9.0, 120 - 130)

throttle more than 3/16 opened

410 {4.2.60)throttle fully closed

I780 {8.0, 110)throttle more than3/16 opened

3rd clutch pressure at 2,000 rpm(lqr posirion)

4th clutch pressure at 2,000 rPm

{E position)

2nd clutch pressure at 2,000 rPm(Elposition)830 - 880 {8.s - 9.0. 120 130)780 (8.0, 110)

1st clutch pressure at 2,000 rpm([O or E position)830 - 880 (8.5 - 9.0, 120 - 130)780 (8.0, 110)

'lst'hold clutch pressure at 2,000 rpm(Elposition)830 - 880 {8.5 - 9.0, 120 - 130}780 (8.0, 110)

Throttle pressure B Throttle fully closedThrotlle Iully opened0 - 1s {0-0.15,0- 21)830 - 880 (8.5 - 9.0, 120 - 130)780 18.0, 110)

Stall speed rpm (Check with car on level ground)2,200 - 2,600Below 2,200,above 2,600

3-9

Page 30 of 1413

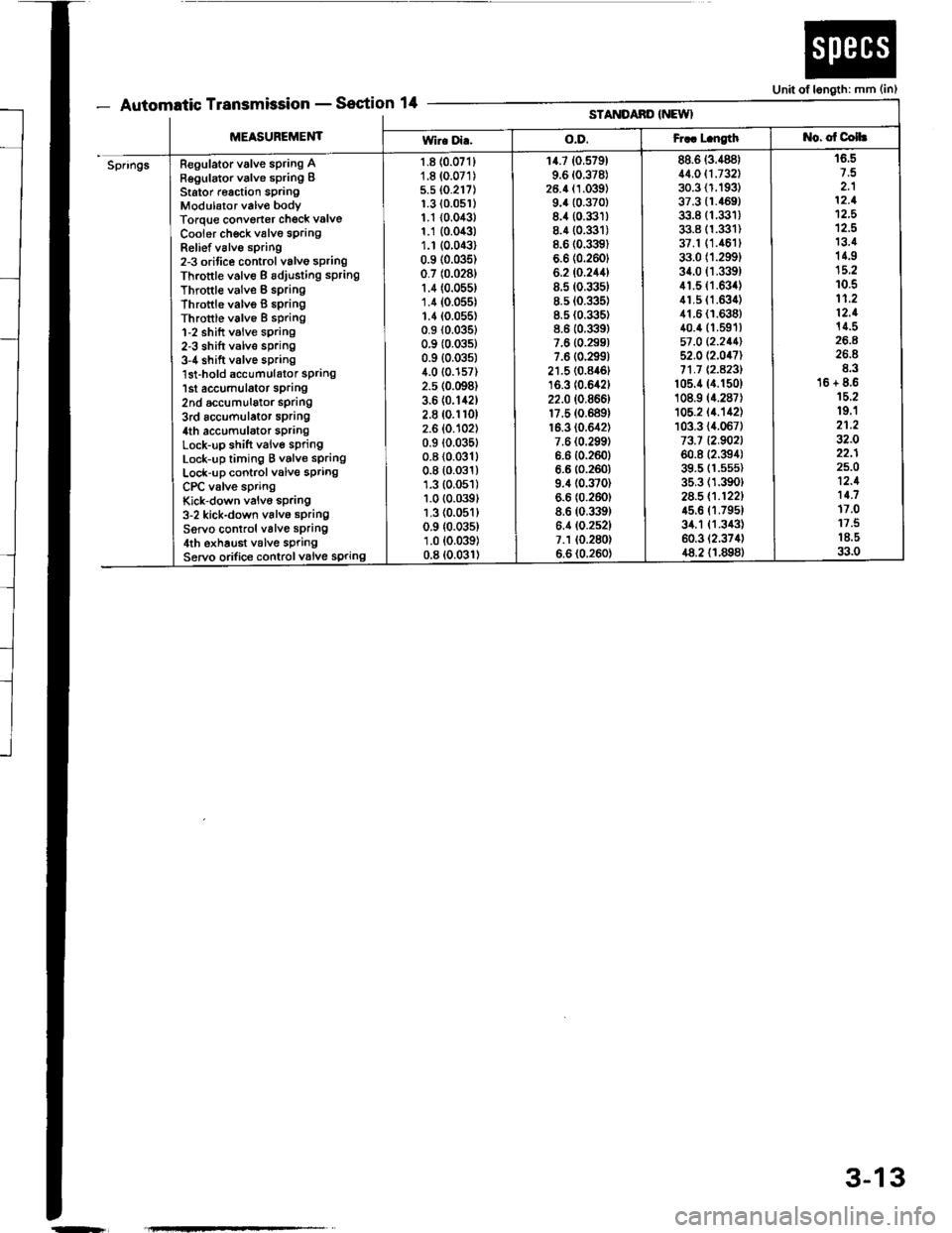

- Automatic TransmissionSection 14Unit of length: mm (in)

[t!'tttltttt tt -

MEASUREMENT

STANDAND INEWI

Wir. Di..o.D.Fr.. L.ngtht{o. of Colh

SpringsRegulator valve spring ARegulator valve spring IStator r€action springModulator valv€ bodyTorque convorter check valve

Cooier ch€ck valve sprangRelief v6lvo spring2-3 orifice control valvo springThrottle valve B adiusting sPring

Throttle valve B springThrottle valvo B 6pringThrottle valve I spring1-2 shift valve sprang2-3 shift valve spring3-4 shift valve spring'lst-hold accumulator spring1st accumulator sprang2nd accumulalor spdng3rd accumulator spring4th accumulator sPrangLock-up shift valve springLock-up timing B valve springLock-up control valve springCPC valve springKick-down valvo spring3-2 kick-down valvo springServo control valve spring4th exhaust v6lve springServo orifice controlvalve spring

1.8 {0.071}1.8 (0.071)

5.5 (0.217)

1.3 {0.0s1)1.1 {0.043}1.1 {0.043)1.r (0.043)

0.9 (0.035)

0.7 (0.0281

1.4 (0.055)

1.4 (0.055)

1.1(0.055)0.9 (0.0351

0.9 (0.0351

0.9 {0.035)4.0 {0.157)2.5 (0.098)

3.6 (0.142)

2.8 (0.1r0)

2.6 (0.102)

0.9 (0.035t

0.8 (0.0311

0.8 (0.031)

1.3 (0.051)

1.0 (0.039t

1.3 (0.051)

0.9 {0.035)1.0 (0.039)

0.8 (0.031)

14.7 (0.579)

9.6 (0.378)

26.4 (1.039)

9.4 {0.370}8.4 (0.331)

8.4 (0.3:]t)

8.6 (0.3l9)

6.6 (0.2601

6.2 (0.244)

8.5 (0.335)

8.5 (0.335)

8.5 (0.335)

8.6 (0.339)

7.6 (0.299)

7.6 (0.2991

21.5 (0.846t

16.3 (0.642)

22.0 (0.866)

17.5 (0.689)

16.3 (0.642)

7.6 {0.299)6.6 {0.260}6.6 (0.260)

9.4 (0.370)

6.6 (0.260)

8.6 (0.339)

6.4 (0.252)

7.1 (0.280)

6.6 (0.260)

88.6 (3.488)

11.011.732130.3 (1.193)

37.3 {1.469)33.8 (1.331)

33.8 (1.331)

37.1 (1.461t

33.0 (1.299)

34.0 fi.339)41.5 (1.634)

41.5 (1.63i1)

41.6 {1.638}40.4 (1.591)

57 ,0 12.211152.0 (2.047)

71.1 Q.A23l't05.4 (4.150)

108.9 (4.287)

105.2 (4.'�142)

103.3 {4.067)73.7 12.902160.8 (2.394)

39.5 (1.5s5)

35.3 (1.390)

2a.5 (.1221

45.6 (1.795t

34.1 {1.343)60.3 (2.374)

48.2 {1.898}

16.5

2.112.1't2,5

12.513.414.9

10.511.212.114.5

26.8E.316 + 8.615.219.'l21.232.022.125.O12.111.717.011.518.533.0

-r

3-13

Page 31 of 1413

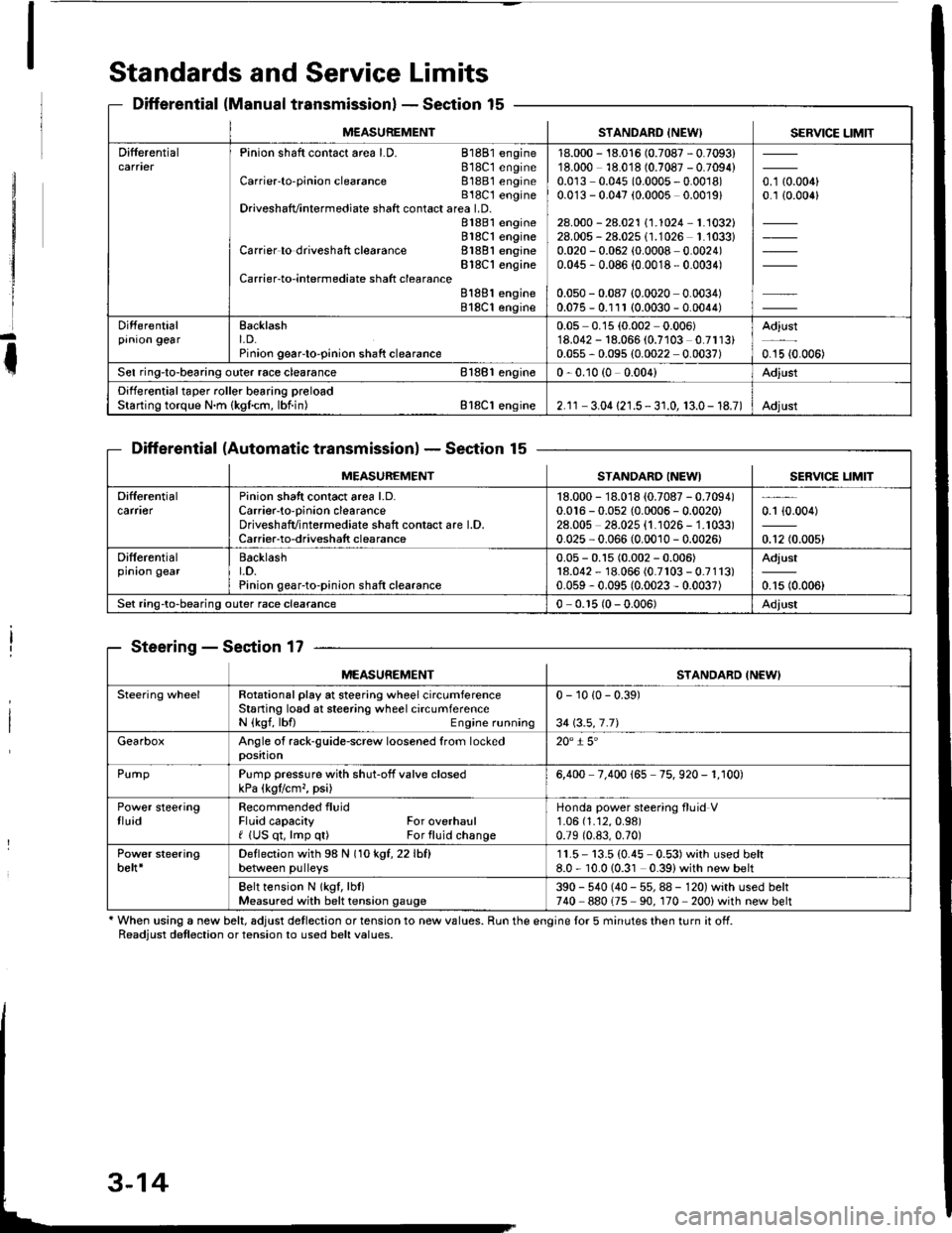

Standards and Service Limits

Differential (Manual transmissionlSection 15

Differential (Automatic transmissionlSection 15

Steering - Section 17

' When using a new belt, adjust detlection or tension to new values. Run the engine lor 5 minutes then turn it off.Readiust detlection or tension to used belt values.

M€ASUREMENTSTANDARD INEW) SERVICE LIMIT

DifferentialPinion shaft contact area LD. 81881 engine818C1 engineCarrier'to-pinion clearance 81881 engineB18C t engineDriveshafvintermediate shaft contact area LD.81881 engine818C1 engineCarrier to driveshaft clearance 81881 engineBlSC'l engineCarrier-to-intermediate shatt clearanceB188l engine818C1 engine

18.000 - 18.016 (0.7087 - 0.7093)18.000 18.018 (0.7087 - 0.7094)0.0r3 0.045 (0.0005 - 0.0018)0.0'13 - 0.047 (0.0005 0.0019)

28.000 - 28.021 \1.1024-1.1032128.005 - 28.025 (1.1026 1.'1033)0.020 - 0.062 (0.0008 0.0024)0.045 , 0.086 {0.0018 - 0.0034)

0.050 - 0.087 (0.0020 0.0034)0.075 - 0.111 (0.0030 - 0.0044)

o. t aron,0.1 {0.006}

Differentialprnron gearEacklasht. D.Pinion geaFto-pinion shaft clearance

0.05 0.15 (0.002 0.006)'18.042 - 18.066 (0.7103 0.7113)0.055 - 0.095 (0.0022 0.0037)

Adjust

0.15 {0.006)

Sel ring-to-bearing outer race clearance 81881 engin€0 - 0.10 (0 0.004)Adjust

Differential taper roller bearing preloadStarting torque N.m {kgfcm, lbf.in) Bl8Cl engine2.1r - 3.04 {21.5 - 3 r.0, 13.0- 18.7)Adjust

MEASUREMENTSTANDARO INEWISERVICE LIM]T

Difterentialcarfl€rPinion shatt contact area l.D.Carrier-to-oinion clearanceDriveshafvintermediate shaft contact are l.D.Carrier-to-driveshatt clearance

18.000 - 18.018 {0.7087 - 0.7094)0.016 - 0.052 {0.0006 - 0.0020)28.00s 28.025 {1.1026 - 1.1033)0.025 - 0.066 (0.0010 - 0.0026)

0.1 {0.004)

0.12 (0.005)

Differentialprnron gearBacklasht.D.Pinion gear-to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.042 - 18.066 (0.7r03 - 0.7113)0.059 - 0.095 (0.0023 - 0.0037)

Adjust

0.15 (0.006)

Set ring-to-bearing outer race clearance0 - 0.r5 (0 - 0.006)Adjust

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning losd at steering wheel circumferenceN {kgf, lbfl Engine running

0 - 10 {0 - 0.39)

34 \3.5,7.71

GearboxAngle of rack-guide-screw loosened from lockedposition20" i 5'

PurnpPump pressure with shut-off valve closedkPa (kgtlcm,, psi)6,400 7.400 165 75. 920 - 1. r00)

Power steeringtluidRecommended fluidFluid capacity For overhaulf (US qt, lmp q0 For fluid change

Honda power steering fluid V1.06 (1.12,0.98)

0.79 (0.83,0.70)

Power steeringbelt*Deflection with 98 N (1okgt,22lhfl

between pulleys11.5- 13.5 (0.45 0.53)with used belt8.0 - 10.010.31 0.39)with new belt

Belt tension N lkgf, lbl)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 880175 90. 170 200) with new belt

Page 32 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual MEASUFEMENTSTANDARD I]{EWI

a gnmentCamber FrontRgarCaster FrontTotaltoe FrontRearFront whe€lturning angle Inward whe€lOutwsrd wh€el

-0. 10 1 1.-0 15 l$igl1. 10�r t"0i2(010.081rN 3:i (0.121ff HONDA INTEGRA 1994 4.G Workshop Manual MEASUFEMENTSTANDARD I]{EWI

a gnmentCamber FrontRgarCaster FrontTotaltoe FrontRearFront whe€lturning angle Inward whe€lOutwsrd wh€el

-0. 10 1 1.-0 15 l$igl1. 10�r t"0i2(010.081rN 3:i (0.121ff](/img/13/6067/w960_6067-31.png)

MEASUFEMENTSTANDARD I]{EWI

a gnmentCamber FrontRgarCaster FrontTotaltoe FrontRearFront whe€lturning angle Inward whe€lOutwsrd wh€el

-0. 10' 1 1.-0' 15' l$igl1. 10'�r t"0i2(010.081rN 3:i (0.121ff)36' 0o' r 2'30. 30'

A1lc€lbearingEnd playFrontRoaa0 - 0.05 (0 - 0.002)0 - 0.05 {0 - 0.002}

Rim runout (Aluminum wheel) AxialRadialRim runout isteelwhgel) AxialRadisl

STANDARD INEWISEBVICE UMIT

0 - 0.7 {0 - 0.03)0 - 0.7 (0 - 0.03)0 - 1.0 {0 - 0.0{)0 - 1.0 (0 - 0.04)

2.0 (0.08)

1.5 (0.06)

2.0 (0.081

r.5 (0.061

SuspensionSestion 18

BrakeSection 19

Air ConditioningScction 22

.1: When using a new bek, adjust dellection or tension to new values. Run the engine tor 5 minules ihen turn it ott.

Readiust detlection or tension to lsed beh values.'2: 81881 engine'3: 818C1 engine

Unit of length: mm {in)

MEASUREMENTSTANDARD {NEWI

trrling brakePlay in strok€ at 200 N {20 kgf, 44 lbt)lever lorceTo b€ lockod when pulled 6 -10

nolchsa

; oot brake,adalPedal heighl lwith floor mat removod)

Free play

M/T160 (6.30)

155 (6.50)

1-5(0.04-0.20)

Vaster cylinderPiston-to-oushrod clearance0 - 0.4 (0 - 0.2)

f,,s4 brakeOisc thickness FrontRe6rDisc runout FrontR6arDisc parallolism Front and rear

Pad lhickness FrontRoar

STANDARD INEWISERVICE LIM]T

20.9 - 21.1 t0.82 - 0.83t8.9 - 9.1 {0.35 - 0.36)

9.5 - 10.5 {0.37 - 0.41}7.0- 8.0 {0.27 - 0.31)

19.0 (0.75)

8.0 (0.31)

0.10 (0.004)

0.r0 (0.00a)

0.015 (0.0006t

r.6 (0.06)

1.6 (0.06)

MEASUREMENTSTANDABO IT{EWI

Ar conditioningLubricant capacity mf (ll oz) Cond€nserEvaporatorLine or hoseReceiverLubricant type: NO-OlL8 {P/N 38899 - PR7 - A0l)

25 (5/6)

40 t1 1/3)10 (lBt

10 (1/31

CompressorLubricant capacity m{ (ll oz}Lubricant tvge: ND-O|L8 (P/N 38899 - PR7 - A01)Stator coil resistance at 68'F (20'C) 0Pulley-to-pressure plate clearance

140';u (4-23';")

3.4- 3.80.5 r 0.15 {0.02 r 0.006)

Compressorb€h'rDetlection with 98 N (10 kgf, 22 lbf)betlveen pulleys

7.5 - 9.5 {0.30 - 0.37)with used b€lt*'�8.5 - 10.5 {0.33 - 0.41}with t/sod belt'35.0 - 7.0 {0.20 - 0.28) with new belt

Belt t€nsion N (kgf, lbl)Measured with belt lension gauge390 - 540 {r0 - 55, 88 - 120} with used beh*'�340 - 490 {35 - 50, 77 - 110} with used belt*3740 - 880 {75 - 90, 170 - 200) with new belt

3-15

Page 34 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38 HONDA INTEGRA 1994 4.G Workshop Manual Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38](/img/13/6067/w960_6067-33.png)

Design Specifications

]TEMMETRICENGLISHNOIES

:' vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.380 mm

4.525 mm

'1,710 mm

1,335 mm

1,370 mm

2,570 mm

2,620 mm

't,475/1,470 mm

150 mm

Four (3 DOOR)

172.1in

178.1 in

67.3 in

52.6 in

101.2 in

103.1 in

5|8.1/57.9 in

Five (4 DOOR)

,rerght (usA)cross V€hicle Weight Rating {GVWR)3,680lbs

'le,ght {CANADA)Gross Vehicls Weight Rating {GVWR)1,670 kg

:\GINEType81881 engine

818C1 engine

Cylinder Arrangement

Bore and Stroke

Displacement

Compression Ratio

81881

818C1

81881

B18C I

81881

B 18C1

81881

818C1

engrne

engane

engrne

engine

engine

engine

engine

engine

L!brication Systom

OilPump Displacement

Wster Pump Displacement

FuelRequired

81881

B18C 1

81881

B 18C1

91881

engrne

engrne

engine

engine

engine

818C1 engine

Water-cooled, 4-stroke DOHC

gasoline engine

Watercooled, 4-stroke DOHC

VTEC gasoline engine

Inline 4-cylinder, transverse

81.0 x 89.0 mm

81.0 x 87.2 mm

1,834 cm3 (mf )

1,797 cm3 (m{)

3.19 x 3.50 in

3.19 x 3.43 in

112 cu-in

110 cu-in

9.2:1

10.0 : 1

Eelt driven, OOHC 4 valve per cylinder

Belt driven, DOHC VTEC

4 valve per cylinder

Forced and wet sump, trochoid pump

50, {53 US qt, 44 lmp qt)/minute'l

71 f {75 US qt, 62 lmp qt)/minute"

140 f (148 US qt, 123 lmp qt)/minute*!

140 f (148 US qt. 123 lmp qt)/minute*'

UNLEADED gasoline with 86 Pump

Octane Numb€r or higher

Premium UNLEADED gasoline wilh

91 Pump Octane Number or higher

STARTERTypo

NormalOutput

NominalVoltage

Hour Rating

Direction of Rotation

Weight

Gear reduction

1.4 kW

12V

30 seconds

Clockwise as viewed lrom g6ar end

3.7 k9 | 8.3lbs

CLUTCHClutch Type

Clutch Facing Area

M/TSingle plate dry, diaphragm spring

Torq!e converter

203 cm'� I 31 sq-in

TRANSMISSIONTransmission Type M/T

Primary Reduction

Synchronized 5-speed forward, 1 reverse

Electronically controlled

4-speed automatic. 1 rcverse

Diract 1 : 1

'1: At 6,000 engine

'2: At 7,600 engine

rpm

rpm

(cont'd)

3-17

Page 35 of 1413

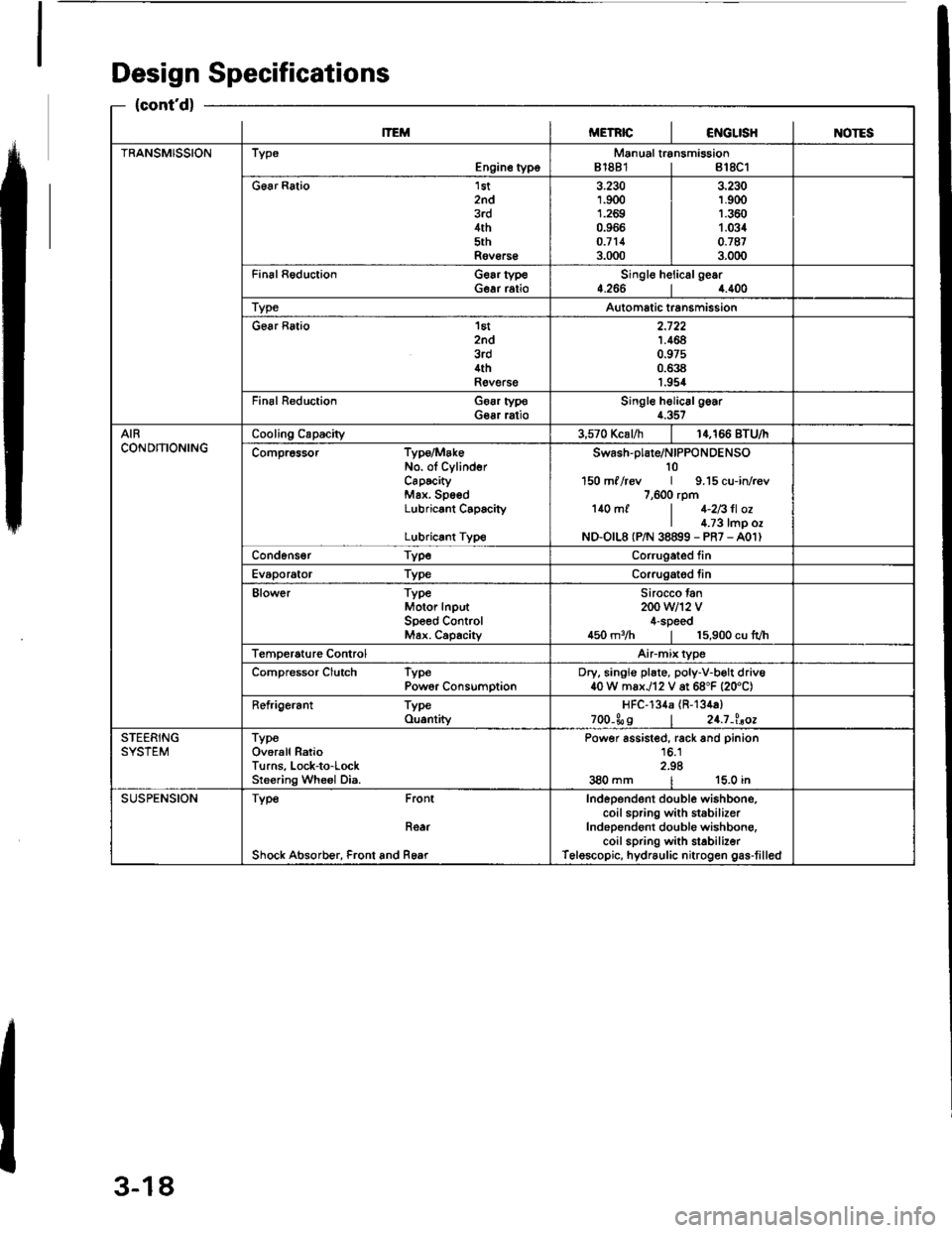

Design Specifications

{cont'd}

lTEMMETRICI€iIGLISHINOTES

TRANSMISSIONTypeEngine typoManual transmission81881 | 818C1

G6ar Ratio 1st2nd3rd4th5thRov€rs€

3.2301.9001.2690.966o.7113.000

3.230r.9(X)1.3601.0340.'t873.000

Fin6l Reduction Gear typeGear ratioSingle helicalge.r4.2664.400

TypeAutomatic transmission

Gear Ratio 'l6t

znd3rd4thRevelse

2.7221.4640.97s0.6381.954

Final R€duction Goar typoGear ratioSingle helic6lgoar4.357

AIRCONDITIONINGCooling Capacity3,570 Kcal/h14,166 BTU/I

Compr6ssor Type/MakeNo. ol CylinderCaPtcityMax. SpsedLubricant C6pacity

Lubricrnt Type

swash-plare/NIPPoNDENSO10150 ml /rcv | 9.15 cu-in/r€v7,600 rpm140 mf | 1-2Bll ozI l.;3 tmp ozND-O|L8 (P/N 38899 - PR7 - A01)

Cond6ns€r TypeCorrugated fin

Evaporator TypeCorrugatod tin

Blower TypeMotor InputSpeed ControMax. Capachy

Sirocco tan200 w12 v4-speed450 m3/h | 15,900 cu lvh

Temperature ControlAirmix type

Compressor Clutch TypePowor ConsumptionDry, singlo plate, poly-V-b€lt driv640 W max./12 V at 68"F {20'C)

Refrigerant TypeOu.ntityHFC-134a (R-134a)

zoo-Ss I 24.7-l.aoe

STEERINGSYSTEMTypeOverall RatioTurns, Lock-to-LockSreering Wheel Dia.

Power assisted, rack and pinion16.12.98380 mm | 15.0 in

SUSPENSIONType Front

Roar

Shock Absorb€r, Front and Rear

Independent double wishbono,coil spring with st6bilizerIndependont double wishbong.coil spring with stabilizerTelescopic, hydraulic nitrogen gas-tilled

3-18