headlights HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 246 of 1681

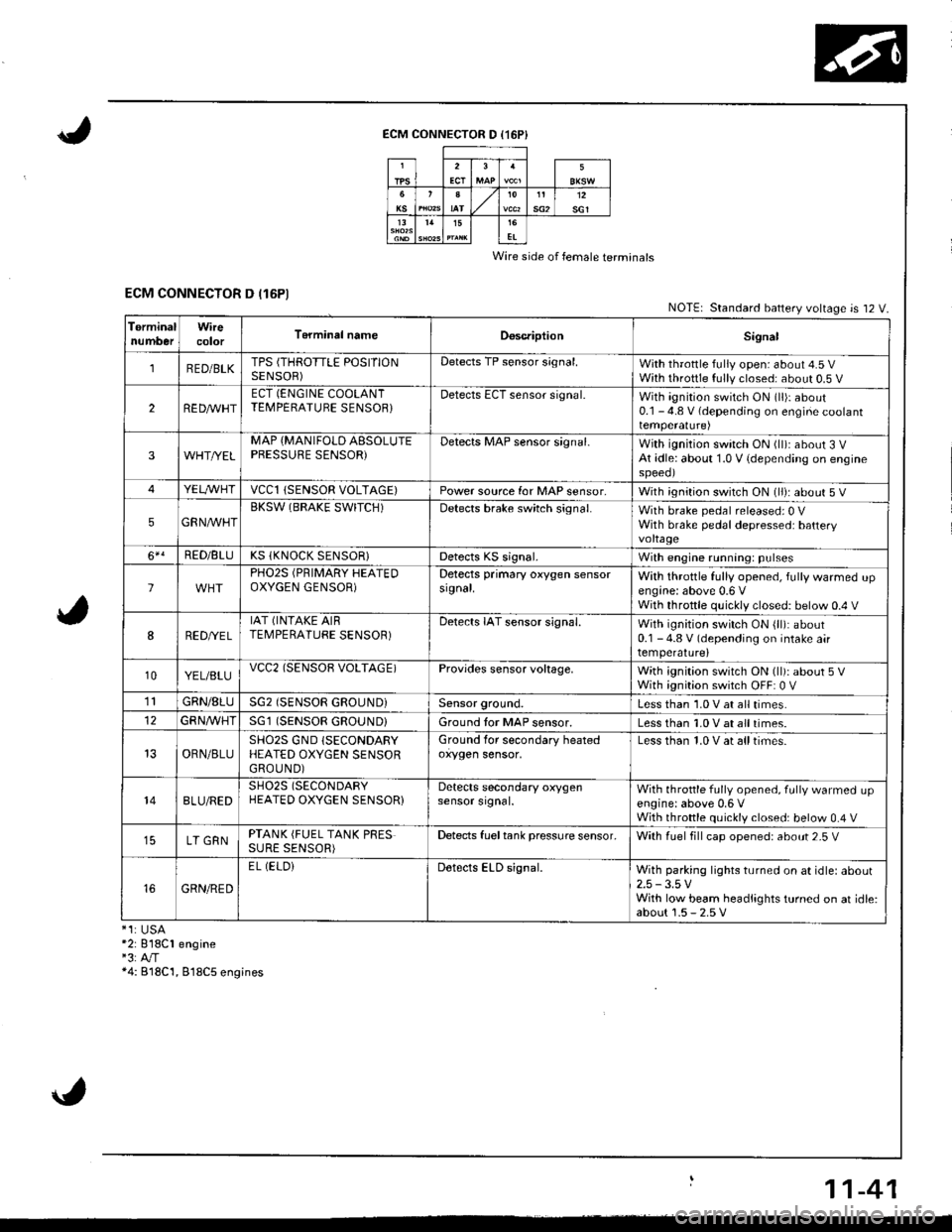

ECM CONNECTOR D (16P}

Wire side of female terminals

ECM CONNECTOR D (16P1NOTE| Standard battery voltage is 12 V.

TerminalnumberWirecolorT6rminal nameDoscriptionSignal

1RED/BLKTPS (THROTTLE POSITIONSENSOR)Detects TP sensor s;gnal.With throttle fully open: about 4.5 VWith throttle fully closed: about 0.5 V

2REDAr'r'HTECT (ENGINE COOLANTTEMPERATUBE SENSOB}Detects ECT sensor signal.With ignition switch ON (ll)r about0.1 - 4.8 V (depending on engine coolanttemperalure)

3WHT//ELMAP {MANIFOLD AESOLUTEPBESSURE SENSOR)Detects MAP sensor signal.With ignition switch ON (ll)iabout 3 VAt idle: about 1.0 V {depending on enginespeeol

4YELA/VHTvccl{SENSOR VOLTAGE)Power source for MAP sensor,With ignition switch ON (ll): about 5 V

5GRNAVHTBKSW (BRAKE SWITCH)Detects brake switch signal.With brake pedal released: 0 VWith brake pedal depressed: batteryvoltage

6*!RED/BLUKS (KNOCK SENSOR}Detects KS signal.With engine running: pulses

lPHO2S (PRIMARY HEATEDOXYGEN GENSOR)Detects primary oxygen sensorsignal.With throttle fully opened, fully warmed upengine: above 0.6 VWith throttle quickly closed: below 0.4 V

8RED/VEL

IAT (INTAKE AIRTEMPERATURE SENSOR)Detects IAT sensor signal.With ignition switch ON {ll): about0.1 - 4.8 V (depending on intake airtemperature)

10YEL/BLUvcc2(SENSOB VOLTAGE)Provides sensor voltage,With ignition switch ON (ll): about 5 VWith ignition switch OFF: 0 V

1lGRN/8LUSG2 (SENSOR GROUND}Sensor ground.Less than 1.0 V at all times.

GFNA/VHT(SENSOR GROUND}Ground tor MAP sensor.Less than 1.0 V at all times.

OBN/BLUSHO2S GND (SECONDARY

HEATED OXYGEN SENSORGROUND)

Ground for secondary heatedoxygen sensor,Less than 1.0 V at alltimes.

148LU/REDSH02S (SECONDARY

HEATED OXYGEN SENSOR}Detects secondary oxygensensor srgnal.With throttle fully opened. fully warmed upengine: above 0,6 VWith throttle quickly closed: below 0.4 V

LT GRNPTANK (FUEL TANK PRESSURE SENSOR)Detects fueltank pressure sensor.With luel fill cap opened: about 2-5 V

GRN/RED

EL (ELOiDetects ELD signal.With parking lights turned on at idle: about2.5 -3.5 VWith low beam headlights turned on at idle:about 1.5 - 2.5 V*1:USA*2: 818C1 engine"3:A"/T*4: B18C'1, 818C5 engines

11-41

Page 293 of 1681

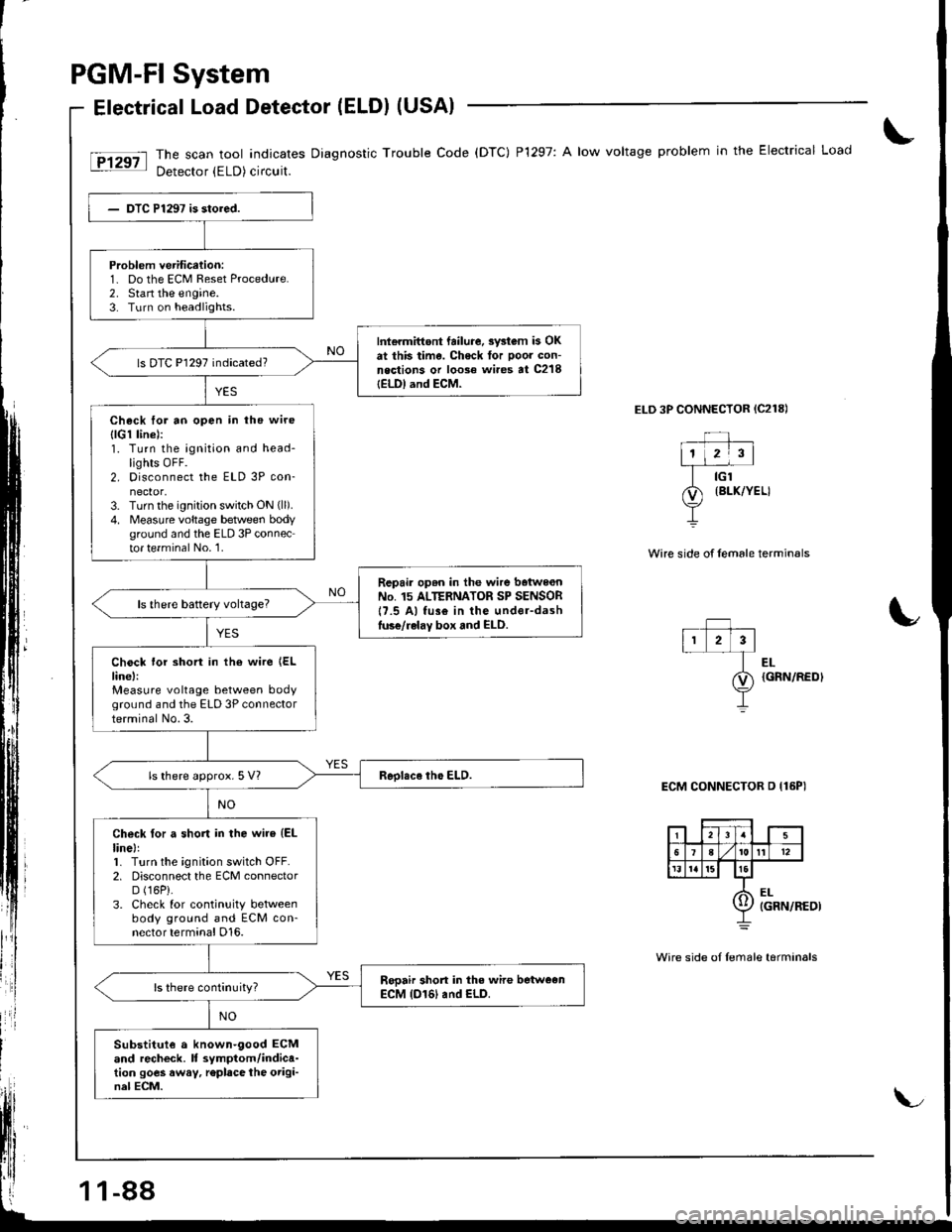

PGM-FI System

Electrical Load Detector (ELDI (USAI

The scan tool indicates Diagnostic Trouble Code (DTC) P1297: A low voltage problem in the Electrical Load

Detector (ELD) circuit.

ELD 3P CONNECTOR {C218)

Wire side of female termin€ls

Problem verification:1- Do the ECM Reset Procedure.2. Stan the engine.3. Turn on headlights.

Int€rmittont failure. swtom b OKat this time. Check tor poor con-neqtions or loose wi.es at C218IELDI and ECM-

ls DTC P1297 indicated?

Check for ao open in the wire

{lG1 linel:1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P con-nector,3. Turn the ignition switch ON (ll).

4. Measure voltage betlveen bodyground and the ELD 3P connector te.minal No.'1.

Repair op6n in the wire baiwe€nNo. 15 ALTERNATOR SP SENSOR17.5 Al fus€ in the under-dashluse/relay box and ELD.

Chock lor short in the wire {ELline,:Measure voltage between bodyground and the ELD 3P connectorterminal No.3.

ls there approx. 5 Vl

Check for a short in the wire (EL

linel:1. Turn the ignition switch OFF.2. Disconnect the ECM connectorD (16P).

3. Check for continuity betweenbody ground and ECM con-nector terminal D16.

Sooair short in the wire betweenECM (D161 and ELD.

Substitut€ a known-9ood ECMand recheck. It symptom/indica-tion goes away, r€place the origi-nal ECM.

EL{GRN/REDI

ECM CONNECTOR D {16PI

Wire side oI Iemale tarminals

11-88

Page 294 of 1681

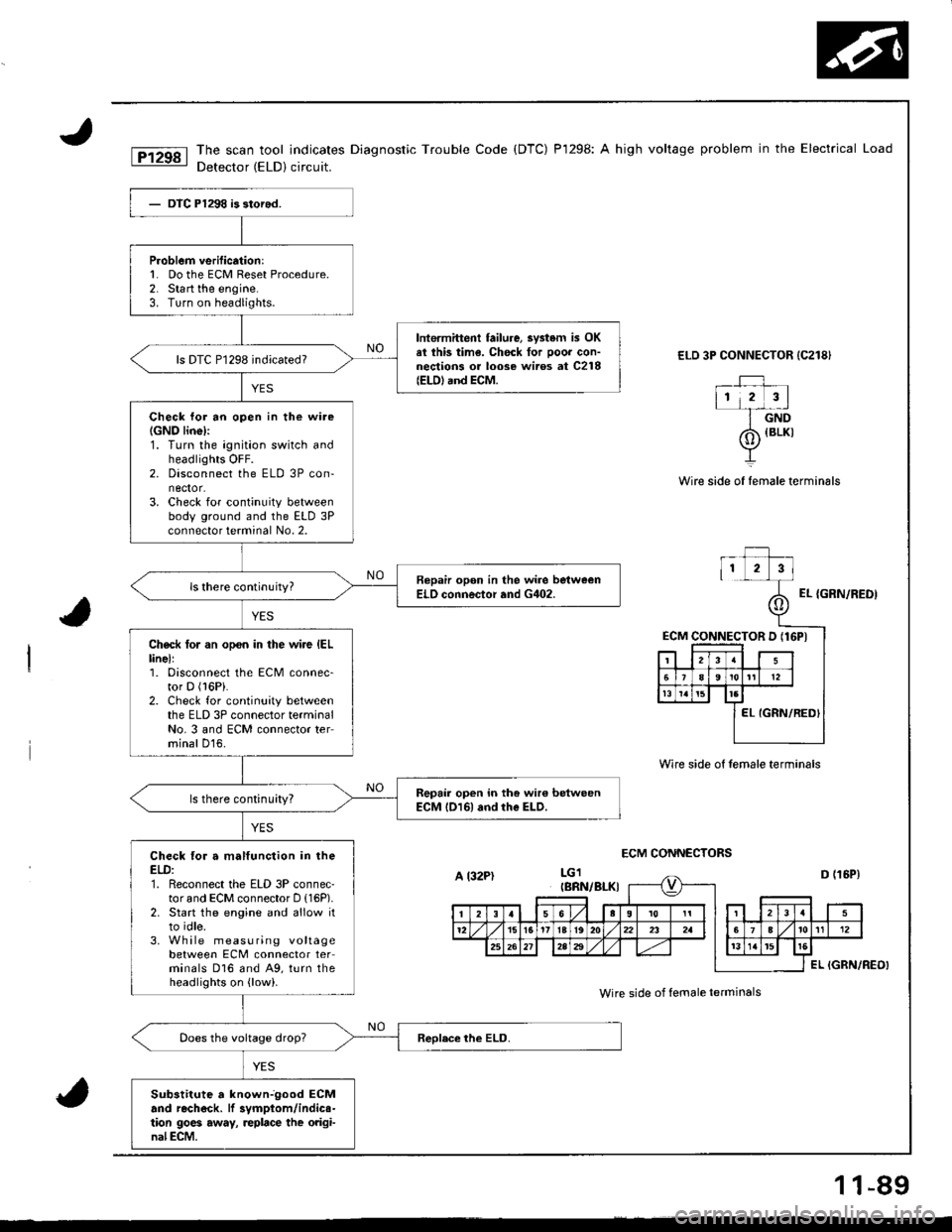

The scan tool indicates Diagnostic Trouble Code (DTC) P1298: A high voltage problem in the Electrical Load

Detector (ELD) circuit.

ELD 3P CONNECTOR {C218}

_rJ ,112 3l-f-dnD

Wire side of female terminals

ECM CONNECTORS

{BLKI

Wire side of female termin6ls

EL {GRN/REDI

ECM CONNECTOR D (16PI

P.oblem verification:l� Do the ECM Reset Procedure.2. Start the engine.3. Turn on headlights.

lntermittent failure, 3vstem is OKel ihis time. Chock for ooor con-nections or loose wiros at C218(EtD) and ECM.

ls DTC P1298 indicated?

Check lor an open in the wire(GNO linel:1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P con-nector.3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2.

Bepair opon in the wire bstweenELO connector and G402.

Check tor an opon in the wire IELlinell1. Disconnect the ECM connec-tor D (l6Pi.

2. Check for continuity betweenthe ELD 3P connector terminalNo. 3 and ECM connector terminal D16.

Repair open in the wir€ betweenECM l016l and rhe ELD.ls there continuity?

Check for a malfunction in theELD:1. Reconnect the ELD 3P connec-tor and ECM connector D (16P).

2. Start the engine and allow itto idle.3. Wh ile measuring voltagebetween ECM connector terminals D16 and A9, turn theheadlights on {low).

Sub3titute a knownjgood ECMand rechock. lf 3vmptom/indics-tion 9oe6 away, replace the original ECM.

A l32PtIBRN/BI-KI

Wire side of female ierminals

1 1-89

Page 303 of 1681

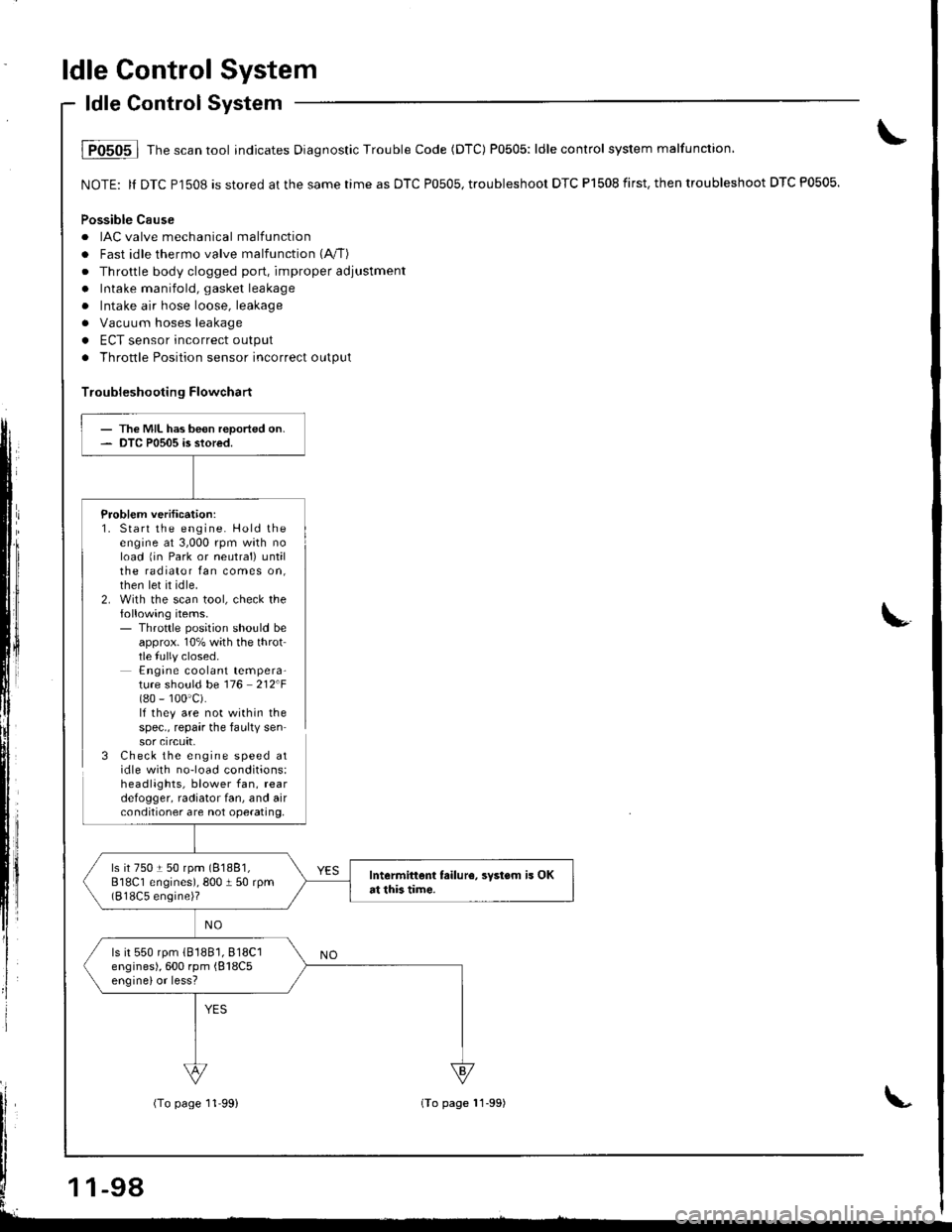

ldle Control System

ldle Control System

i P0505 | fne scan tool indicates Diagnostic Trouble Code (DTC) P0505: ldle control system malfunction,

NOTE: ll DTC Pl508 is stored at the same time as DTC P0505, troubleshoor DTC P1508 first. then troubleshoot DTC P0505.

Possible Cause

. IAC valve mechanical malfunctiorr

. Fast idle thermo valve malfunction (A"/T)

. Throttle body clogged port, improper adjustment

. Intake manifold, gasket leakage

. Intake air hose loose, leakage

a Vacuum hoses leakage

. ECT sensor incorrect output

. Throttle Position sensor incorrect output

Troubleshooting Flowchart

Problem verification:1. Start the engine. Hold theengine at 3,000 rpm wath noload 1in Park or neutral) untilthe radiator fan comes on,then let it idle.2. With the scan tool, check thefollowing items.- Throttle position should beapprox. 10% with the throttle fully closed.Engine coolant tempera-ture should be 116 212F(80 - 100'c).lf they are not within thespec., repair the faulty sensor crrcuft,3 Check the engine speed atidle with no-load conditions:headlights, blower fan, reardefogger, radiator fan, and airconditioner are not operating,

- The MIL has been reported on.- DTC P0505 is stored.

ls it 750 t 50 rpm (81881,

818C1 engines), 800 I 50 rpm(818C5 engine)?

Intermittent failur6, svstsm is OKat this tim€.

ls it 550 rpm (81881,818C1

engines), 600 rpm {818C5enginelor less?

-98

(To page 11'99)(To page 11-99)

Page 306 of 1681

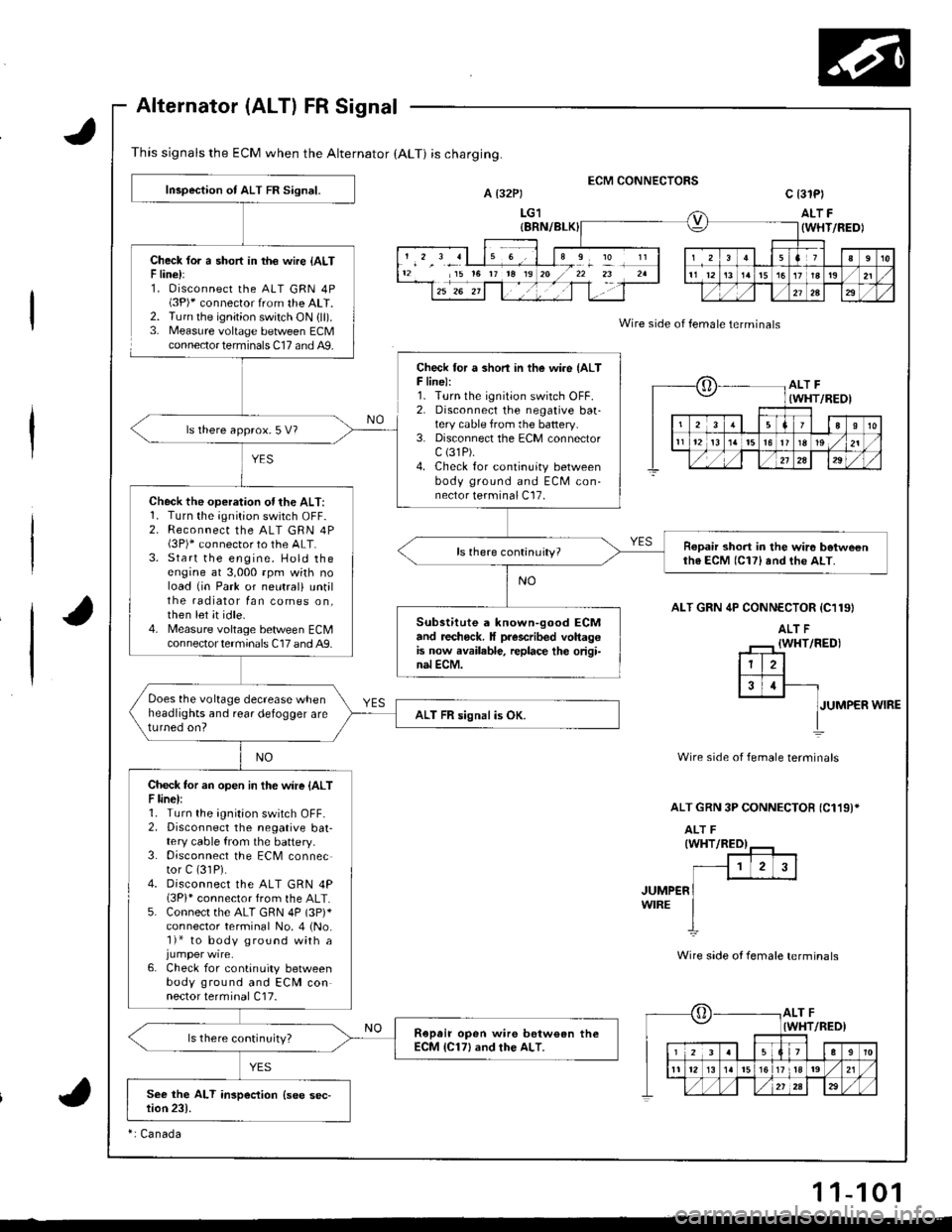

This signals the ECM when the Alternator (ALT) is charging.

Alternator (ALT) FR Signal

Check lor a short in th€ wire {ALTF line):1. Oisconnect the ALT GRN 4P(3P)* connector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECMconnector terminals C17 and A9.

ECM CONNECTORSA t32Pt

LG1

c 13lPl

ALT F(WHT/FEDI

Wire side of female terminals

ALT GRN 4P CONN€CTOR {C119}

JUMPER WIRE

Wire side of female terminals

ALT GRN 3P CONNECTOB {C119)*

JUMP€RWIRE

Wire side ot female terminals

12 15 t6 rr t8 19I

?

oALT F(WHT/REOI

23aI10

t112t3t5l6r819 ,/21

./,/,/2a29

[,ALT FIWHT/RED)

12339

11 12l517 tla19 ,/21

Inspection of ALT FR Signal.

Check for a shon in the wire {ALTF line):1. Turn the ignition switch OFF.2. Disconnecl the negative baatery cable from the battery.3. Disconnect the ECM connectorc (31P).

4. Check for continuity betweenbody ground and ECM con-nector terminal C17.

ls there approx.5 V?

Check the operation ofthe ALT:1. Turn the;Onition switch OFF-2. Reconnect the ALT GRN 4P(3P)* connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm wkh noload {in Park or neutral) untilthe radiator fan comes on,then let it idle.4. Measure voltage bet/veen ECMcon nector termina ls C17 and A9.

Ropair short in the wir6 betweenth6 ECM (C17) and the ALT.

Substitute a known-good ECMand recheck. It prescribed voltagGis now available, replace th€ origi-nal ECM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR signal is OK.

Check tor an open in the wire {ALTF line):1. Turn the ignition switch OFF-2. Disconnect the negative bat-tery cable from the battery.3. Disconnect the ECM connector C (31P).

4. Disconnect the ALT GRN 4P(3Pi* connector from the ALT.5. Connect the ALT GRN 4P (3p)*

connector terminal No. 4 (No.'l)* to body ground with a

6. Check for continuity betweenbody ground and ECM connector terminal C17.

Ropair open wire bstw€an theECM {C17} and rhe ALT.ls there continuity?

ri Canada

11-101

Page 316 of 1681

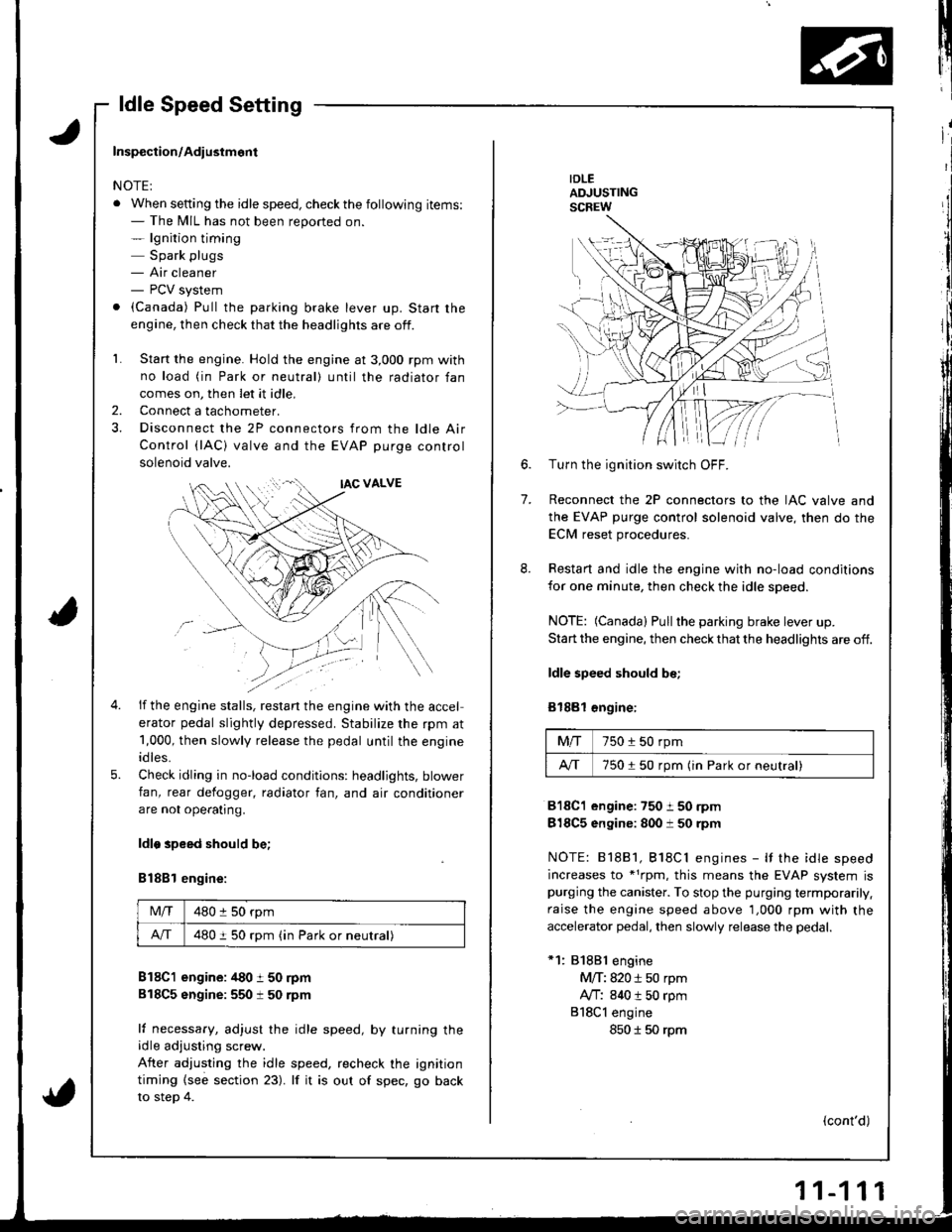

ldle Speed Setting

IDLEADJUSTINGSCREW

7.

6.Turn the ignition switch OFF.

Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM reset procedures.

Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pullthe parking brake lever up.

Start the engine, then check that the headlights are off.

ldle speed should be;

Bl88l €ngine:

Mfi750 i 50 rpm

A/T750150 rpm (in Park or neutral)

818C1 engine:750 i 50 rpm

818C5 engine: 800 i 50 rpm

NOTE: 81881, Bl8Cl engines - It the idle speed

increases to *1rpm, this means the EVAP system ispurging the canister. To stop the purging termporarily.

raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.

*1: 81881 engine

M/T: 820 i 50 rpm

Ay'T: 840 t 50 rpm

818Cl engine

850 I 50 rpm

(cont'd)

Inspection/Adiustmont

NOTE:

. When setting the idle speed, checkthe following items:- The MIL has not been reported on.- lgnition timing

Spark plugs- Air cleaner- PCV system

. (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Disconnect the 2P connectors from the ldle Air

Control (lAC) valve and the EVAP purge control

solenoid valve.

2.

5.

if the engine stalls, restan the engine with the accel

erator pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and air conditioner

are not ope€tlng.

ldlo speed should be;

B188l engine:

Mlf480 :l 50 rpm

A/T480 i 50 rpm (in Park or neutral)

B18C1 engine: /t80 t 50 rpm

818C5 sngine:550 t 50 rpm

lf necessary, adjust the idle speed, by turning theidle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing {see section 23). lf it is out of spec, go back

to steo 4.

Page 317 of 1681

ldle Control System

ldle Speed Setting (cont'dl

ldle the engine for one minute with headlights (Low)

ON and check the idle speed.

ldle 3peed should b€;

B1881 engine:

MIT750 t 50 rpm

750 i 50 rDm (in Park or neutrall

818C1 engine: 7501 50 nm

818C5 engine: 8001 50 rpm

Turn the headlights off. ldle the engine for one min-

ute with heater fan switch at Hl and air conditioner

on, then check the idle speed.

ldl. spood should be;

Bl8Bl ongin.:

M/T820 i 50 rpm

lvT840 t 50 rpm (in Park or neutral)

818C1 €ngino: 850 i 50 rpm

818C5 engino: 1,050 t 50 rpm

NOTE: lf the idle speed is not within specification.

see Symptom Chart on page 1!-36.

\

L

i

lIh:

lffiiltfl!

ffi

| 11-112

\

I

Page 343 of 1681

t"iI

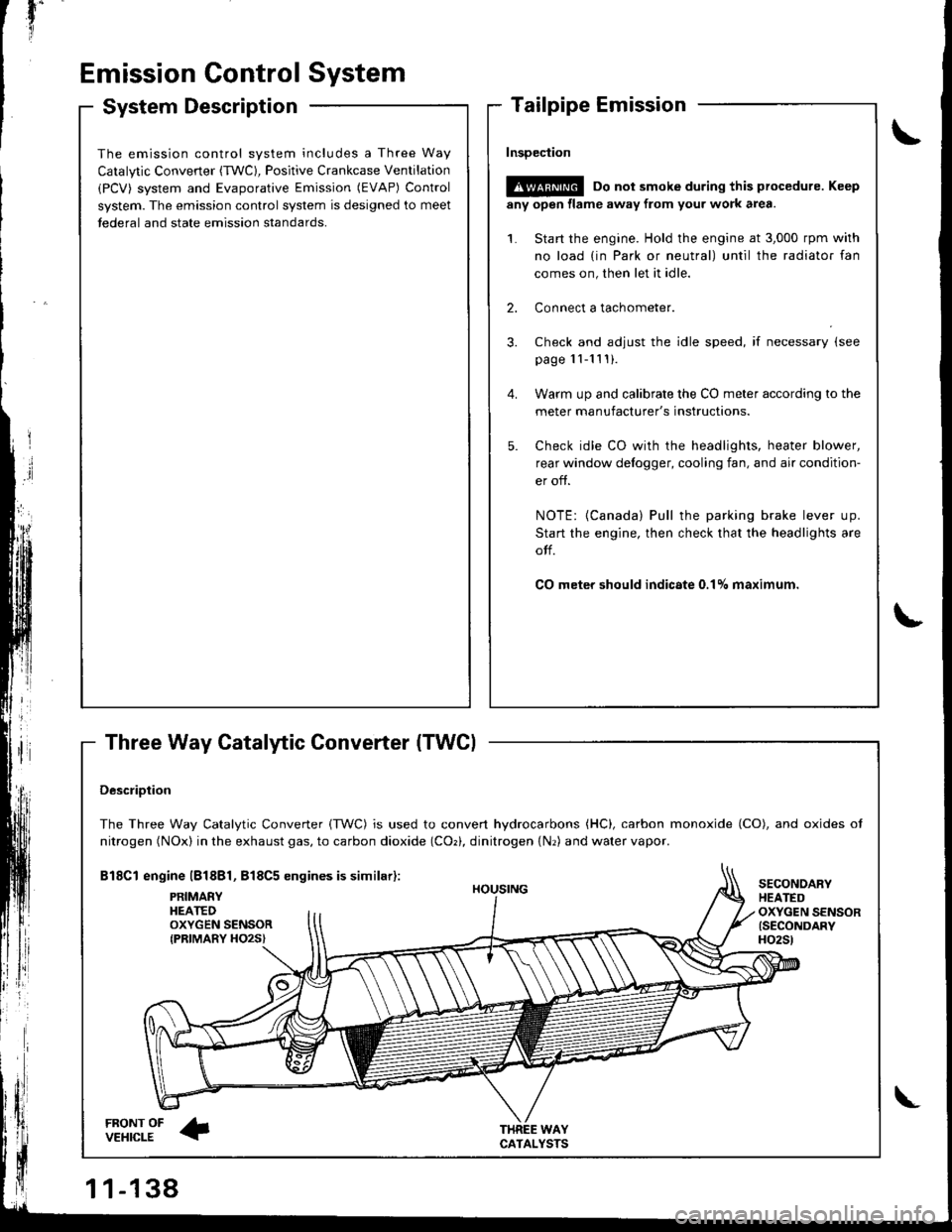

Emission Gontrol System

System Description

Three Way Catalytic Converter (TWCI

\

t

The emission control system includes a Three Way

Catalytic Converter (TWC), Positive Crankcase Ventilation

(PCV) system and Evaporative Emission (EVAP) Control

system. The emission control system is designed to meet

tederal and state emission standards.

InsDeciion

!@@ Do not smoke during this procedure. Keep

any open llame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Connect a tachometer.

Check and adjust the idle speed, if necessary (see

page '11-11 ! ).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with rhe headlights, heater blower,

rear window defogger, cooling fan, and air condition-

er off.

NOTE: {Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights are

olf.

CO meter should indicste 0.17o maximum.

DescriDtion

The Three Way Catalytic Converter {TWC) is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of

nitrogen (NOx) in the exhaust gas, to carbon dioxide (COr), dinitrogen {Nr) and water vapor.

Bl8Cl engine l818Bl, 818C5 engines is similar):

FRONT OFVEHICLE

PRIMAEYHEATEDOXYGEN SENSORIPRIMARY HO2S}

HOUSING

WAYCATALYSTS

SECONOARYHEATEDOXYGEN SENSOR{SECONDARYH02St

\

Page 1058 of 1681

J

Electrical

Speciaf Toofs ..........................23-2

Troubleshooting

Tips 8nd Precautions .......................,..,.,.,.,.,......,..., 23-3

Five-step Troubleshooting ............,......,.,.,...,..,....., 23-5

Schsmatic Svmbols ...............23-6

Wire Color Code3 .. ................. 23-6

Relay and Control Unit Locations

Engine Compartment ......,.,.................,.,.,.,.,.,,,, 23-7

Dashboard and Door .........,...........,.....,.,....,.,.... 23-8

Dashboard and Floor ......................................... 23-10

Ouarter Pan€f .,,.,...,.,..,...,,,23-12

Connector ldontification and WireHarness Routing ......,.,......23-'13

Index to Circuits and Systems

Airbag

* Integrated Control Unit .....,.,.,.....23-152* Interlock Sytem .,...,.,...........,. 23.146

Lights, Exterior

Eack-up LighB ..................23.187

Brake Ligh$ ......................23-190*Daytime Running Lights (Canada) ................... 23"164

Front Parking Lights .......................................... 23-173

Front Side Marker Lights .................................. 23-173

Front Turn Signal Lights ..................-.......,...,.,. 23-173* Hazard Warning Lights ....................,........,....... 23-192

Headlights.....23-169

23-253 powerDistribution..................... 23-5/r

Air Conditioning.....,....... Soction 21

Alternator ..........,................... 23.99

iCigarette Lighter .........23-212

*Cruise Control

Distributor

'.'.,.'.'.,.'...,,,,.,''.'.,.',.'''.' 23.277

.............................. 23.88

................... 23-90lgnition Timing ......

Indicator Lights

Key-in Reminder System

Maintenance Reminder System*Seat Belt R€mindor System .,...........................* Side Marker/Turn Signal/HazardFlashcr Svstem .................23-192

Spark Plugs ............................23-98

Starting System .....................23-74* Stereo Sound System ...,......,..........,...,......,.,.,.,..,., 23-196

Supplemental Restraint System (SRS) ................ 23-277

Vshicle Speed Sensor (VSS) ................................. 23.130r Wiper/Washer System .........................................., 23-265

*Read SRS precautions on Psge 23-283 before working

in those areas,

23-154

23.136

23"133

Page 1217 of 1681

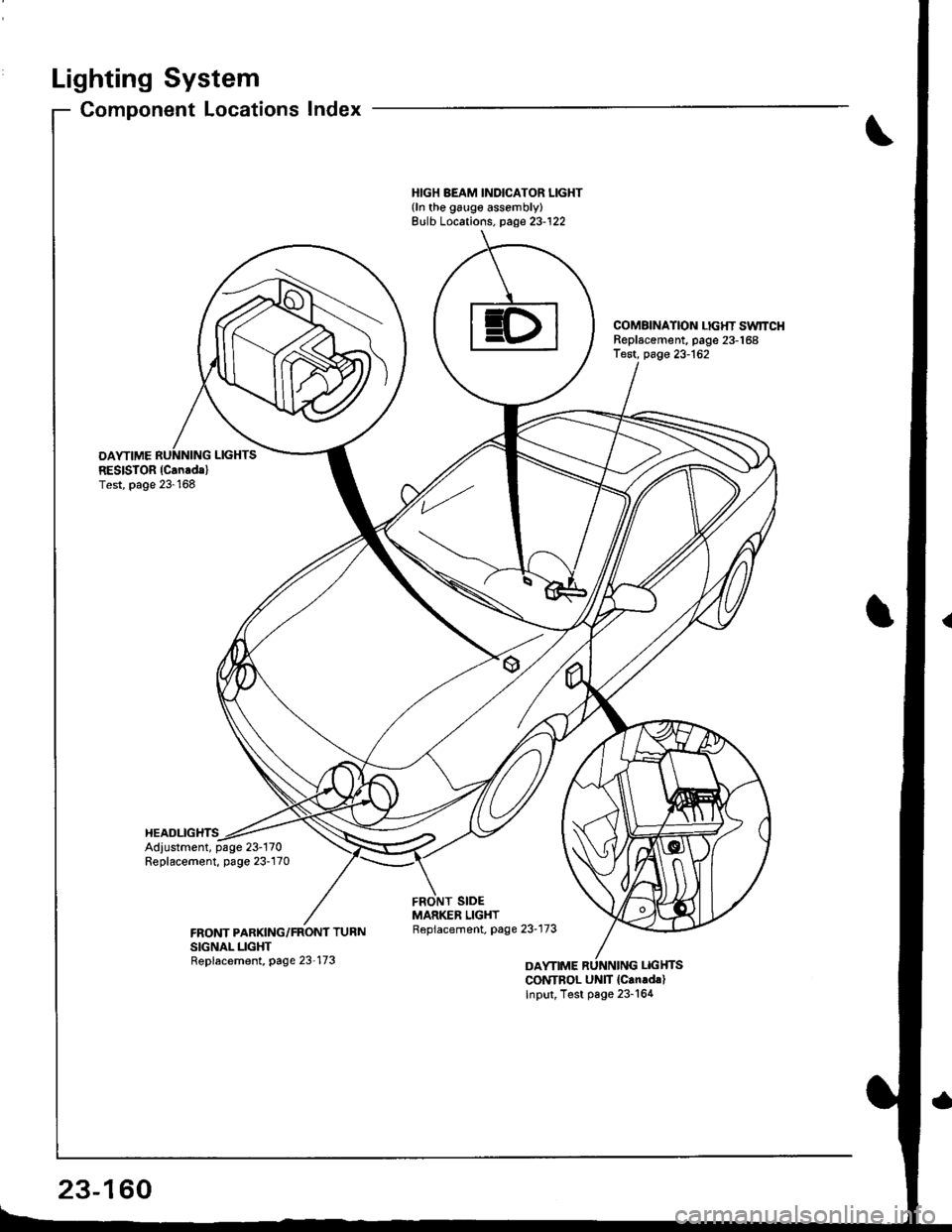

Lighting System

OAYTIMERESISTOR (Can.dal

Test, page 23-168

HEADLIGHTS

Component Locations Index

HIGH BEAM INDICATOR LIGHT{ln the galge assembly}Bulb Locations. page 23-122

COMAINATION LIGHT SwlTCHReplscement, page 23-168Test, page 23-162

Adjustment, page 23-170Replacement, page 23-170

CONTBOL UNIT {Can.d.)Input, Test page 23-164

23-160