check engine light HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 306 of 1681

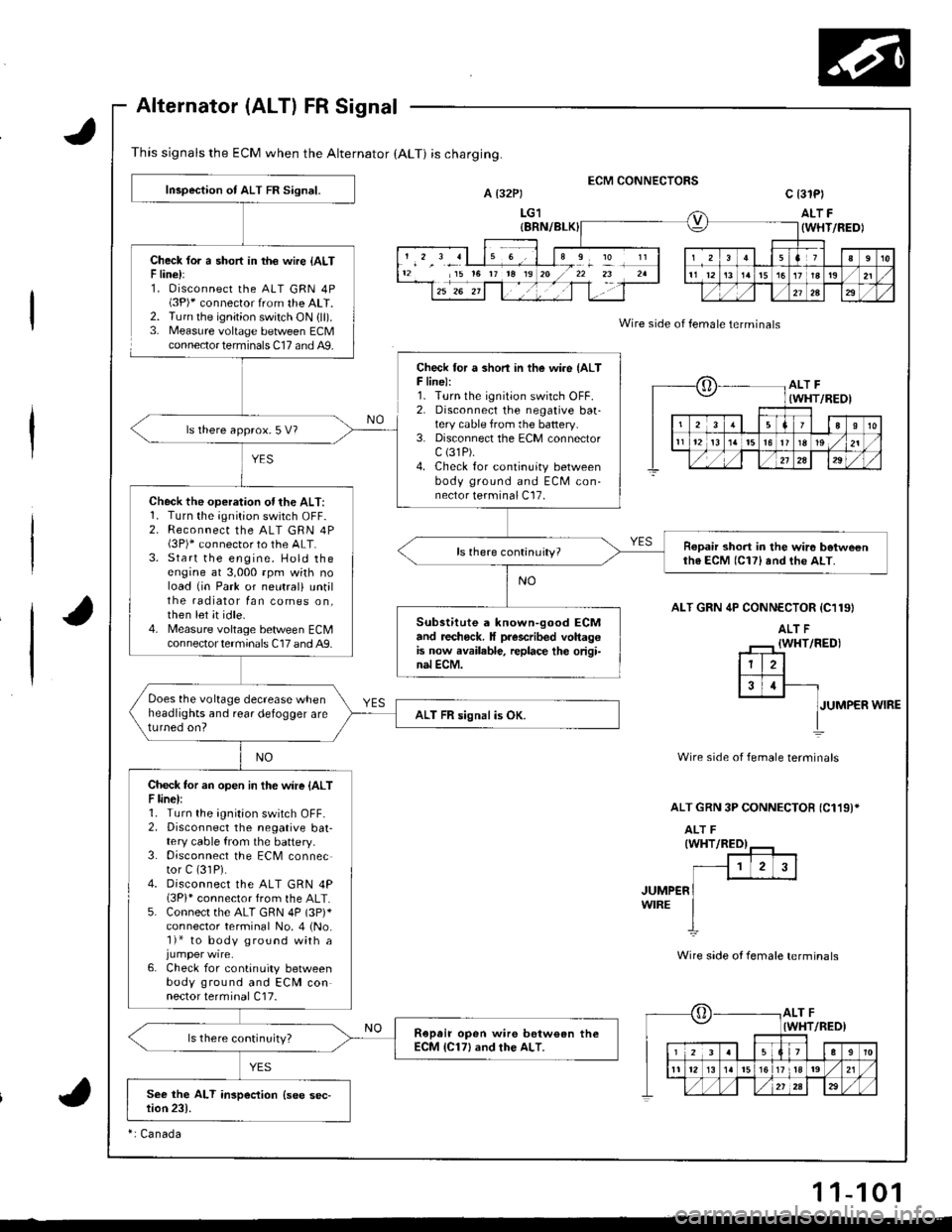

This signals the ECM when the Alternator (ALT) is charging.

Alternator (ALT) FR Signal

Check lor a short in th€ wire {ALTF line):1. Oisconnect the ALT GRN 4P(3P)* connector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECMconnector terminals C17 and A9.

ECM CONNECTORSA t32Pt

LG1

c 13lPl

ALT F(WHT/FEDI

Wire side of female terminals

ALT GRN 4P CONN€CTOR {C119}

JUMPER WIRE

Wire side of female terminals

ALT GRN 3P CONNECTOB {C119)*

JUMP€RWIRE

Wire side ot female terminals

12 15 t6 rr t8 19I

?

oALT F(WHT/REOI

23aI10

t112t3t5l6r819 ,/21

./,/,/2a29

[,ALT FIWHT/RED)

12339

11 12l517 tla19 ,/21

Inspection of ALT FR Signal.

Check for a shon in the wire {ALTF line):1. Turn the ignition switch OFF.2. Disconnecl the negative baatery cable from the battery.3. Disconnect the ECM connectorc (31P).

4. Check for continuity betweenbody ground and ECM con-nector terminal C17.

ls there approx.5 V?

Check the operation ofthe ALT:1. Turn the;Onition switch OFF-2. Reconnect the ALT GRN 4P(3P)* connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm wkh noload {in Park or neutral) untilthe radiator fan comes on,then let it idle.4. Measure voltage bet/veen ECMcon nector termina ls C17 and A9.

Ropair short in the wir6 betweenth6 ECM (C17) and the ALT.

Substitute a known-good ECMand recheck. It prescribed voltagGis now available, replace th€ origi-nal ECM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR signal is OK.

Check tor an open in the wire {ALTF line):1. Turn the ignition switch OFF-2. Disconnect the negative bat-tery cable from the battery.3. Disconnect the ECM connector C (31P).

4. Disconnect the ALT GRN 4P(3Pi* connector from the ALT.5. Connect the ALT GRN 4P (3p)*

connector terminal No. 4 (No.'l)* to body ground with a

6. Check for continuity betweenbody ground and ECM connector terminal C17.

Ropair open wire bstw€an theECM {C17} and rhe ALT.ls there continuity?

ri Canada

11-101

Page 316 of 1681

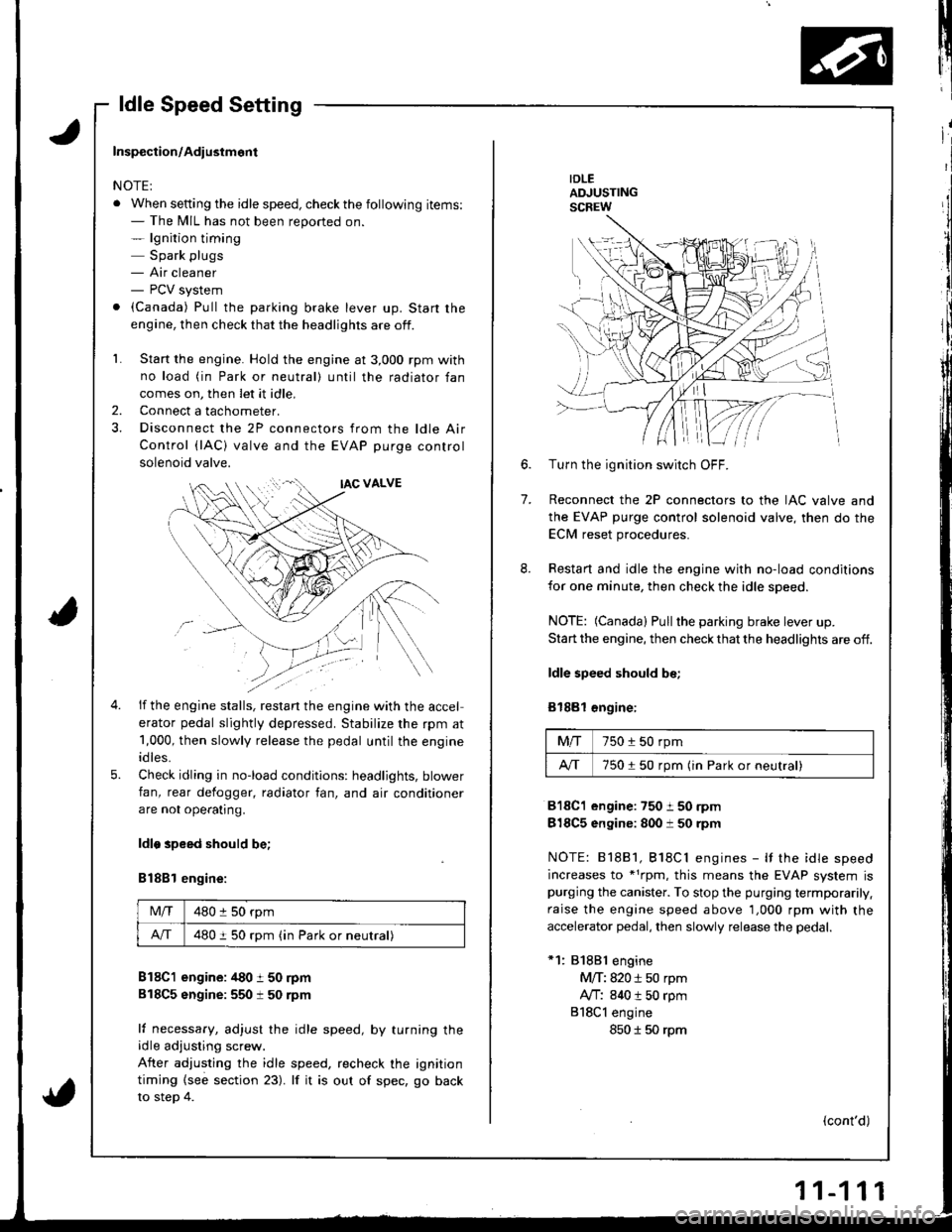

ldle Speed Setting

IDLEADJUSTINGSCREW

7.

6.Turn the ignition switch OFF.

Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM reset procedures.

Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pullthe parking brake lever up.

Start the engine, then check that the headlights are off.

ldle speed should be;

Bl88l €ngine:

Mfi750 i 50 rpm

A/T750150 rpm (in Park or neutral)

818C1 engine:750 i 50 rpm

818C5 engine: 800 i 50 rpm

NOTE: 81881, Bl8Cl engines - It the idle speed

increases to *1rpm, this means the EVAP system ispurging the canister. To stop the purging termporarily.

raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.

*1: 81881 engine

M/T: 820 i 50 rpm

Ay'T: 840 t 50 rpm

818Cl engine

850 I 50 rpm

(cont'd)

Inspection/Adiustmont

NOTE:

. When setting the idle speed, checkthe following items:- The MIL has not been reported on.- lgnition timing

Spark plugs- Air cleaner- PCV system

. (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Disconnect the 2P connectors from the ldle Air

Control (lAC) valve and the EVAP purge control

solenoid valve.

2.

5.

if the engine stalls, restan the engine with the accel

erator pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and air conditioner

are not ope€tlng.

ldlo speed should be;

B188l engine:

Mlf480 :l 50 rpm

A/T480 i 50 rpm (in Park or neutral)

B18C1 engine: /t80 t 50 rpm

818C5 sngine:550 t 50 rpm

lf necessary, adjust the idle speed, by turning theidle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing {see section 23). lf it is out of spec, go back

to steo 4.

Page 317 of 1681

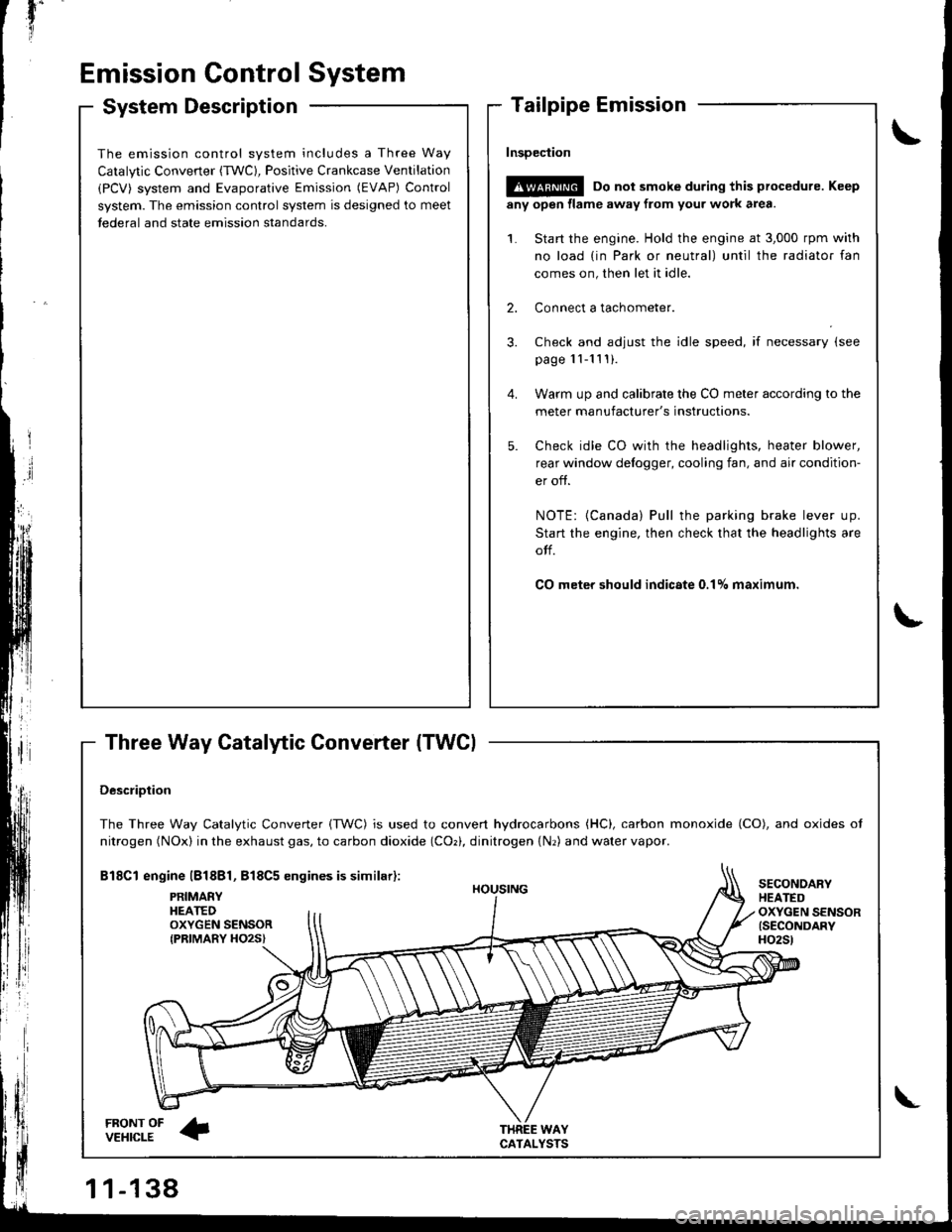

ldle Control System

ldle Speed Setting (cont'dl

ldle the engine for one minute with headlights (Low)

ON and check the idle speed.

ldle 3peed should b€;

B1881 engine:

MIT750 t 50 rpm

750 i 50 rDm (in Park or neutrall

818C1 engine: 7501 50 nm

818C5 engine: 8001 50 rpm

Turn the headlights off. ldle the engine for one min-

ute with heater fan switch at Hl and air conditioner

on, then check the idle speed.

ldl. spood should be;

Bl8Bl ongin.:

M/T820 i 50 rpm

lvT840 t 50 rpm (in Park or neutral)

818C1 €ngino: 850 i 50 rpm

818C5 engino: 1,050 t 50 rpm

NOTE: lf the idle speed is not within specification.

see Symptom Chart on page 1!-36.

\

L

i

lIh:

lffiiltfl!

ffi

| 11-112

\

I

Page 343 of 1681

t"iI

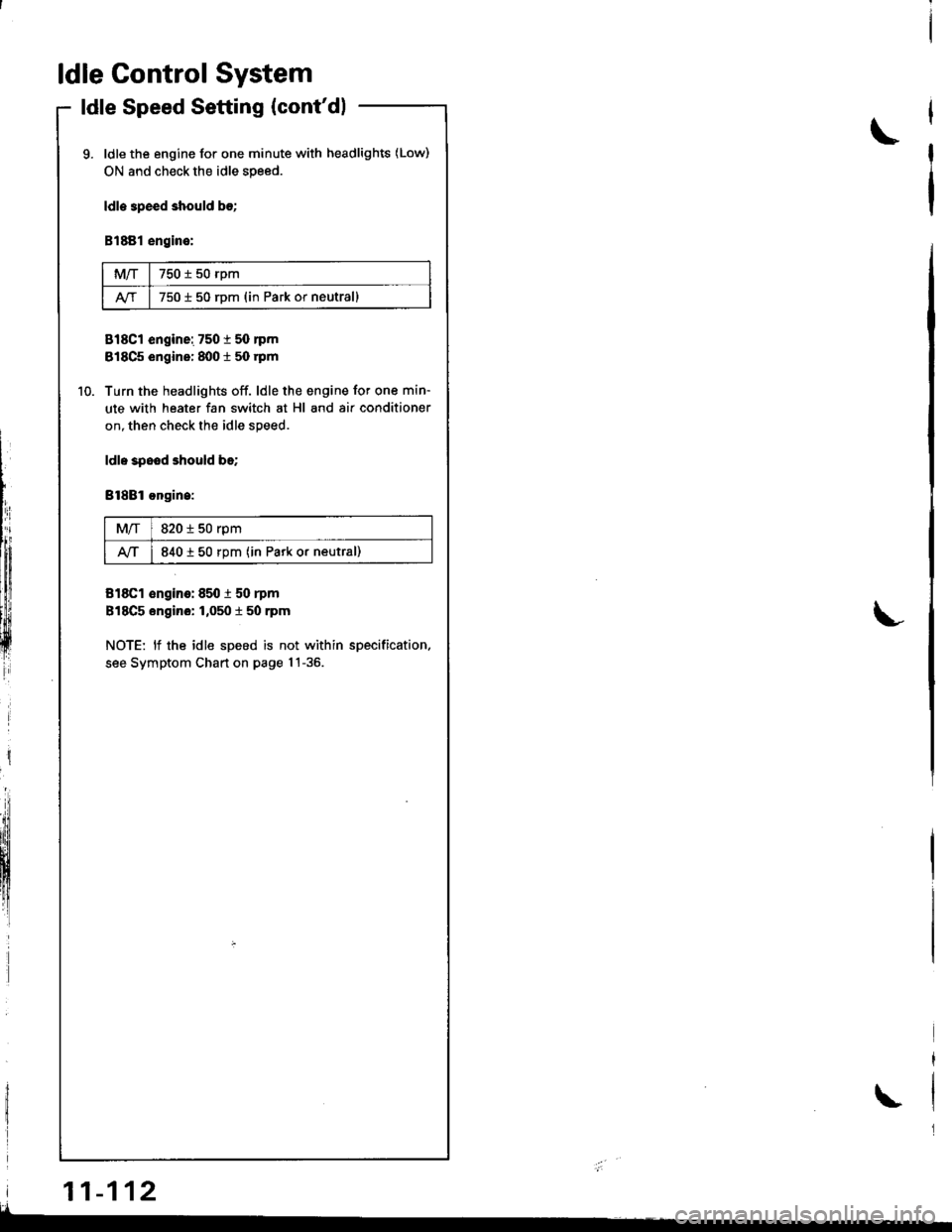

Emission Gontrol System

System Description

Three Way Catalytic Converter (TWCI

\

t

The emission control system includes a Three Way

Catalytic Converter (TWC), Positive Crankcase Ventilation

(PCV) system and Evaporative Emission (EVAP) Control

system. The emission control system is designed to meet

tederal and state emission standards.

InsDeciion

!@@ Do not smoke during this procedure. Keep

any open llame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Connect a tachometer.

Check and adjust the idle speed, if necessary (see

page '11-11 ! ).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with rhe headlights, heater blower,

rear window defogger, cooling fan, and air condition-

er off.

NOTE: {Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights are

olf.

CO meter should indicste 0.17o maximum.

DescriDtion

The Three Way Catalytic Converter {TWC) is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of

nitrogen (NOx) in the exhaust gas, to carbon dioxide (COr), dinitrogen {Nr) and water vapor.

Bl8Cl engine l818Bl, 818C5 engines is similar):

FRONT OFVEHICLE

PRIMAEYHEATEDOXYGEN SENSORIPRIMARY HO2S}

HOUSING

WAYCATALYSTS

SECONOARYHEATEDOXYGEN SENSOR{SECONDARYH02St

\

Page 345 of 1681

'il

Emission Gontrol System

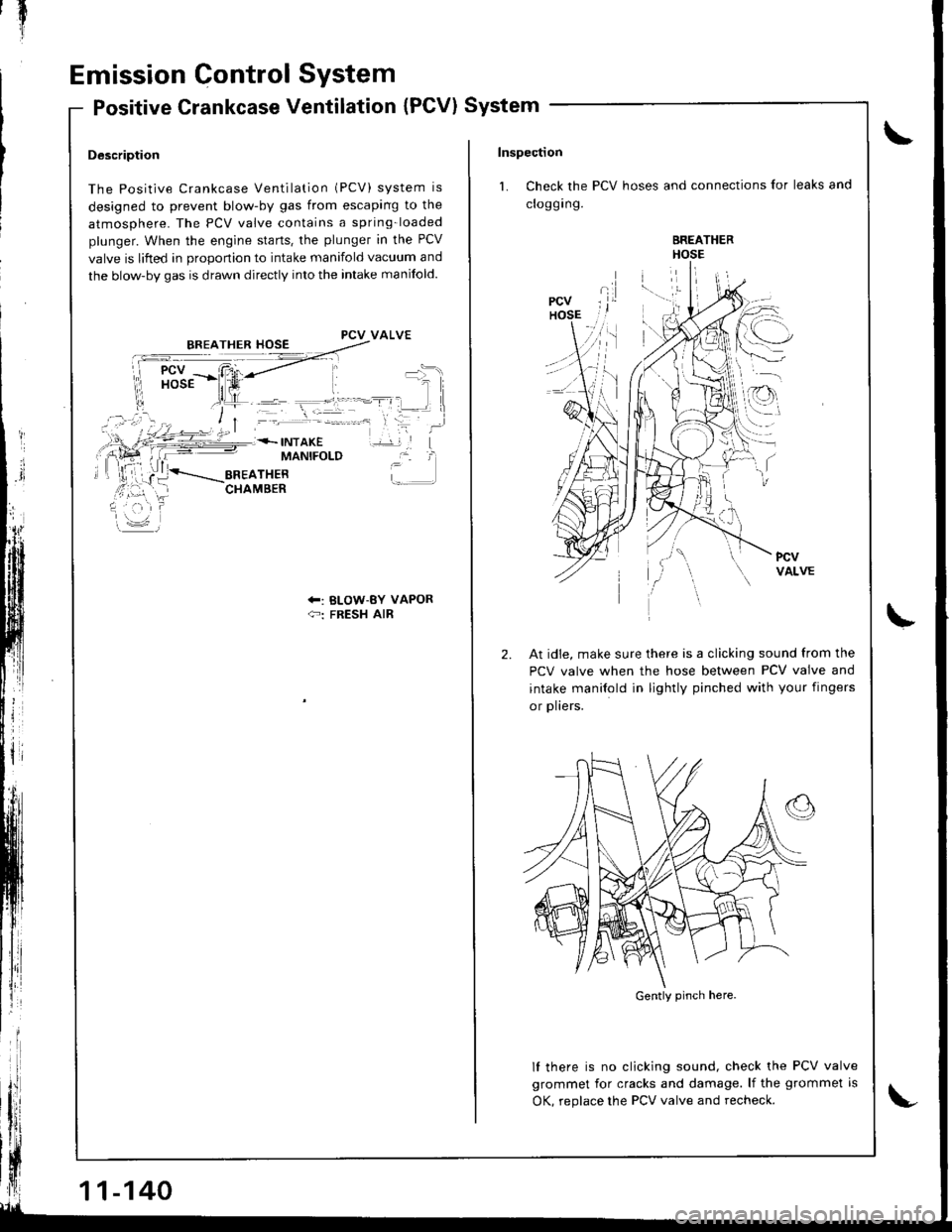

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts. the plunger in the PCV

valve is lifted in orooonion to intake manifold vacuum and

the blow-by gas is drawn directly into the intake manifold.

PCV VALVE

MANIFOLD

+: BLOW-BY VAPOR{-: FRESH AIR

11-140

Inspection

1. Check the PCV hoses and connections for leaks and

croggrng.

BREATHERHOSE

l.--:\

,.r

I

2.At idie, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manilold in lightly pinched with your fingers

or plters.

lf there is no clicking sound, check the PCV valve

grommet for cracks and damage. lf the grommet is

OK, reolace the PCV valve and recheck.

Gently pinch here.

Page 372 of 1681

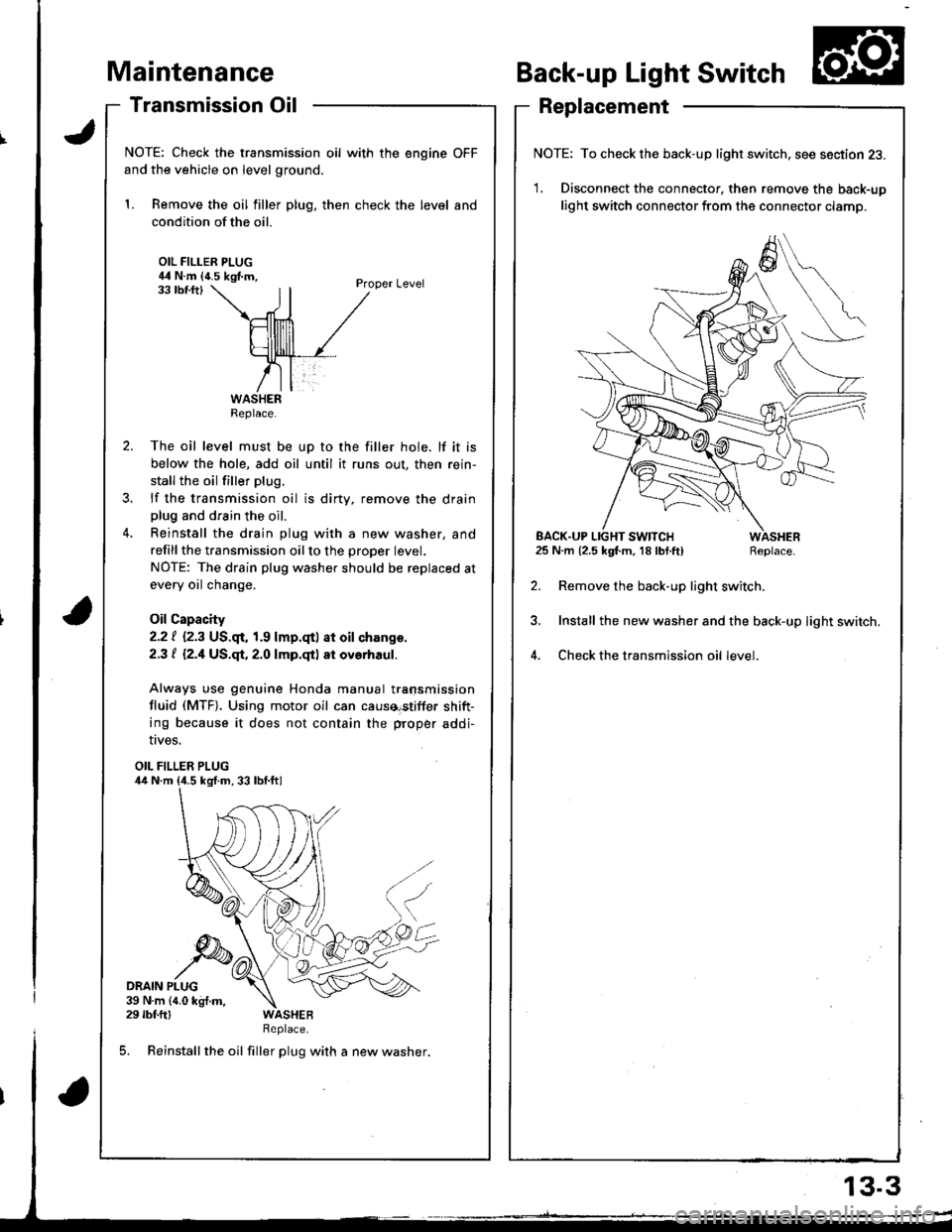

aintenance

Transmission Oil

NOTE: Check the transmission oil with the engine OFF

and the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

OIL FILLER PLUG44 N.m {4.5 kgf.m,Proper Level33 tbf.ftl

The oil level must be up to the filler hole. lf it is

below the hole, add oil until it runs out, then rein-

stall the oil filler plug.

lf the transmission oil is dirty, remove the drainplug and drain the oil.

Reinstall the drain plug with a new washer, and

refillthe transmission oilto the proper tevet.

NOTE: The drain plug washer should be replaced at

every oil change.

Oil Capacity

2.2 | i.2.3 US.qr,1.9 lmp.qtl at oil ch.nge.

2.3 t l2.1US.qt,2.O lmp.qtl at ovorhaul.

Always use genuine Honda manual transmission

fluid (MTF). Using motor oil can causa€tiffer shift-

ing because it does not contain the proper addi-

Back-up Light Switch

Replacement

NOTE: To check the back-up light switch. see section 23.

1. Disconnect the connector, then remove the back-up

light switch connector from the connector clamp.

l.m {2.5 kgf.m, 18lbf.ft) Replace.

Remove the back-up light switch.

Install the new washer and the back-up light switch.

Check the transmission oil level.

!ves.

OIL FILLER PLUG

DRAIN PLUG39 N.m {4.0 kg{.m,29 rbf.ftlReplace.

5. Reinstall the oil filler plug with a new washer,

Replace.

EACK.UP LIGHT SWITCH25 N.m {2.5 kgf.m, 18 lbf.ft)

13.3

Page 471 of 1681

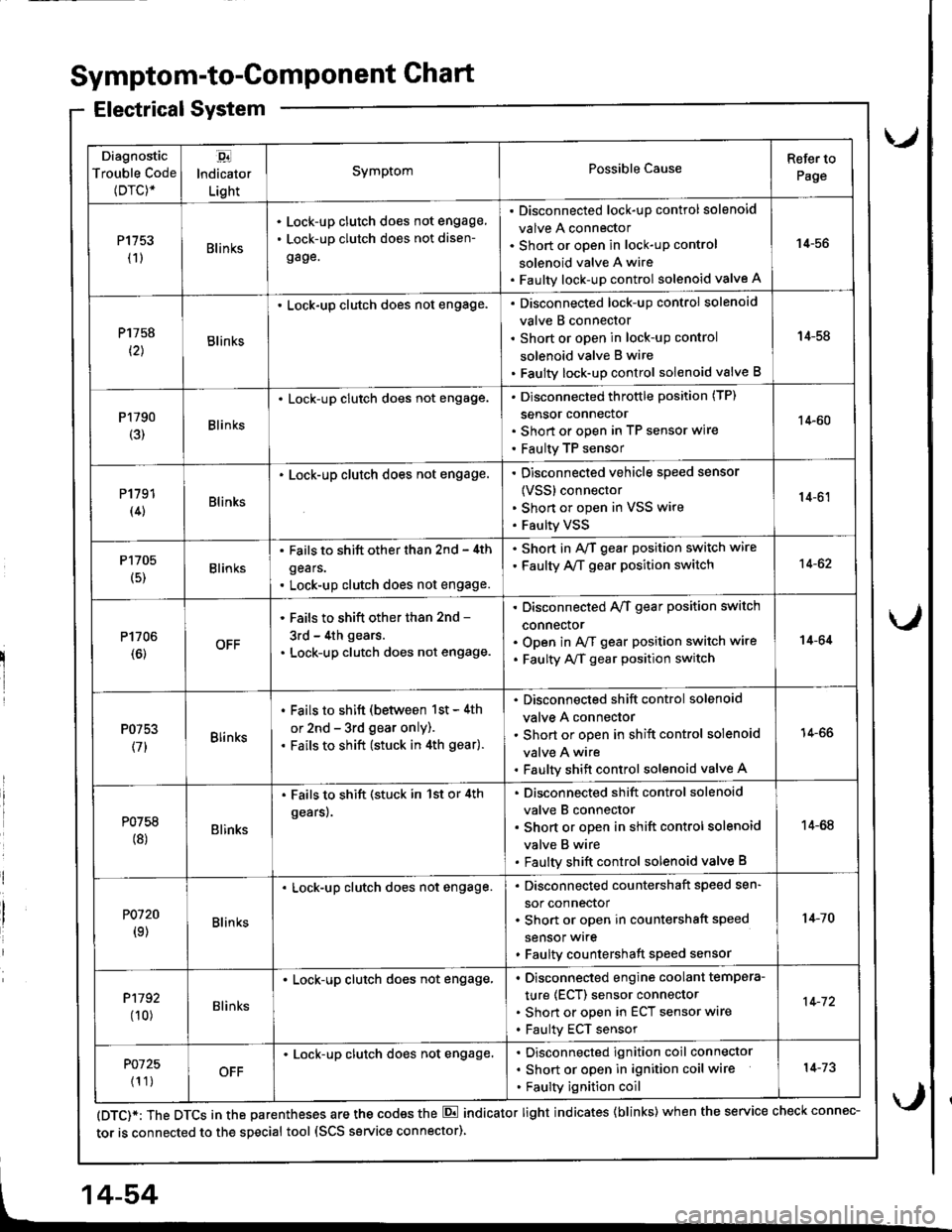

Diagnostic

Trouble Code(Drc)*

,94

lndicator

Light

SymptomPossible CauseRefer to

Page

P1153(1)Blin ks

Lock-up clutch does not engage,

Lock-up clutch does not disen-

gage.

Disconnected lock-up control solenoid

valve A connector

Short or open in lock-uP control

solenoid valve A wire

Faulty lock-up control solenoid valve A

14-56

P1758

t2lBlinks

. Lock-up clutch does not engage.Disconnected lock-up control solenoid

valve B connector

Short or open in lock-uP control

solenoid valve B wire

Faulty lock-up control solenoid valve B

14-58

P1790(3)Blinks

. Lock-up clutch does not engage.Disconnected throttle position (TP)

sensor connector

Short or open in TP seflsor wire

Faulty TP sensor

14-60

P1191(4)Blinks

. Lock-up clutch does not engage.Disconnected vehicle speed sensor

{VSS} connector

Shon or open in VSS wire

Faulty VSS

14-61

P1705

(5)Blinks

. Fails to shift other than 2nd - 4th

gears.

. Lock-up clutch does not engage.

. Shod in AvT gear position switch wire

. Faulty A,/T gear position switch14-62

P1706(6)OFF

' Fails to shift other than 2nd -

3rd - 4th gears.

. Lock-up clutch does not engage.

Disconnected A/T gear position switch

connector

Open in A/f gear position switch wire

Faulty A/f gear position switch

14-64

P0753

(71Blinks

. Fails to shift (between 1st - 4th

or 2nd - 3rd gear only).. Fails to shift (stuck in 4th gear).

Disconnected shift control solenoid

valve A connector

Short or open in shift control solenoid

valve A wire

Faulty shift control solenoid valve A

14-66

P0758(8)Blinks

. Fails to shift (stuck in 1st or 4th

gears).

Disconnected shift control solenoid

valve B connector

Short or open in shift control solenoid

valve B wire

Faulty shift control solenoid valve B

14-68

P0120(9)Blin ks

Lock-up clutch does not engage.Disconnected countershaft speed sen-

sor connector

Short or open in countershaft speed

sensor wrre

Faulty countershaft speed sensor

1+10

P1192

00)Blinks

. Lock-up clutch does not engage,Disconnected engine coolant tempera-

ture (ECT) sensor connector

Short or open in ECT sensor wire

Faulty ECT sensor

14-72

P0725

{1 1)OFF

Lock-up clutch does not engage.Disconnected ignition coil connector

Short or open in ignition coil wire

Faulty ignition coil

14-73

Symptom-to-ComPonent Chart

Electrical System

(DTC)*: The DTCS in the parentheses are the codes the E indicator light indicates {blinks) when the service check connec-

tor is connected to the special tool (SCS service connector)

4-54

Page 489 of 1681

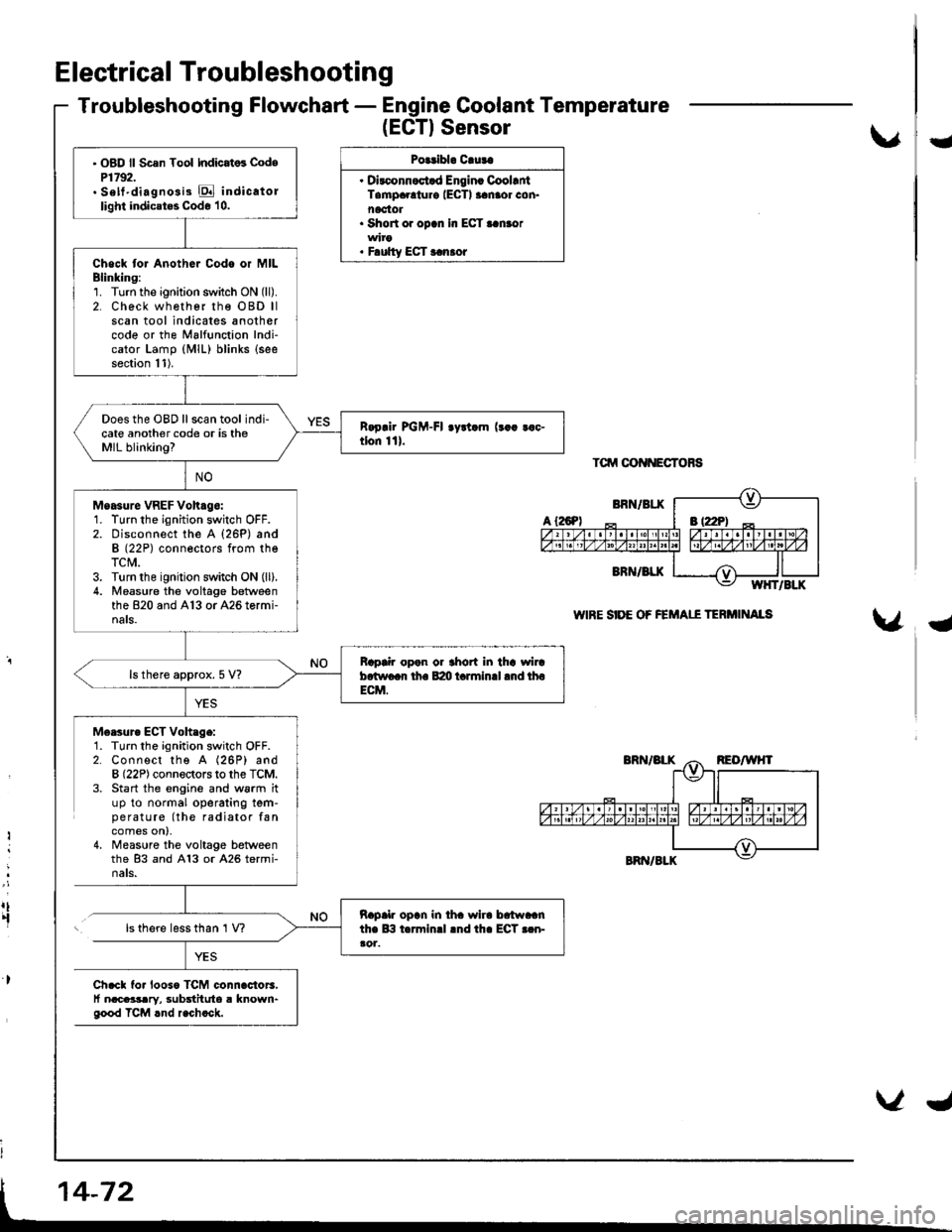

Electrical Troubleshooting

Troubleshooting Flowchart - Engine Coolant Temperature

(EGTISensor

Polribl. Cluta

. Dirconnoct.d Engin. CoollntTampaolur€ IECTI aanaor con.noctot. Short or opcn In ECT..n.or

. F.ulty ECT r.n.or

Tctrrt oot{NEcToRs

WIRE SIDE OF FEMAII TERi'IINAIS

U

{

M6esur. ECT Voh.ge:1. Turn the ignition switch OFF.2. Connect the A (26P) andB (22P) connectors to the TCM.3. Start the engine and w6rm ituP to normal operating tem-pe ratu re (the radiator fancomes on),4, Measure the voltage betweenthe 83 and A13 or A26 termi-nats.

Ii

:

rt.fls there less than 1 V?

Ch.cl fo. looso TCM connac{or3,t nacaasary, substituto a known"good TCM rnd r.chock.

' OBD ll Scsn Tool Indicat6 CodeP1792.. Sett'diagno3i3 E indicatollight indicates Code 10.

Chock tor Anothor Codo or MILBlinking:1. Turn the ignition switch ON (ll).

2. Check wh€ther rhe OBD llscan tool indicates anothercode or the Malfunction Indi-cator Lamp (MlL) blinks (see

section 11).

Does the OBD ll scan tool indi-cate another code or is theMIL blinking?

Moasure VREF Voh.go:1. Turn the ignition switch OFF.2. Disconnect the A {26P) andB (22P) conneotors from theTCM.3. Turn the ignition switch ON (ll).

4. Measu.e the voltage betweenthe 820 and A13 or A26 tormi-nals.

Bap|ir open or thort in tha wircb.two.r th. B:m t.rminll .nd thoECM.

ls there approx. 5 V?

napalr opln in iha wlra brtwaanthe lB t.rminrl lnd th. ECT r.n-ao1.

Page 493 of 1681

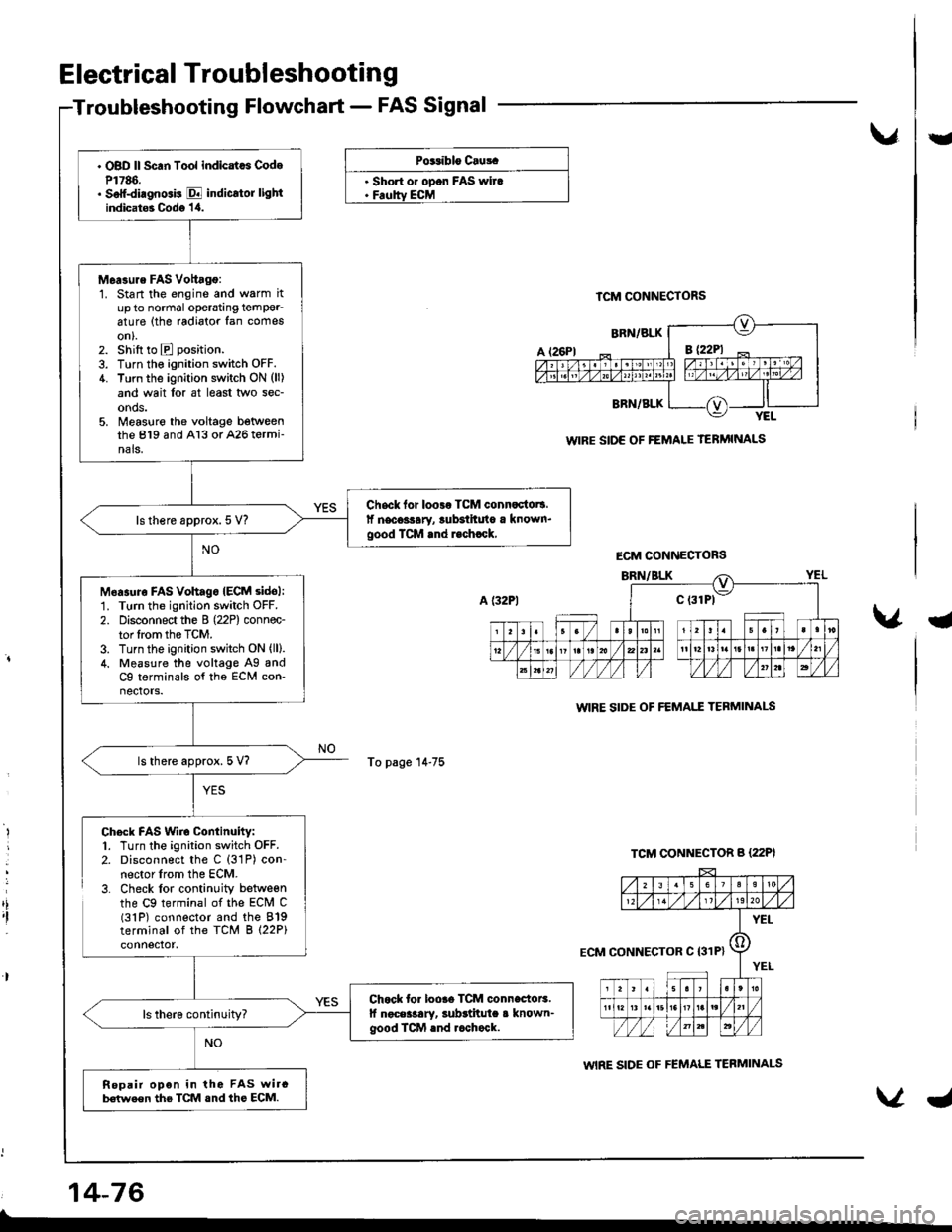

. OBD ll Scan Tool indicatcs CodeP1786.. Soff-diagnGis E indicrtor lightindicat6 Codo '1,0.

M6a3ure FAS Vottago:1. Start the engine and warm itup to normal operatang temPer_6ture (the radiator fan comeson).2. shift to E position.

3. Turn the ignition switch OFF.4. Turn the ignition switch ON (ll)

and wait lor at least two sec-onds.5. Measlre the voltage betweenthe 819 and A13 or A26 termi-nals.

Chsck for loo3r TCM connactot!.lf necoslary, lubsihuto a known.good TCM rnd r.chrck,ls there approx. 5 V?

M6asuro FAs vohagoIECM sidol:1. Turn the ignition switch OFF.

2. Disconnect the B (22P) connec-tor lrom the TCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage Ag andC9 terminals of tho ECM con-nectors.

ls there approx. 5 V?

Chock for loore TCM connectoE.lf noceilary, subrtitula a known-good ICM rnd rcchock.

Repair opon in the FAS wircb€(we€n the TCM snd ths ECM.

Electrical Troubleshooting

Troubleshooting Flowchart - FAS Signal

vU

PG.iblo Cru!.

. Short o. opon FAS wira. Feoltv ECM

To page 14-75

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

WIRE SIDE OF FEMAI.T TEBMINAI-S

WIRE SIDE OF FEMALE TERMINALS

a

,i,I

Chock FAS Wiro Continuity:1. Turn the ignition switch OFF.2. Disconnect the C (31P) con-nector lrom the ECM.3. Check lor continuity betweenthe C9 terminal of the ECM C(31P) connector and the 819terminal of the TCM B (22P)

14-76

ECM CONNECTORS

ECM CONNECTOR C I31P}

Page 507 of 1681

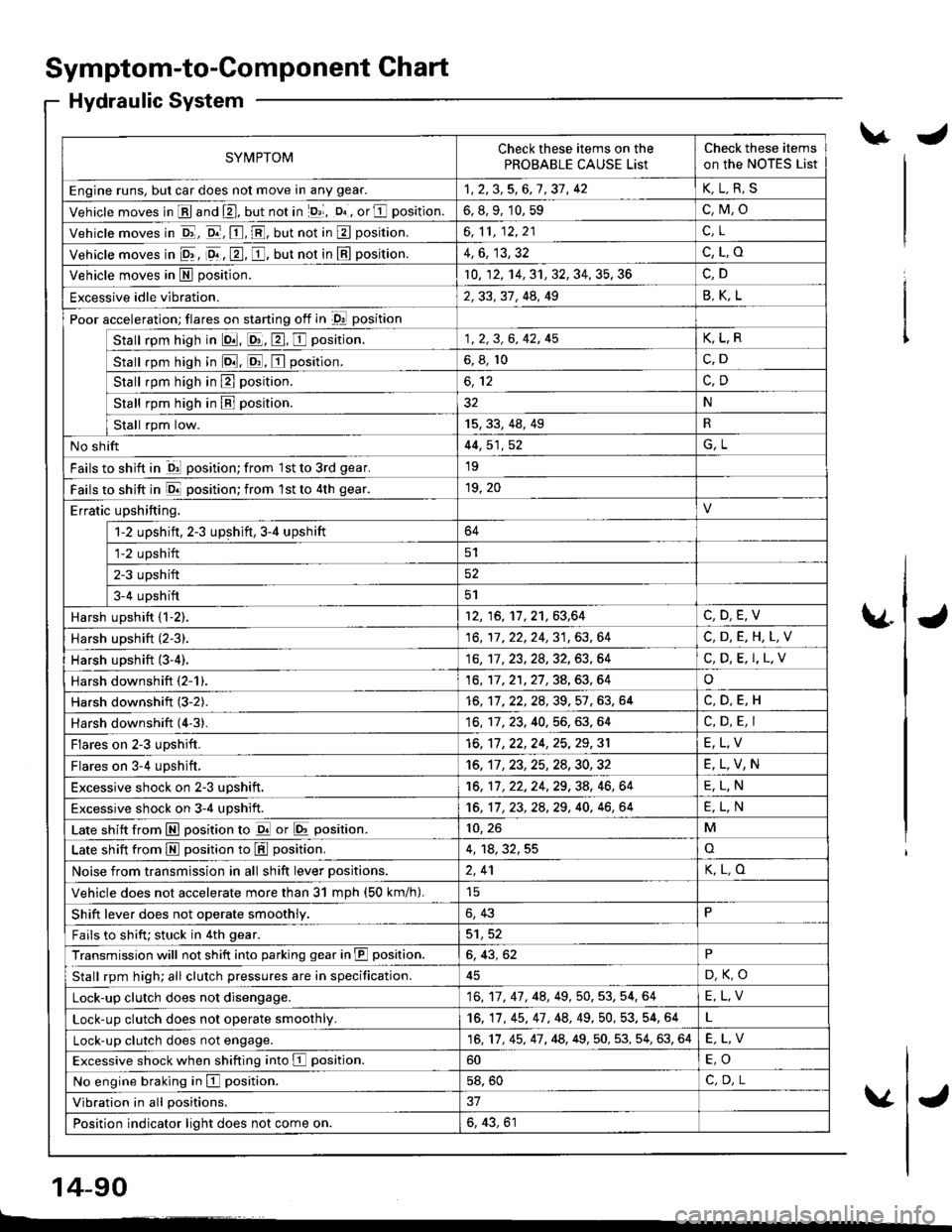

Symptom-to-Component Chart

Hydraulic System

SYMPTOMCheck these items on the

PROBABLE CAUSE List

Check these items

on the NoTES List

Engine runs, but car does not move in any gear.1,2,3,5,6,7,37, 42K,L.R,S

Vehicle moves in E and E, but not in lD,l, D. , or E position.6, 8, 9, 10, 59c,M,o

Vehicle moves in E, o.-, E, E, but not in E position.6,11,12,21c.L

Vehicle moves in 9r, 9. , E, E, but not in E position.4,6, 13,32c,L,o

Vehicle moves in E position.10, 12, 14, 31, 32, 34, 35, 36

Excessive idle vibration.2,33, 31, 44, 49B,K,L

Poor acceleration; flares on starting off in D! position

Stall rpm high in lQ|. E, E, E position.1, 2, 3, 6, 42, 45K,L,R

stall rpm high in lo.tl. ld, E position.6, 8, 10c.D

Stall rpm high in E position.

Stall rpm high in B position.32N

tat"tkp,ril"*'15,33,48,49R

No shift44, 51, 52G,L

Fails to shift in ql position; from 1st to 3rd gear.19

Fails to shift in E position; from lst to 4th gear.19, 20

Erratic upshifting.

1-2 upshift, 2-3 upshift,3-4 upshift64

fiz upshift

ETupshift52

Ia-+ upstrifi5l

Harsh upshift {1-2).12, 16, 11,21,63,64C,D,E,V

Harsh upshift (2-3).16,17,22,24,31,63,64C,D,E.H,L,V

Harsh upshift (3-4).16,'�tl. 23, 28, 32, 63, 64C, D, E. I,L.V

Harsh downshift (2-1).16, 17,21,27,34,63,64o

Harsh downshift (3-2).16, 11 ,22,2A,39,57 ,63, 64

Harsh downshift (4'3).16, 17, 23. 40, 56, 63. 64C, D, E, I

Flares on 2-3 upshift.16, 17 ,22,24, 25,29,31E,L,V

Flares on 3-4 upshift,16, 11 ,23,25,24,30,32E,L,V,N

Excessive shock on 2-3 uDshift.16, 11, 22, 24, 29, 38, 46, 64E,L.N

Excessive shock on 3-4 upshift.16, 11 , 23, 2a,29, 40, 46, 64E,L,N

Late shift from E position to d or E position.10, 26M

Late shift from M position to L!!l position.4, 18,32,55o

Noise from transmission in all shift lever Dositions.2,41K,L,O

Vehicle does not accelerate more than 31 mDh (50 km/h).

Shift lever does not operate smoothly.6, 43P

Fails to shifu stuck in 4th gear.5'1,52

Transmission will not shift into parking gear in JII position.6, 43, 62P

Stall rpm high; all clutch pressures are in specification.D,K,O

Lock-up clutch does not disengage.16,17, 47, 48,49, 50, 53, 54, 64E,L,V

Lock-up clutch does not operate smoothly.16, 17, 45, 47 , 48, 49,50, 53. 54, 64

Lock-up clutch does not engage.16,17, 45, 47, 48, 49,50, 53, 54, 63, 64E,L,V

Excessive shock when shifting into E position.60

No engine braking in E position.58, 50C,D.L

Vibration in all positions.

Position indicator light does not come on.6, 43, 61

\.J

\4J

v

14-90

L------�

J