coolant temperature HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 247 of 1681

1l

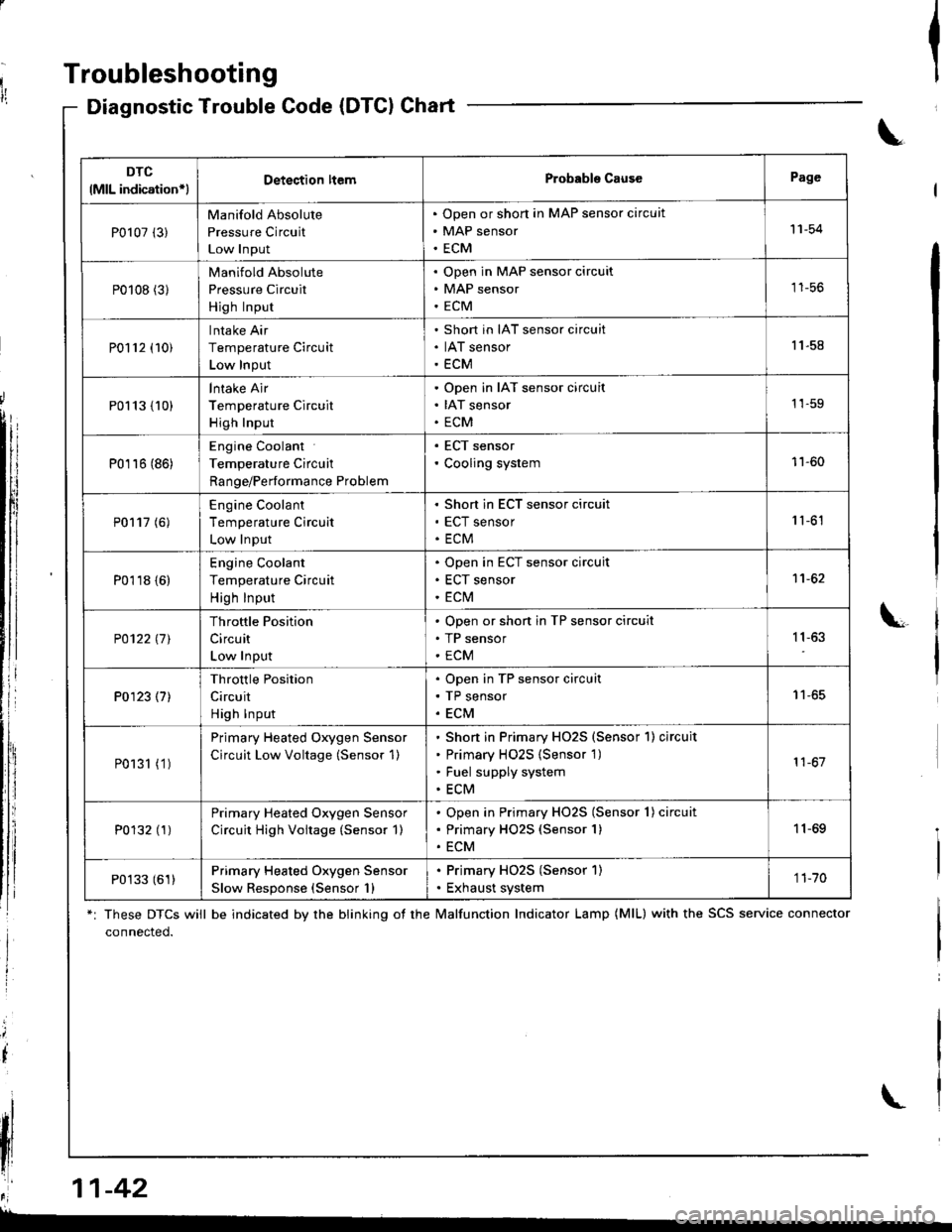

Troubleshooting

Diagnostic Trouble Gode (DTCI Chart

*: These DTCS will be indicated by the blinking ot the lvalfunction Indicator Lamp (MlL) with the SCS service connector

connected.

Ia

\

\

il

\

DTC

lMlL indication*lDetection ltemProbabls CausePage

P0107 (3)

Manifold Absolute

Pressure Circuit

Low Input

Open or short in MAP sensor circuit

MAP sensor

ECM

'11-54

P0108 (31

Manifold Absolute

Pressure Circuit

High Input

Open in MAP sensor circuit

MAP sensor

ECM

tt-5t,

P0112 (10)

Intake Air

Temperature Circuit

Low Input

Short in IAT sensor circuit

IAT sensor

ECM

11.58

P0113 {10)

lntake Air

Temperature Circuit

High Input

Open in IAT sensor circuit

IAT sensor

ECM

1'�1-59

P0116 (86)

Engine Coolant

Temperature Circuit

Range/Performance Problem

. ECT sensor' Cooling system11-60

P0117 (6)

Engine Coolant

Temperature Circuit

Low Input

Short in ECT sensor circuit

ECT sensor

ECM

1 '�t-61

P0118 {6)

Engine Coolant

Temperature Circuit

High Input

Open in ECT sensor circuit

ECT sensor

ECt\,4

1't -62

P0122l7l

Throttle Position

Circuit

Low Input

Open or shon in TP sensor circuit

TP sensor

ECM

11,63

P0123 (7)

Throttle Position

Circuit

High Input

Open in TP sensor circuit

TP sensor

ECM

I t-oc

P0131 (1 )

Primary Heated Oxygen Sensor

Circuit Low Voltage (Sensor 1)

Shon in Primary HO2S (Sensor'l) circuit

Primary H02S {Sensor 1)

Fuel supply system

ECM

11-67

P0132 (1)Primary Heated Oxygen Sensor

Circuit High Voitage (Sensor 1)

Open in Primary HO2S (Sensor 1) circuit

Primary HO2S (Sensor 1)

ECM

11-69

P0133 (61)Primary Heated Oxygen Sensor

Slow Response (Sensor 1)

. Primary HO2S (Sensor 1). Exhaust system1 1-70

,r:' 11-42

L

Page 253 of 1681

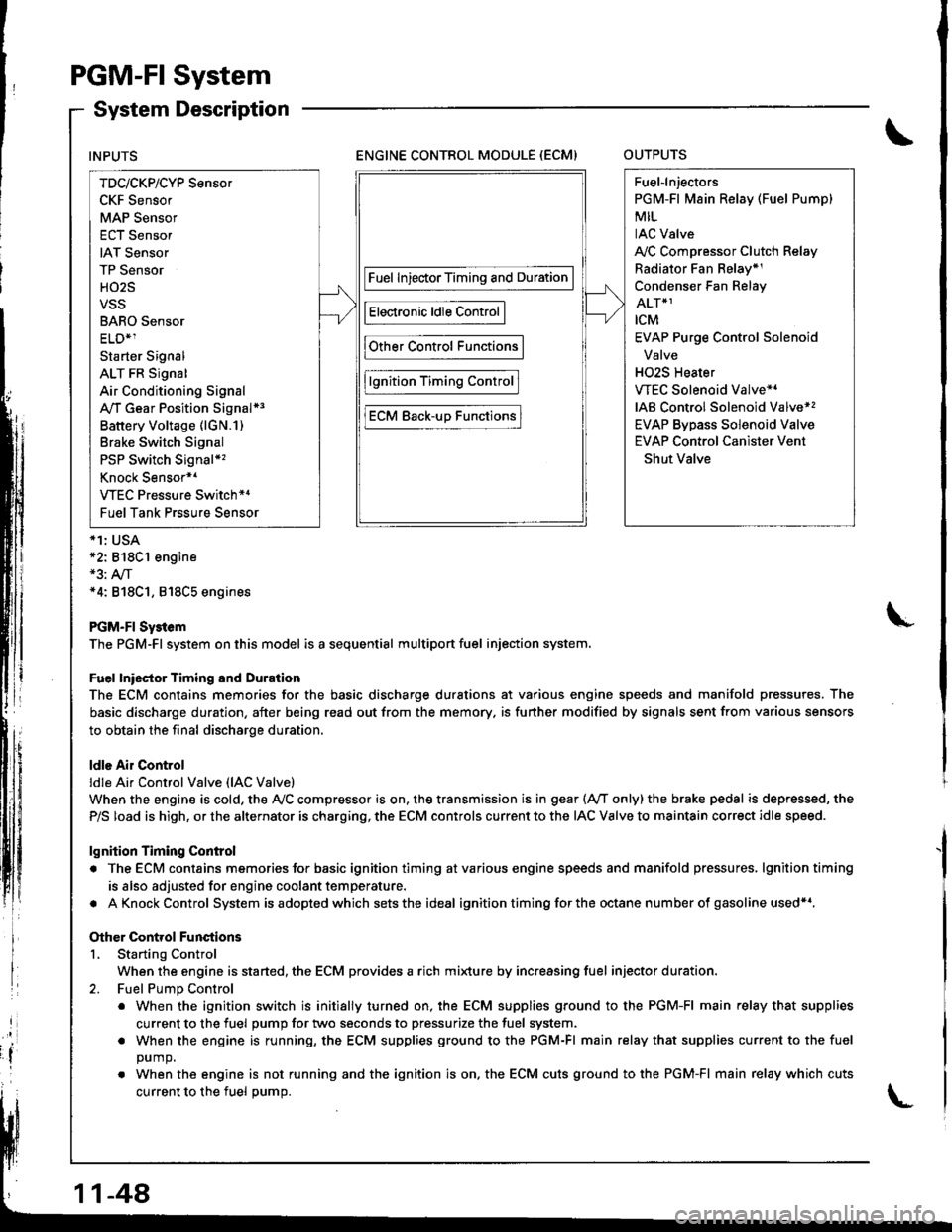

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECM)OUTPUTS

*1: USA*2: 818C1 engine*3: A,/T*4: 818C1, 818C5 engines

PGM-FI Sy3tem

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel lniector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory. is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Ai. Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on. the transmission is in gear (Ay'T only)the brake pedal is depressed, the

P/S load is high, or the alternator is charging, the ECM controls current to the IAC Valve to maintain correct idle speed.

lgnition Timing Control

. The ECM contains memories for basic ignition timing atvarious engine speeds and manifold pressures, lgnitiontiming

is also adjusted for engine coolant temperature.

. AKnockControl System isadoptedwhich sets the ideal ignition timing for the octane n um ber of gasoline used*r,

Other Control Functions

L Starting Control

When the engine is started, the ECM provides a rich mi{ure by increasing fuel injector duration.

2. Fuel PumD Control

. When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel

DUmO.

. When the engine is not running and the ignition is on. the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel oumo.

INPUTS

TDc/CKP/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

HO2S

VSS

BARO Sensor

ELD*1

Starter Signal

ALT FR Signal

Air Conditioning Signal

A,/T Gear Position Signal*3

Battery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal*'�

Knock Sensor*1

VTEC Pressure Switch*4

Fuel Tank Prssure Sensor

Fuel InjectorTiming and Duration

Electronic ldle Control

Other Control Functions

lgnition Timing Control

ECM Back-uD Functions

Fuel-lnjectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

A,/C Compressor Clutch Relay

Radiator Fan Belay*1

Condenser Fan Relay

ALT*1

rcM

EVAP Purge Control Solenoid

Valve

H02S Heater

VTEC Solenoid Valve*'

IAB Control Solenoid Valve*,

EVAP Bypass Solenoid Valve

EVAP Control Canister Vent

Shut Valve

11-48

Page 265 of 1681

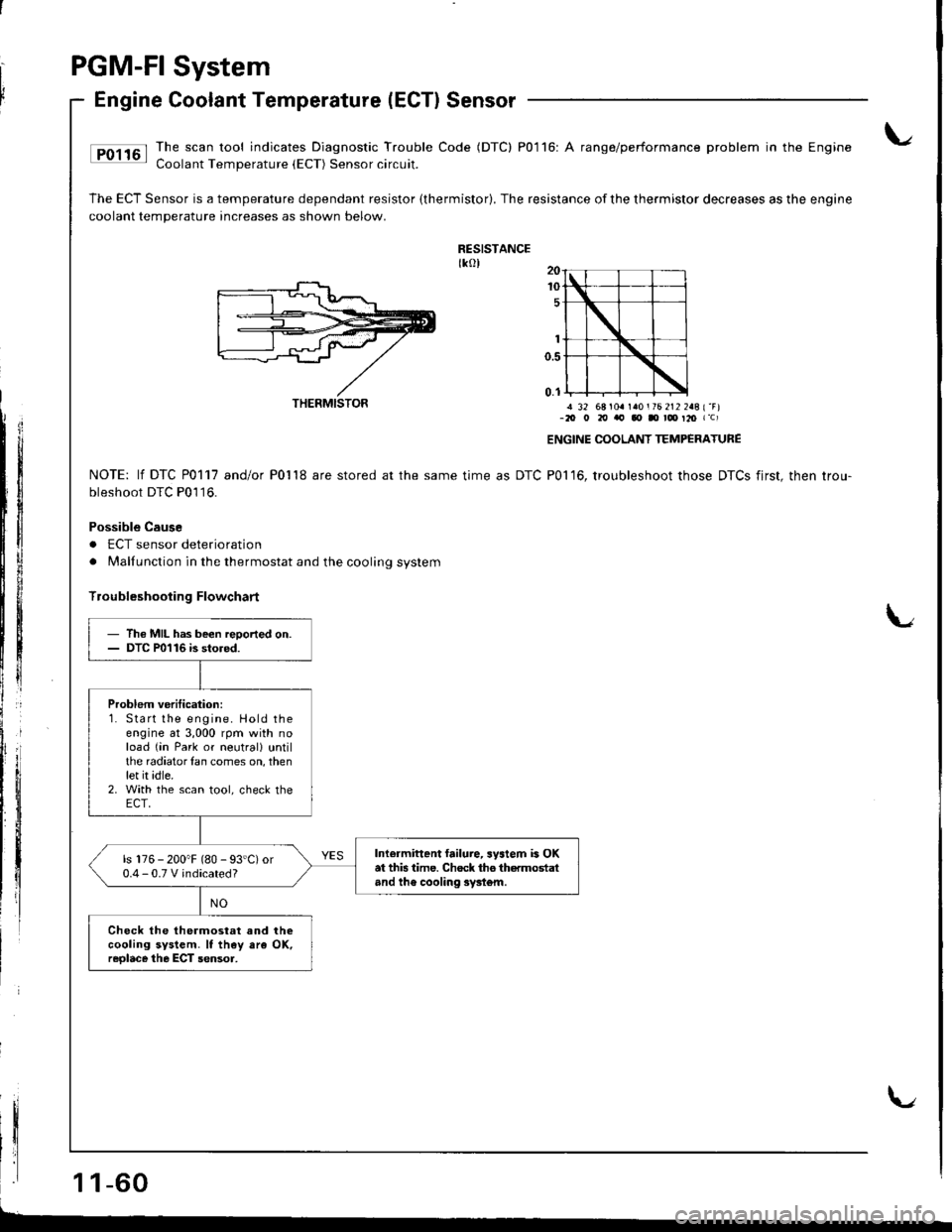

PGM-FI System

Engine Coolant Temperature (ECTI Sensor

Ip01161 Ihe,scaltool indicates Diagnostic Trouble Code (DTC) P0116: A range/performance problem in the Engine: Coolant Temperature {ECT) Sensor circuit.

The ECT Sensor is a temperature dependant resistor (thermistor). The resistance of the thermistor decreases as the engine

coolant temperature increases as shown below.

RESISTANCEtkol

! 32 68 104 140 i 76 212 248 { "F)-20 o 20 'ra, qt Il rd' t20 r'c)

ENGINE COOLANT TEMP€RATURE

P01 16, troubleshoot those DTCS first, then trou-NOTE: lf DTC P0117 andlo( Po'l'18 are stored at the same time as DTC

bleshoot DTC P0'l16.

Possible Cause

. ECT sensor deterioration

. Malfunction in the thermostat and the cooling system

lroubleshooting Flowchart

I

1 1-60

THERMISTOR

- Th€ MIL has been reoorted on.- DTC P0116 is stored.

Problem veritication:1. Start lhe engine. Hold theengine at 3,000 rpm with noload (in Park or neutrall untilthe radiatorlan comes on, thenlet it idle.2. With the scan tool, check theECT,

Inlermittent failure, system is OKat this time. Chock tho thermostaland th€ cooling syst6m.

ls 176 - 200"F (80 - 93'C) or0.4-0.TVindicated?

Check the thermostat and thecooling system. It th€y ara OK,reolace the ECT sensor,

Page 266 of 1681

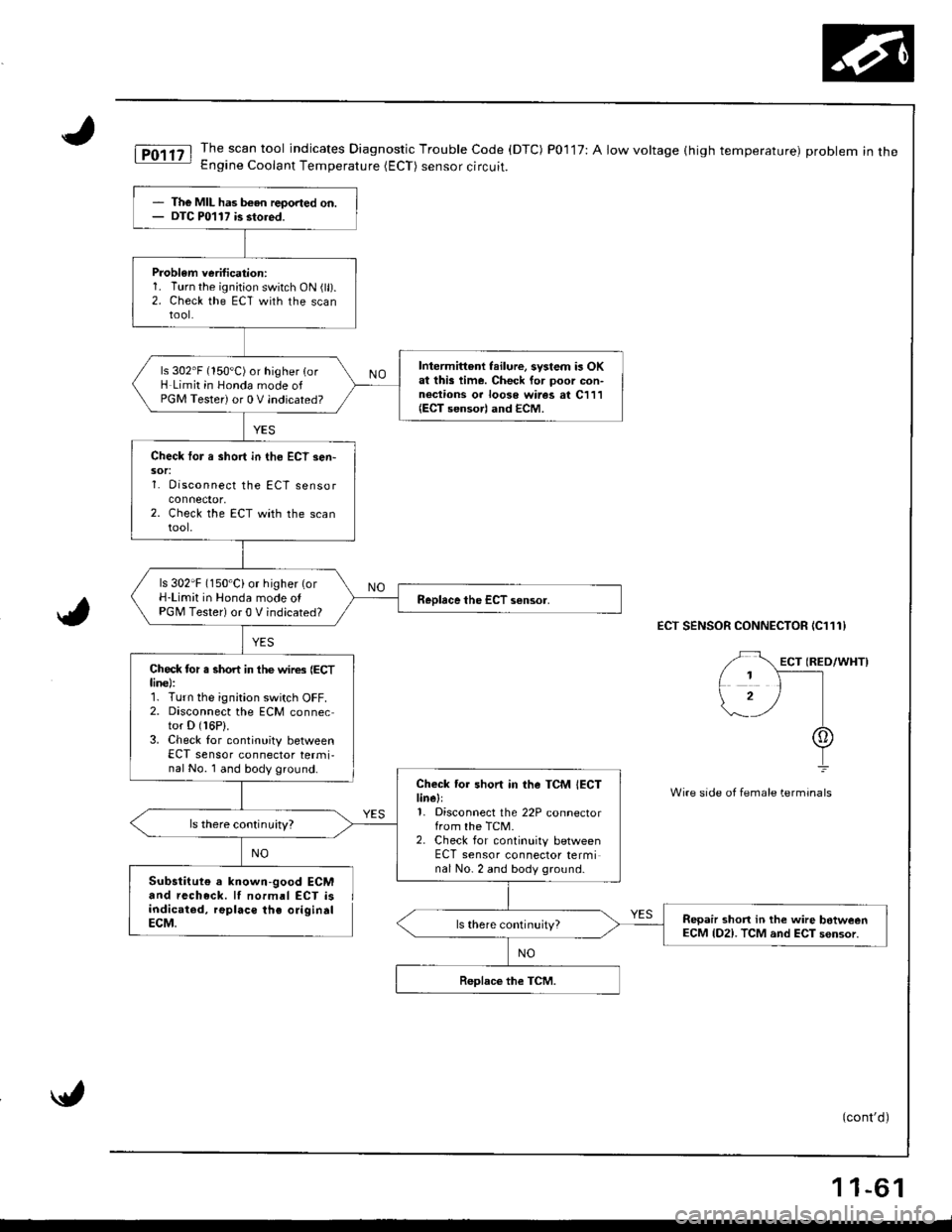

The MIL has b€en reoorted on.DTC P0117 is stored.

Problem verification:1. Turn the ignition switch ON (ll).2. Check the ECT with the scantool.

Intermittent failure, system is OKat this time. Check for poor con-nections or looso wires at C111(ECT sensorl and ECM.

ls 302'F (150'C) or higher {orH Limit in Honda mode ofPGM Tester) or 0 V indicated?

Check tor a short in tho ECT sen-sor:1. Disconnect the ECT sensor

2. Check the ECT with the scantool.

ls 302'F (150'Ci or higher (orH-Limit in Honda mode olPGM Tester) or 0 V indicated?

Check tor s short in the wires (ECTline):r. r urn Ine rgnrtron swttch uFf,2. Disconnect the ECM connector D (16P).

3. Check lor continuity betweenECT sensor connector termi,nal No. 1 and body ground.

Check tor short in the TCM IECTlinell1, Disconnect the 22P connectorfrom the TCM.2. Check for continuity betweenECT sensor connector terminal No- 2 and body ground.

ls there continuity?

Repair shon in the wire botweenECM lD2). TCM and ECT sensor.

iT,011tl The.scan tool indicates Diagnostic Trouble Code (DTC) P0117:Alowvoltage(hightemperature) probleminthe- Engine Coolant Temperature (ECT) sensor circuit.

ECT SENSOR CONNECTOR IC111}

Wire side of fem6le terminals

Substitute a known-good ECMand recheck. lI normal ECT isindicated, replaco the origindlECM.

(cont'd)

NO

11-61

Page 267 of 1681

\

r

I

Ir

PGM.FI

Engine

System

Coolant Temperature (ECTI Sensor (cont'dl

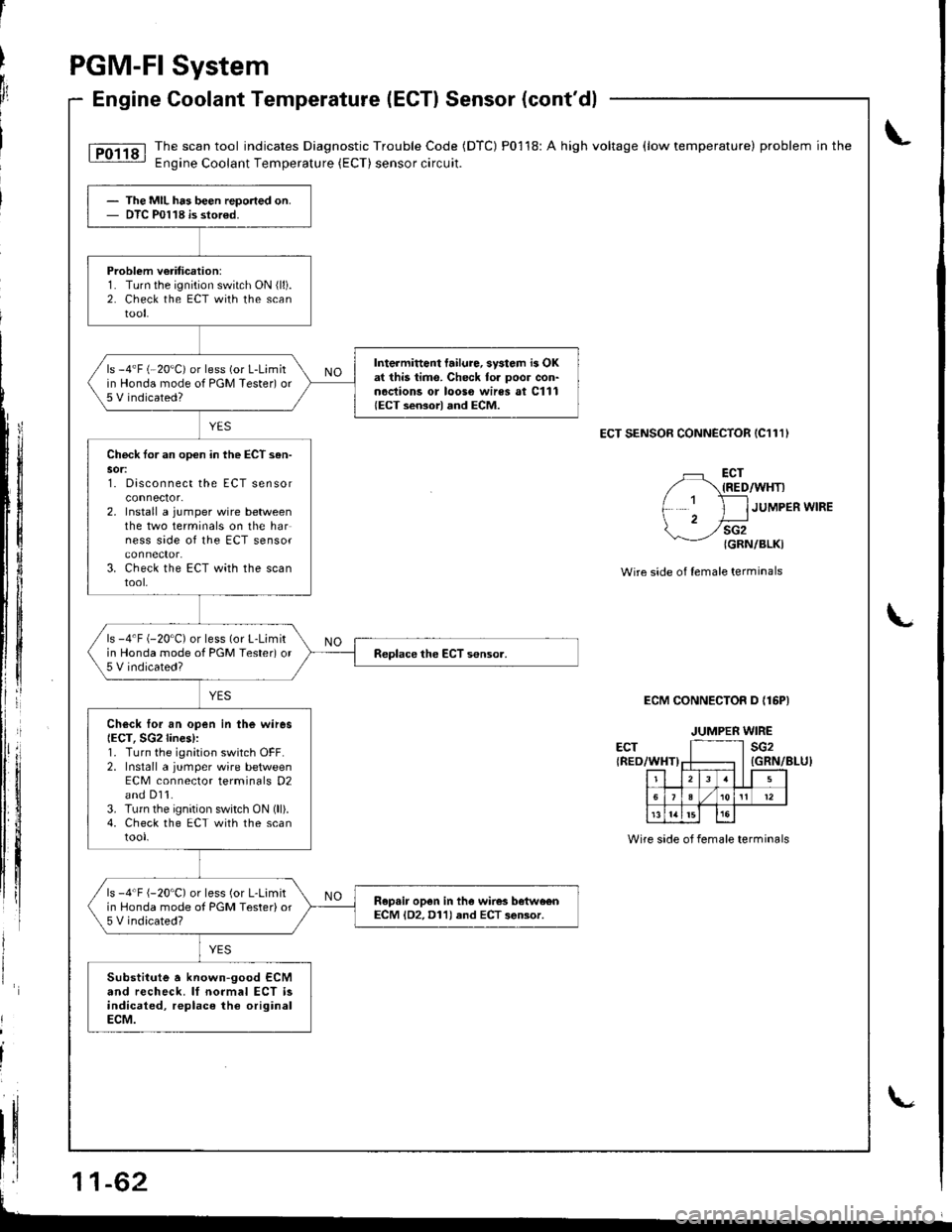

lTo1ig I The.scan tool indicates Diagnostic Trouble Code (DTC) P01 18: A high voltage (low temperature) problem in the.- Engine Coolant Temperature (ECT) sensorcircuit.

ECT SENSOR CONNECTOR (C111)

L

li

li

tllll

tl

fl

ECT{RED/WHT)

sG2{GRN/BLKI

JUMPER WIRE

Wire side o{ lemale terminals

ECM CONNECTOR D {16PI

ECT{RED/WHT)

The MIL has been repo.ted on.DTC P0118 is stor€d.

Problem v€riticetion:1. Turn the ignition switch ON (ll).

2. Check the ECT with the scantool.

Intermittont failure, svstom i3 OKat this time. Check for poor con-noctions or looso wires at C111{ECT sensorl and ECM.

ls -4'F (-20"C) or less (or L-Limitin Honda mode of PGM Tester) or5 V indicated?

Chock tor an opon in the ECT s6n-sor:t. utsconnect tne EL I sensor

2. Install a jumper wire betweenthe two terminals on the harness side of the ECT sensor

3. Check the ECT with the scantool,

ls -4'F (-20"C) or less (or L-Limitin Honda mode of PGM Tested or5 V indicated?

Ch6ck Ior an open in the wiresIECT, SG2lines):1. Turn the ignition switch OFF.2. Install a jumper wire betweenECM conneclor terminals D2and D11.3. Turn the ignition switch ON (ll).4. Check the ECT with the scantool.

ls -4'F {-20'C) or less (or L-Limitin Honda mode ol PGM Tester) or5 V indicated?

Ropair op6n in the wires betwo€nECM lD2, D11) and ECT 3eBor.

Substitute a known-good ECMand recheck. lf normal ECT isindicated, replace the originalECM.

JUMPER WIRE

sG2

r-zlr r5

5e I/ 101t't2

l5

Wire side of female terminals

L

Page 302 of 1681

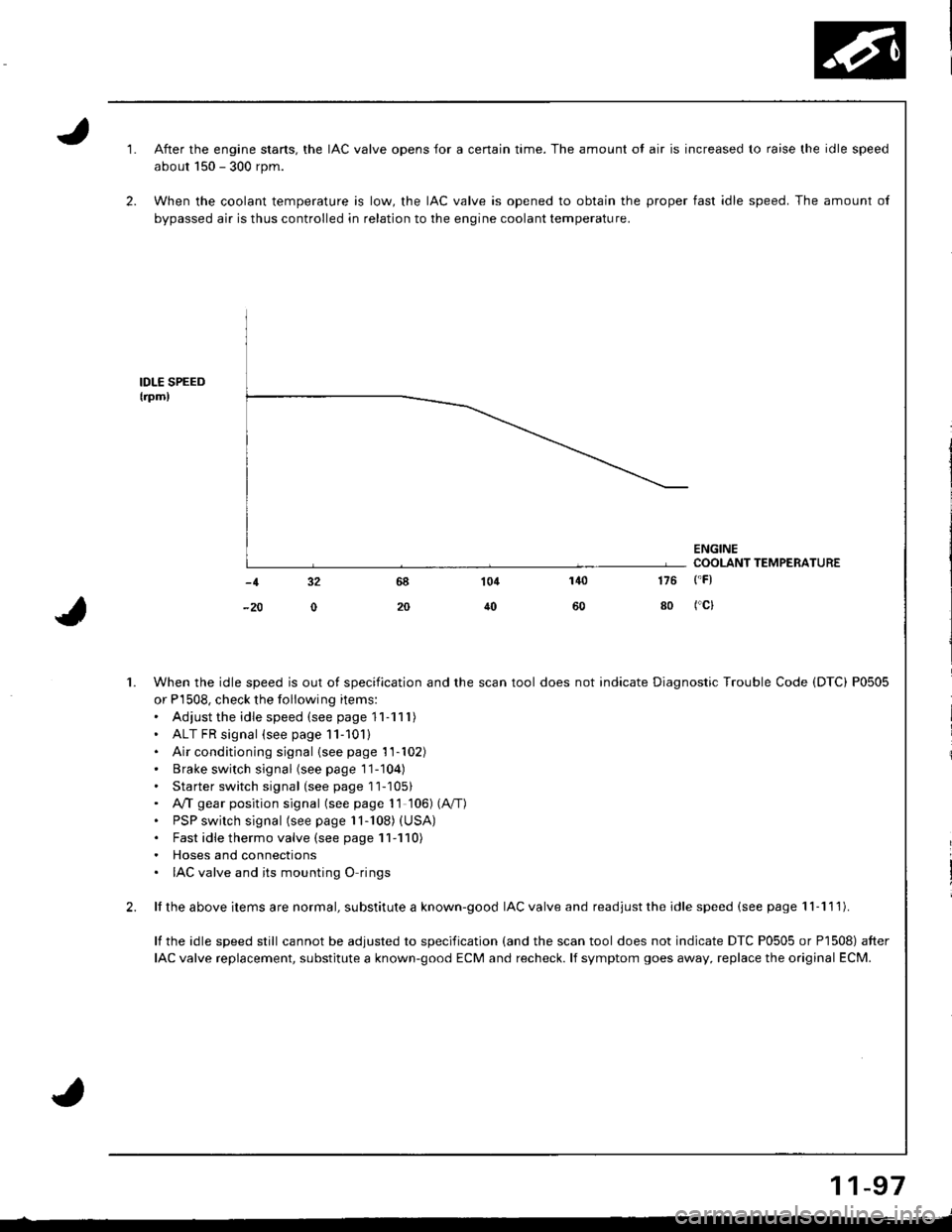

2.

1.

1.

2.

After the engine stans, the IAC valve opens for a certain time. The amount ol air is increased to raise the idle speed

about 150 - 300 rpm.

When the coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. The amount of

bypassed air is thus controlled in relation to the engine coolant temperature.

IDLE SPEEDtrpm,

ENGINECOOLANT TEMPERATURE

140

50

104

40

-1 32

-20 0

176 ('F)

80 fcl

When the idle speed is out of specification and the scan tool does not indicate Diagnostic Trouble Code (DTC) P0505

or P'1508, check the following items:. Adiust the idle speed (see page '11-111)

' ALT FR signal (see page 11-101). Air conditioning signal {seepage'11-102)' Brake switch signal (seepagell-104)

. Starter switch signal (see page 11-1051. A,4 gear position signal (see page 1l 106) (A"/T)

. PSP switch signal (see page 11-108) (USA)

. Fast idle thermo valve (see page 11-110). Hoses and connections. IAC valve and its mounting O rings

ll the above items are normal, substitute a known-good IAC valve and readjust the idle speed (see page 'l I -1 1 l).

lf the idle speed still cannot be adjusted to specification (and the scan tool does not indicate DTC P0505 or P1508) after

IAC valve replacement, substitute a known-good ECM and recheck. lf symptom goes away, replace the original ECM.

11-97

Page 315 of 1681

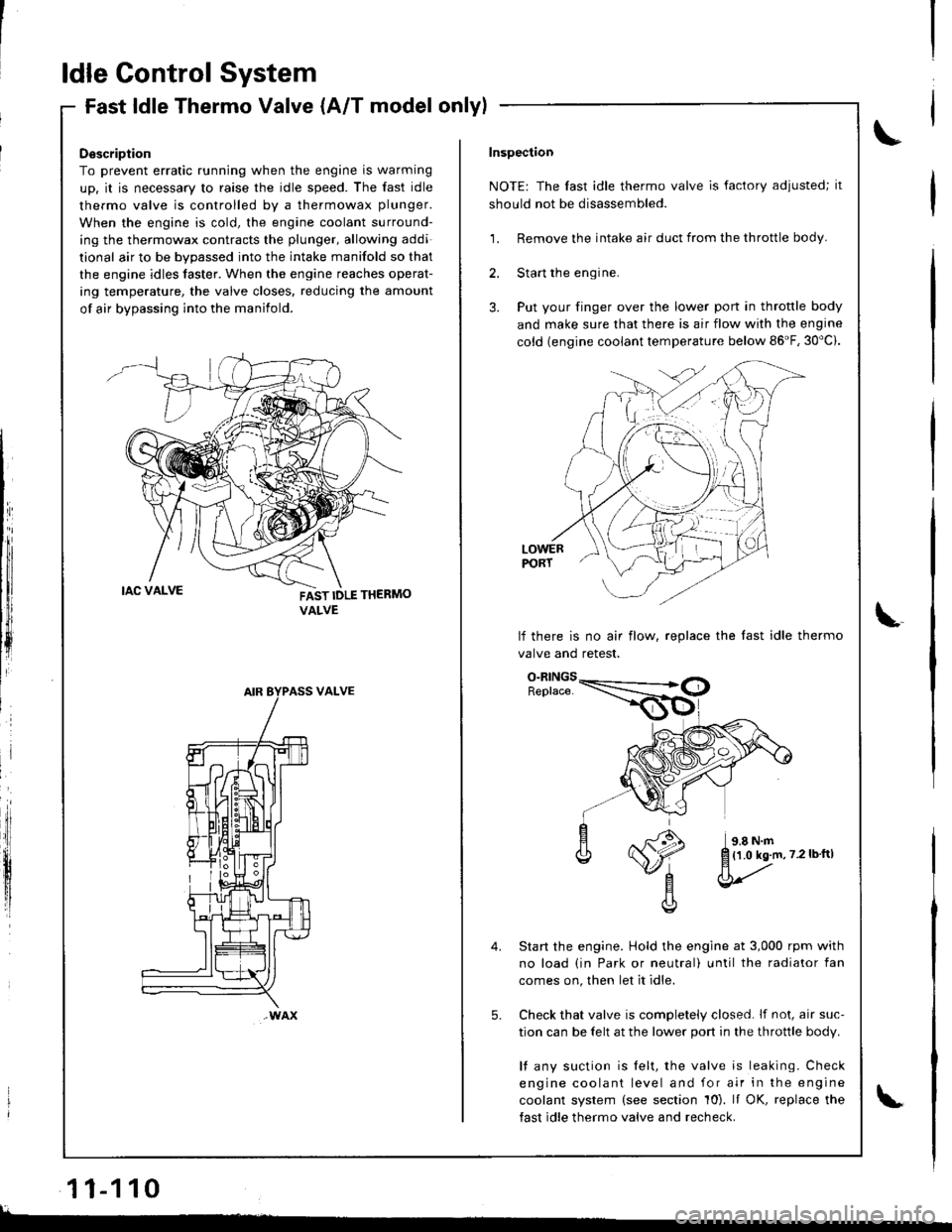

ldle Control System

Fast ldle Thermo Valve (A/T model onlylFast ldle I nermo valve (A/ | mooel

Description

To prevent erratic running when the engine is warming

up. it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi

tional air to be bvoassed into the intake manifold so that

the engine idles taster. When the engine reaches operat-

ing temperature, the valve closes. reducing the amount

of air bypassing into the manifold.

FAST IDLE THERMO

VALVE

VALVE

wAx

Inspection

NOTE: The fast idle thermo valve is factory adiusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine.

3. Put your finger over the lower port in throttle body

and make sure that there is air flow with the engine

cold {engine coolant temperature below 86'F, 30"c).

LOWERPORT

lf there is no air flow, replace the last idle thermo

valve and retest.

Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Check that valve is completely closed. lf not, air suc-

tion can be felt at the lower port in the throttle body.

l{ any suction is felt, the valve is leaking. Check

engine coolant level and for air in the engine

coolant system (see section 10). It OK, replace the

fast idle thermo valve and recheck.

5.

{1.0 kg.m,7.2lbftl

l

11-110

lL.�

Page 437 of 1681

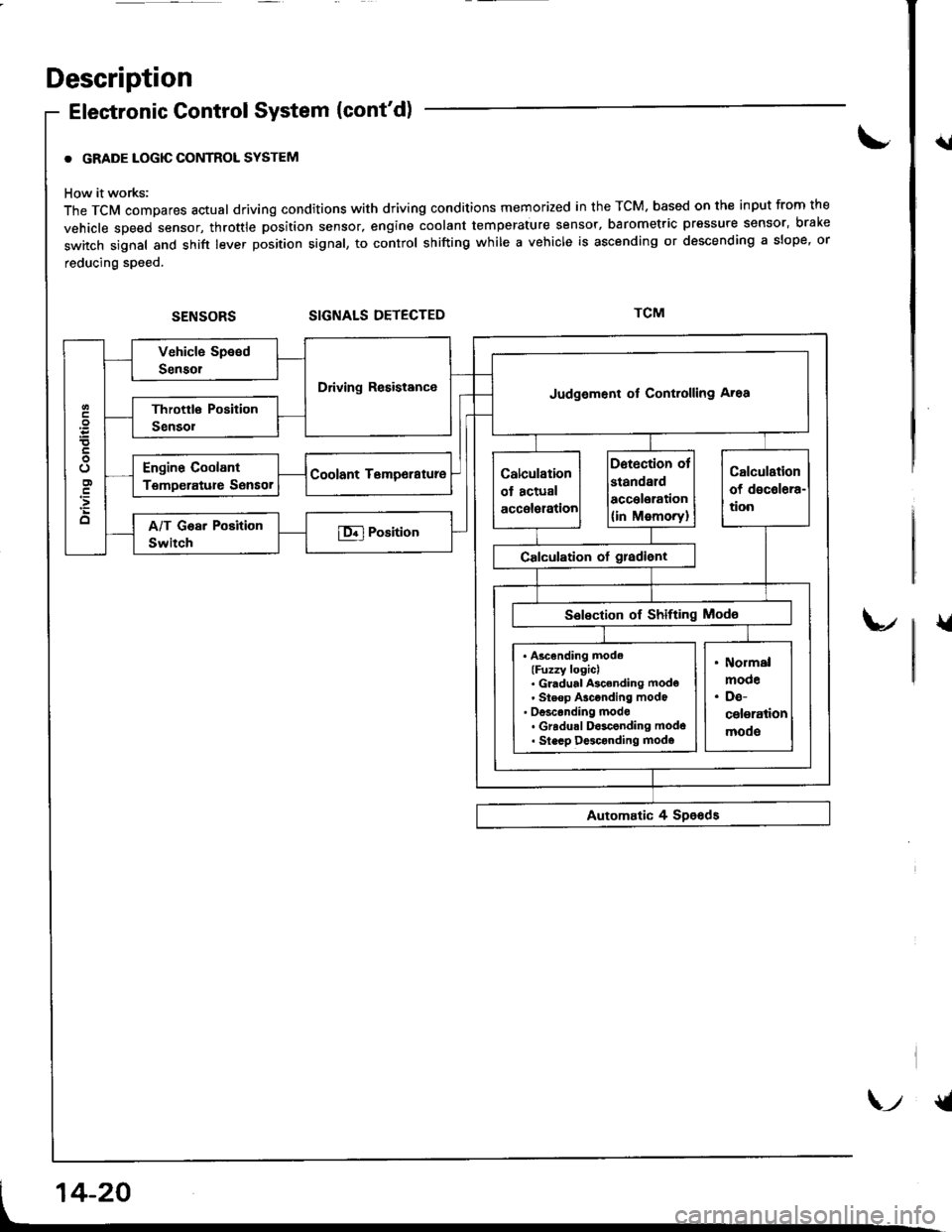

Description

Elestronic Control System (cont'd)

. GRADE LOGIC CONTROL SYSTEM

How it works:

The TCM compares actual driving conditions with driving conditions memorized in the TCM. based on th€ input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, bral(e

switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a slope, or

reducing speed.

SIGNALS DETECTED

{l

{

Driving ResistanceJudgement of Controlling Aroa

. Ascending mode(Fuzzy logicl. Gl.dual Ascending mode' Steop Asconding mode' oesconding mode. Gradu.l D$conding modo. Slecp D$conding modo

\-t {t

Page 464 of 1681

'.J

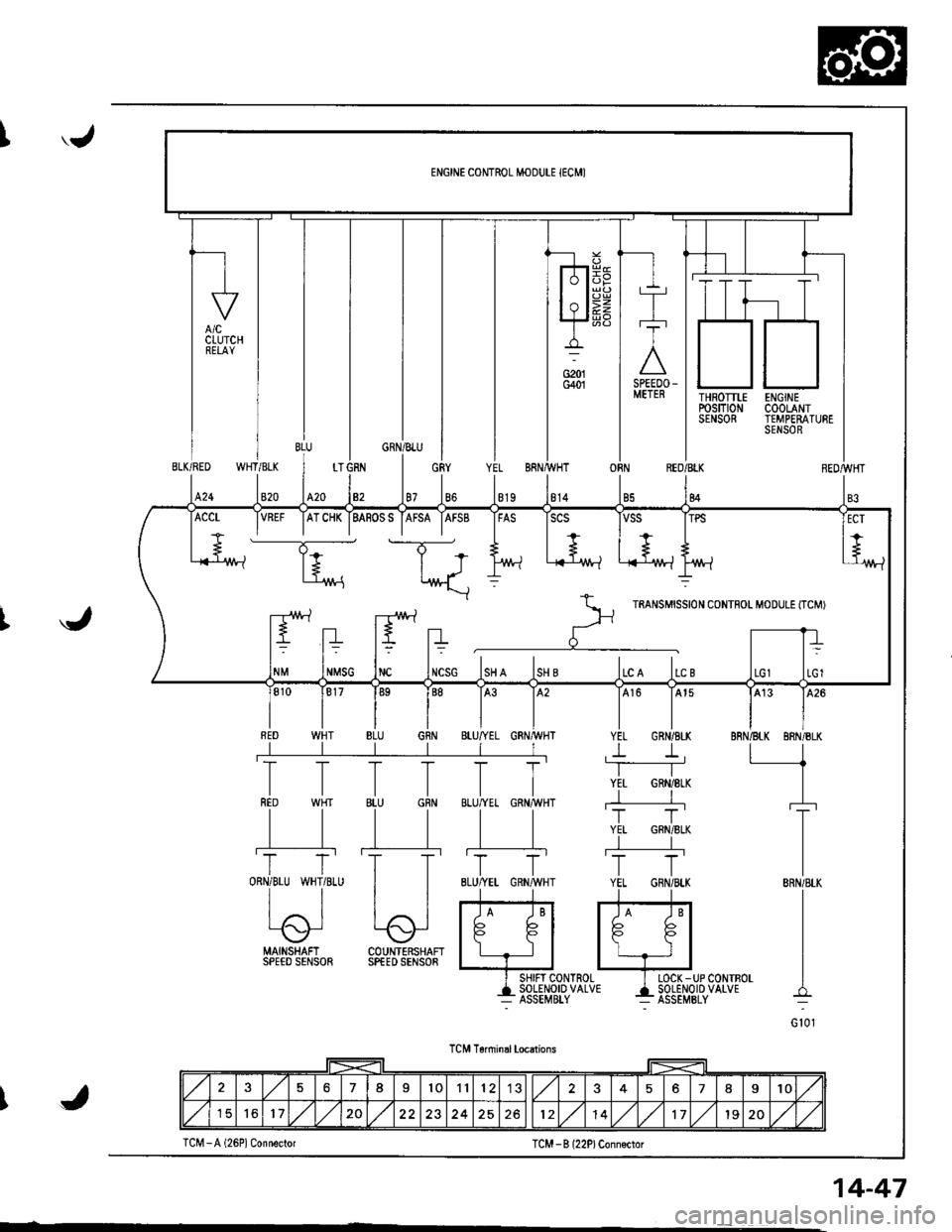

THROTTLErcsm0NSENSOR

ENGINECOOLANTTEMPERATURESENSOR

WHT/BLKBLK/RED

820424

OBNREO/BLK

84

J

MAINSHAFI COUNTERSHAFISPEED SENSOR SPfED SENSOR

I SHIFT CONTROL I LOCK -UP CONTBOL

+135Eil,?1o'uo'u' 4i85El,o''P'uo'u'

TCM T6nninal locations

TCM -B l22P)Conn€ctor

VREF IATCHK IBASOSS IAFSA IAFSB IFAS ISCS

----T;- t-T-*

+.. | +.., I + ,+

l+ | J l/vt-l .i{-'1M-l L-{-lr^/t-lt't'/!-?

*\::

r--rr!\.1 -r!\./ rartsurssrot coNTFoL M'DULE tTcMr

ltEltn r' -rrt= t= t? t=

NMSG INC INCSG ISH A ISH B ILC A ILC B

576I101112578I10

151617,/1,/20251214,/1,/171920,/1,/J

TCM -A (26P1 Connector

14-47

Page 466 of 1681

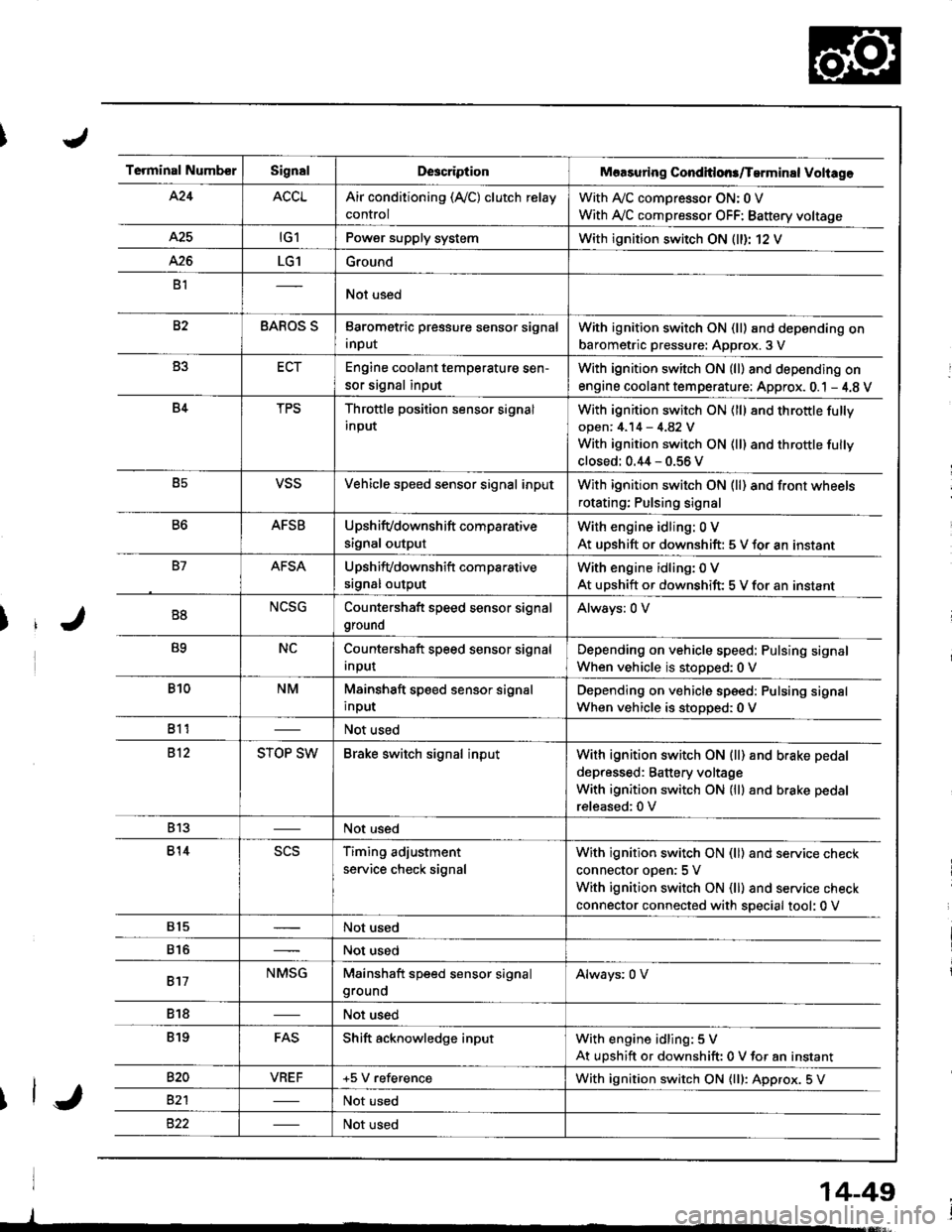

Terminal NumberSignalDescriptionMaasuring Conditlons/Tarminal Voliage

424ACCLAir conditioning (Ay'C) clutch relay

control

With A,/C comDressor ON: 0 V

With Ay'C compressor OFF: Battery voltage

A25tG1Power supply systemWith ignition switch ON (ll)r 12 V

426LG1Ground

B1Not used

82BAROS SBarometric pressure sensor signal

input

With ignition switch ON (ll) and depending on

barometric pressure: Approx. 3 V

B3ECTEngine coolant temperature sen-

sor signal input

With ignition switch ON (ll) and depending on

engine coolant tem perature: Approx. 0.1 - 4.8 V

B4TPSThrottle position sensor signal

input

With ignition switch ON (ll) 8nd throttle fully

open: 4.14 - 4.82 V

With ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

B5VSSVehicle speed sensor signal inputWith ignition switch ON (ll) and front wheels

rotating; Pulsing signal

B6AFSBUpshifvdownshift comparative

signal output

With engine idling: 0 V

At uDshift or downshift: 5 V for an instant

B7AFSAUpshifvdownshift com parative

srgnal output

With engine idling: 0 V

At upshift or downshift: 5 V for an instant

B8NCSGCountershaft speed sensor signal

ground

Always: 0 V

B9NCCountershaft speed sensor signal

Input

Depending on vehicle speed: Pulsing signal

When vehicle is stopped:0 V

B10NMMainshaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stoDoed: 0 V

811Not used

812STOP SWBrake switch signal inputWith ignition switch ON {ll) and b.ake pedal

depressed: Battery voltage

With ignition switch ON (lll and brake pedal

released:0 V

813Not used

814scsTiming adjustment

service check signal

With ignition switch ON (ll) and service check

connector oDen:5 V

With ignition switch ON (ll) and service check

connector connected with special tool: 0 V

815Not used

816Not used

817NMSGMainshaft speed sensor signalgroundAlways: 0 V

818Not used

819FASShift acknowledge inputWith engine idling: 5 V

At upshift or downshift: 0 V for an instant

820VBEF+5 V referenceWith ignition switch ON {lll: Approx. 5 V

82'lNot used

Not used

14-49