fuel pressure HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 246 of 1681

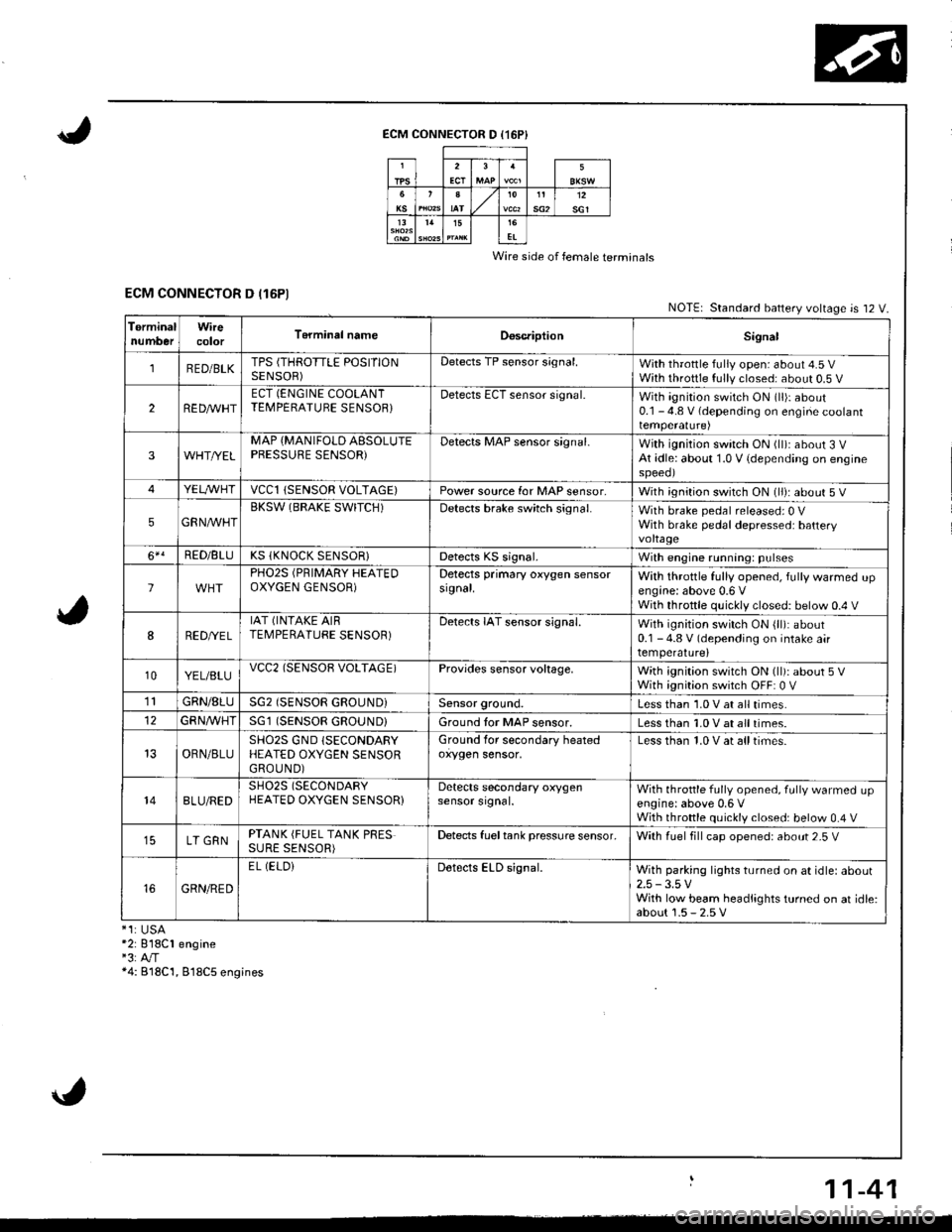

ECM CONNECTOR D (16P}

Wire side of female terminals

ECM CONNECTOR D (16P1NOTE| Standard battery voltage is 12 V.

TerminalnumberWirecolorT6rminal nameDoscriptionSignal

1RED/BLKTPS (THROTTLE POSITIONSENSOR)Detects TP sensor s;gnal.With throttle fully open: about 4.5 VWith throttle fully closed: about 0.5 V

2REDAr'r'HTECT (ENGINE COOLANTTEMPERATUBE SENSOB}Detects ECT sensor signal.With ignition switch ON (ll)r about0.1 - 4.8 V (depending on engine coolanttemperalure)

3WHT//ELMAP {MANIFOLD AESOLUTEPBESSURE SENSOR)Detects MAP sensor signal.With ignition switch ON (ll)iabout 3 VAt idle: about 1.0 V {depending on enginespeeol

4YELA/VHTvccl{SENSOR VOLTAGE)Power source for MAP sensor,With ignition switch ON (ll): about 5 V

5GRNAVHTBKSW (BRAKE SWITCH)Detects brake switch signal.With brake pedal released: 0 VWith brake pedal depressed: batteryvoltage

6*!RED/BLUKS (KNOCK SENSOR}Detects KS signal.With engine running: pulses

lPHO2S (PRIMARY HEATEDOXYGEN GENSOR)Detects primary oxygen sensorsignal.With throttle fully opened, fully warmed upengine: above 0.6 VWith throttle quickly closed: below 0.4 V

8RED/VEL

IAT (INTAKE AIRTEMPERATURE SENSOR)Detects IAT sensor signal.With ignition switch ON {ll): about0.1 - 4.8 V (depending on intake airtemperature)

10YEL/BLUvcc2(SENSOB VOLTAGE)Provides sensor voltage,With ignition switch ON (ll): about 5 VWith ignition switch OFF: 0 V

1lGRN/8LUSG2 (SENSOR GROUND}Sensor ground.Less than 1.0 V at all times.

GFNA/VHT(SENSOR GROUND}Ground tor MAP sensor.Less than 1.0 V at all times.

OBN/BLUSHO2S GND (SECONDARY

HEATED OXYGEN SENSORGROUND)

Ground for secondary heatedoxygen sensor,Less than 1.0 V at alltimes.

148LU/REDSH02S (SECONDARY

HEATED OXYGEN SENSOR}Detects secondary oxygensensor srgnal.With throttle fully opened. fully warmed upengine: above 0,6 VWith throttle quickly closed: below 0.4 V

LT GRNPTANK (FUEL TANK PRESSURE SENSOR)Detects fueltank pressure sensor.With luel fill cap opened: about 2-5 V

GRN/RED

EL (ELOiDetects ELD signal.With parking lights turned on at idle: about2.5 -3.5 VWith low beam headlights turned on at idle:about 1.5 - 2.5 V*1:USA*2: 818C1 engine"3:A"/T*4: B18C'1, 818C5 engines

11-41

Page 247 of 1681

1l

Troubleshooting

Diagnostic Trouble Gode (DTCI Chart

*: These DTCS will be indicated by the blinking ot the lvalfunction Indicator Lamp (MlL) with the SCS service connector

connected.

Ia

\

\

il

\

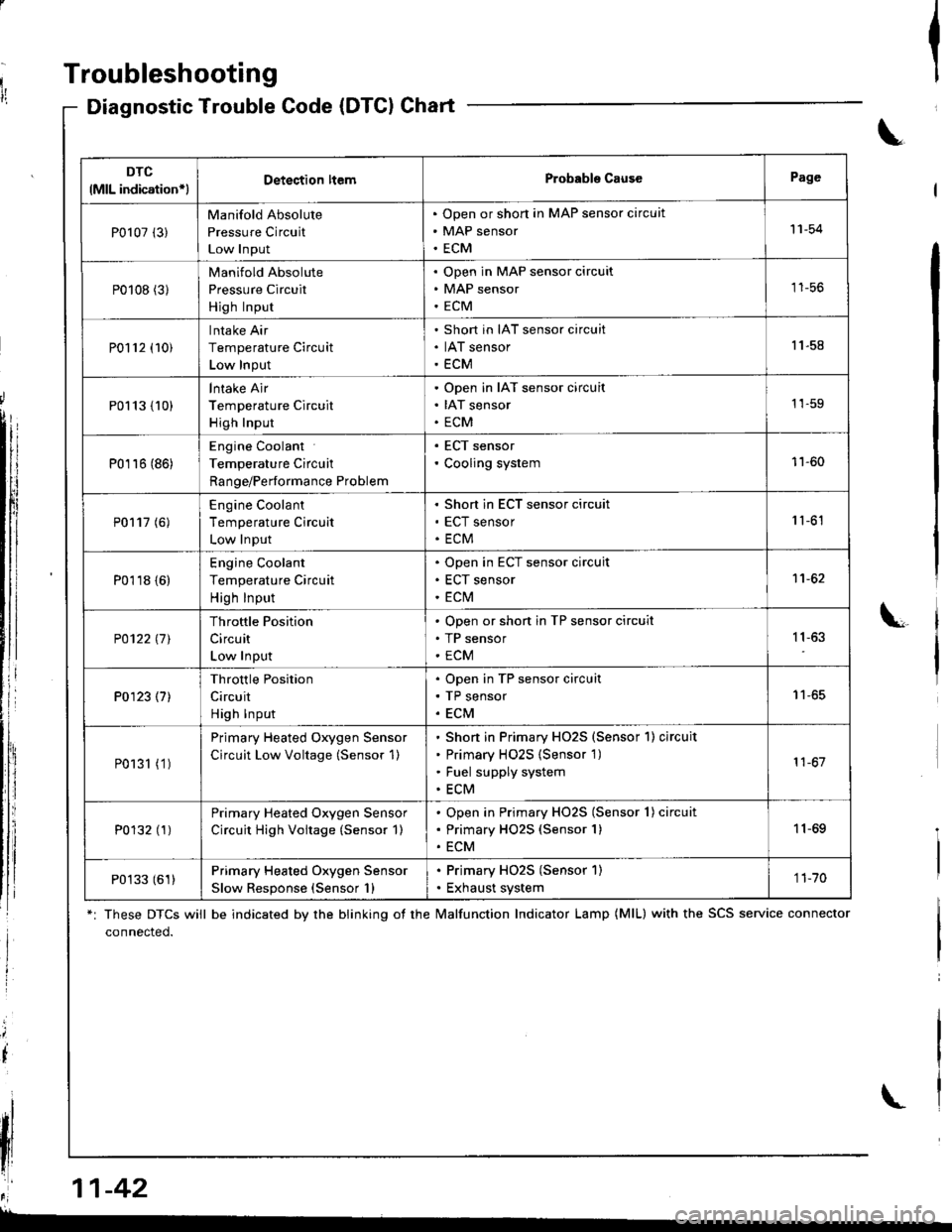

DTC

lMlL indication*lDetection ltemProbabls CausePage

P0107 (3)

Manifold Absolute

Pressure Circuit

Low Input

Open or short in MAP sensor circuit

MAP sensor

ECM

'11-54

P0108 (31

Manifold Absolute

Pressure Circuit

High Input

Open in MAP sensor circuit

MAP sensor

ECM

tt-5t,

P0112 (10)

Intake Air

Temperature Circuit

Low Input

Short in IAT sensor circuit

IAT sensor

ECM

11.58

P0113 {10)

lntake Air

Temperature Circuit

High Input

Open in IAT sensor circuit

IAT sensor

ECM

1'�1-59

P0116 (86)

Engine Coolant

Temperature Circuit

Range/Performance Problem

. ECT sensor' Cooling system11-60

P0117 (6)

Engine Coolant

Temperature Circuit

Low Input

Short in ECT sensor circuit

ECT sensor

ECM

1 '�t-61

P0118 {6)

Engine Coolant

Temperature Circuit

High Input

Open in ECT sensor circuit

ECT sensor

ECt\,4

1't -62

P0122l7l

Throttle Position

Circuit

Low Input

Open or shon in TP sensor circuit

TP sensor

ECM

11,63

P0123 (7)

Throttle Position

Circuit

High Input

Open in TP sensor circuit

TP sensor

ECM

I t-oc

P0131 (1 )

Primary Heated Oxygen Sensor

Circuit Low Voltage (Sensor 1)

Shon in Primary HO2S (Sensor'l) circuit

Primary H02S {Sensor 1)

Fuel supply system

ECM

11-67

P0132 (1)Primary Heated Oxygen Sensor

Circuit High Voitage (Sensor 1)

Open in Primary HO2S (Sensor 1) circuit

Primary HO2S (Sensor 1)

ECM

11-69

P0133 (61)Primary Heated Oxygen Sensor

Slow Response (Sensor 1)

. Primary HO2S (Sensor 1). Exhaust system1 1-70

,r:' 11-42

L

Page 249 of 1681

Troubleshooting

Diagnostic Trouble Code (DTCI Chart (cont'd)

L

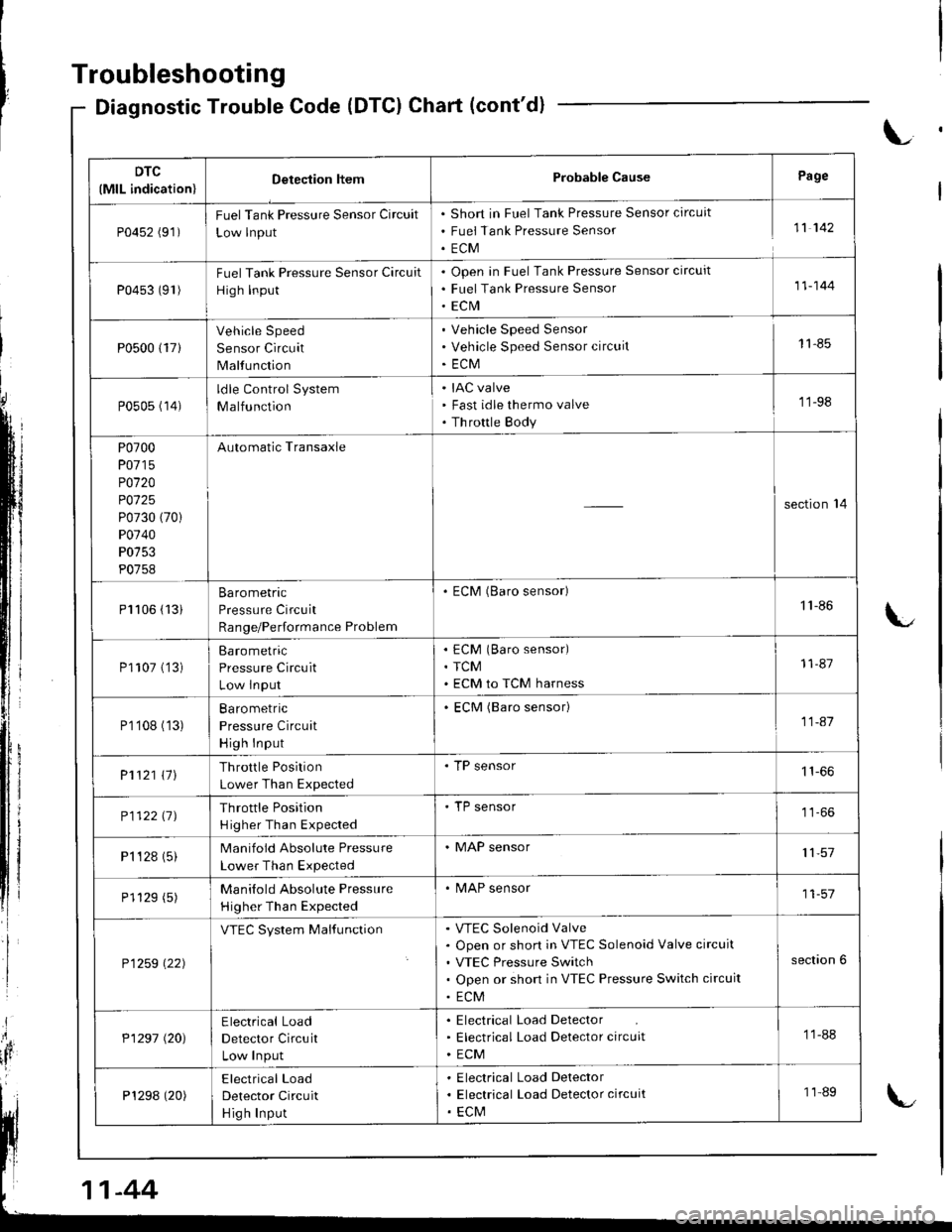

DTC

(MlL indication)Detection ltemProbable CausePage

P0452 (91)FuelTank Pressure Sensor Circuit

Low lnput

Short in Fuel Tank Pressure Sensor circuit

Fuei Tank Pressure Sensor

ECM

11 142

P0453 (91)Fuel Tank Pressure Sensor Circuit

High Input

Open in Fuel Tank Pressure Sensor circuit

Fuel Tank Pressure Sensor

ECrVI

11-144

P0500 {17}

Vehicle Speed

Sensor Circuit

Malfunction

Vehicle Speed Sensor

Vehicle Speed Sensor circuit

ECM

11-85

P0505 (14)ldle Control System

Malfunction

IAC valve

Fast idle thermo valve

Th rottle Body

'11-98

P0700

P0715

P0120

P0125

P0730 (70)

P0740

P0753

P0758

Automatic Transaxle

section'14

Pl106 (13iBarometric

Pressure Circuit

Range/Performance Problem

. ECM (Baro sensor)1'l -86

P1107 ('�]3)Barometric

Pressure Circuit

Low lnput

ECM (Baro sensor)

TCM

ECM to TCM harness

11-87

P1'108 (13)Ba ro metric

Pressure Circuit

High Input

ECM (Baro sensor)11-41

P1121 \11Throttle Position

Lower Than Expected

. TP sensor

P112211JThrottle Position

H igher Than Expected

'TP sensor

P1 '�t 28 (5)Manifold Absolute Pressure

Lower Than Expected

. MAP sensor11,57

P1129 (5)Manilold Absolute Pressure

Higher Than Expected

. MAP sensor11-57

P1259 \22)

VTEC System MalfunctionVTEC Solenoid Valve

Open or short in VTEC Solenoid Valve circuit

VTEC Pressure Switch

Open or short in VTEC Pressure Switch circuit

ECM

section 6

P1297 (20)Electrical Load

Detector Circuit

Low Input

Electrical Load Detector

Electrical Load Detector circuit

ECM

11-88

P1298 (20)Electrical Load

Detector Circuit

Hig h Input

Electrical Load Delector

Electrical Load Detector circuit

ECM

11-89

-44

Page 250 of 1681

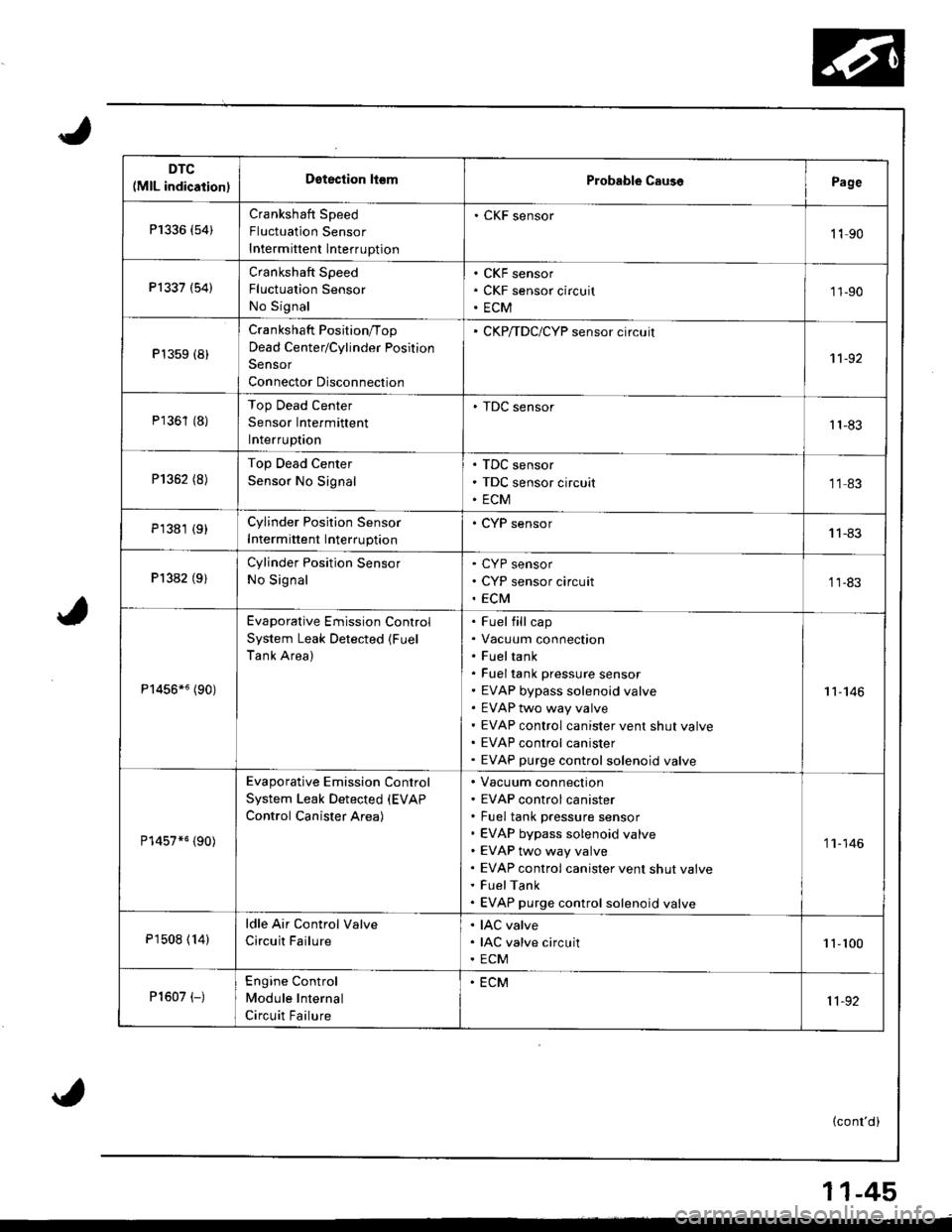

DTC(MlL indication)Dstection ll€mProbable CausePage

P1336 (54)Crankshaft Speed

Fluctuation Sensor

Intermittent lnterruption

. CKF sensor

1190

Pl337 (54)Crankshaft Speed

Fluctualion Sensor

No Signal

CKF sensor

CKF sensor circuit

ECM

'11-90

P't359 (8)

Crankshaft Position/Top

Dead Center/Cylinder Position

Sensor

Connector Disconnection

CKP/TDC/CYP sensor circuit

1't -92

P1361 (8)Top Dead Center

Sensor Intermittent

Interruptaon

. TDC sensor't1-83

P1352 (8)Top Dead Center

Sensor No Signal

TDC sensor

TDC sensor circuit

ECM

1183

P1381 {9}Cylinder Position Sensor

Intermittent Interruption

. CYP sensor11-83

Pl382 (9)Cylinder Position Sensor

No Signal

CYP sensor

CYP sensor circuit

ECM

11-83

P1456*6 (90)

Evaporative Emission Control

System Leak Detected (Fuel

Tank Area)

Fuel fill cap

Vacuum connection

Fueltank

Fuel tank pressure sensor

EVAP bypass solenoid valve

EVAP two way valve

EVAP control canister vent shut valve

EVAP control canister

EVAP purge control solenoid valve

11-146

P14s7*5 {90)

Evaporative Emission Control

System Leak Detected (EVAP

Control Canister Area)

Vacuum connection

EVAP control canister

Fuel tank pressure sensor

EVAP bypass solenoid valve

EVAP two way valve

EVAP control canister vent shut valve

FuelTank

EVAP purge control solenoid valve

'1 'l - 146

P1508 ( 14)

ldle Air Control Valve

Circuit Failure

IAC valve

IAC valve circuit

ECM

1 1-100

P1607 (-)Engine Control

Module Internal

Circuit Failure

. ECM

11-92

(cont'd)

11-45

Page 253 of 1681

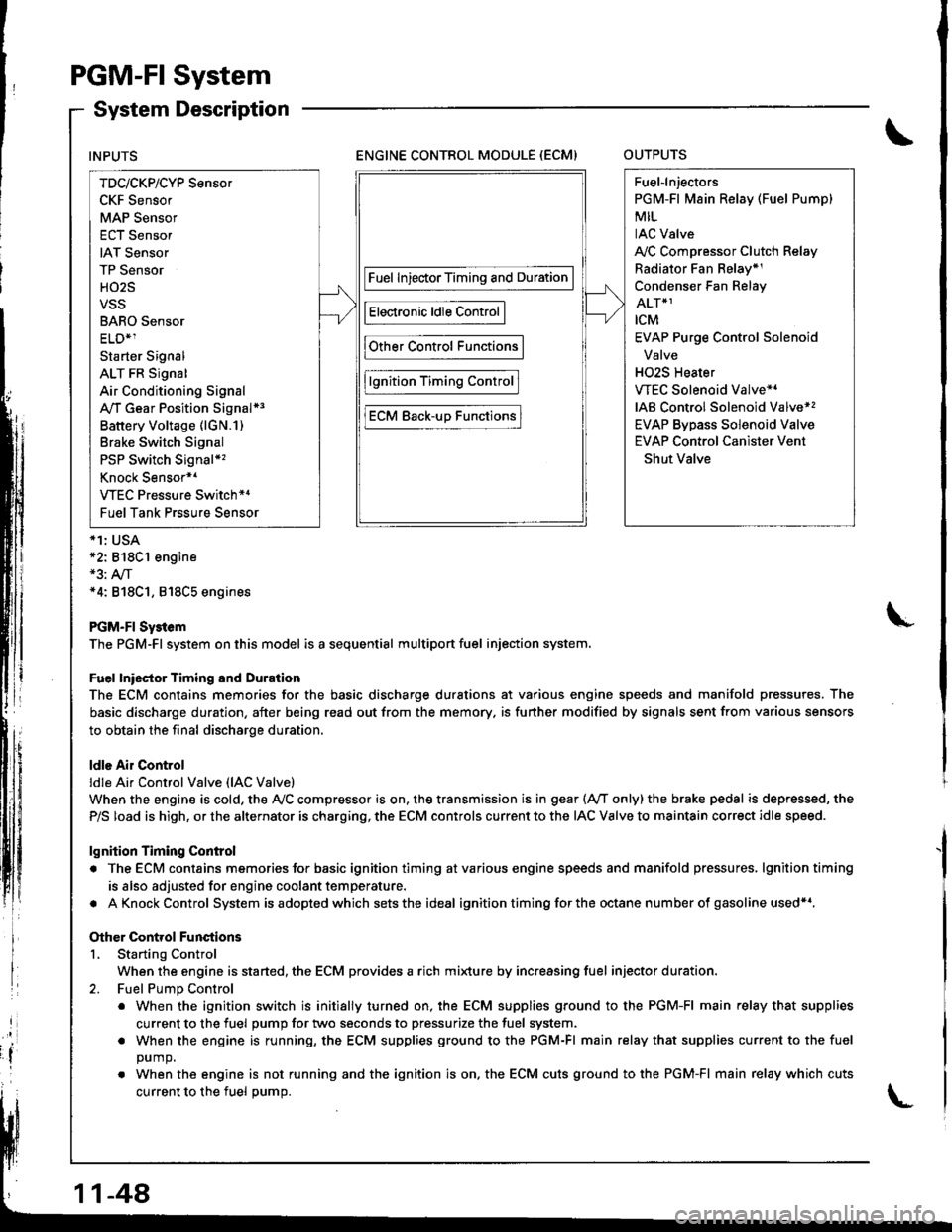

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECM)OUTPUTS

*1: USA*2: 818C1 engine*3: A,/T*4: 818C1, 818C5 engines

PGM-FI Sy3tem

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel lniector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory. is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Ai. Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on. the transmission is in gear (Ay'T only)the brake pedal is depressed, the

P/S load is high, or the alternator is charging, the ECM controls current to the IAC Valve to maintain correct idle speed.

lgnition Timing Control

. The ECM contains memories for basic ignition timing atvarious engine speeds and manifold pressures, lgnitiontiming

is also adjusted for engine coolant temperature.

. AKnockControl System isadoptedwhich sets the ideal ignition timing for the octane n um ber of gasoline used*r,

Other Control Functions

L Starting Control

When the engine is started, the ECM provides a rich mi{ure by increasing fuel injector duration.

2. Fuel PumD Control

. When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel

DUmO.

. When the engine is not running and the ignition is on. the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel oumo.

INPUTS

TDc/CKP/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

HO2S

VSS

BARO Sensor

ELD*1

Starter Signal

ALT FR Signal

Air Conditioning Signal

A,/T Gear Position Signal*3

Battery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal*'�

Knock Sensor*1

VTEC Pressure Switch*4

Fuel Tank Prssure Sensor

Fuel InjectorTiming and Duration

Electronic ldle Control

Other Control Functions

lgnition Timing Control

ECM Back-uD Functions

Fuel-lnjectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

A,/C Compressor Clutch Relay

Radiator Fan Belay*1

Condenser Fan Relay

ALT*1

rcM

EVAP Purge Control Solenoid

Valve

H02S Heater

VTEC Solenoid Valve*'

IAB Control Solenoid Valve*,

EVAP Bypass Solenoid Valve

EVAP Control Canister Vent

Shut Valve

11-48

Page 257 of 1681

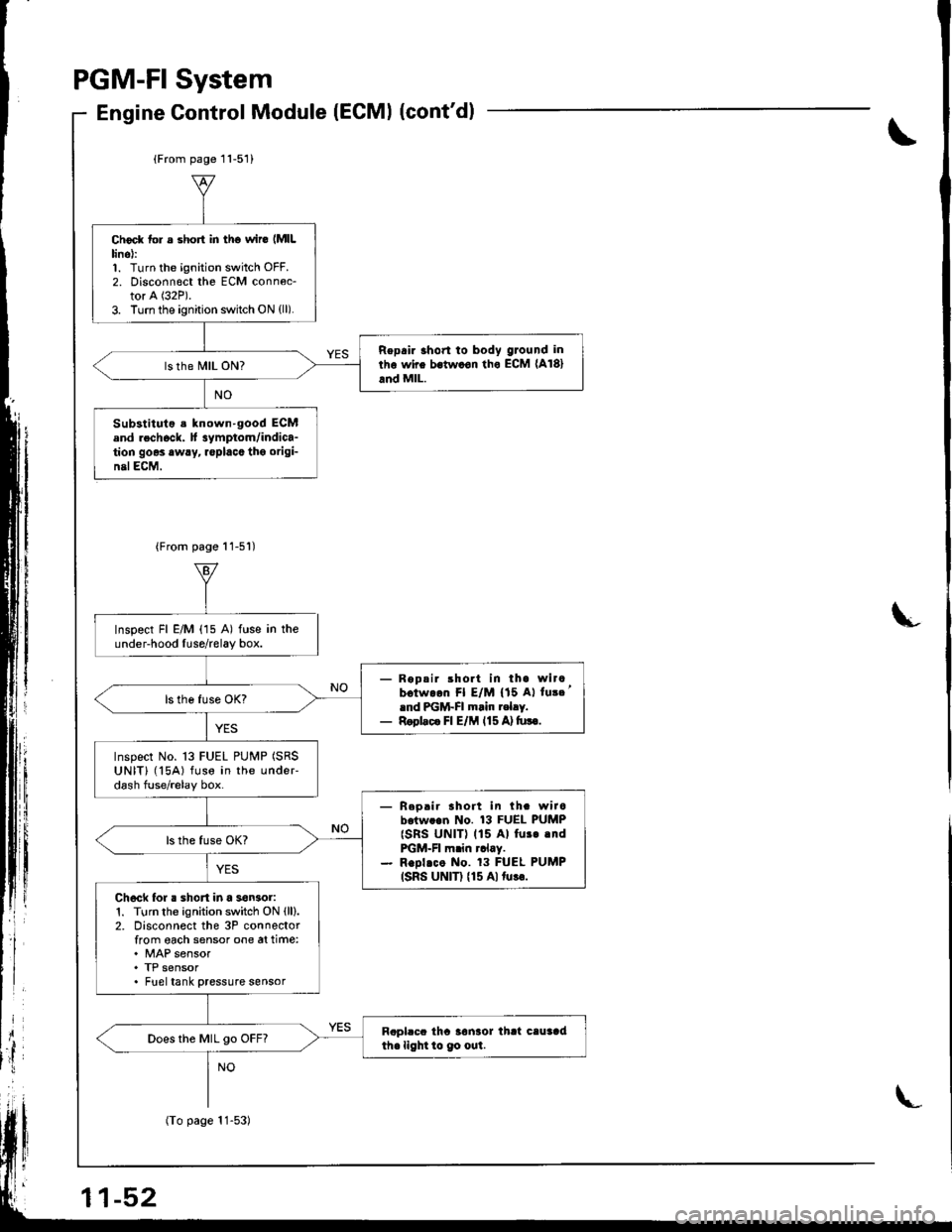

PGM.FISystem

Gontrol Module (ECMI (cont'dlEngine

\

L

(From page 11-51)

Choc* tol s short in tho wir6 lMlLlino):1. Turn the ignition switch OFF.2. Disconn€ct the ECM conn6c-tor A (32P).

3. Turn the ignition switch ON (ll).

Repair 3hon to body ground in

rhe wire bstw.on tho ECM (A181

and MlL.

Substituto s known-good ECMend rechock. H 3ymptom/indica-tion goes awry, replacc tho origi-nelECM,

{From page 11-51)

Inspect Fl E/M (15 A) fuse in theunder-hood Iuse/relay box.

- Ropsir short in tha wircbotw.on Fl E/M {'15 Al tu3c'rnd PGM-FI m.in t.lry.- Rool.c. Fl E/M l15A)tu!€.

Inspect No. 13 FUEL PUMP (SRS

UNIT) ('l5A) fuse in the undeFdash fuse/relay box.

- Reo.ir sholt in th. wirobotw..n No. 13 FUEL PUMP

{SRs UNIT) (15 Al fur..ndFGM-FI m.in rclay.- Repl.co No. 13 FUEL PUMP(SRS UNIT) {15 Alturr.

Ch6ck for . shon in a son3or1. Turn the ignition switch ON (ll).

2. Disconnect the 3P connectorfrom oach sensor one at time:. MAP sensor. TP sensor. Fueltank pressure sensor

Rapl.cc tha 3onaor thrt cauaadihe light to 9o out.Does the MIL go OFF?

1-52

(To page 11-53)

Page 281 of 1681

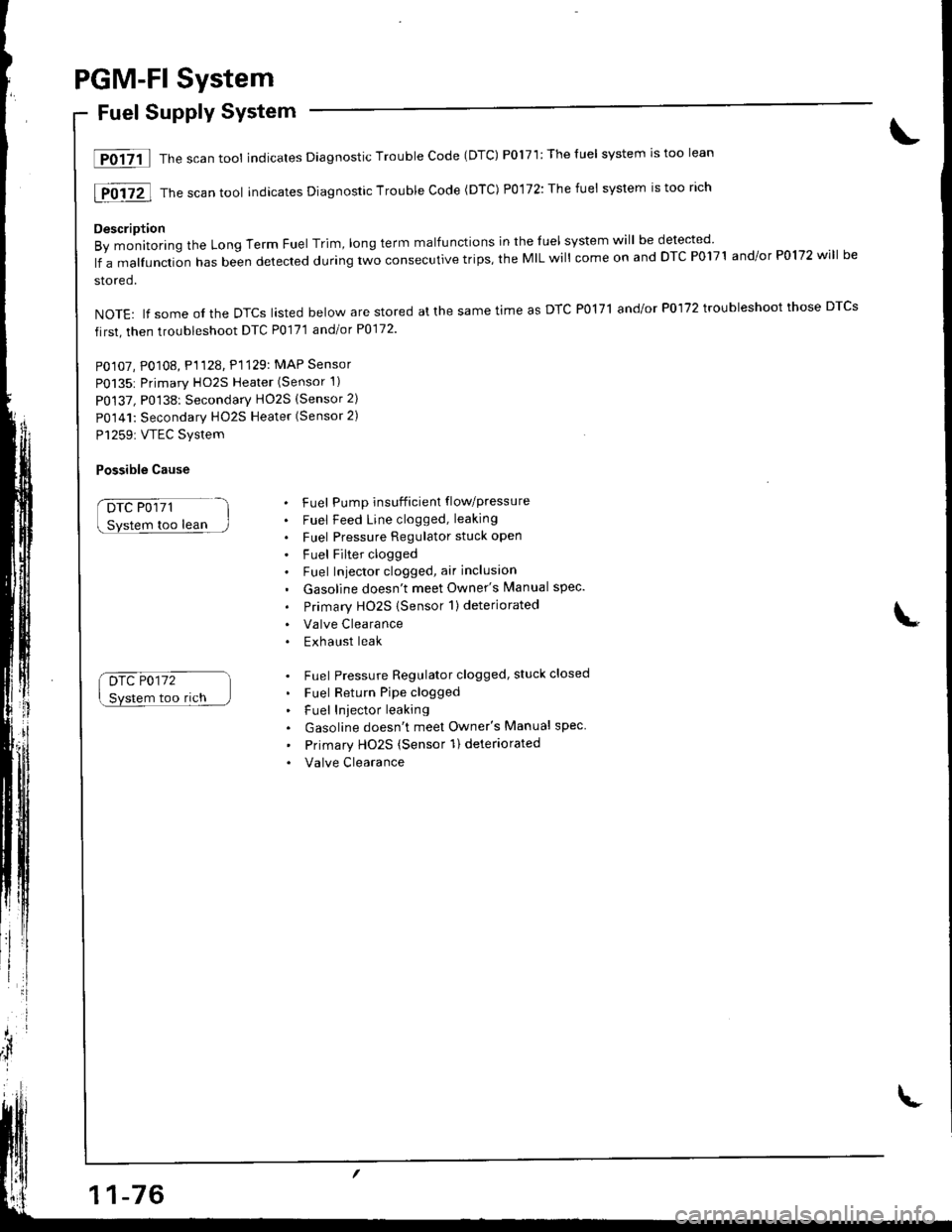

PGM-Fl System

Fuel Supply System

lF0{7il Thescantool indicates Diagnostic Trouble Code (DTC) P0171:Theluel system rstoo lean

[F0i72l Th" ""un tool indicates Diagnosric Trouble code (DTc) p0,172: The fuet system is too rich

Description

By monitoring the Long Term Fuel Trim, long term malfunctions in the luel system will be detected

lf a malfunction has been detected during two consecutive trips, the MIL will come on and DTC P0171 and/or P0172 will be

stored.

NOTE: lf some ol the DTCS lasted below are stored at the same time as DTC PolTl and/or P0172 troubleshoot those DTCS

first, then troubleshoot DTC P0171 andlot P0172

PO107, P0108, P1128. P1129: MAP Sensor

P0135: Primary HO2S Heater (Sensor 1)

P0137, P0138: Secondarv HO2S (Sensor 2)

P0141: Secondary HO2S Heater (Sensor 2)

P1259: VTEC Svstem

Possible Cause

DTC P0171

too lean

Drc P0172

Svstem too rich

. Fuel Pump insufficient flowpressure

. Fuel Feed Line clogged, leaking

. Fuel Pressure Regulator stuck open

. Fuel Filter clogged. Fuel Iniector clogged, air inclusion

. Gasoline doesn't meet Owner's Manual spec.

. Primary HO2S (Sensor 1)deteriorated

. Valve Clearance. Exhaust leak

. Fuel Pressure Regulator clogged, stuck closed

. Fuel Return Pipe clogged

. Fuel Iniector leaking

. Gasoline doesn't meet Owner's Manual spec

' Primary Ho2s (Sensor 1) deteriorated

. Valve Clearance

Page 282 of 1681

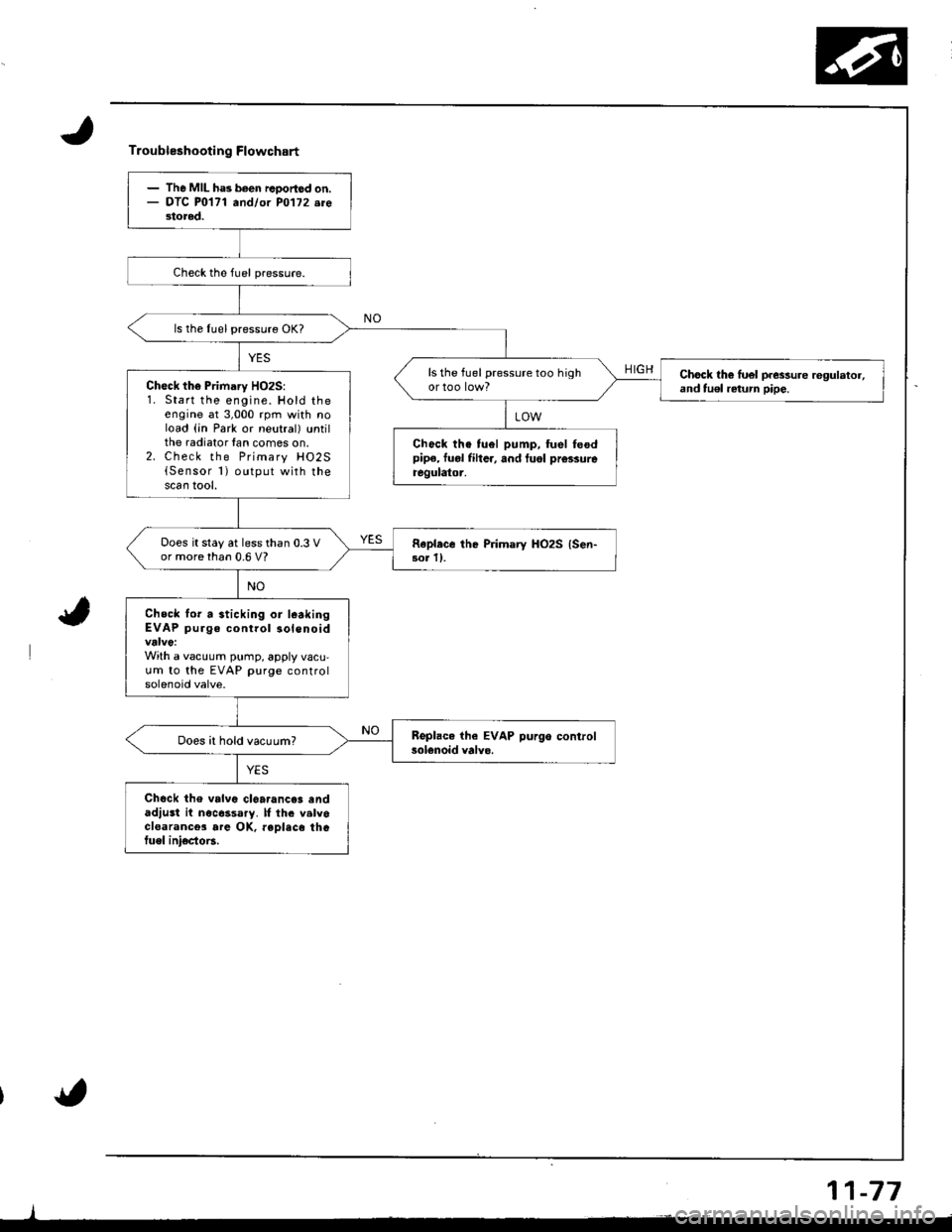

Troubleshooting Flowchart

HIGH

- The MIL ha3 been rcoortod on.- OTC P0171 andlor PO'l72.re3tored.

ls the Iuel pressure OK?

ls the fuel pressure too highChock th€ luel p.essure regulator,and tu€l return pipe.Ch€ck the Primary HO2S:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator lan comes on.2. Check the Primary HO2S{Sensor 1) output with thescan tool.

Chock the tuel pump, fuel feodpipe, fuol fiher, and tuol prcssureregulator.

Does it stay at less than 0.3 Vor more than 0.6 V?Rapl.ce the Primary HO2S {Sen-3or ll.

Check lor a sticking or l€akingEVAP purge control solenoid

With a vacuum pump, apply vacu,um to the EVAP purge controlsolenoid valve.

Does it hold vacuum?

Chock the valvc cl6a.ance3 andadjust it nocessary. lf th. valvocloarance3 are OK, reDlaco thGtuel ini€cto6.

11-77

Page 283 of 1681

PGM-FI System

Random Misfire

1T0-500 1 a nd Fo-30ittrrousFF0304-lThB scan tool indicates Diagnostic Trouble Code {DTC) P0300 and some of

P0301 - P0304: Random misfire.

Doscription

Misfir; detection is accomplished by monitoring the crankshaft speed with the crankshaft speed fluciuation sensor which

is attached to the crankshsft.

lf misfiring strong enough to damage the catalyst is detected, the MIL will blink during iho time of its occurrence, and DTC

p0300 and some of DTCS p0301 through P0304 will be stor€d. Then, after misfire has ceased, the MIL will come on.

lf misfiring that increases emissions is detected during two consecutive driving cycles, the MIL will come on, and DTC

PO3O0 and some ot DTCS P0301 through P0304 will be stored

NOTE: lJ some of the DTCS listed below are stored at the same time as a misfire DTC, troubleshoot those DTCS first. then

troubleshoot the misfire DTC.

P0171, P0172: Fuel metering

P0505: ldle Control SYstem

P1361, P1362: TDC sensor

P1381. P1382: CYP sensor

P1508: IAC valve

Possible Cause

. Fuel pump insufficient fuel pressure. amount of flow

. Fuel line clogging, blockage, leakage

. Fuel {ilter clogging

a Fuel pressure regulator stuck open

. Distributormallunction

o lgnition coil wire open, leakage

. lgnition control module malfunction

. Valves carbon deposit

a Compression low

. IAC valve malfunction

. Fast idle thermo valve malfunction

o Fuel does not meet Owner's Manual spec., lackotfu€l

. VTEC system malfunction

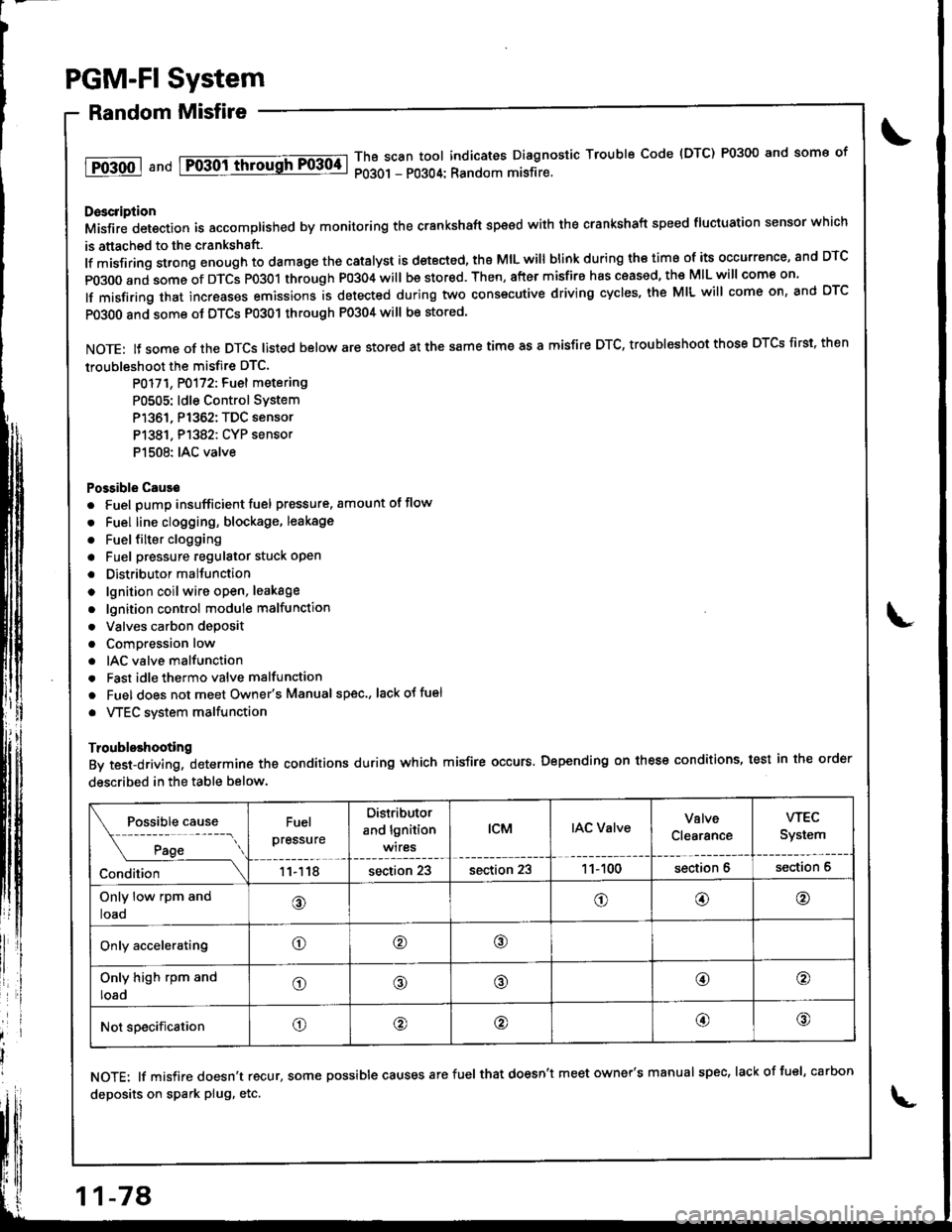

Troubleshooting

By test-driving, determine the conditions during which misfire occurs. Depending on these conditions, test in the order

described in the table below.

Fuel

pressure

Distributor

and lgnition

wires

tcMIAC ValveValve

Clearance

wEc

System

11118section 23section 231 1- 100section 6section 6

Only low rpm and

loao@o@@

Only acceleratingo@o

Only high rpm and

loado@@@o

Not specificationo@@@@

NOTE: lf misfire doesn't recur, some possible causes arefuel that doesn't meet owner's manual spec, lackoffuel, carbon

deposits on spark plug, etc.

11-78

Page 320 of 1681

Fuel Tube/Ouick-Connect Fittings

Prgcautions

!@@ Do not smoke while working on the fuel

sysiem. K€ep open flames away from your work area.

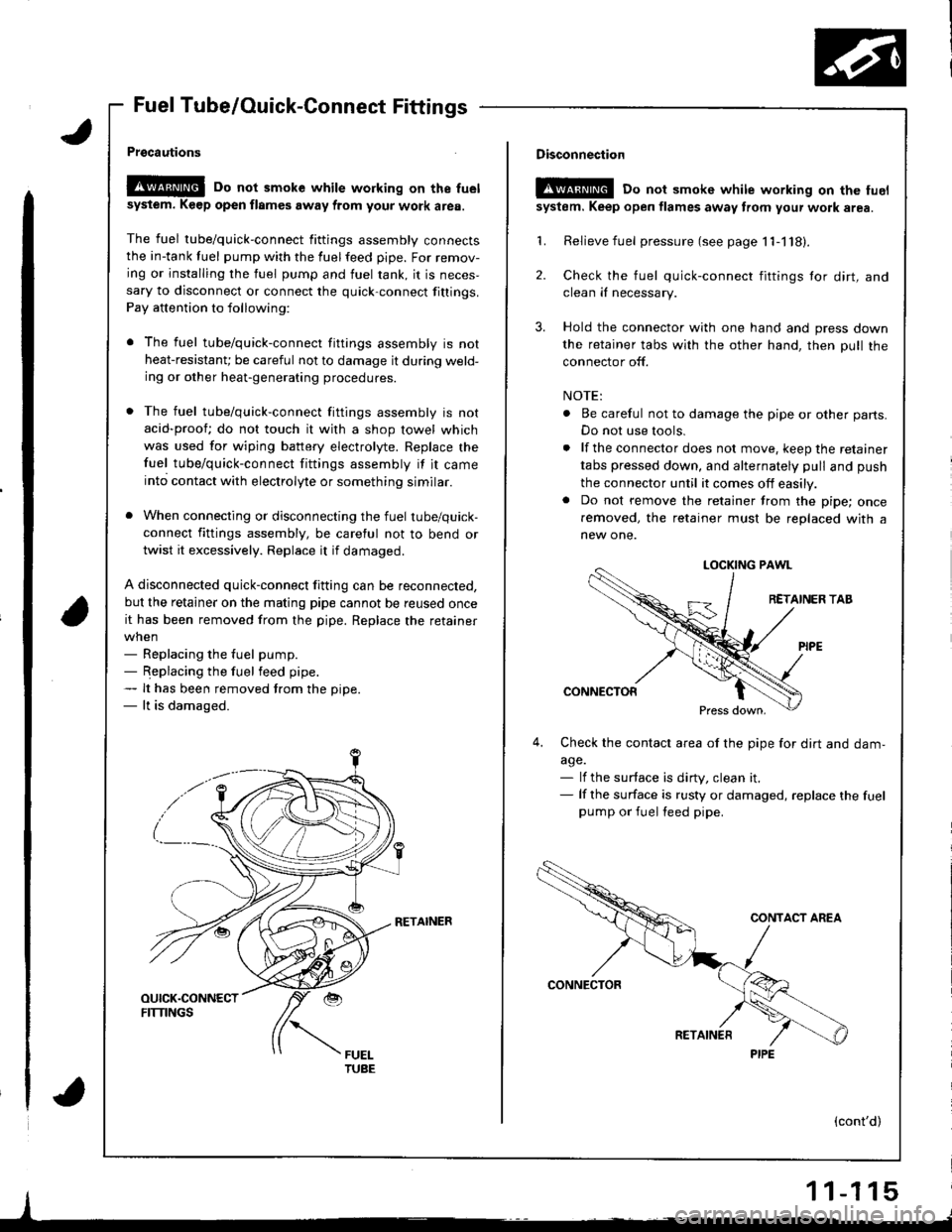

The fuel tube/quick-connect fittings assembly connectsthe in-tank tuel pump with the fuelfeed pipe. For remov-

ing or installing the fuel pump and fuel rank, it is neces,sary to disconnect or connect the quick-connect fittings.

Pay attention to following:

r The fuel tube/quick-connect fittings assembly is not

heat-resistanU be careful not to damage it during weld-ing or other heat-generating procedures.

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. Replace the

fuel tube/quick-connect fittings assembly if it came

into contact with electrolyte or something similar.

. When connecting or disconnecting the fuel tube/quick-

connect fittings assembly, be careful not to bend or

twist it excessively. Replace it if damaged.

A disconnected quick-connect fitting can be reconnected,

but the retainer on the matlng pipe cannot be reused once

it has been removed from the pipe. Replace the retainer

when- Replacing the fuel pump.- Replacing the fuel feed pipe.- It has been removed trom the oiDe.- lt is damaged.

RETAINER

I

Disconnection

t!!@ Do not smokc white working on the fuel

system. Keep open flames away from your wotk area.

'L Relievefuel pressure (see page 11-118).

2. Check the fuel quick-connect fittings tor dirt, andclean iI necessary.

3. Hold the connector with one hand and press down

the retainer tabs with the other hand, then pull the

connector off.

NOTE:

. Be careful not to damage the pipe or other parts.

Do not use tools.

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.. Do not remove the retainer from the pipe; once

removed, the retainer must be replaced with a

new one.

LOCKING PAWL

RETAINER TAB

CONNECTOR

Press down,

4,Check the contacl area of the pipe for dirt and dam,

a9e.- lf the surface is dirty, clean it.- lf the surface is rusty or damaged, replace the fuelpump or fuel feed pipe.

(cont'd)

1 1-1 15

PIPE