charging HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1052 of 1681

Compressor

a

a

Clutch Overhaul (cont'dl

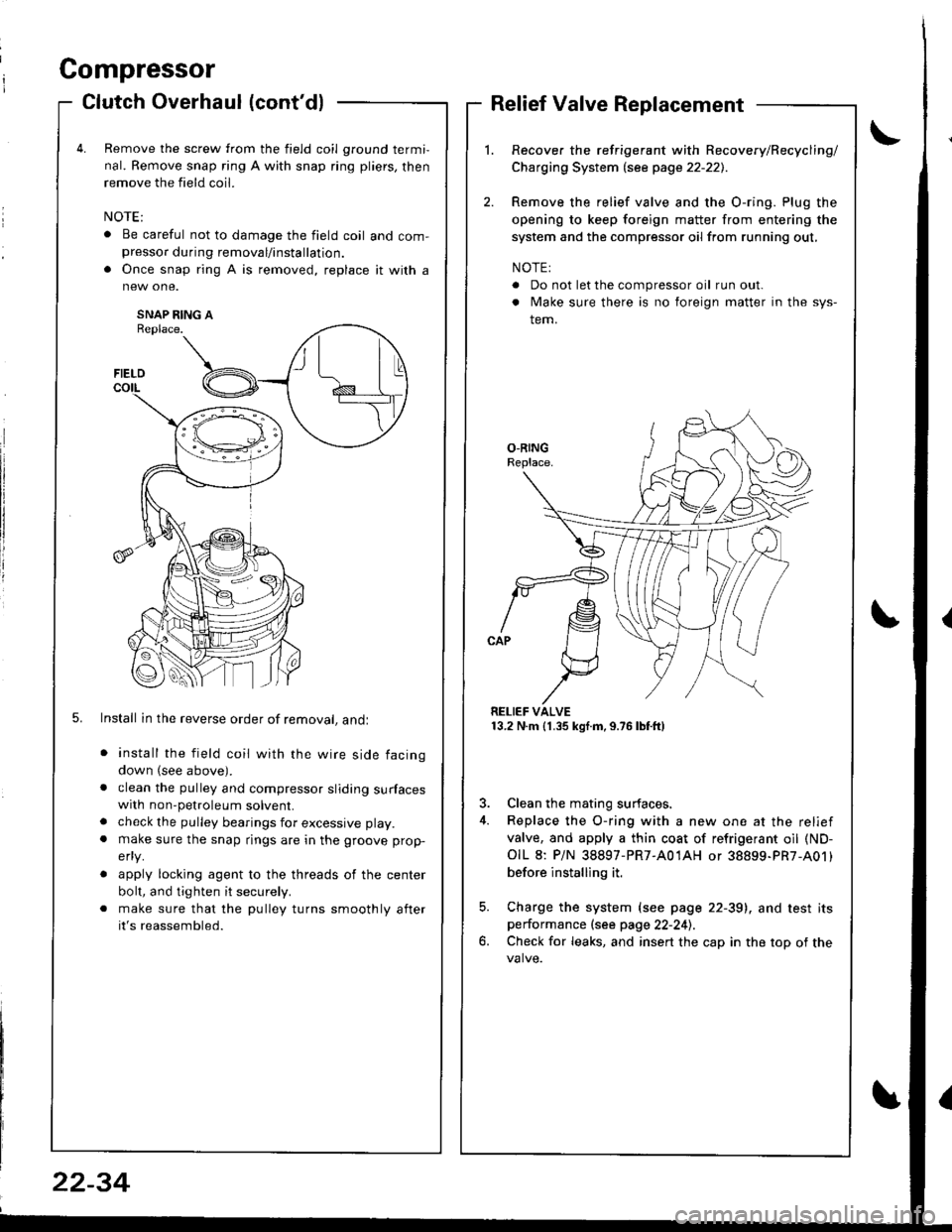

Remove the screw from the field coil ground termi,

nal. Remove snap ring A with snap ring pliers, then

remove the field coil.

. Be careful not to damage the field coil and com-presso. during removal/installation.

. Once snap ring A is removed, replace it with a

SNAP RING AReplace.

5. Install in the reverse order of removal, andl

install the field coil with the wire side facing

down (see above).

clean the pulley and compressor sliding surfaceswith non-petroleum solvent.

check the pulley bearings for excessive play.

make sure the snap rings are in the groove prop-

efly.

apply locking agent to the threads of the center

bolt, and tighten it securely.

make sure that the pulley turns smoothly after

it's reassembled.

Relief Valve Replacement

Recover the refrigerant with Recovery/Recycling/

Charging System lsee page 22-221.

Remove the relief valve and the O-ring. Plug the

opening to keep foreign matter from entering the

system and the compressor oil from running out,

NOTE:

. Do not let the compressor oil run out.

. Make sure there is no foreign matter in the sys-

tem.

RELIEF VALVE13.2 N.m (1.35 kgf.m,9.76lbtft)

3. Clean the mating surfaces.

4. Replace the O-ring with a new one at the relief

valve, and apply a thin coat of refrigerant oil (ND-

OIL 8: P/N 38897-PR7-A01AH or 38899-PR7-A01)

before installing it.

5. Charge the system (see page 22-39), and test itsperformance (see page 22-241.

6. Check for leaks, and insert the cap in the top of the

FIELD

t\I lu

B _t_:---\-lr

\,/

22-34

Page 1055 of 1681

Condenser

J

Replacement

RADIATOR UPPERMOUNT BRACKETS

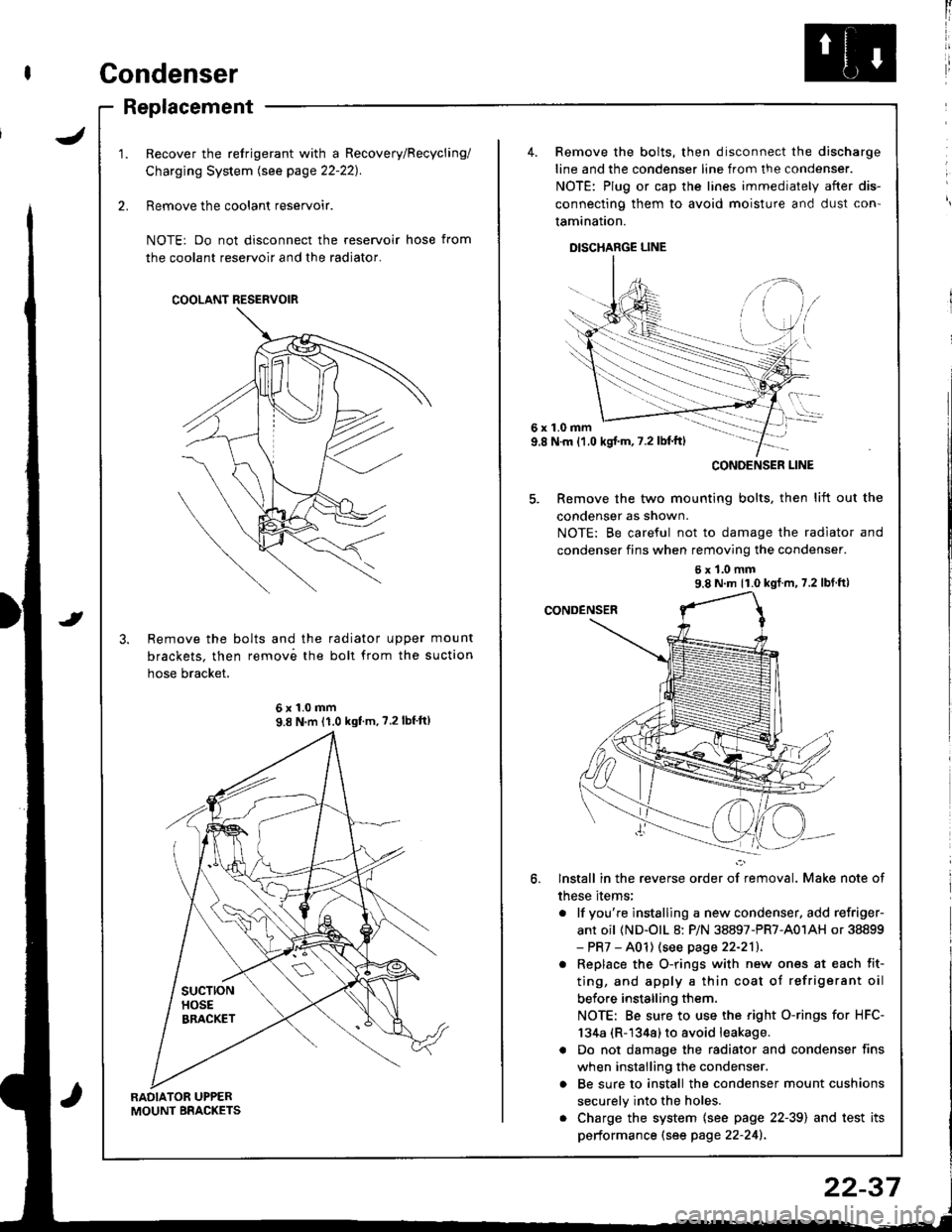

Recover the refrigerant with a Recovery/Recycling/

Charging System lsee page 22-221.

Remove the coolant reservoir.

NOTE: Do not disconnect the reservoir hose from

the coolant reservoir and the radiator.

Remove the bolts and the radiator upper mount

brackets. then remov6 the boll from the suction

hose bracket.

COOLANT RESERVOIR

6x1.0mm9.8 N'm 11.0 kgf'm, ?.2lbf'ft)

4. Remove the bolts, then disconnect the discharge

line and the condenser line from the condenser.

NOTE: Plug or cap the lines immediately after dis-

connecting them to avoid moisture and dust con'

tamination.

DISCHARGE LINE

6x1.0mm9.8 N.m {1.0 kgj'm, 7.2 lbl'ft)

5. Remove the two mounting bolts, then lift out the

condenser as shown.

NOTE: Be careful not to damage the radiator and

condenser fins when removing the condenser.

6x1.0mm9.8 N m 11.0 kgf m, 7.2 lbf ft)

lnstall in the reverse order of removal. Make note of

these items;

. lf you're instslling a new condenser, add refriger-

ant oil (ND-olL 8: P/N 38897-PR7-A01AH or 38899- PR7 - A01) (see page 22-211.

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-1344) to avoid leakage.

a Do not damage the radiator and condenser fins

when installing the condenser.

o Be sure to install the condenser mount cushions

securely into the holes.

. Charge the system {see page 22-39) and test its

performance (see page 22-241.

CONOENSER LINE

22-37

Page 1056 of 1681

A/C System Service

Evacuation

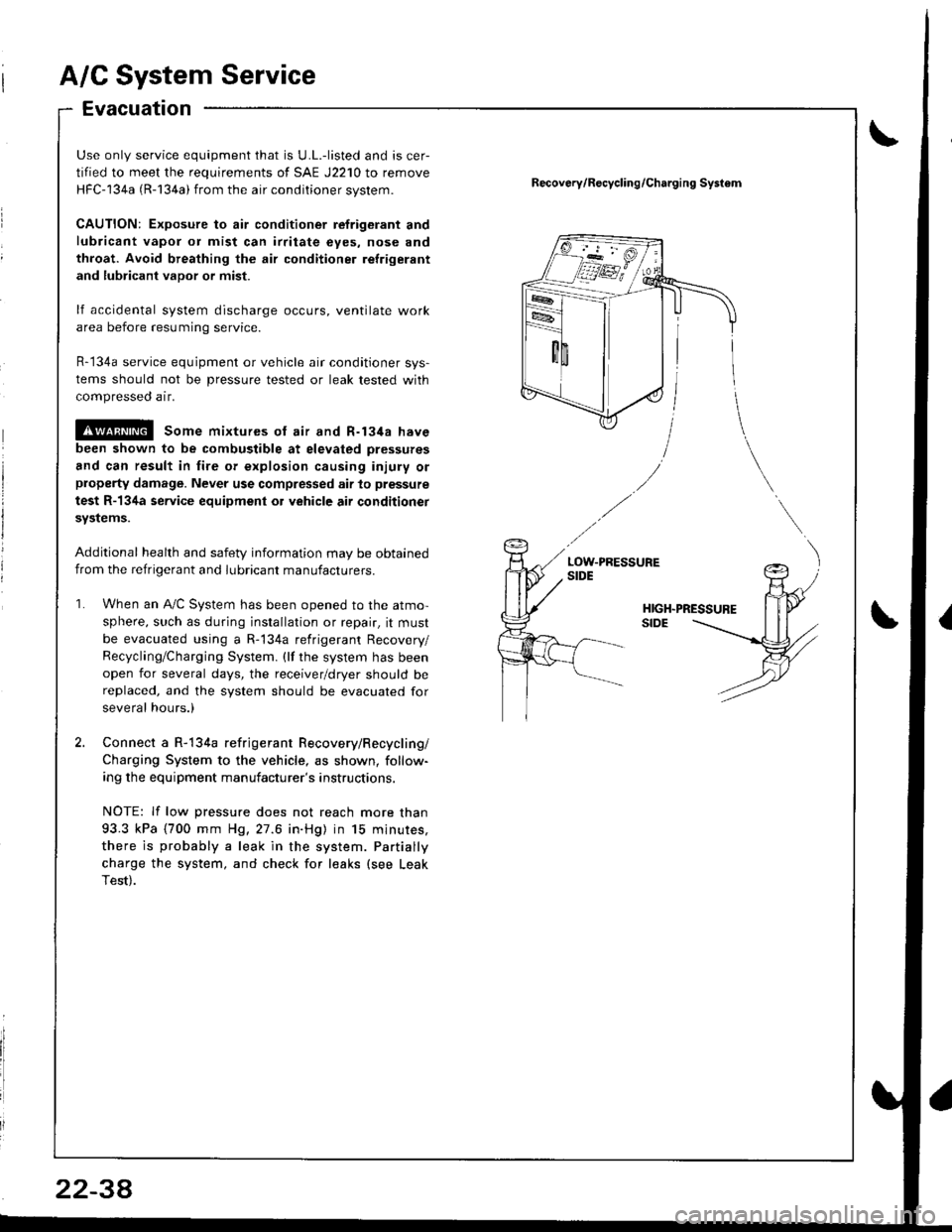

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstem.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irtitate eyes, nose and

throat. Avoid breathing the air conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

!@@l some mixtures ot air and R-t3ita have

been shown to be combustible at elevated pressures

and can result in fire of explosion causing injury orproperty damage. Never use compressed air to pressure

test R-134a service equipment or vehicle air conditionet

svstems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

When an A"/C Svstem has been ooened to the atmo-

sphere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant Recovery/

Recycling/Charging System. (lf the system has been

open for several days, the receiver/dryer should bereplaced, and the system should be evacuated for

several hours.)

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, follow-

ing the equipment manufacturer's instructions.

NOTE: lf low pressure does not reach more than

93.3 kPa (700 mm H9,27.6 in.Hg) in 15 minures,

there is probably a leak in the system. Partially

charge the system, and check for leaks (see Leak

Test).

Recov6ry/R€cycling/Charging Systom

2234

Page 1057 of 1681

I

I

ChargingLeak Test

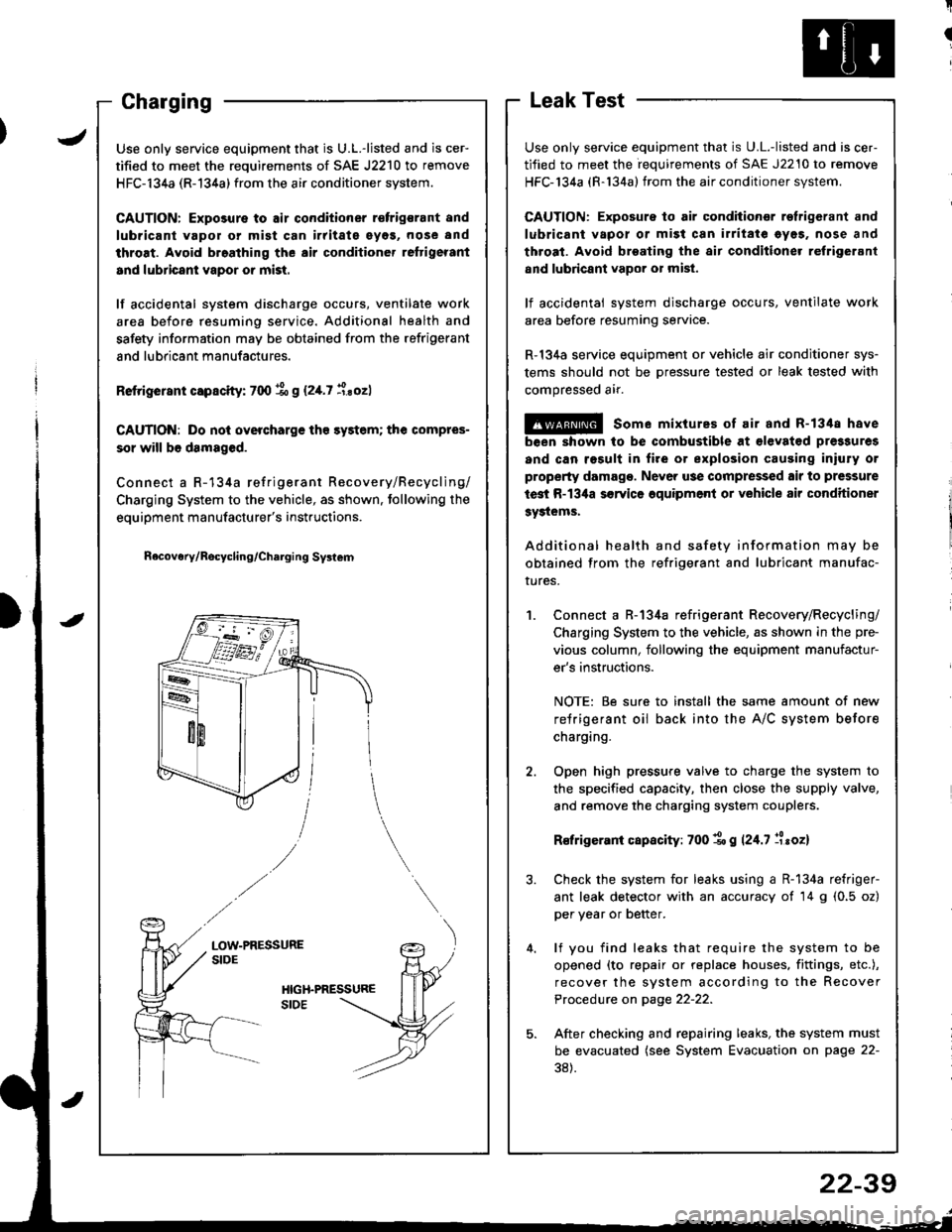

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrig6rant and

lubricant vapol or mist can irritate eyes. nose and

throat. Avoid broating the air conditione. relrigerant

and lubricant vapor o; mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

@ some mixtures of air and R-1348 have

been shown to be combustible at €levat€d pre3sures

and can rosult in fire or explosion causing iniury or

property damage. Never use compressed air to pressure

test R-134a s€rvics oquipment or vehicle air conditioner

Systems.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufac-

rures.

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before

charging.

Open high pressure valve to charge the system to

the specified capacity, then close the supply valve,

and remove the charging system couplers.

R€frigerani capacity: 700 1o g 124.7 llroz)

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 g (0.5 oz)

per year or better.

lf you find leaks that require the system to be

opened (to repair or replace houses. fittings, etc.),

recover the system according to the Recover

Procedure on page 22-22.

After checking and repairing leaks, the system must

be evacuated (see System Evacuation on page 22-

38).

JUse only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner r€frigsrant and

lubricant vapol or mist can irritate eyos, nose and

throat. Avoid broathing the air conditioner reftigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service. Additional health and

safety information may be obtained from the refrigerant

and lubricant manufactures.

Retrigerant capscity: 700 % g (2,[.7 i.sozl

CAUTION: Do nol overcharge tho sy3tem; the compres-

sor will b6 damaged.

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown. tollowing the

equipment manufacturer's instructions.

n6covery/Rocycling/Charging Svslem

LOW-PRESSURESIDE

22-39

Page 1106 of 1681

T

I

1

J)

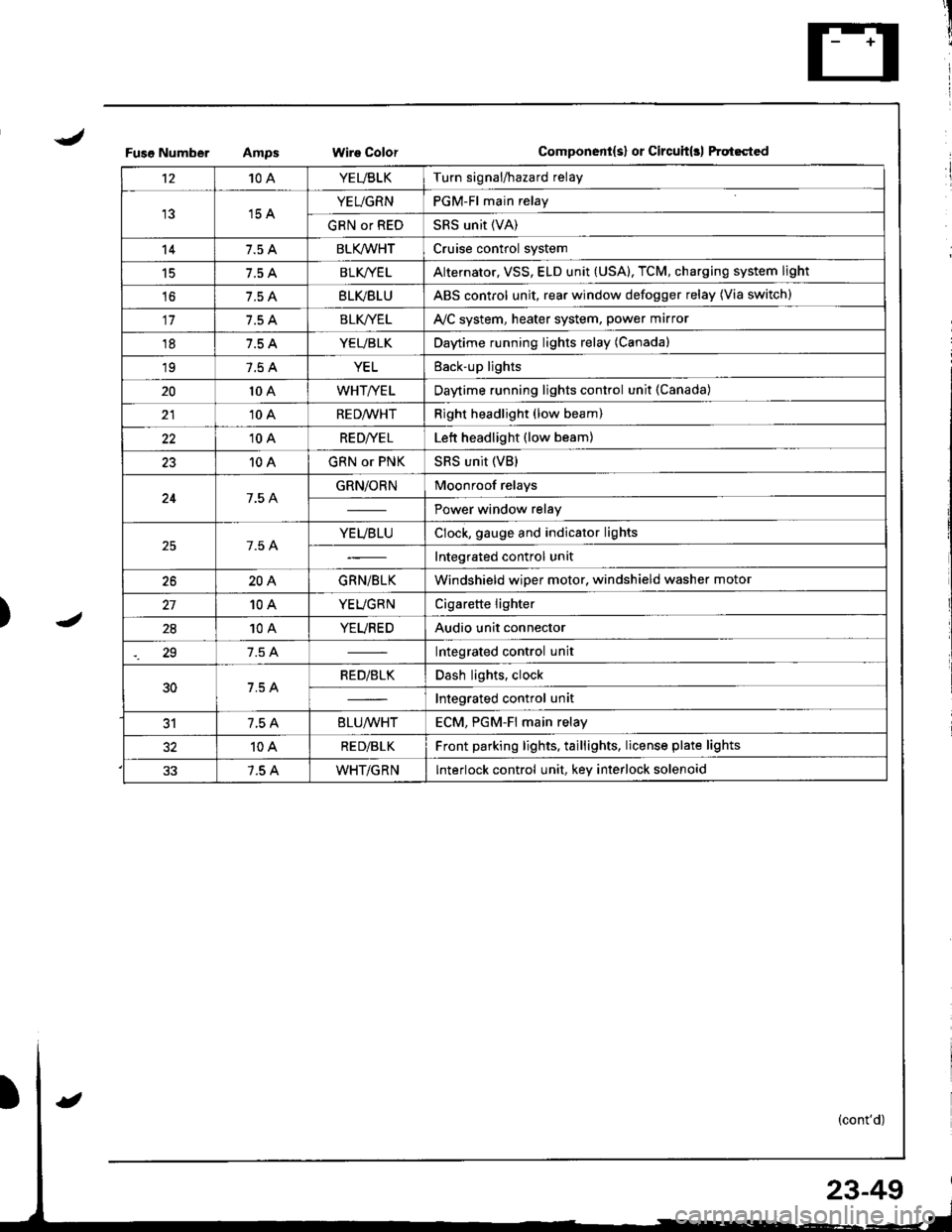

Fuso NumberWire ColorComponent{s} or Circuit(rl ftqt6cted

't210AYEUBLKTurn signal/hazard relay

15 AYEUGRNPGM-Fl main relay

GRN or REDSRS unit (VA)

147.5 ABLK/WHTCruise control system

15BLK/YE LAlternator, VSS, ELD unit (USA), TCM, charging system light

't67.5 ABLVBLUABS control unit, rear window defogger relay (Via switch)

117.5 ABLK//ELAVC system, heater system, power marror

187.5 AYEUBLKDaytime running lights relay (Canada)

197.5 AYELEack-up lights

2010 AWHT/YELDaytime running lights control unit (Canada)

2110 ARED/WHTRight headlight (low beam)

2210 ARE D|YE LLett headlight (low beam)

2310 AGRN or PNKSRS unit (VB)

247.5 AGRN/ORNMoonroof relays

Power window relay

7.5 AYEUBLUClock, gauge and indicator lights

Integrated control unit

2620AGRN/BLKWindshield wiper motor, windshield washer motor

10AYEUGRNCigarette lighter

2810AYEUREDAudio unit connector

29Integrated control unit

30RED/BLKDash lights, clock

Integrated control unit

317.5 A8LU/WHTECM. PGM-Fl main relav

10ARE D/BLKFront parking lights, taillights, license plate lights

7.5 AWHT/GRNInterlock control unit, key interlock solenoid

23-49

Page 1113 of 1681

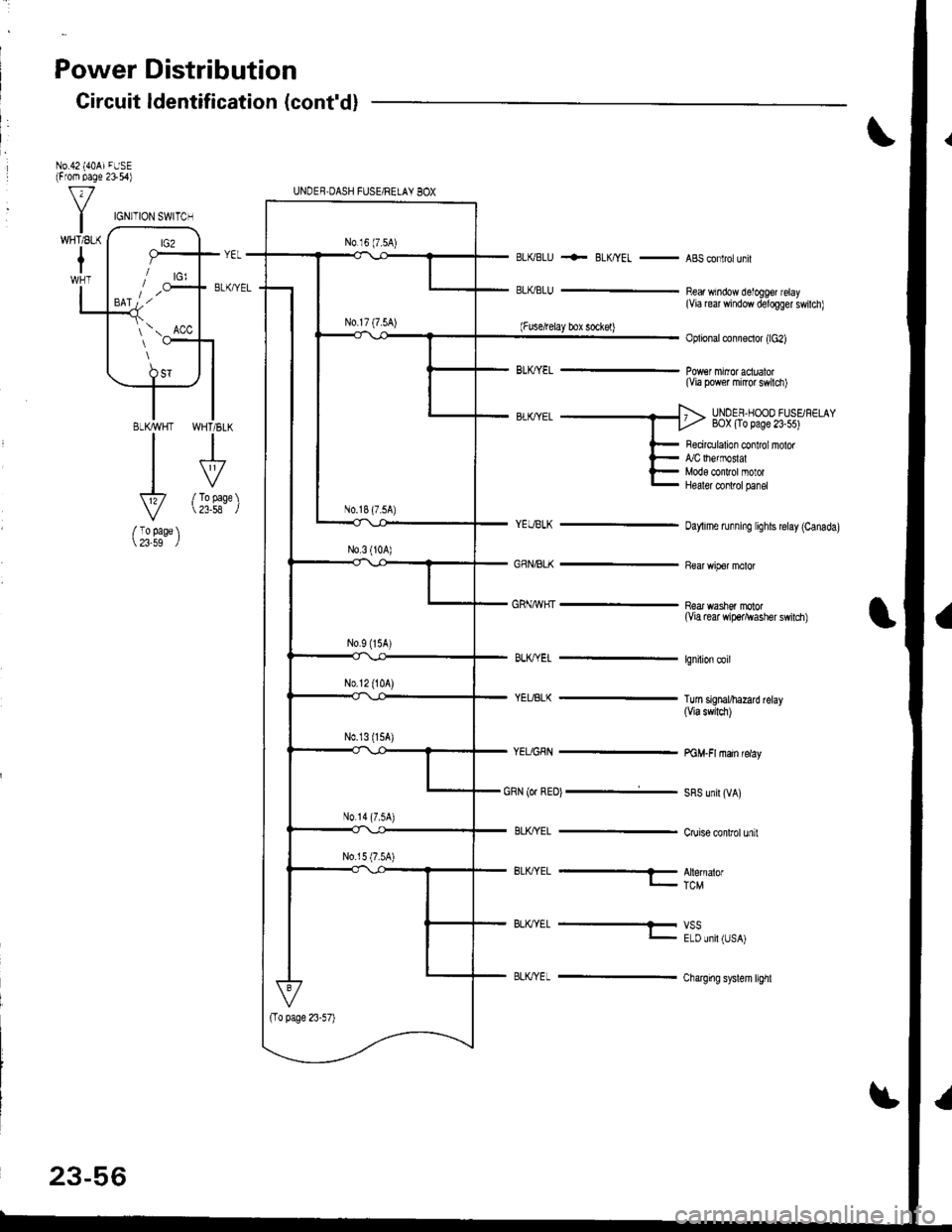

Power Distribution

Gircuit ldentification (cont'd)

No.42 {40AiFUSE(From page 2154)

BLKBLU

ELKBLU

+- BLK/YEL -ABSconlrolunil

Bear window detoggef relay(Via re window delogger swilch)

Oplional connoctor (lc2)

(Via power mircr swilch)

UNOEF,HOOO FUSSF€LAYBOX (To page 23-55)

I

VTo page23-58

BLKWHT

I

V

/ To page 23-59

(Fuse,telay box sockel)

cRN {or REot -i-

BLK'YEL -

Recirdlalion conlrol nolof,/C lhefmoslalMods conlrol motorHealer conlrol panel

oaylime running lights relay (Canada)

near washor molor(Via rear wiper^vasher swilch)

lgnilion coil

Tuln signal/harad relay(via swrtcl)

PGM.FI main relay

SRS unil (VA)

Cruise conlrol unit

BLK,TYEL --- Alernalorr_. TcM

BLK/YEL ---t- vss- E-D Jril (JSAj

Charging syslem l€hl

UNDEB-DASH FIJSE/RELAY BOX

N0.18 (7.5A)

N0.14 (7.5A)

IGN]TION SWI'TCH

\ Acc

23-56

Page 1156 of 1681

)

)

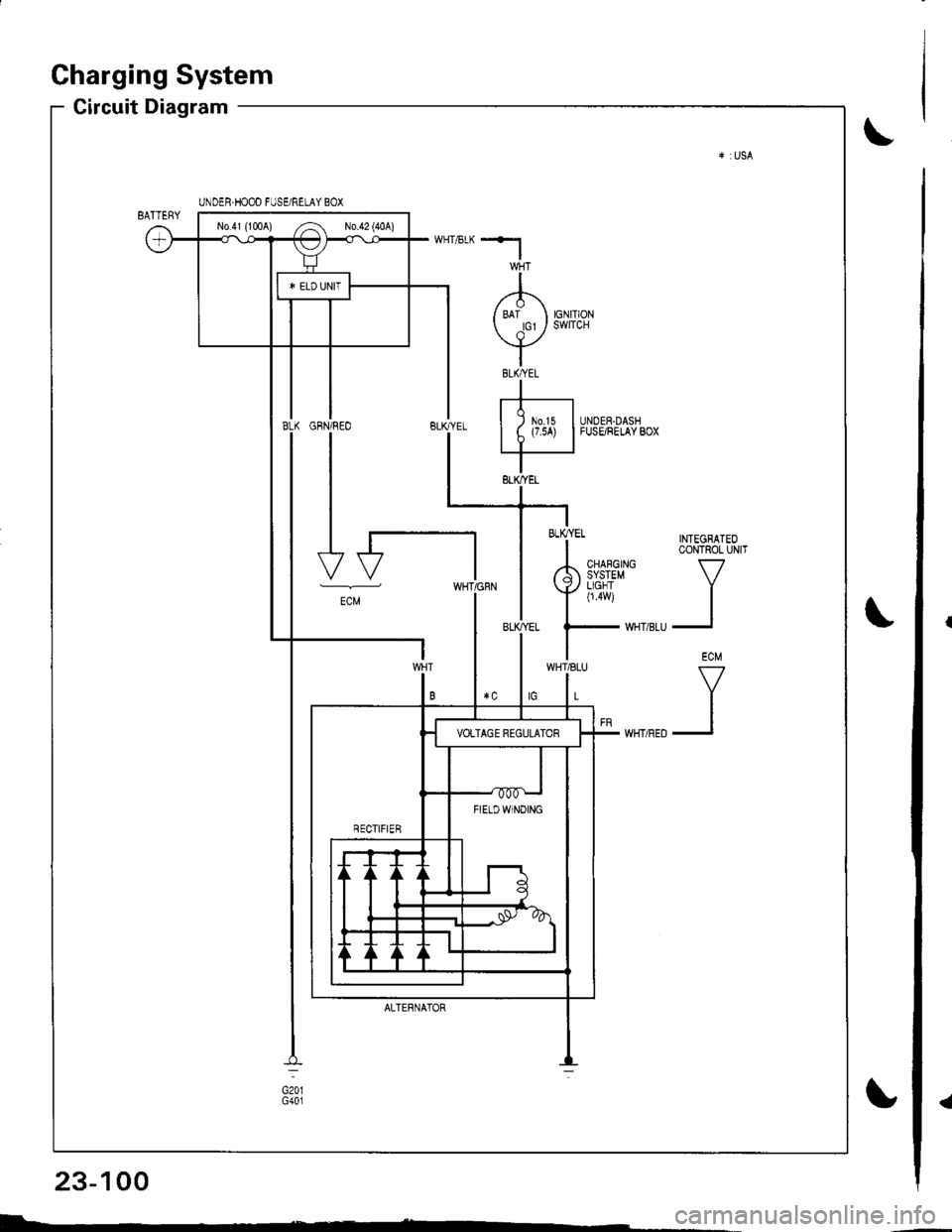

Charging System

Component Locationlndex

CHARGING SYSTEM LIGHT(ln the gauge assembly)Test, pages 23-102,103Bulb Locations, page 23-122

UNDER-HOOD FUSE/RELAY BOX(USA: HAS bUiIt-iN ELECTRICALLOAD DETECTOR (ELD) UNIT}Troubleshooting of ELD, secrion 11

BATTERYTest,

ALTERNATOR BELTInsp€ction and Adiustment, page 23_115ALTERNATORTroubleshooting, page 23'102Alternator/FegulatorTosl, pages 23-105,'106Replacement, page 107Overhaul, page 23-108

23-99

.t-

Page 1157 of 1681

a

Charging System

Circuit Diagram

INTEGRATEOCONTROL UNIT

V

II

ECM

V

II

UNDER.HOOD FUSE/RELAY BOX

No41 (1tl0A) /^ N0.42 (40A)

FIETDWINOING

WHT/8LU

L

GFN/REO

I

I

I

I-t

-"

ALTERNATOR

BLK/YEL

23-100

I-

Page 1159 of 1681

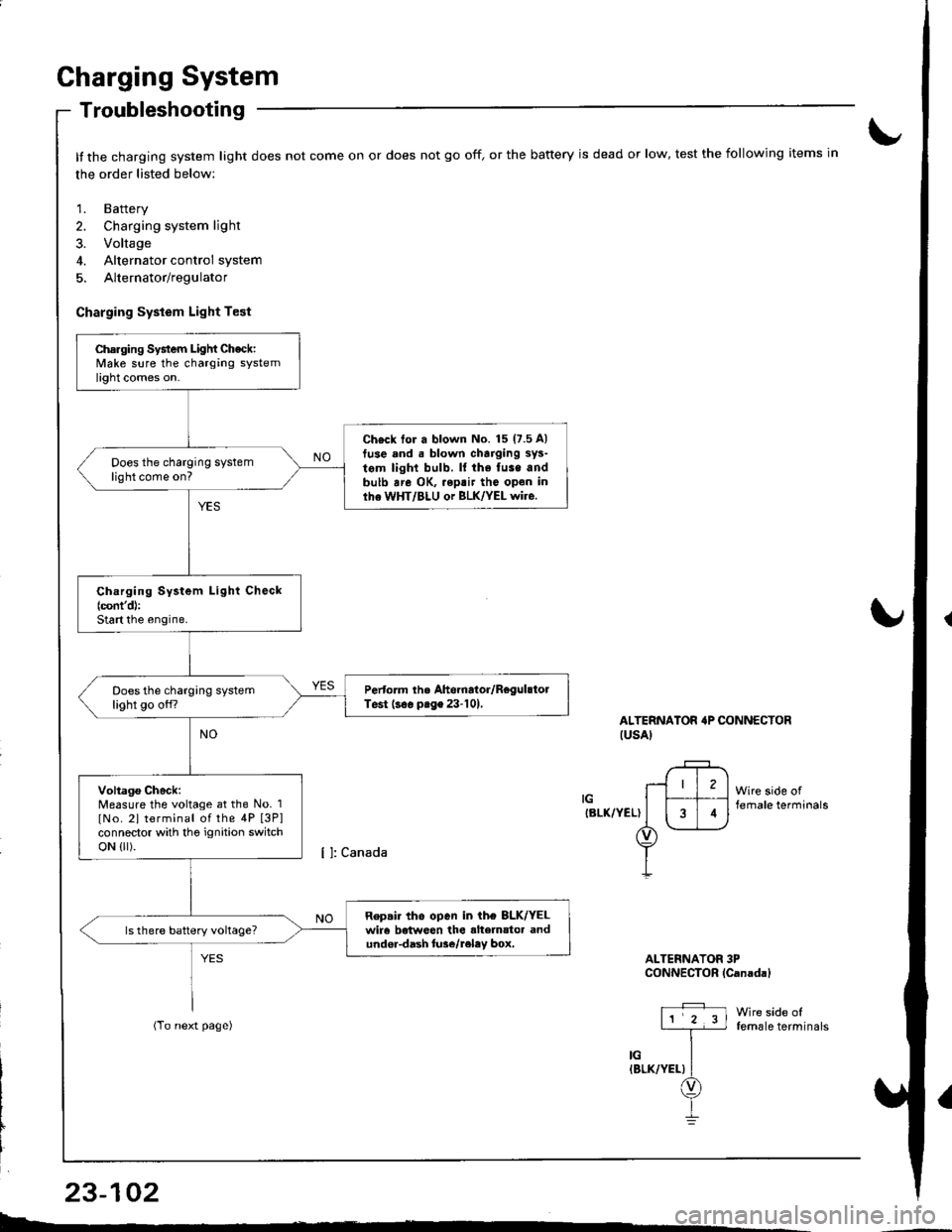

Charging System

Troubleshooting

It the charging system light does not come on or does not go off, or the battery is dead or low, test the following items in

the order listed below:

1. Battery

2. Charging system light

3. Voltage

4. Alternator control system

5. Alternator/regulator

Charging System Light Test

ALTERNATOR'P CONNECTORIUSAI

IGIBLK/YEL)

Wire side offemale terminals

Wire side offemale terminals

ALTERNATOR 3PCONNECTOR lCanadal

Charging System Light Check:Make sure the charging systemlight comes on.

Ch€ck tor a blown No. 15 (7.5 A)

tuse and . blown charging sys-

tem light bulb. ll the fuse andbulb are OK, .eptir tho open inlhe WHT/BLU or BLK/YEL wire.

Does the charging systemlight come on?

Ch.rging System Light Check(cont'd):

Start the engine.

Pertorm the Ahernator/RegulstolTest (s€. prge 23-101,Does the charging systemlight go off?

Voltago Check:Measure the voltage at the No. 1

lNo. 2l terminal of the 4P [3P]connector with tho ignition switchoN {lr).

Repair tho open in ih€ 8LK/YELwir6 betweon the alte]nator andundor-dash lure/reley box.

I4

L-*

23-102

Page 1160 of 1681

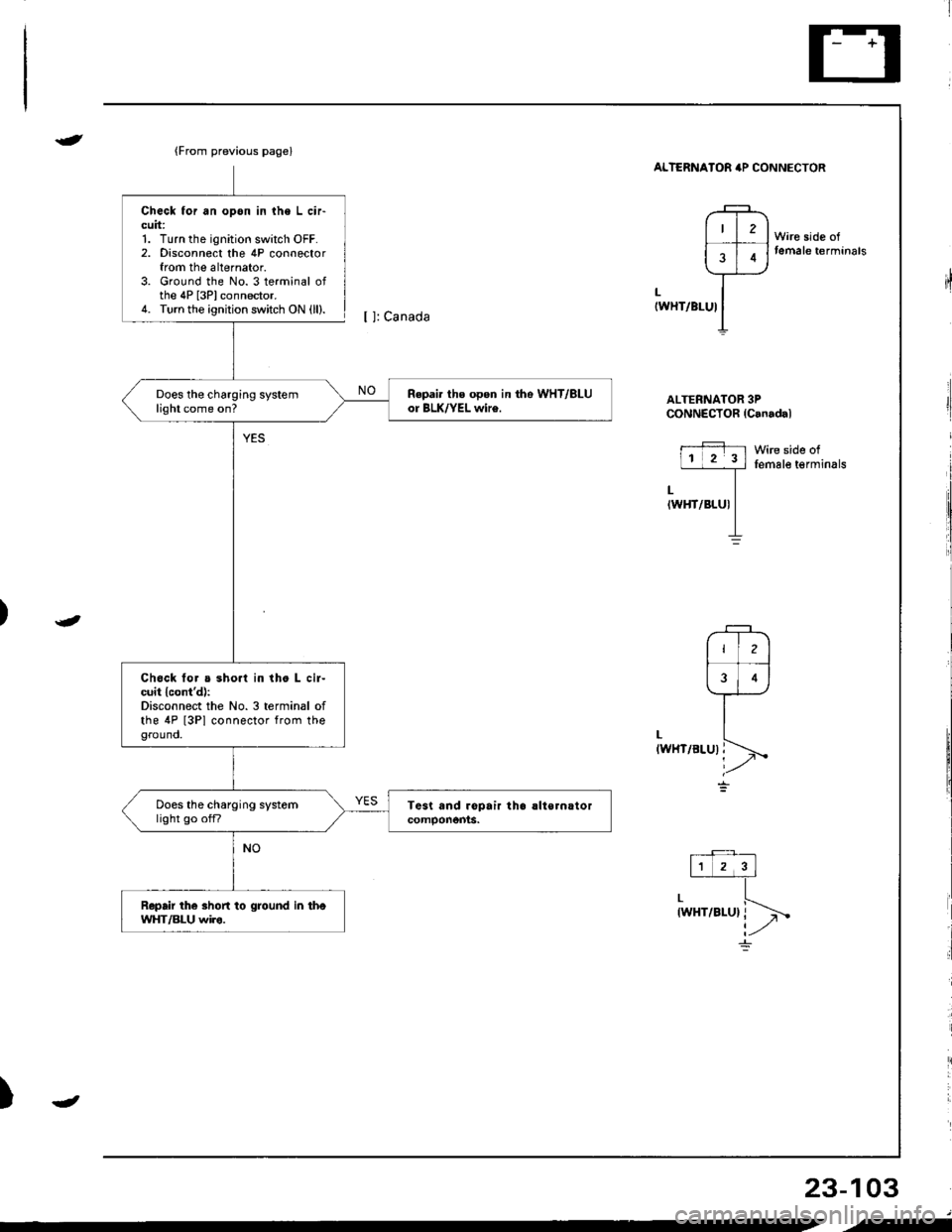

{From previous page}

Repai. ths open in tho WHT/ALUor BLK/YEL wir€.Does the charging systemlight come on?

Chock tor a sho.l in the L cir-cuit lcont'd):Disconnect the No.3 terminal ofthe 4P [3Pl connector from theground.

Does the charging systemlight go offi

Repair the shon to ground in thoWHT/BLU wiro.

{

t

Check for an opon in lhe L cir-cuit:1. Turn the ignition switch OFF.2. Disconnect the 4P connectorfrom the alternator.3. Ground the No. 3 terminal ofthe 4P [3Plconnector.4. Turn the ignition switch ON (ll).

ALTERNATOB irP CONNECTOR

ALTERNATOR 3PCONNECTOR {Canadal

11 2 3l

,l

iin"vr.rr\

Wire side oftemale t€rminals

[ ]: Canada

LIWHT/BLUI

LIWHT/BLU)

Wire side offemale terminals

)

23-103

4

--