fuel pressure HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 322 of 1681

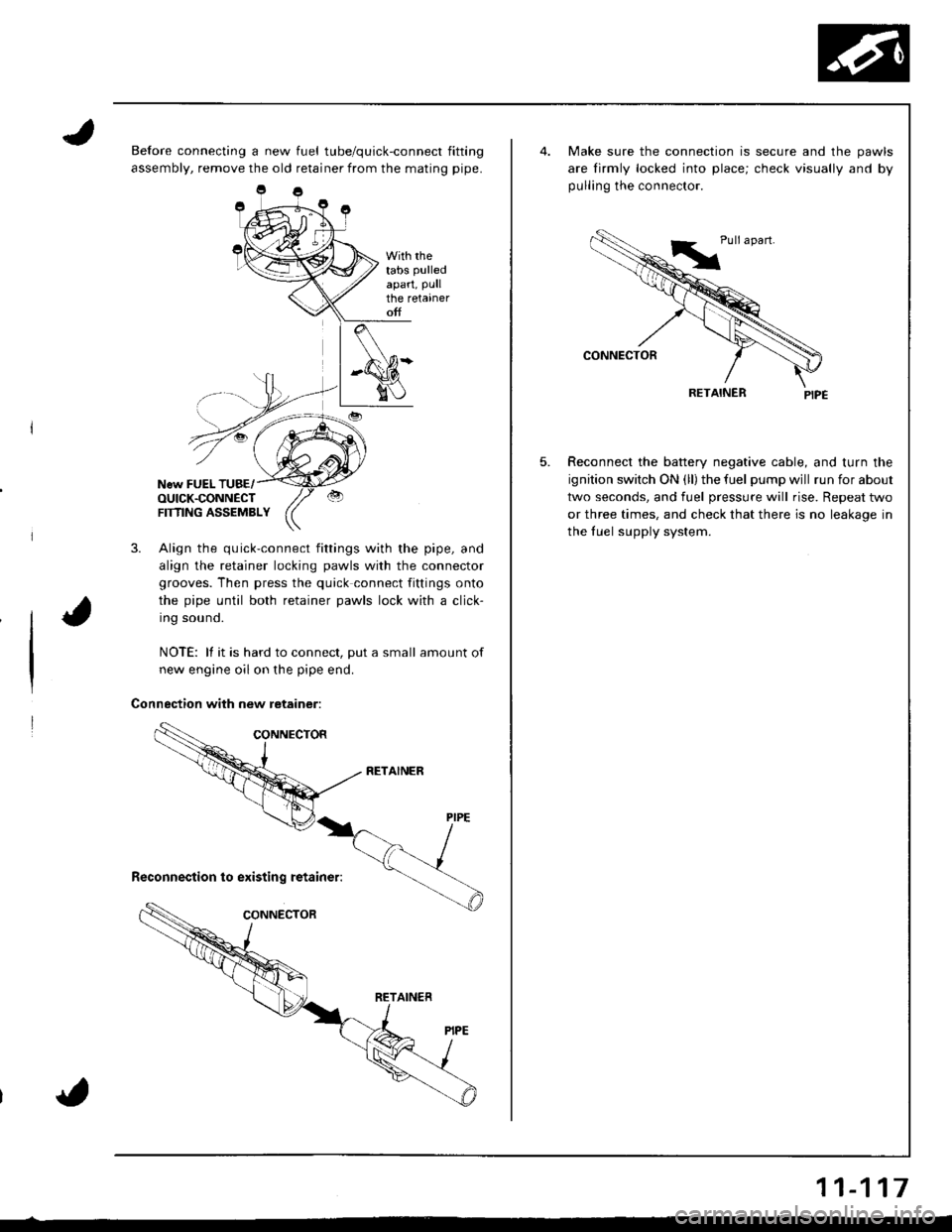

Before connecting a new fuel tube/quick-connect fitting

assembly, remove the old retainer from the mating pipe.

With rhetabs pulled

apart, Pullthe retaineroff

New FUEL TUBE/OUICK.CONNECTFTflNG ASSEMBLY

3. Align the quick-connect fittings with the pipe, and

align the retainer locking pawls with the connector

grooves. Then press the quick connect fittings onto

the pipe until both retainer pawls lock with a click-

Ing souno.

NOTE: lf it is hard to connect, put a small amount of

new engine oil on the pipe end.

Connection with new retainer:

5.

Make sure the connection is secure and the pawls

are lirmly locked into place; check visually and by

pulling the connector.

RETAINER

Reconnect the battery negative cable, and turn the

ignition switch ON (ll) the fuel pump wjll run for about

two seconds, and fuel pressure will rise. Repeat two

or three times, and check that there is no leakage in

the fuel supply system.

11-117

Page 323 of 1681

The fuel supply system co

high pressure fuel pump, t

fuel pressure regulator. f

damper, and fuel delivery i

delivers pressure-regulated

cuts the luel delivery when

Fuel Supply System

System Description

consists of a fuel tank, in-tank

r, PGM-Fl main relay, fueffilter,

. fuel injectors, fuel pulsation

y and return lines. This system

ed fuel to the fuel injectors and

rn thq engine is not running.

Fuel Pressure

Relieving

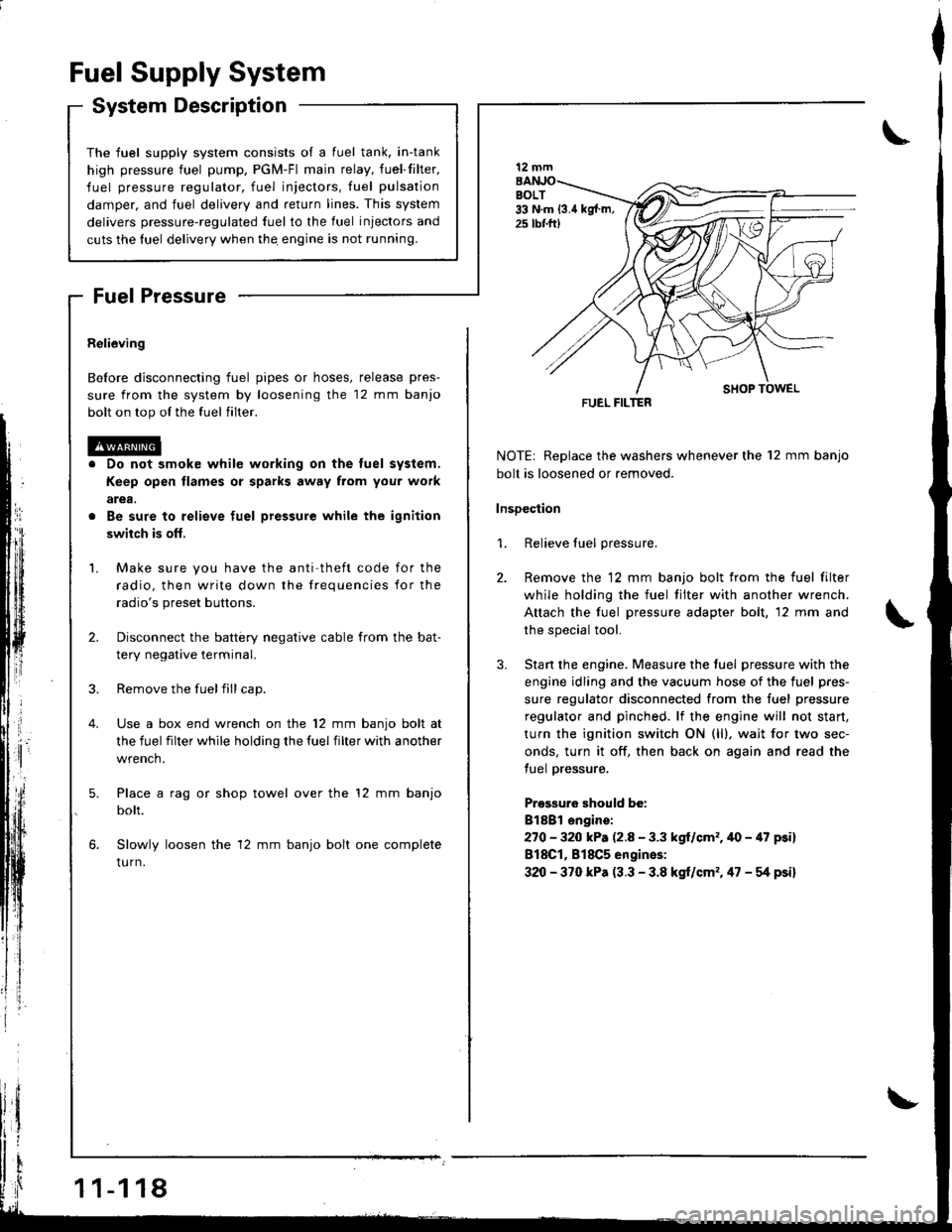

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on top ol the fuel filter.

Do not smok€ while working on the tuel system,

Keep open flames or sparks away from you. work

arga.

Be sure to relieve fuel pressure while the ignition

swiich is ofl,

Make sure you have the anti theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

Disconnect the battery negative cable from the bat-

tery negative terminal.

Remove the fuelfill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with another

wrench.

Place a rag or shop towel over the '12 mm banjo

bolt.

Slowly loosen the 12 mm banjo bolt one complete

tu rn.

1 1-1 18

I

NOTE| Replace the washers whenever the 12 mm banjo

bolt is loosened or removed.

lnsDection

1. Relieve fuel pressure.

2. Remove the 12 mm banjo bolt from the fuel filter

while holding the fuel tilter with another wrench.

Attach the fuel pressure adapter bolt, 12 mm and

the special tool.

3. Stan the engine. Measure the tuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch ON (ll), wait for two sec-

onds, turn it off, then back on again and read the

tuel pressure.

Pressuro should be:

Bl8Bl engire:

270 - 320 kP. (2.8 - 3.3 kgl/cm'�.40 - 47 psi)

818C1, 818C5 engines:

320 - 370 kPa (3.3 - 3.8 kgt/cm'�. 47 - g psi)

12 mm

FUEL FILTER

Page 324 of 1681

Reconnect vacuum hose to the fuel pressure reguta_ror.

Pressure should be:

818B1 engin€:

250 - 290 kPa (2.5 - 3.0 kgt/cm,, 36 - 4,:t p3i)818C1, B18C5 onginss:

260 - 310 kPa (2.7 - 3.2 kgl/cm,, 38 - 46 psi)

FUEL PRESSURE GAUGE07406 - 004{xr0r

ADAPTER BOIT, i2 mmt90008-PD6_010)

lf the fuel pressure is not as specified, first check the fuelpump (see page 11-123). tf the fuet pump is OK, checkthe following:

. lf the fuel pressure is higher than specified, inspecttor:- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page l l _121).. lf the fuel pressure is lower than specified, inspectfor:- Clogged fuel fitter.- Faulty fuel pressure regulator (see page .ll-.121).

- Fuel line leakage.

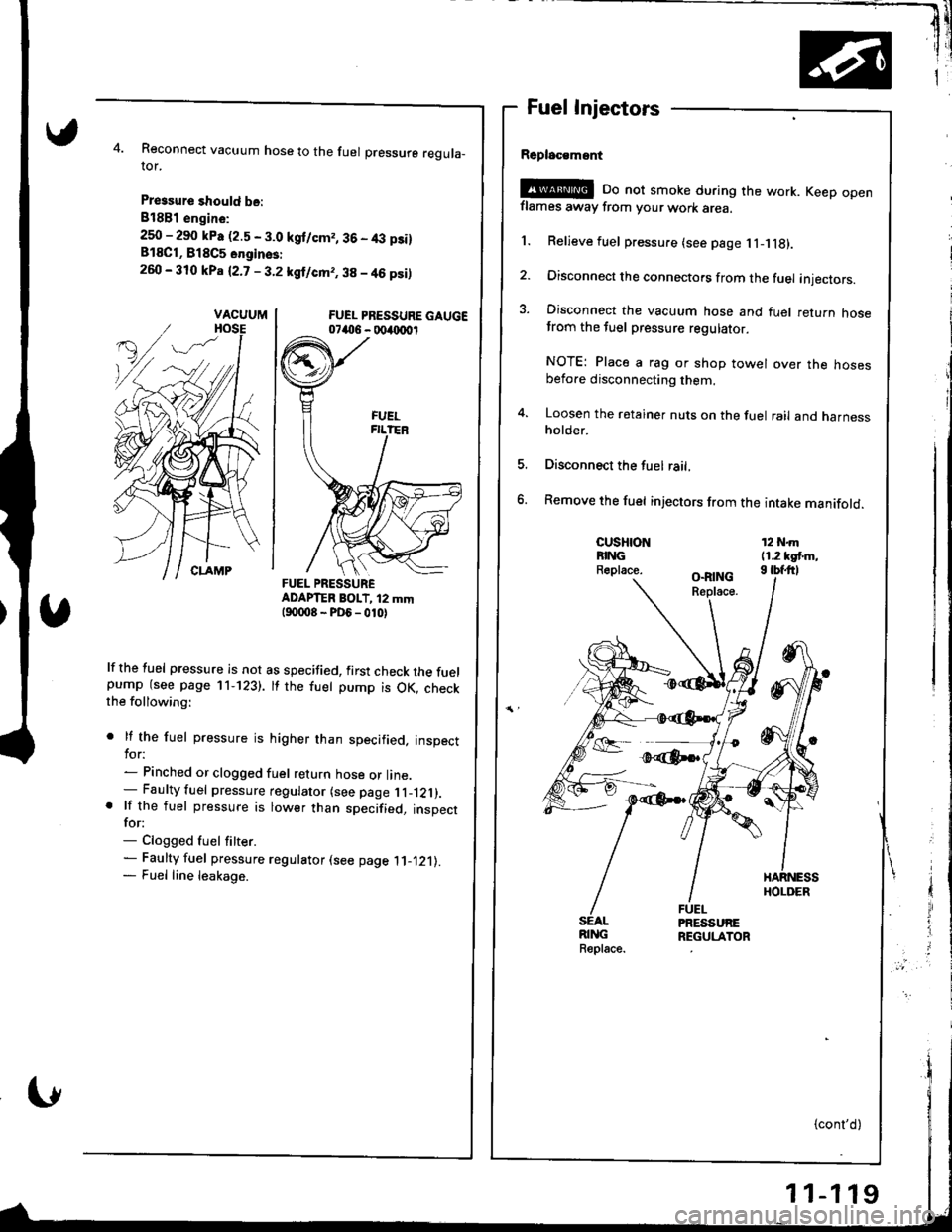

Fuel Injectors

Rsplac€msnt

!@E oo not smoke during the work. Keep openflames away from your work area.

1. Relieve fuel pressure (see page 1l- g).

2. Disconnect the connectors from the fuel injectors.

3. Disconnect the vacuum hose and fuel return hosetrom the tuel pressure regulatot.

NOTE: Place a rag or shop towel over the hosesbefore disconnecting them.

4. Loosen the retainer nuts on the fuel rail and harnessholder.

Disconnect the fuel rail,

Remove the fuel injectors from the intake manifold.

CUSHIONFINGR.place.

12 N.m11.2 kgt m,I tbfftl

SEALRINGReplace.

VACUUM

FUEL PRESSURE

Page 325 of 1681

I

Fuel Supply System

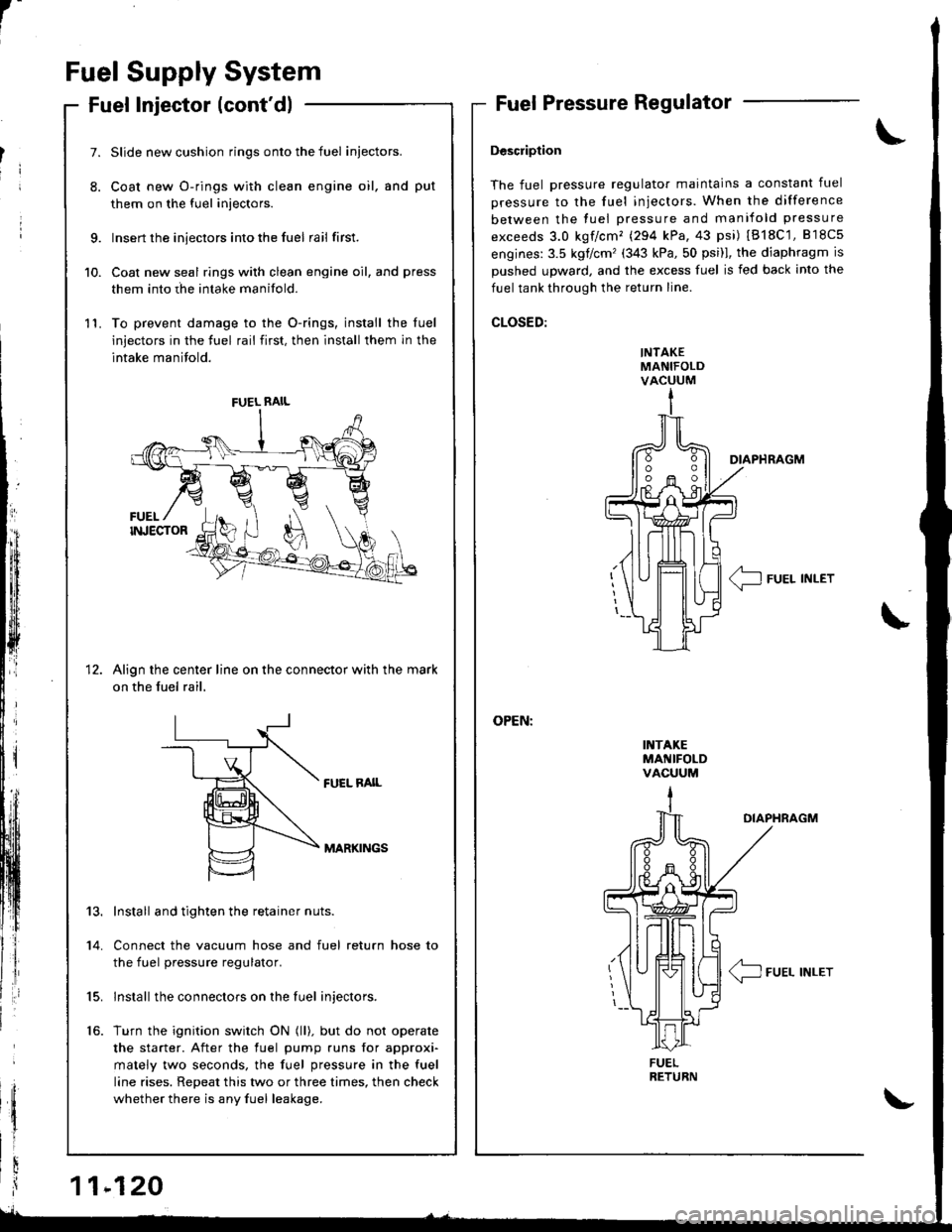

Fuel Injector (cont'dlFuel Pressure Regulator

Description

The fuel pressure regulator maintains a constant fuel

pressure to the fuel injectors. When the difference

between the fuel pressure and manifold pressure

exceeds 3.0 kgf/cm'� (294 kPa,43 psi) IB18C'1,818c5

engines:3.5 kglcm'(343 kPa,50 psi)l, the diaphragm is

Dushed uDward, and the excess fuel is fed back into the

fuel tank through the return line.

CLOSED:

INTAKEMANIFOLDVACUUM

I1{TAKEMANIFOLDVACUUM

DIAPHRAGM

< IFUEL INLET\-

\

OIAPHRAGM

/4_\T-J FUEL INLET

9.

10.

11.

7.

8.

1t

Slide new cushion rings onto the fuel iniectors.

Coat new O-rings with clean engine oil, and put

them on the fuel injectors.

Insert the injectors into the fuel rail first.

Coat new seal rings with clean engine oil, and press

them into rhe intake manifold.

To prevent damage to the O-rings, install the luel

injectors in the fuel rail first, then install them in the

intake manifold.

Align the center line on the connector with the mark

on the fuel rail,

FUEL RAIL

MARKINGS

13.

14.

15.

16.

Install and tighten the retainer nuts.

Connect the vacuum hose and fuel return hose to

the fuel pressure regulator.

lnstall the connectors on the fuel injectors.

Turn the ignition switch ON (ll). but do not operate

the starter. After the fuel pump runs for approxi'

mately two seconds, the fuel pressure in the fuel

line rises. Repeat this two or three times, then check

whether there is any fuel leakage.

FUEL RAIL

FUEL

Page 326 of 1681

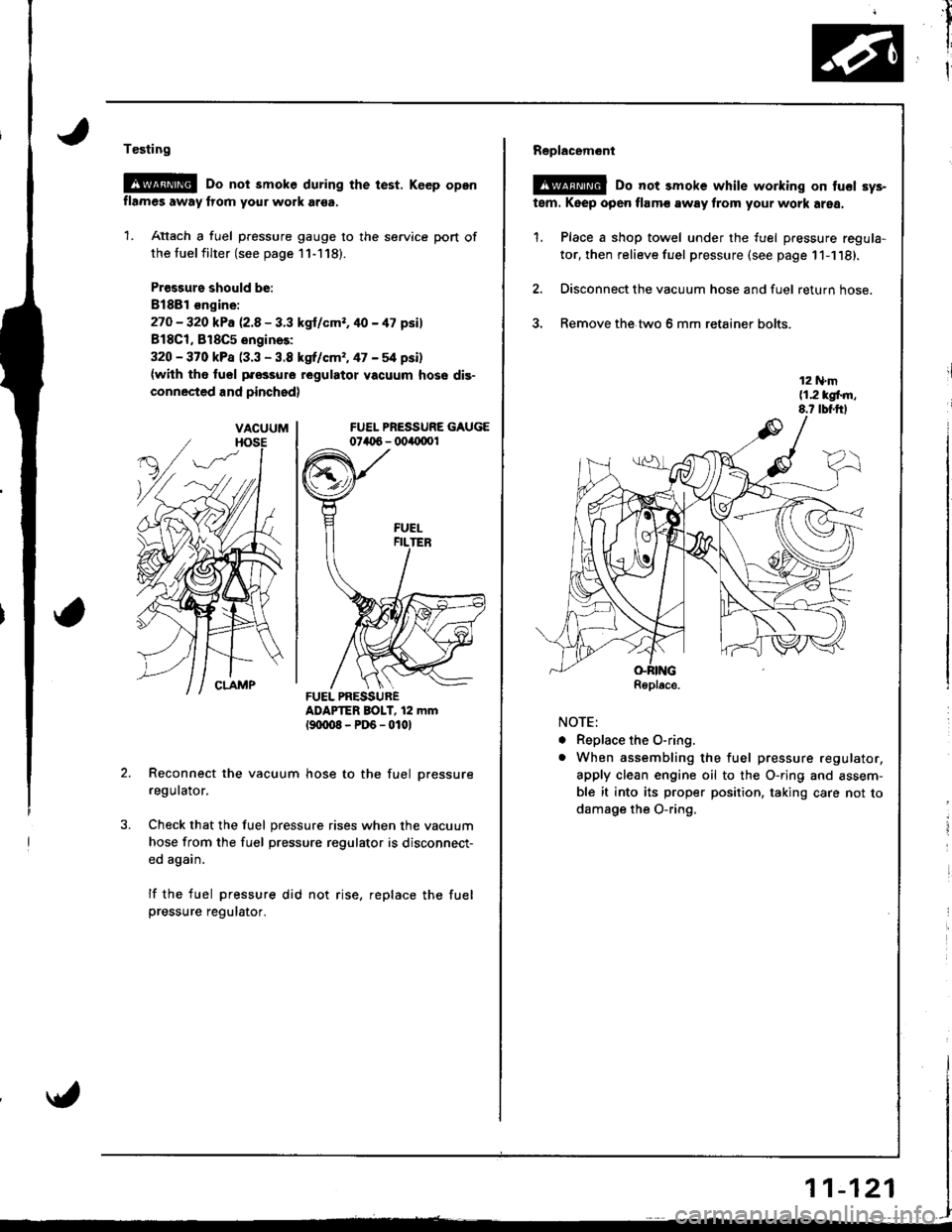

Testing

@G Do not smoke during the test. Keep opon

flames away lrom your work ar€a.

1. Attach a fuel pressure gauge to the service port of

the tuel filter (see page 11-118).

Pr€ssurs should be:

8188l €ngine:

27O - 320 kPa 12.8 - 3.3 kgl/cmr. 40 - 47 psil

818C1, 818C5 engines:

320 - 370 kPa (3.3 - 3.8 kgrf/cm,, 47 - 54 psi)

{with tho fuol pfossure regulatot vacuum hose dis-

connected and pinchsd)

FUEL PRESSURE GAUGE074t 6 - 004{1001

ADAPTER BOIT, 12 mm(9txt08-PD6-0101

Reconnect the vacuum hose to the fuel pressure

regulator.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnect-

ed again.

lf the fuel pressure did not rise, replace the fuelpressure regulator.

VACUUM

FUEL PRESSURER€place.

AA

,il

I

I

Replacem6nl

@ Do not smoke while working on tucl sys-

tem. Keep open flamc away from your work area.

1. Place a shop towel under the fuel pressure regula-

tor, then relieve fuel pressure (see page 11-1'18).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the.two 6 mm retainer bolts.

NOTE:

. Replace the O-ring.

o When assembling the fuel pressure regulator,

apply clean engine oil to the O-ring and assem-

ble it into its proper position, taking care not to

damage the O-ring.

r1

i

i

11-121

Page 327 of 1681

rr*

Fuel Supply System

Fuel Filter

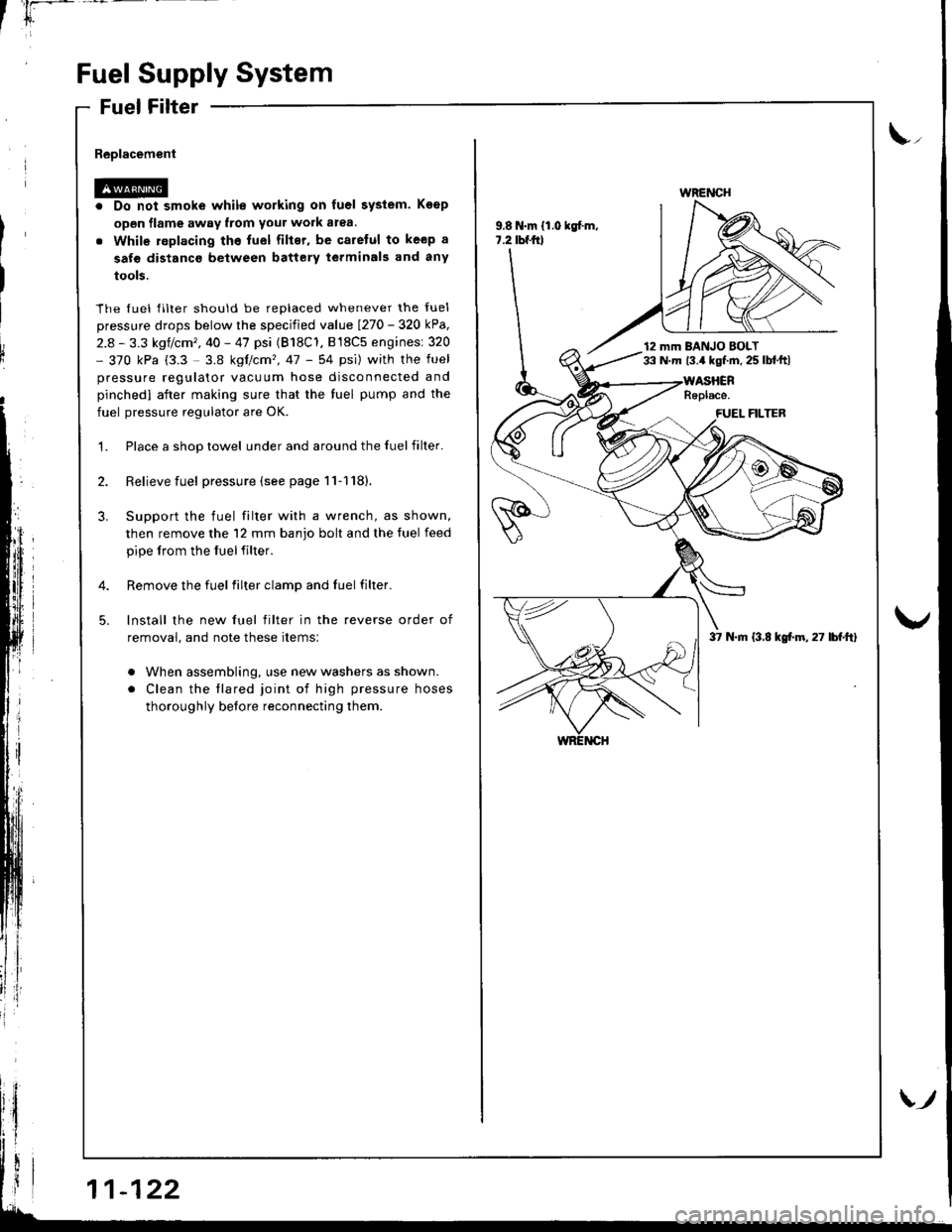

Replacement

Do not smoke while working on fuel system. Koop

open flame away from your work atea.

While replacing the fuel filter, be qaretul to keep a

sate distanco between battery terminals and any

tools.

The fuel filter should be replaced whenever the fuel

pressure drops below the specified value I27o - 32O kPa,

2.8 - 3.3 kgf/cm', 40 - 47 psi (B18C'1, B l8C5 enginesi 320- 370 kPa (3.3 - 3.8 kgtcm'�,47 - 54 psi) with the fuel

pressure regulator vacuum hose disconnected and

pinchedl aiter making sure that the tuel pump and the

fuel pressure regulator are OK.

Place a shop towel under and around the fuelfilter.

Relieve fuel pressure {see page 11-1'18}.

Support the fuel filter with a wrench, as shown,

then remove the 12 mm banjo bolt and the tuel feed

pipe lrom the fuelfilter.

Remove the fuel filter clamp and fuel filter.

lnstall the new fuel filter in the reverse order of

removal, and note these items:

. When assembling, use new washers as shown.

. Clean the tlared joint of high pressure hoses

thoroughly before reconnecting them.

\,,

9.8 N.m {1.0 kgf.m,7.2 tbf.frl

WRENCH

12 mm BANJO BOLT33 N.m 13.4 kgf.m. 25 lbl.ftl

37 N.m (3.8 kgf.m,27 lbf.ft)

Page 332 of 1681

1r

;

J

I

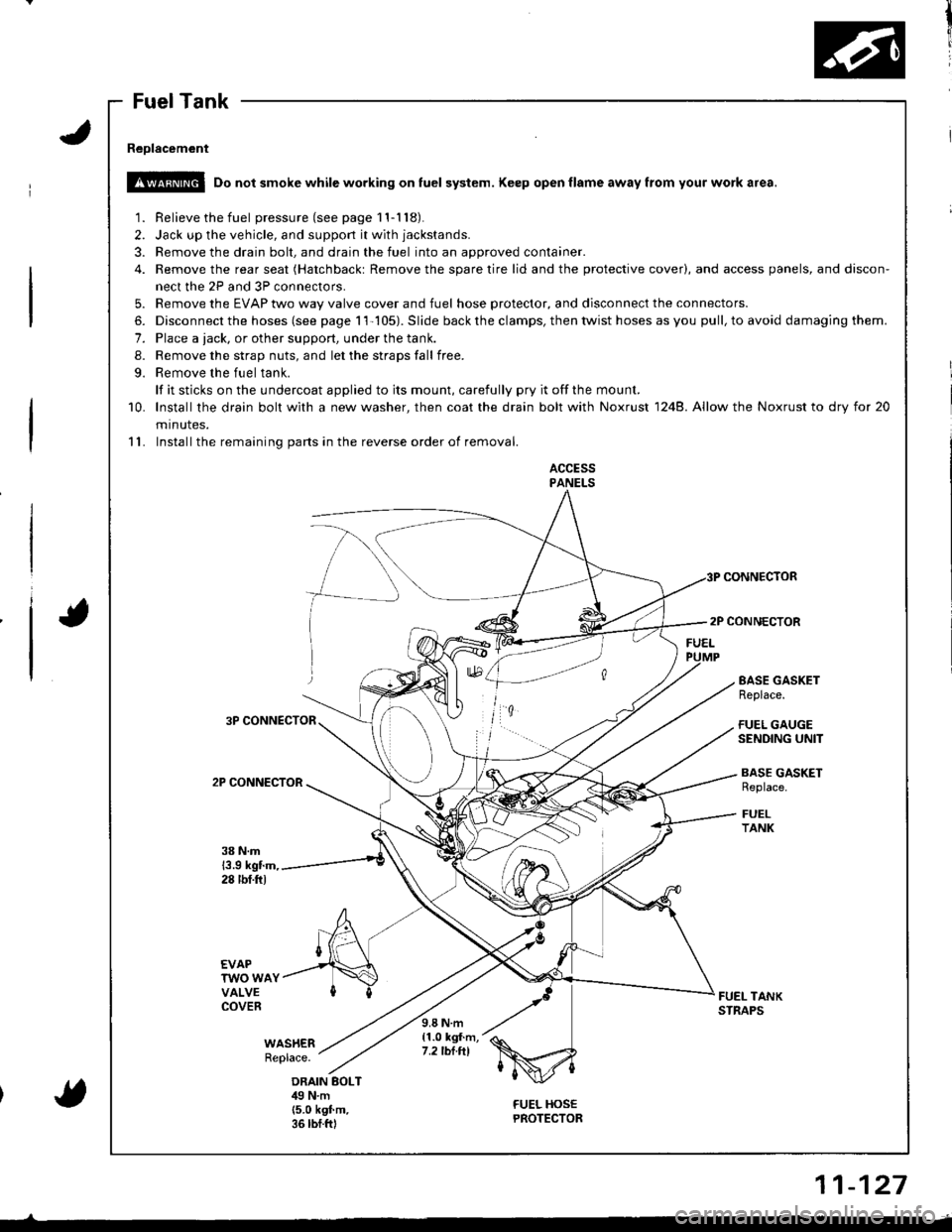

Fuel Tank

Reolacement

!!@ Do not smoke while working on fuel system. Keep open flame away from your work a.ea.

1. Relieve the fuel pressure(seepagell-118).

2. Jack up the vehicle, and support it with jackstands.

3. Remove the drain bolt, and drain the fuel into an approved container.

4. Remove the rear seat (Hatchbackt Remove the spare tire lid and the protective cover), and access panels, and discon-

nect the 2P and 3P connectors.

5. Remove the EVAP two way valve cover and fuel hose protector, and disconnect the connectors.

6. Disconnect the hoses (see page 11-105). Slide back the clamps, then twist hoses as you pull, to avoid damaging them.

7. Place a tack, or other support, under the tank.

8. Remove the strap nuts, and let the straps fall free.

9. Remove the fuel tank.

lf it sticks on the undercoat applied to its mount, carefully pry it offthe mount.

10. lnstallthe drain bolt with a new washer, then coat the drain bolt with Noxrust 1248. Allow the Noxrust to dry tor 20

minutes.

11. Installthe remaining parts in the reverse order of removal.

ACCESSPANELS

CONNECTOR

2P CONNECTOR

3P CONNECTOR

2P CONNECTOR

EASE GASKETReplace.

FUEL GAUGESENDING UNIT

BASE GASKETReplace.

FUELTANK

38 N.m13.9 kgtm,28 tbf.ftl

EVAPTWO WAYVALVECOVERFUEL TANKSTNAPS

WAS}IERReplace.

9.8 N.m{1.0 kgf.m,7.2 tbt.tll

ORAIN BOLTilg N.m(5.0 k9f.m.36 rbf.ftl

FUEL HOSEPROTECTOR{

11-127

Page 346 of 1681

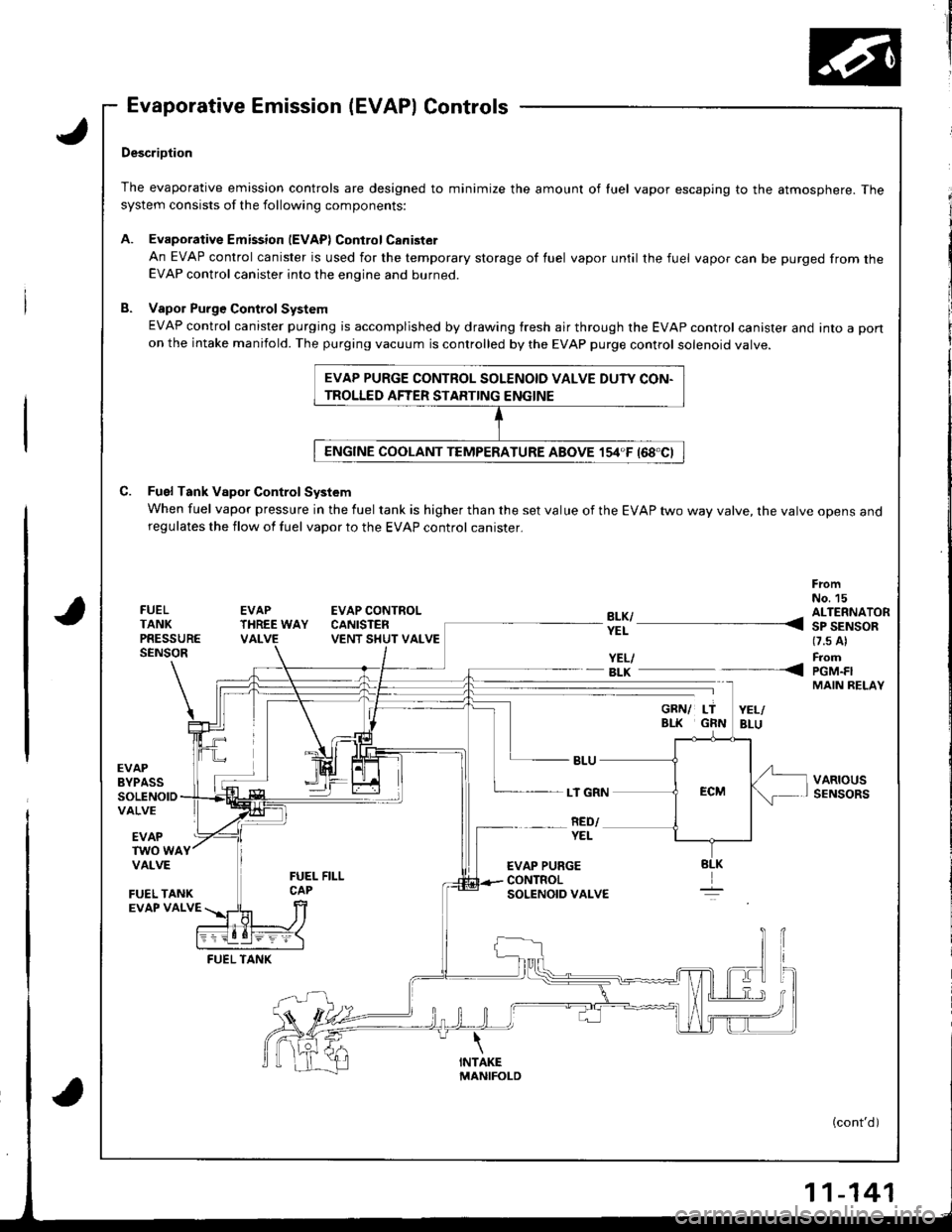

Evaporative Emission (EVAP) Controls

,J

a

DescriDtion

The evaporative emission controls are designed to minimize the amount of luel vapor escaping to the atmosphere. Thesystem consists of the following components:

A. EvaporativeEmission lEVAPlControlCanister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from theEVAP control canister into the engine and burned.

B. Vapol Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the varve opens anoregulates the flow of fuel vapor to the EVAP control canister.

FrcmNo. 15FUELTANKPRESSURESENSOR

EVAPTHREE WAYVALVE

EVAP CONTROLCANISTENVENT SHUT VALVE

YEL/- BLK

EVAPBYPASSSOLENOIDVALVE

LT GRN

RED/EVAPTWO WAYVALVE

FUEL TANKEVAP VALVE

FUEL TANK

EVAP PURGE CONTROL SOLENOID VALVE DUTY CON-

TROLLED AFTER STARTING ENGINE

?!l ---- 311'AiS-*(7.s Al

FromPGM.FIMAIN RELAY

VARIOUSSENSORS

----<

YEL

EVAP PURGECONTROLSOLENOID VALVE

(cont'd)

-141

Page 347 of 1681

lT

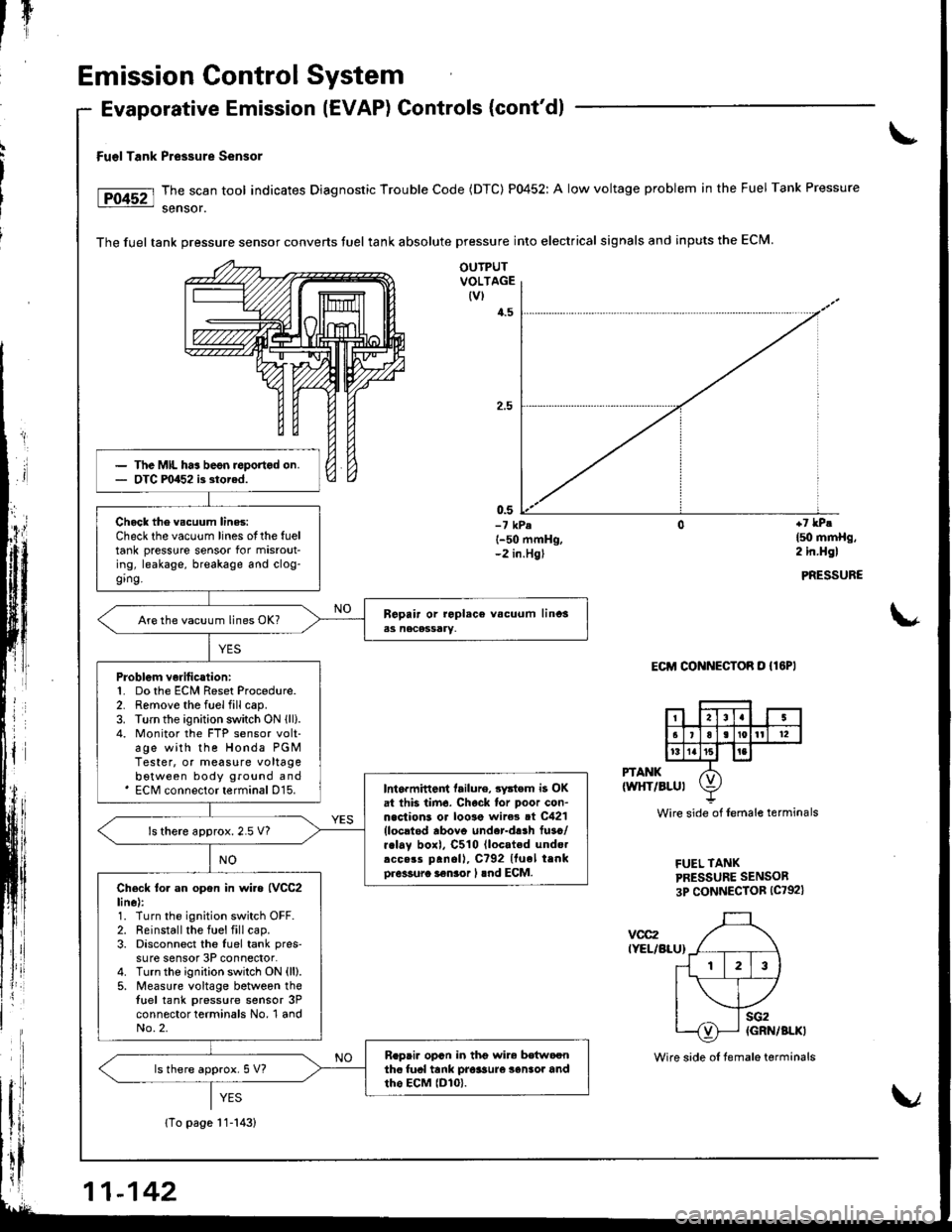

Emission Control System

YES

{To page 11-143}

Fu€l Tank Pressure Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensor.

The fuel tank pressure sensor converts tuel tank absolute pressure into electrical signals and inputs the ECM.

Evaporative Emission (EVAP) Controls (cont'dl

OUTPUTVOLTAGE(vl

4.5

0.5-7 kPel-50 mmHg,-2 in.Hgl

+7 lPe

l5o mmHg,2 in.Hgl

PRESSURE

\*

Eclrl CONNECToR o {lEPl

PTANK(wltT/BLul

vcc2IYEL/BLU}

Wire side of lemale terminals

FUEL TANKPRESSURE SENSOR

3P CONNECTOR (C792)

The MIL ha3 beon roportod on.OTC F0452 i3 storad.

Chock the vscuum lines:Check the vacuum lines otthe fueltank pressure sensor for misrout-ing, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problgm verilication:1. Do the ECM Reset Procedure.2. Remove the fuel fill cap.3. Turn the ignition switch ON lll).4. Monitor the FTP sensor volt-age with the Honda PGMTester, or measure voltagebotween body ground and' ECM connector terminal D15.Int6rmittent tailure, 3ystem i3 OKat thb tirn6. Chock lor poor con-n.clions or loo3e wire3 ot C421{locltod rbovo under-d!.h fuso/r.lay boxl, C510 lloc.ted undo.rcc.rs panoll, C?92 Ituel trnko.6sura i€nior I lnd ECM.

ls there approx.2.5 V?

Check to. an opon in wi.a {VCC2line):1. Turn the ignition switch OFF.2. Reinstall the fuel fill cap.3. Disconnect the luel tank pres'su re sensor 3P connector.4. Turnthe ignition switch ON (ll).

5. Measure voltage between thetuel tank pressure sensor 3Pconnector terminals No, 1 andNo.2.

R.pai. opcn in thg wir6 bdtwoonthc fual tank pro$ure 3enlor andtho EcM lDlo).ls there approx. 5 V?

11-142

Wire side oI temale terminals

Page 348 of 1681

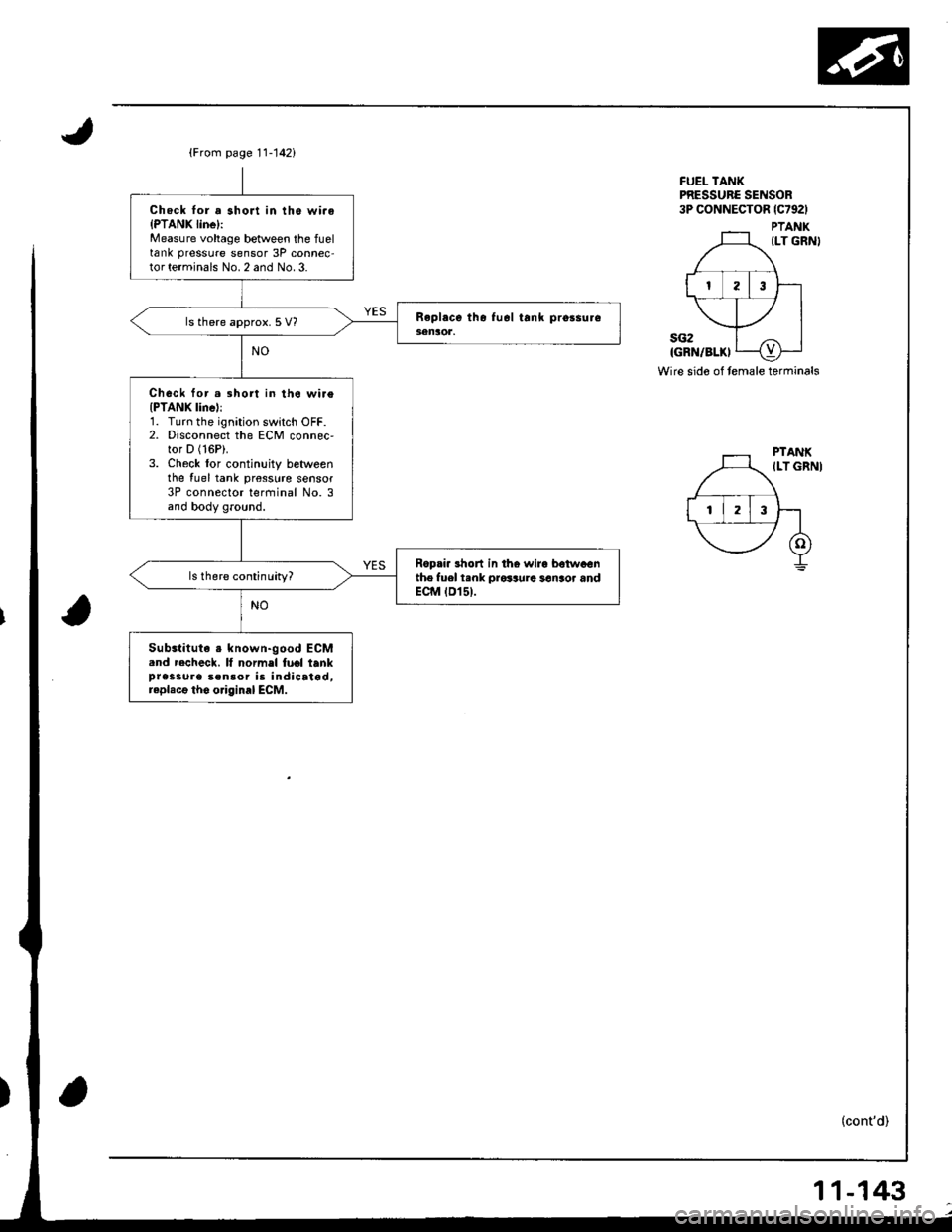

{From page 11-142i

Chock lor a short in tho wi.oIPTANK linel:Measure voltage between the fueltank pressure sensor 3P connec-tor terminals No. 2 and No. 3.

ls there approx. 5 V?

Chock for.3hort in th6 wi.e(PTANK lincl:1. Turn the ignition switch OFF.2. Disconnect the ECM connec,tor D (16P).

3. Check lor continuity betweenthe {uel tank pr€sslrre sensor3P connector terfiinal No. 3and body ground.

Ropri. 3hon in tho wira betwaGnthe fuel t.nk prosaura san3or andECM tD15t.

Substituta s known-good ECM.nd recheck. It normel fuel tenkpressure son30r is indicatod,raplacg tho o.iginal ECM.

FUEL TANKPRESSURC SENSOR3P CONNECTOR lc792l

PTANKILT GRN}

sG2IGRN/BLKI

Wire sido of temale terminals

(cont'd)

11-143