check engine light HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 757 of 1681

a

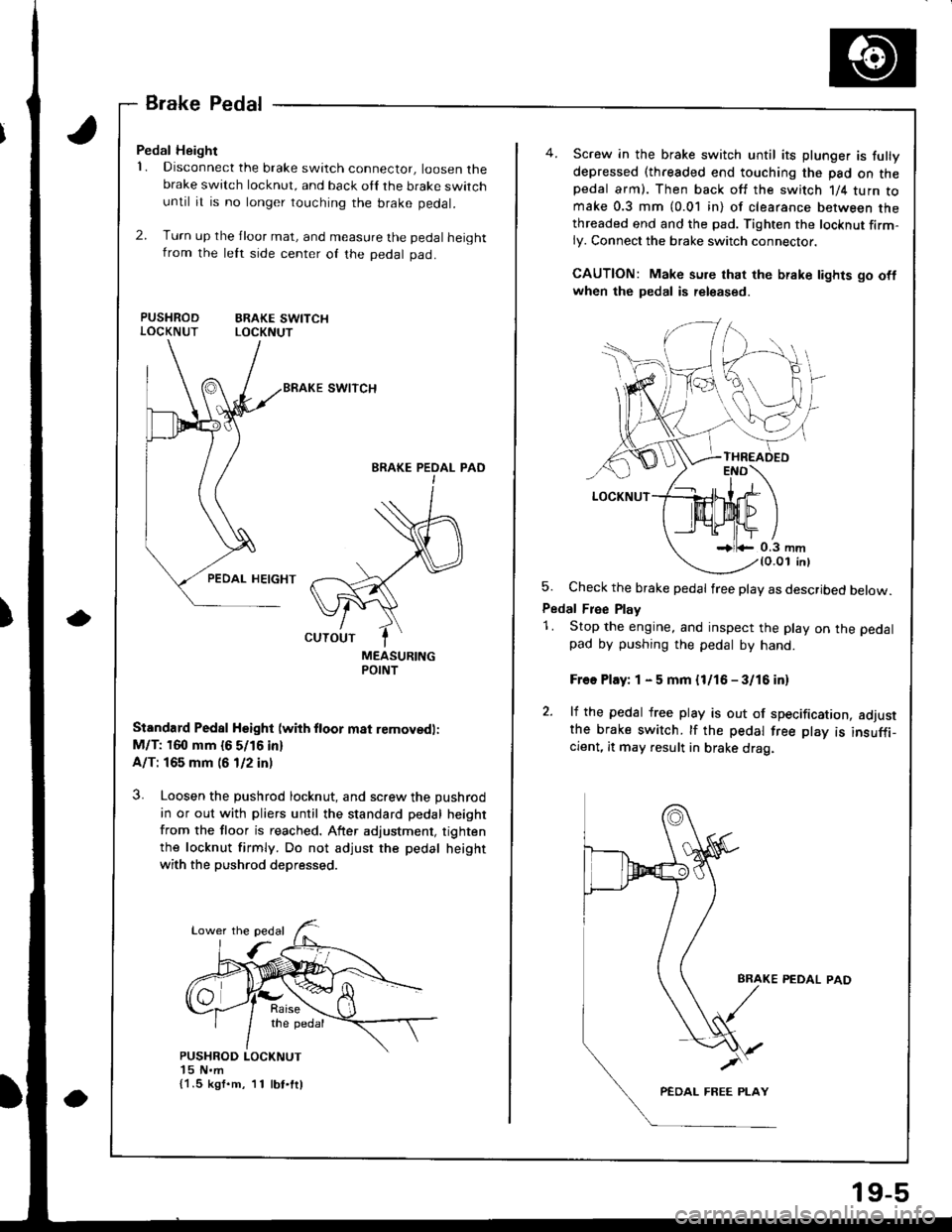

BrakePedal

Pedal Height

1. Disconnect the brake switch connector, loosen thebrake switch locknut, and back oll the brake switchuntil it is no longer touching the brake pedal.

2. Turn up the jloor mat, and measure the pedal heightfrom the lett srde center of the pedal pad.

PUSHROD ERAKE SWITCHLOCKNUT LOCKNUT

swtTcH

BRAKE PEOAL PAOI

MEASURINGPOINT

Standard Pedal Hsight (wiih ftoor m8t removedl:

M/T: 160 mm {6 5/16 in}

A/T: 165 mm (6 1/2 in)

3. Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. After adjustment, tighten

the locknut firmly. Do not adjust the pedal height

with the pushrod depressed.

{1.5 kgf.m, 11 lbt.ftl

19-5

Screw in the brake switch until its plunger is fully

depressed (threaded end touching the pad on thepedal arm). Then back off the switch 1/4 turn tomake 0.3 mm (0.01 in) of clearance between thethreaded end and the pad. Tighten the locknut firm-ly. Connect the brake switch connector.

CAUTION: Make sure that the brake lights go oflwhen the pedal is released.

5. Check the brake pedal free play as described below.

Pedal Free Play

1. Stop the engine, and inspect the play on the pedal

pad by pushing the pedal by hand.

Free Play: 1 - 5 mm {l/16 - 3/16 in)

2. lf the pedal free play is out of specification, adjustthe brake switch. tf the pedal free play is insuffi_cient, it may result in brake drag.

PEDAL PAD

Page 758 of 1681

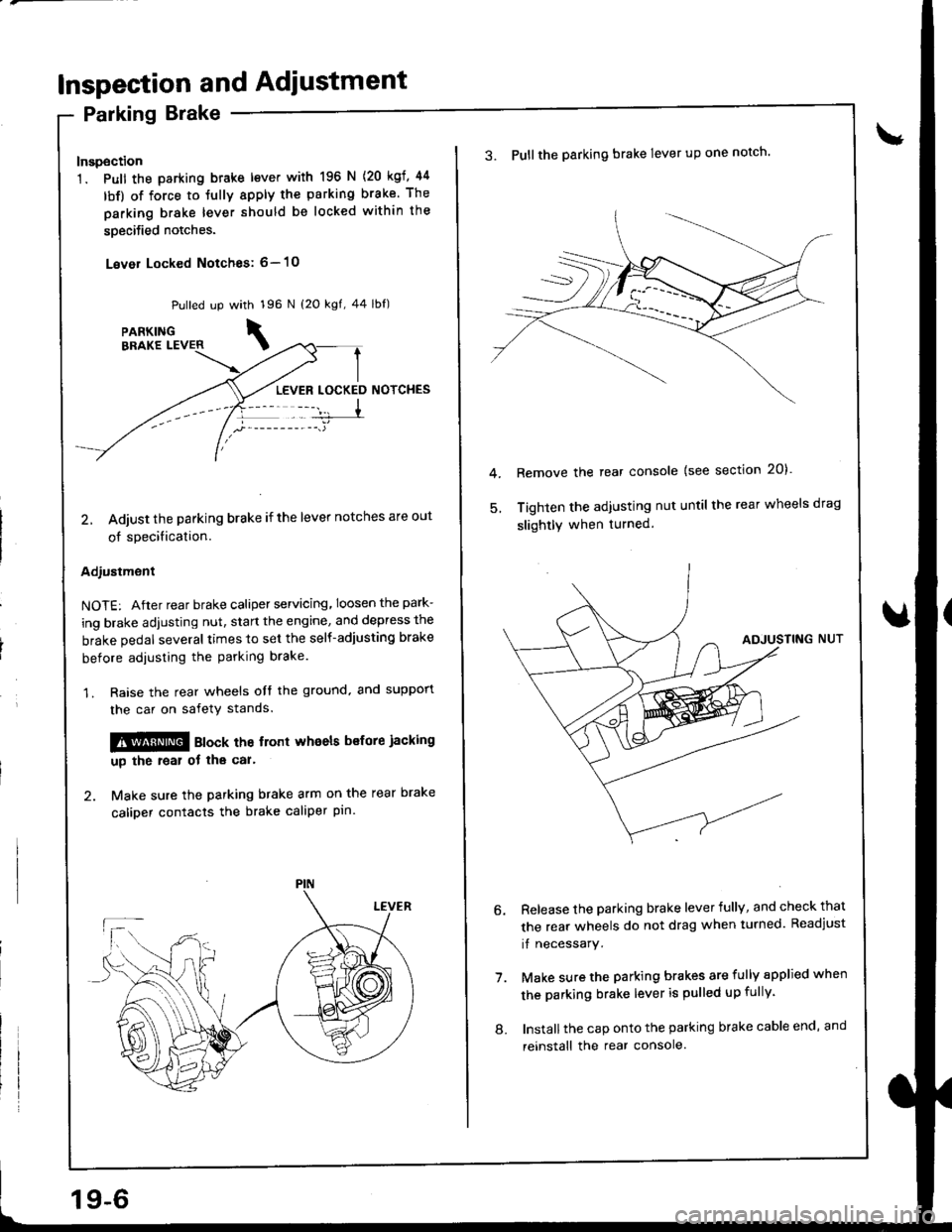

Inspection and Adiustment

Parking Brake

Inspection

1. Pull the parking btake lever with 196 N

lbf) of force to Jully apply the parking

parking brake lever should be locked

soecified notches.

Lever Locked Notches: 6- l0

{20 kgf, 44

brake. The

within the

Pulled up with 196 N {2O kgf, 44 lbf)

LEVER LOCKED NOTCHES

2, Adjust the parking brake if the lever notches are out

of specification.

Adjustment

NOTE: After rear brake caliper servicing.loosen the park-

ing brake adjusting nut, start the engine, and depress the

brake pedal several times to set the self-adjusting brake

before adiusting the parking brake

1. Raise the rear wheels oIt the ground. and suppon

the car on safety stands.

!!@ ato"t the trort whoels bsfore jacking

up the roal ot tha car'

2. Make sure the parking brake arm on the rear brake

caliDer contacts the brake caliper pin.

19-6

8.

3. Pullthe parking brake lever up one notch'

Remove the rear console {see section 20)'

Tighten the adjusting nut until the rear wheels drag

slightly when turned.

7.

Release the parking brake lever fully, and check that

the rear wheels do not drag when turned. Readjust

if necessary.

Make sure the parking brakes are fully spplied when

the parking brake lever is pulled up fully.

Install the cap onto the parking brake cable end, and

reinstall the rear console.

Page 767 of 1681

1.

8.

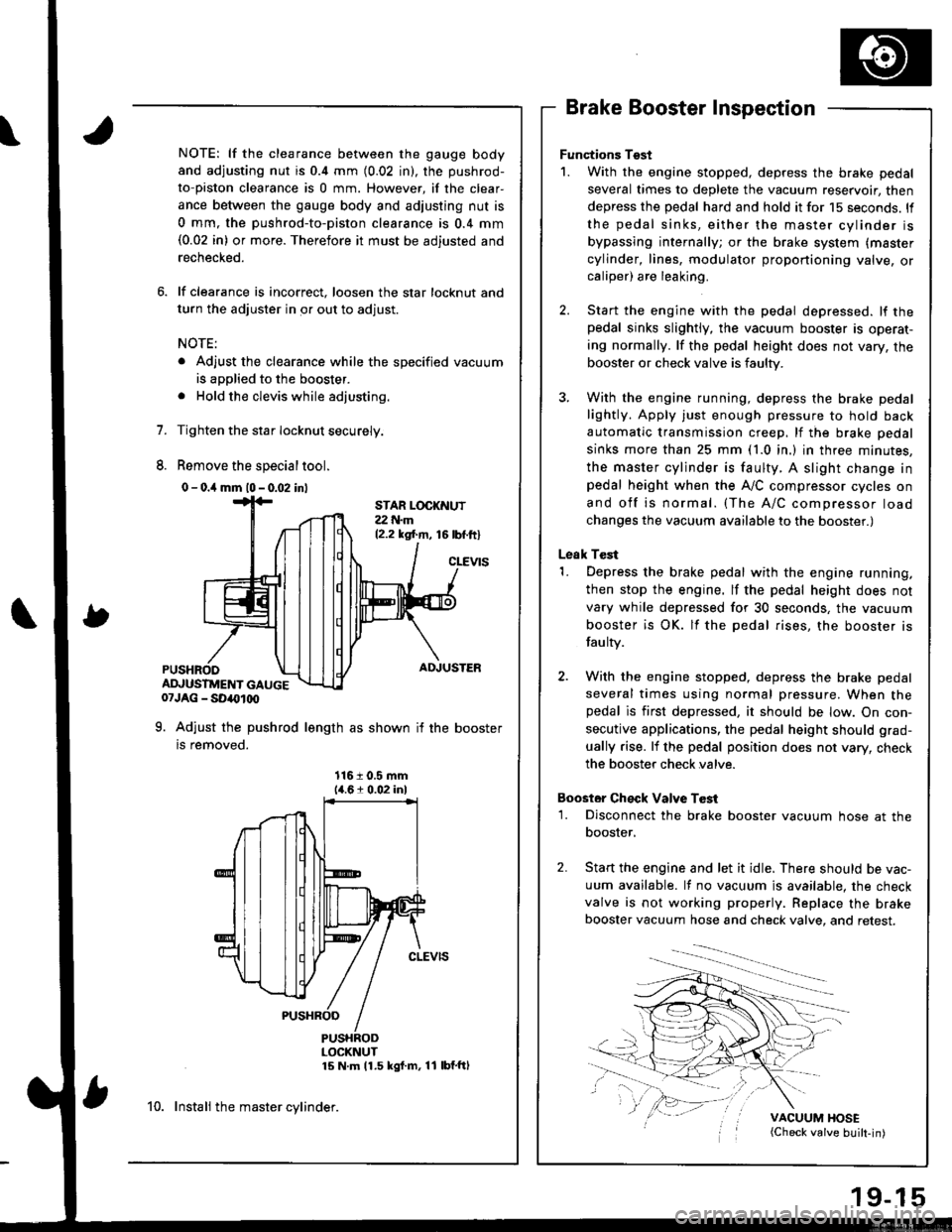

NOTE: lf the clearance between the gauge body

and adjusting nut is 0.4 mm (0.02 in), the pushrod-

to-piston clearance is 0 mm. However, if the clear-

ance between the gauge body and adjusting nut is

0 mm, the pushrod-to-piston clearance is 0.4 mm(0.02 in) or more. Therefore it must be adjusted and

rechecked.

lf clearance is incorrect, loosen the star locknut and

turn the adjuster in or out to adjust.

NOTE:

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star Iocknut securely.

Remove the special tool.

0 - o.il mm l0 - 0.02 inl

Brake Booster Inspection

Functions Tgst

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. ll

the pedal sinks, either the master cylinder is

bypassing internally; or the brake system (master

cylinder, lines, modulator proportioning valve, orcaliper) are leaking.

Start the engine with the pedal depressed. lf thepedal sinks slightly, the vacuum booster is operat-

ing normally. lf the pedal height does not vary, the

booster or check valve is faulty.

With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep, lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cylinder is faulty. A slight change inpedal height when the A,,/C compressor cycles on

and off is normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises, the booster is

fau lty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When thepedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. lf the pedal position does not vary, check

the booster check valve.

Boostor Ch€ck Valve T6st

1. Disconnect the brake booster vacuum hose at the

booster,

Start the engine and let it idle. There should be vac-

uum available. It no vacuum is available. the check

valve is not working properly. Replace the brake

booster vacuum hose and check valve, and retest.

VACUUM HOSE(Check valve built-in)

STAR LOCKNUT22 t{.m12.2 ksl.m, 16lbf.ftl

cLEVtS

ADJUSTER

ADJUSTMENT GAUGE07JAG - SD40t00

9. Adjust the pushrod length as shown if the booster

is removed.

1161 0.5 mm14.61 0.02 inl

PUSHRODLOCKNUT15 N m 11.5 kgf m, 11 lbf'ftl

10. Instali the master cylinder.

Page 794 of 1681

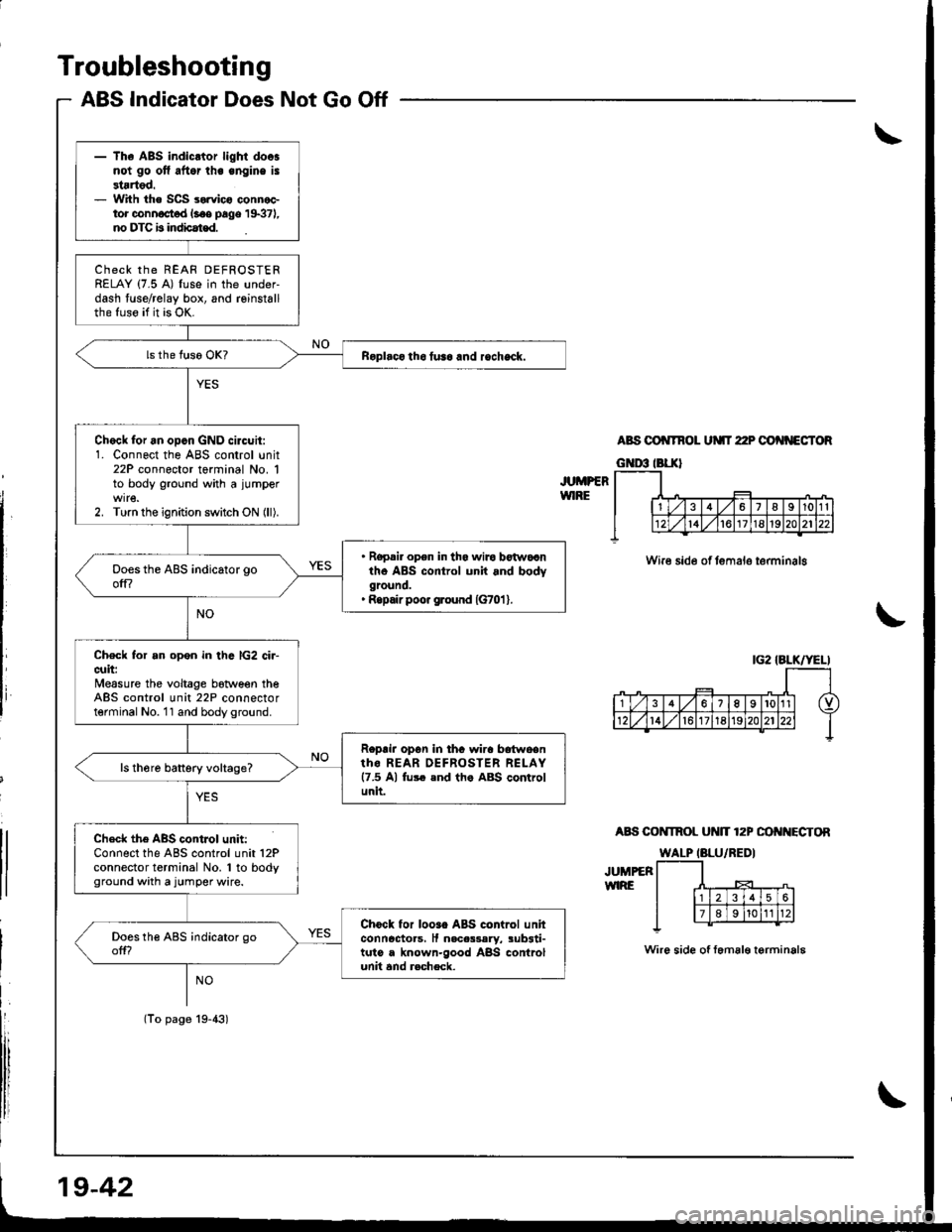

Troubleshooting

ABS Indicator Does Not Go Off

JUMPERWIRE

ABS OO TNOL UMT 22P OO'{NECTOR

Wire side of temalo terminalg

A8S COI{TROL Ut{lT 12P OO I{ECTOR

JUMPEFWIRE

Wire side of femal€ terminala

|G2 IALK/YELI

- The ABS indicltor light doosnot go ofl aftor lhe engine is3tartod.- With the SCS sorvico connoctor connoct d l.oe page 19371,no DTC b indbat€d.

ChECK thE REAF DEFROSTERRELAY (7.5 A) fuse in the under-dash fuse/relay box, and reinstallthe fuso if it is OK.

Roplaco tho tusa and rocheck.

Chock for an opcn GND circuit:1. Connect the ABS control unit22P connector terminal No. 1to body ground with a jumper

2. Turn the ignition switch ON (ll).

. Ropair opon in tha wiro botwocntho ABS control unit and bodyground.' Ropair poo. ground {G701 }.

Check for an open in thc lG2 ci.-cuit:Measure the voltage botween theABS control unit 22P connectorterminal No. 11 and body ground.

Roprir opon in thc wira bdtwoentho REAR OEFROSTER RELAY17.5 Al fu$ end th. ABS controlunit.

ls th6re battery voltage?

Check the ABS contJol unit:Connect the ABS control unit 12Pconnector terminal No. 1 to bodyground with a jumper wire.

Chock for looao ABS control unhconncctoas, It nacas3aly, sub3ti-tuto a known-good ABS controlunit and r.check.

(To page 19-43)

19-42

Page 1159 of 1681

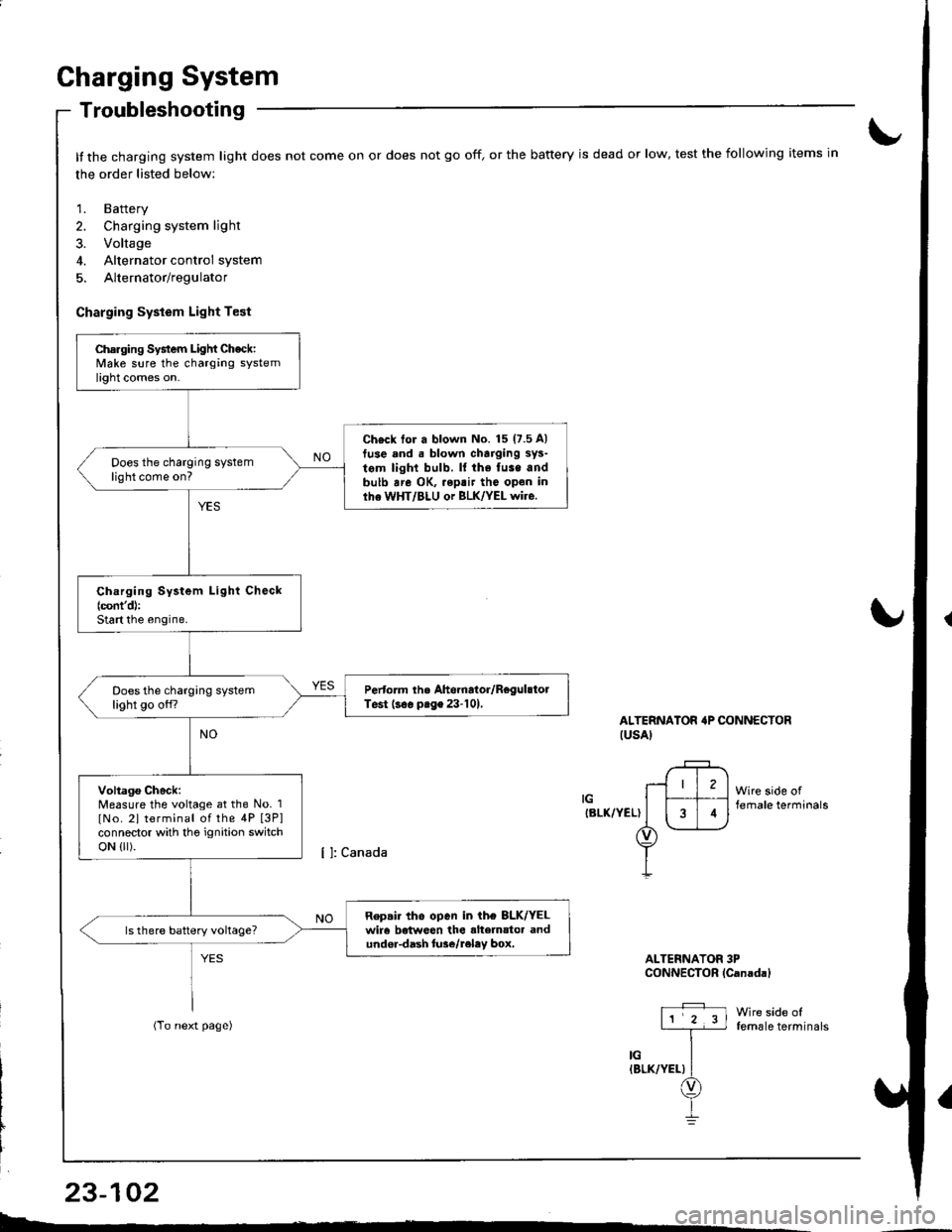

Charging System

Troubleshooting

It the charging system light does not come on or does not go off, or the battery is dead or low, test the following items in

the order listed below:

1. Battery

2. Charging system light

3. Voltage

4. Alternator control system

5. Alternator/regulator

Charging System Light Test

ALTERNATOR'P CONNECTORIUSAI

IGIBLK/YEL)

Wire side offemale terminals

Wire side offemale terminals

ALTERNATOR 3PCONNECTOR lCanadal

Charging System Light Check:Make sure the charging systemlight comes on.

Ch€ck tor a blown No. 15 (7.5 A)

tuse and . blown charging sys-

tem light bulb. ll the fuse andbulb are OK, .eptir tho open inlhe WHT/BLU or BLK/YEL wire.

Does the charging systemlight come on?

Ch.rging System Light Check(cont'd):

Start the engine.

Pertorm the Ahernator/RegulstolTest (s€. prge 23-101,Does the charging systemlight go off?

Voltago Check:Measure the voltage at the No. 1

lNo. 2l terminal of the 4P [3P]connector with tho ignition switchoN {lr).

Repair tho open in ih€ 8LK/YELwir6 betweon the alte]nator andundor-dash lure/reley box.

I4

L-*

23-102

Page 1161 of 1681

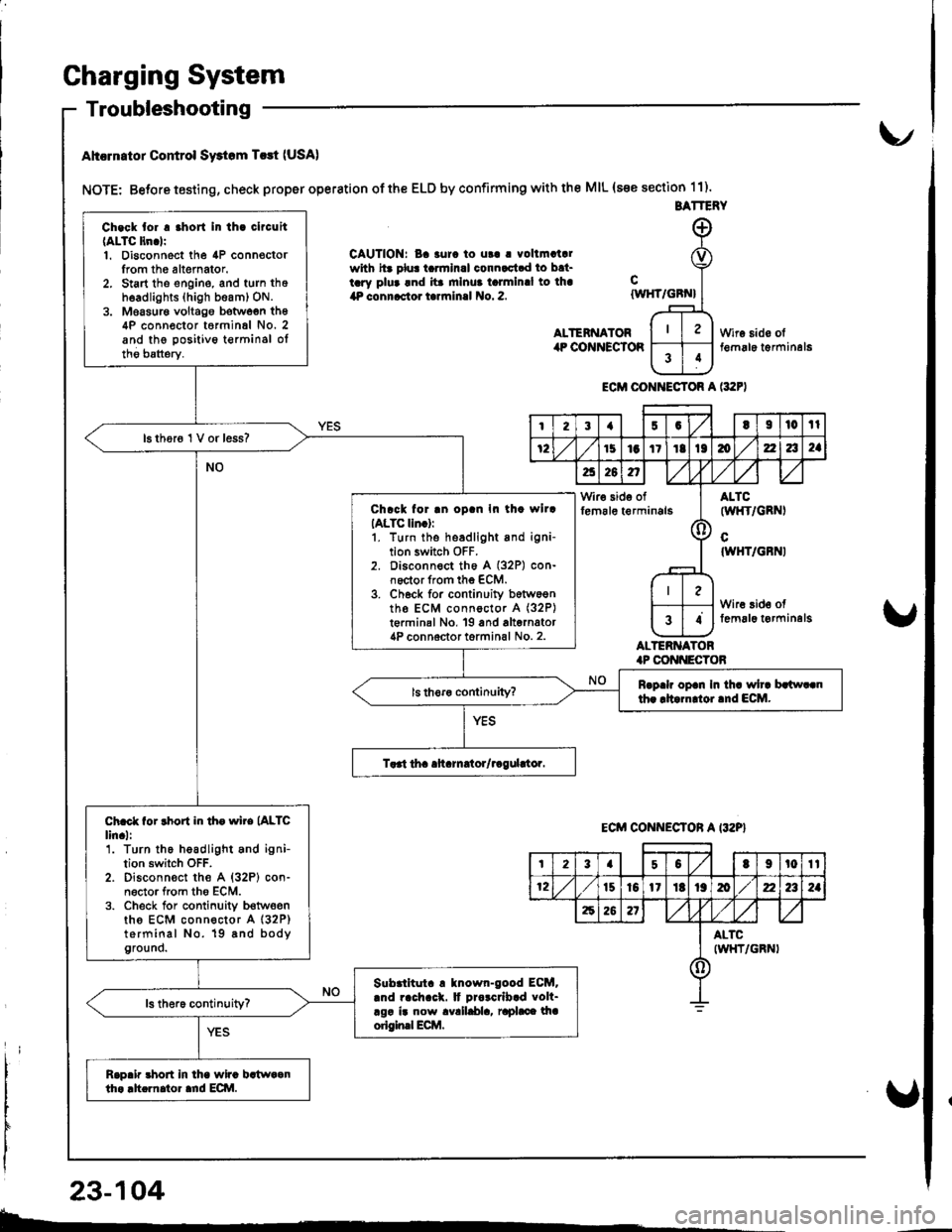

Gharging System

Troubleshooting

Ahcrn.tor Control Swtom T.rt (USA)

NOTE: Betore testing, check proper operation of the ELD by confirming with the MIL (s€e section 11).

CAUTION: Ba 3urc to ut! | vollmatalwith hr plu! tarmlnal connactad to bat-tary plua and ita mlnua talmlnal to lha4P connactor tarrninal No. 2.

ALTENNATORilP COiINECTOR

cIWHT/GBN}

ALTERNATOR.P CONI{ECTOB

Wire sido olt€m6le t€rminal6

ECM CONI{ECTOR A l:t2F)

BATTERY

Ch.ck tor . .hort In th. clrcuit(ALTC ltn.lr1. Disconnect the 4P connoctorIrom th6 altemator.2. Start tho engine, and turn thoh6adlights (high beam) ON.3. Moasur€ voltago botwoen th64P conn€ctor t6rminal No. 2and the positivo t€rminsl oltho batterv.

16 thor6 1 V or less?

Chrck for .n oD.n In th. wllrIALTC lln.):1. turn the headlight and igni-tion switch OFF.2. Disconnect th6 A (32P) con-noctor from the ECM.3. Ch6ck for continuity b6tw6entho ECM connoctor A (32P)

t€rminal No, 19 and alternator4P connoctor torminal No. 2.

Rrp.h op.n In th. wh. brlw..nth. rltarn oi.nd ECM.

Ch.ct for rhort in th. wire (ALTC

lin.l:'1. Turn the headlight and ignition switch OFF.2. Disconn€ct the A {32P} con-n6ctor from tho ECM.3. Check for conlinuity b€twoenths ECM connector A (32P)

terminal No. 19 8nd bodyground.

Slbrlltut. ! tnown-good ECM..nd rach.ck. It Drorcrlb.d volt-rgr ir now avalldla, raphce lhaorigin.l Ecilt.

Rap.ir 3hort in lha wira bstwaanth. .h.rnator ard ECI\|.

I23{5GtI|l0tl

72151aItIt136zla2a

a26n,/,V

Wir€ side offem6le t€rminals(l

ALTC(wl{T/GRNI

cIWHT/GBNI

Wire 3id€ offemal6 t€rminelg34

ECM CONNECTON A I32P}

t23a50t9t0tt

12t510l1Itt9mz2a2a

62621

ALTCIWHT/GRNI()

23-104

b-.

Page 1209 of 1681

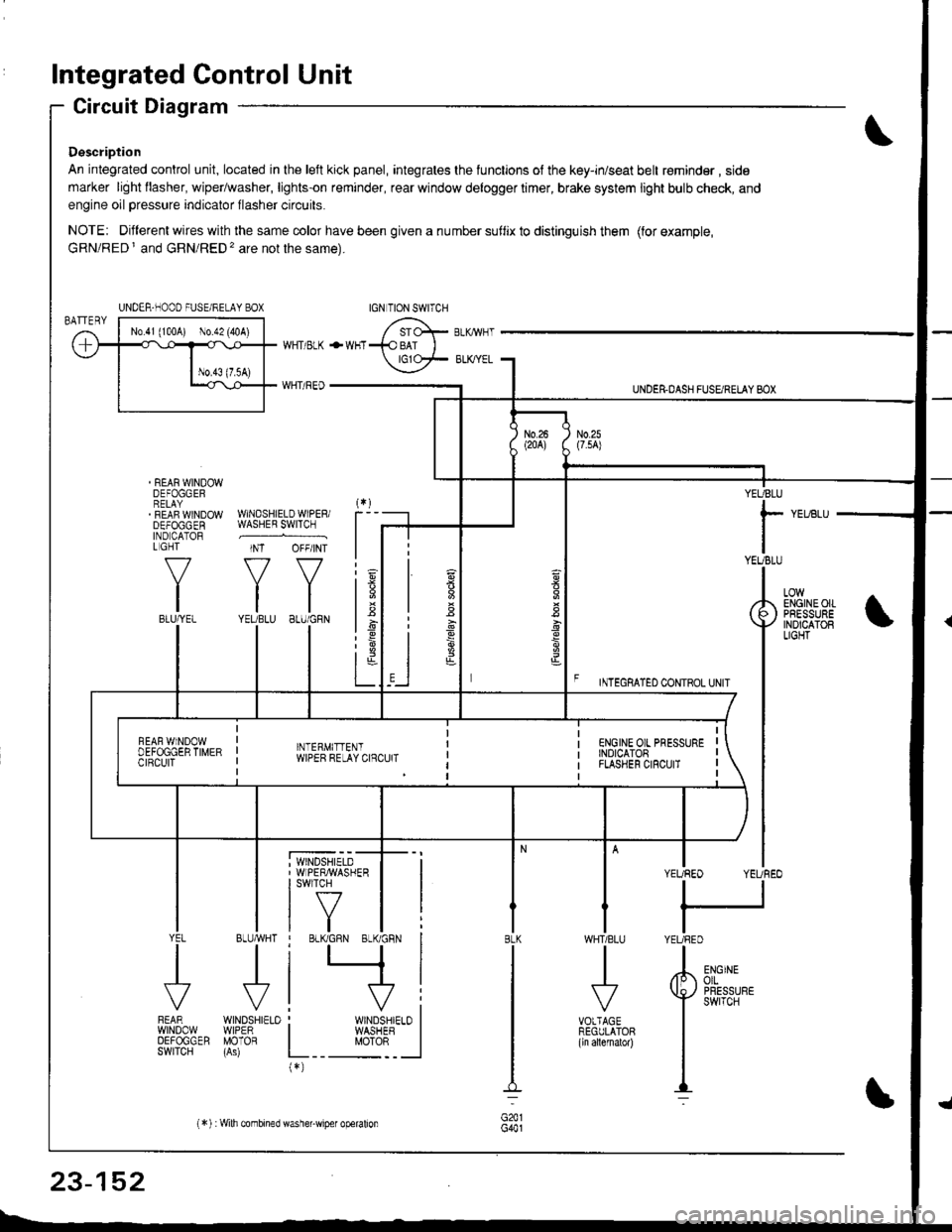

Integrated Control Unit

Circuit Diagram

Description

An integrated control unit, located in lhe left kick panel, integrates the lunctions of the key-in/seat belt r€minder , side

marker light llasher, wiper/washer, lights-on reminder, rear window delogger timer, brake system light bulb check, and

engine oil pressure indicator flasher circuits.

NOTE: Different wires with the same color have been given a nu mber suflix to distinguish them (for example,

GRN/RED I and GRN/RED'� are not the same).

REAR WINDOWDEFOGGERRELAYREAF WINDOWDEFOGGENIND CATORL GHT

f-7

IIBLU/YEL

WHT/ BLK

WHT/ REO

+WHT

WNDSHIELDWIPERiWASHER SWITCH

INT OFF/INT

f7 f7

tltlYEUBLU 8LU/GRN

BLUMHT

J

wtN0sHr€10WIPERMOTOR

UNDER.DASH FUSARETAY BOX

F rmecnlleo counoL ultr

YEUBLU

rYEUBLU

YEUREO YEUREO

tl

IYEURED

LOWENGINEOIIPRESSUREINOICATOBLIGHT

; WINDSHIELD' WIPERMASHERI swlTcH

tf7IVtlYEL

J

FEARwtN00wOEFOGGERSWITCH

WHTIBLU

J

VOTTAGEREGULATOR(ln allernatol)

BLK

G441

ENGINEolLPRESSUREswrTcH

UNDER-NOOO FUSE/RELAY BOX

1.6

:6

t;t-L

i

"'i'- 'i*-

|

I Il

I vi: WINDSHIELO II WASHEB I

L__ "oto: _ __l(*)

n

s

s

,]

23-152

(*) :Wilh combined washer-wiper operalion

Page 1213 of 1681

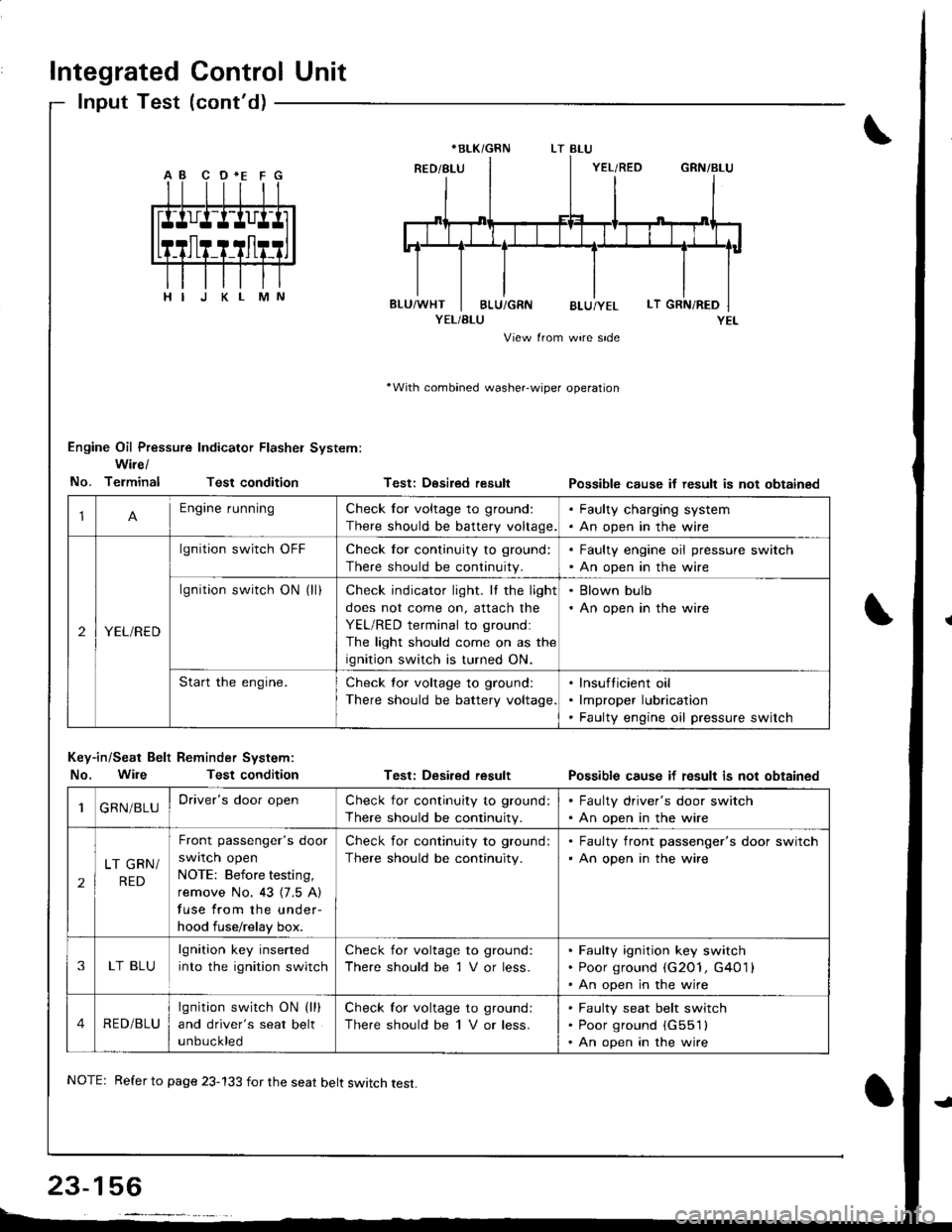

Integrated Control Unit

lnput Test (cont'd)

YEL/BLU

View from wire side

'With combined washer-wiper operation

Engine Oil Pressure Indicator Flasher System:

Wire/

No. TerminalTest condition

Key-in/Seat Belt Reminder System:

No. WileTest condition

Testi Desired result

Test: Desired result

Possible cause if result is not obtainsd

Possible cause if fesult is not obtained

*BLK/GRN

1Engine runningCheck for voltage to ground:

There should be battery voltage.

. Faulty charging system. An open in the wire

2YEL/RED

lgnition switch OFFCheck for continuity to ground:

There should be continuity.

. Faulty engine oil pressure switch. An open in the wire

lgnition switch ON (ll)Check indicator light. It the light

does not come on, attach the

YEL/RED terminal to groundl

The light should come on as the

ignition switch is turned ON.

. Blown bulb. An open in the wire

Start the engine.Check tor voltage to ground:

There should be battery voltage

lnsufticient oil

lmproper lubrication

Faulty engine oil pressure switch

1GRN/BLUDriver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An open in the wire

2

LT GRN/

RED

Front passenger's door

swrlcn open

NOTE: Before testing,

remove No. 43 {7.5 A)

fuse from the under-

hood fuse/relay box.

Check for continuity to ground:

There should be continuity.

. Faulty front passenger's door switch'An open in the wire

3LT BLU

lgnition key inserted

into the ignition switch

Check for voltage to ground:

There should be 1 V or less.

Faulty ignition key switch

Poor ground (G2O1, G401 l

An open in the wire

4RED/BLU

lgnition switch ON (lll

and driver's seat belt

unbuckled

Check for voltage to ground:

There should be 1 V or less.

Faulty seat belt switch

Poor ground (G551l

An open in the wire

NOTE: Refer to page 23-133 for the seat belt switch test.

Page 1313 of 1681

Cruise Control

- Control Unit InputTest(cont'dl

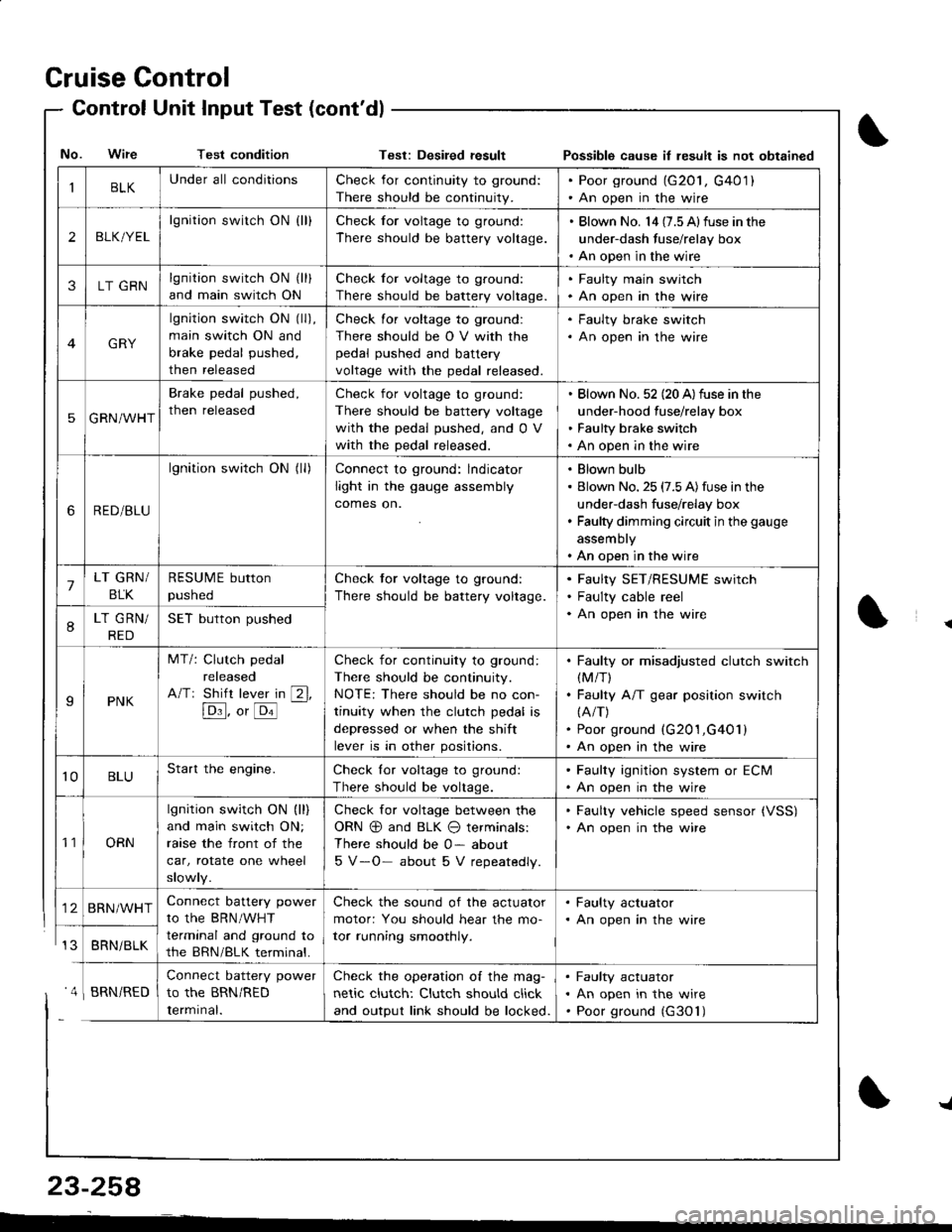

IBLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G20l, G401). An open in the wire

2BLK/YEL

lgnition switch ON {ll}Check for voltage to ground:

There should be battery voltage.

. Blown No. l4 (7.5 Alfuse in the

under-dash fuse/relay box. An open in the wire

3LT GRNlgnition switch ON (ll)

and main switch ON

Check for voltage to ground:

There should be battery voltage.

. Faulty main swjtch. An open in the wire

GRY

lgnition switch ON (ll),

main switch ON and

brake pedal pushed,

then released

Check for voltage to ground:

There should be O V with the

pedal pushed and battery

voltage with the pedal released.

. Faulty brake switch. An open in the wire

5GRN/WHT

Brake pedal pushed,

then released

Check for voltage to ground:

There should be battery voltage

with the pedal pushed, and 0 V

with the pedal released.

Blown No. 52 (20 A)fuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

6RED/BLU

lgnition switch ON (ll)Connect to ground: lndicator

light in the gauge assembly

comes on.

Blown bulb

Blown No. 25 (7.5 A)fuse in the

under-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

7LT GRN/

BLK

RESUME button

pushed

Check tor voltage to ground:

There should be battery voltage.

Faulty SET/RESUME switch

Faulty cable reel

An open in the wire8LT GRN/

RED

SET button pushed

IPNK

MT/: Clutch pedal

released

A/Tr Shift lever in [2l,

[Dl]. o, [o'l

-

Check for continuity to ground:

There should be continuity.

NOTE: There should be no con-

tinuity when the clutch pedal is

depressed or when the shift

lever is in other positions.

Faulty or misadjusted clutch switch(M/T)

Faulty A/T gear position switch(A/T)

Poor ground (G201,G401)

An open in the wire

't0BLUStart the engine.Check lor voltage to ground:

There should be voltage.

. Faulty ignition system or ECM. An open in the wire

't1ORN

lgnition switch ON (ll)

and main switch ON;

raase the front of the

car, rotate one wheel

slowly.

Check for voltage between the

ORN @ and BLK O terminals:

There should be 0- about

5 V-O- about 5 V repeatedly.

. Faulty vehicle speed sensor {VSS). An open in the wire

BRN/WHTConnect battery power

to the BRN/WHT

terminal and ground to

the BRN/BLK terminal.

Check the sound of the actuator

motor: You should hear the mo-

tor running smoothly.

. Faulty actuator. An open in the wire

BRNi BLK

Connect battery power

to the BRN/RED

Iermrnal.

Check the operation of the mag-

netic clutch: Clutch should click

and output link should be locked.

Faulty actuator

An open in the wire

Poor ground (G30'l)

No. Wire Test conditionTest: Desiled result Possible cause il lesult is not obtained

' 4 I BRN/RED

{

{

23-258

-L

Page 1390 of 1681

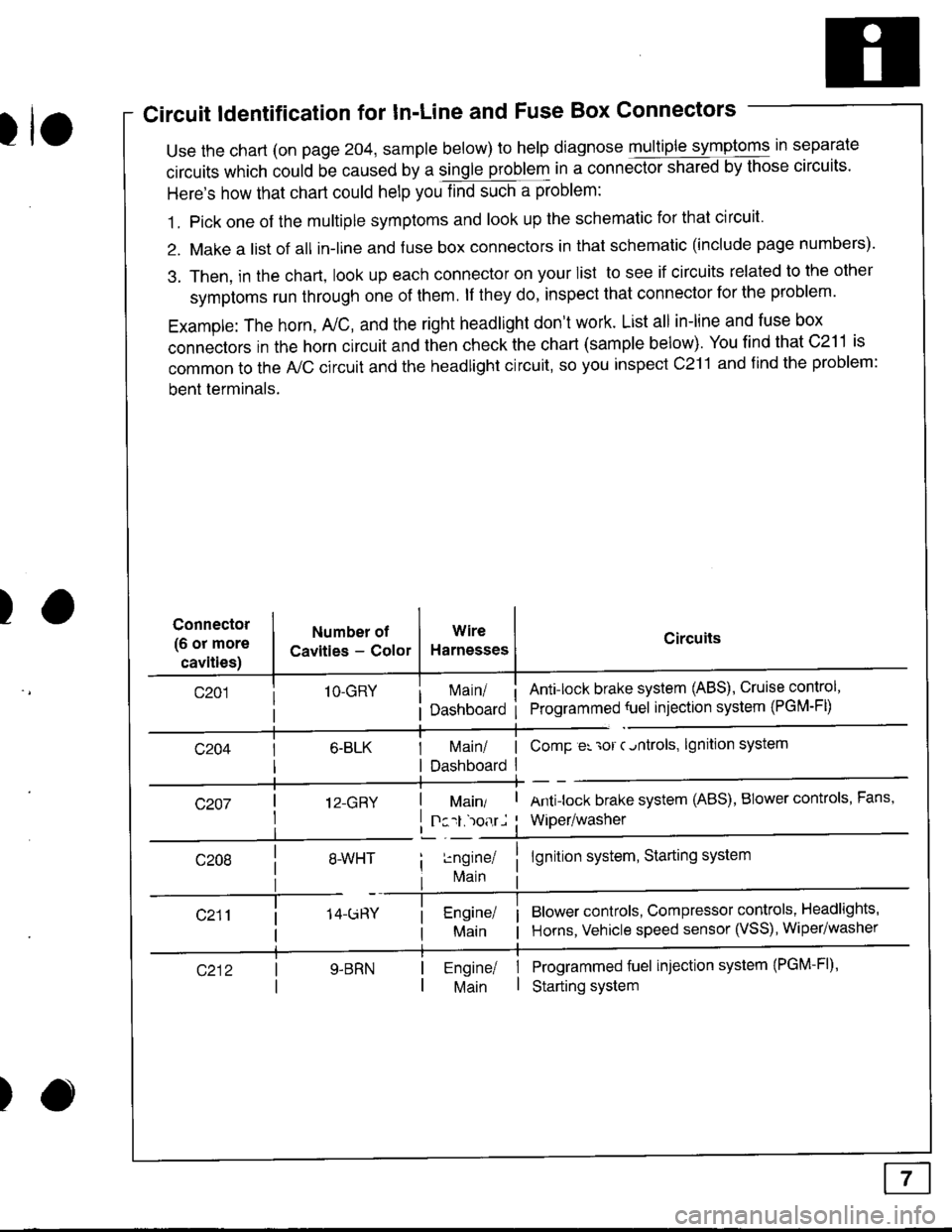

Circuit ldentification for In'Line and Fuse Box Connectors

tuse the chart (on page 204, sample below) to help diagnose multiple symptoms in separate

circuits which could be caused by a single problem in a connect,oishared by those circuits'

Here's how that chart could help you find such a problem:

1. Pick one of the multiple symptoms and look up the schematic for that circuit'

2. Make a list of all in-lrne and fuse box connectors in that schematic (include page numbers).

3. Then, in the chart, look up each connector on your list to see if circuits related to the other

symptoms run through one of them. lf they do, inspect that connector for the problem.

Example: The horn, A,/C, and the right headlight don't work. List all in-line and fuse box

connectors in the horn circuit and then check the chart (sample below). You find that C211 is

common to the A,/C circuit and the headlight circuit, so you inspect c211 and find the problem:

bent terminals.

)Connector

(6 or more

cavities)

Numbel of

Cavities - Color

1O-GRY

I 12-GRY

I

Wire

Harnesses

I Main/ | ComP er 'ror c.ntrols,

I Dashboard I

Circuits

Ant!lock brake system (ABS), Cruise control,

Programmed {uel injection system (PGM-FD

!ngrnei

lvlain

lgnition system

Antilock brake system (ABS), BIower controls, Fans,

Wiper/washer

lgnition system, Starting system

Blower controls, Compressor controls, Headlights'

Horns, Vehicle speed sensor (VSS), Wiper/washer

Programmed fuel injection system (PGM-Fl)'

Starting system

Engine/ |Main I

)