HONDA S2000 2001 1.G Owners Manual

Manufacturer: HONDA, Model Year: 2001, Model line: S2000, Model: HONDA S2000 2001 1.GPages: 276, PDF Size: 3.79 MB

Page 171 of 276

6-spee

d Manua l Transmissio n Flui d

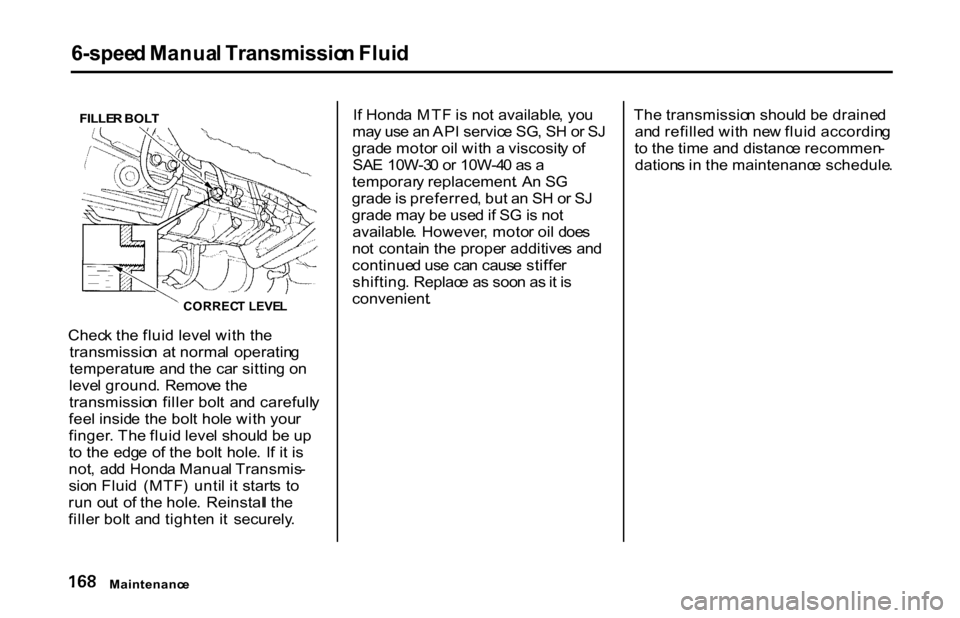

FILLE R BOL T

CORREC T LEVE L

Chec k th e flui d leve l wit h th e

transmissio n a t norma l operatin g

temperatur e an d th e ca r sittin g o n

leve l ground . Remov e th e

transmissio n fille r bol t an d carefull y

fee l insid e th e bol t hol e wit h you r

finger . Th e flui d leve l shoul d b e u p

t o th e edg e o f th e bol t hole . I f i t i s

not , ad d Hond a Manua l Transmis -

sio n Flui d (MTF ) unti l i t start s t o

ru n ou t o f th e hole . Reinstal l th e

fille r bol t an d tighte n i t securely .I

f Hond a MT F is no t available , yo u

ma y us e a n AP I servic e SG , S H o r S J

grad e moto r oi l wit h a viscosit y o f

SA E 10W-3 0 o r 10W-4 0 a s a

temporar y replacement . A n S G

grad e is preferred , bu t a n S H o r S J

grad e ma y b e use d if S G is no t

available . However , moto r oi l doe s

no t contai n th e prope r additive s an d

continue d us e ca n caus e stiffe r

shifting . Replac e a s soo n a s it i s

convenient . Th

e transmissio n shoul d b e draine d

an d refille d wit h ne w flui d accordin g

t o th e tim e an d distanc e recommen -

dation s i n th e maintenanc e schedule .

Maintenanc e

Page 172 of 276

Differentia

l Flui d

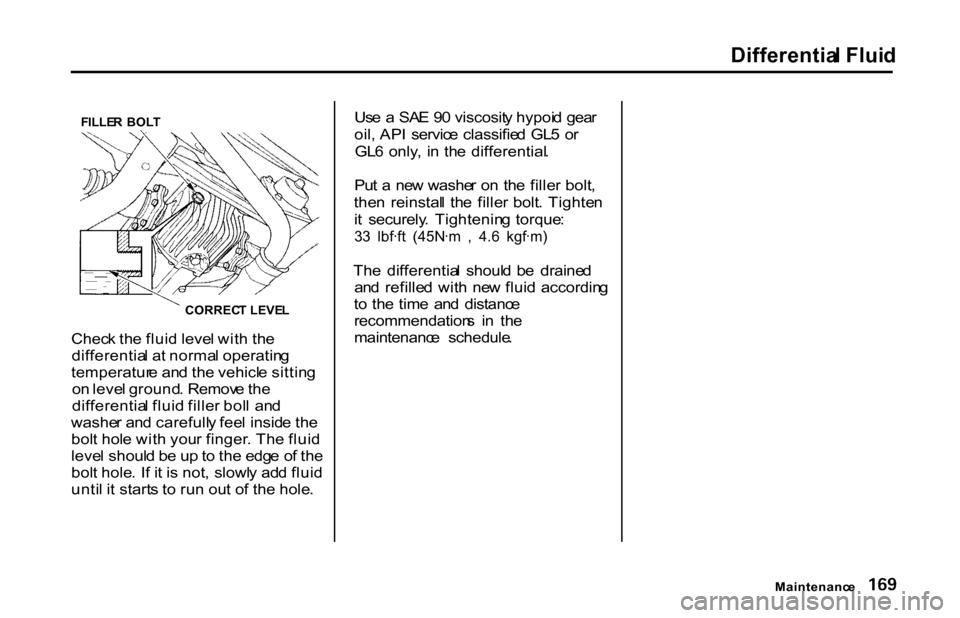

Chec k th e flui d leve l wit h th e

differentia l a t norma l operatin g

temperatur e an d th e vehicl e sittin g

o n leve l ground . Remov e the

differentia l flui d fille r bol l an d

washe r an d carefull y fee l insid e th e

bol t hol e wit h you r finger . Th e flui d

leve l shoul d b e u p to th e edg e o f th e

bol t hole . I f i t i s not , slowl y ad d flui d

unti l i t start s t o ru n ou t o f the hole . Us

e a SA E 9 0 viscosit y hypoi d gea r

oil , AP I servic e classifie d GL 5 o r

GL 6 only , i n th e differential .

Pu t a ne w washe r o n th e fille r bolt ,

the n reinstal l th e fille r bolt . Tighte n

i t securely . Tightenin g torque :

33 lbf .

ft (45N .

m , 4.6 kgf .

m )

Th e differentia l shoul d b e draine d

an d refille d wit h ne w flui d accordin g

t o th e tim e an d distanc e

recommendation s i n th e

maintenanc e schedule .

Maintenance

FILLE

R BOL T

CORREC T LEVE L

Page 173 of 276

Brak

e an d Clutc h Flui d

Chec k th e flui d leve l i n th e reser -

voir s monthly . Ther e ar e tw o reser -

voirs . The y are :

Brak e flui d reservoi r Clutc

h flui d reservoi r

Th e brak e flui d shoul d b e replace d

accordin g to th e tim e recommenda -

tio n in th e maintenanc e schedule .

Brak

e Flui d

Alway s us e Hond a Heav y Dut y

Brak e Flui d DO T 3 . I f i t i s no t

available , yo u shoul d us e onl y DO T 3

o r DO T 4 fluid , fro m a seale d

container , a s a temporar y

replacement . However , th e us e o f

an y non-Hond a brak e flui d ca n caus e

corrosio n an d decreas e th e lif e o f th e

system . Hav e th e brak e syste m

flushe d an d refille d wit h Hond a

Heav y Dut y Brak e Flui d DO T 3 a s

soo n a s possible .

Brak e flui d marke d DO T 5 is no t

compatibl e wit h you r car' s brakin g

syste m an d ca n caus e extensiv e

damage .

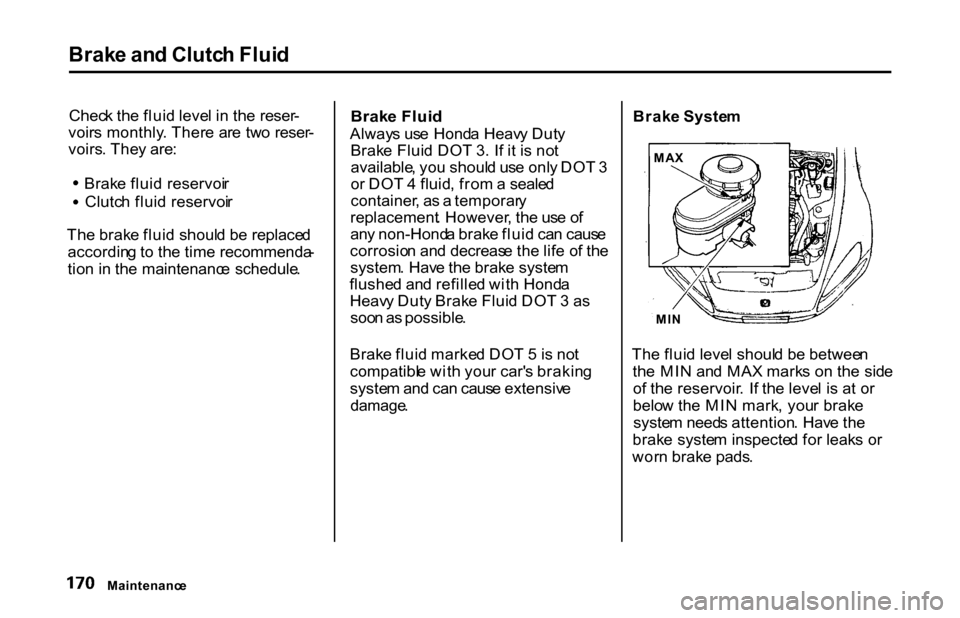

Brak

e Syste m

Th e flui d leve l shoul d b e betwee n

th e MI N an d MA X mark s o n th e sid e

o f th e reservoir . I f th e leve l i s a t o r

belo w th e MI N mark , you r brak e

syste m need s attention . Hav e th e

brak e syste m inspecte d fo r leak s o r

wor n brak e pads .

Maintenanc e

MA

X

MI N

Page 174 of 276

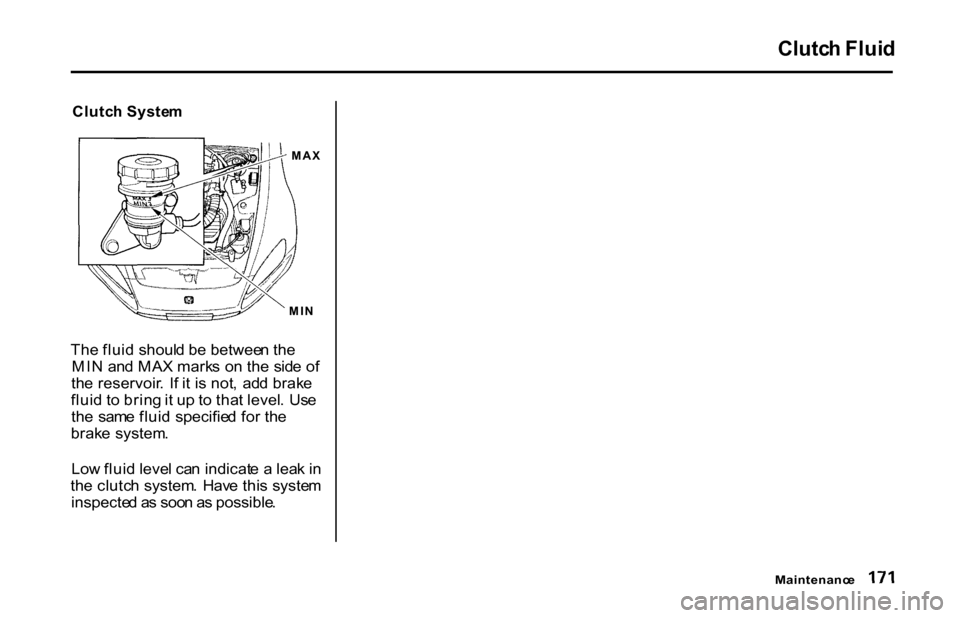

Clutc

h Syste m

Th e flui d shoul d b e betwee n th e

MI N an d MA X mark s o n th e sid e o f

th e reservoir . I f i t i s not , ad d brak e

flui d t o brin g it u p t o tha t level . Us e

th e sam e flui d specifie d fo r th e

brak e system .

Lo w flui d leve l ca n indicat e a lea k i n

th e clutc h system . Hav e thi s syste m

inspecte d a s soo n a s possible .

Clutc

h Flui d

Maintenanc e

MA

X

MI N

Page 175 of 276

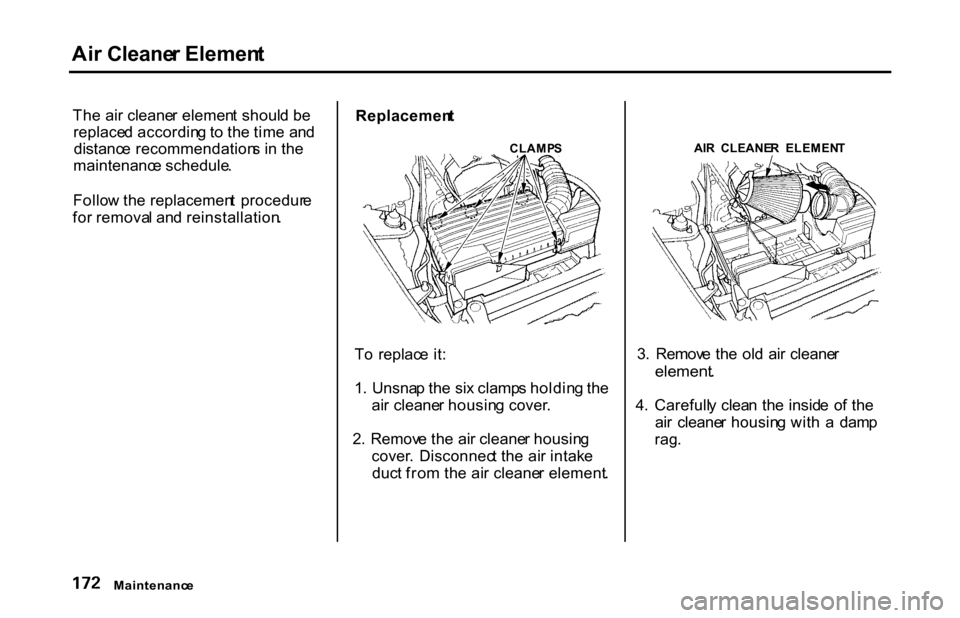

Ai

r Cleane r Elemen t

Th e ai r cleane r elemen t shoul d b e

replace d accordin g to th e tim e an d

distanc e recommendation s i n th e

maintenanc e schedule .

Follo w th e replacemen t procedur e

fo r remova l an d reinstallation .Replacemen

t

T o replac e it :

1 . Unsna p th e si x clamp s holdin g th e

ai r cleane r housin g cover .

2 . Remov e th e ai r cleane r housin g

cover . Disconnec t th e ai r intak e

duc t fro m th e ai r cleane r element . AI

R CLEANE R ELEMEN T

3 . Remov e th e ol d ai r cleane r

element .

4 . Carefull y clea n th e insid e o f th e

ai r cleane r housin g wit h a dam p

rag .

Maintenanc e

CLAMP

S

Page 176 of 276

Ai

r Cleane r Elemen t

Maintenanc e

5

. Attac h th e ne w ai r cleane r

elemen t t o th e duct . Instal l th e

ne w ai r cleane r elemen t i n th e ai r

cleane r housing . Mak e sur e th e

pi n o n th e edg e o f th e elemen t fit s

i n th e hol e i n th e botto m o f th e

housing .

6 . Reinstal l th e ai r cleane r housin g

cover , sna p th e si x clamp s bac k

int o place .

Page 177 of 276

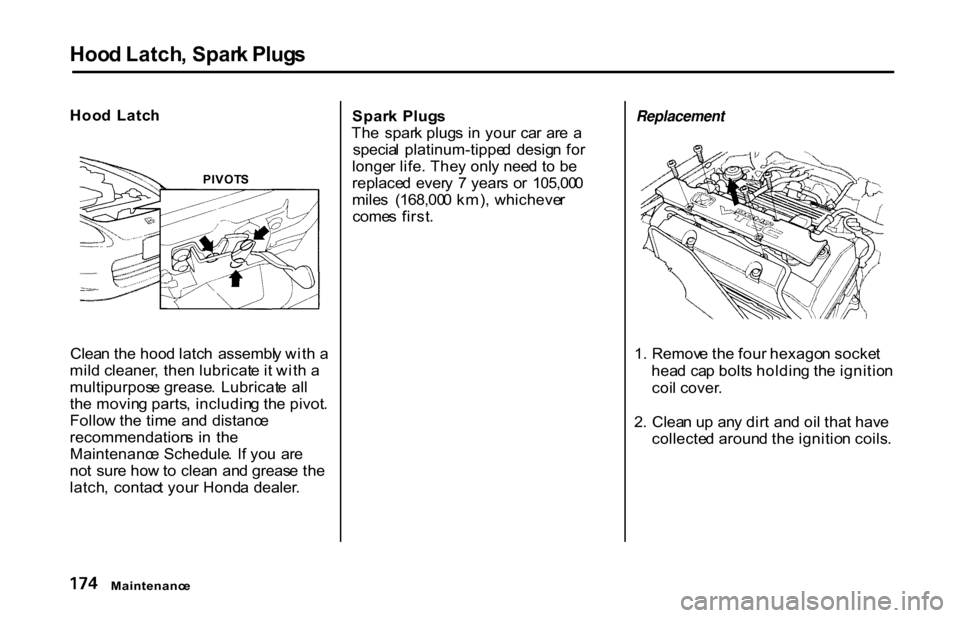

Hoo

d Latch , Spar k Plug s

Hoo d Latc h

Clea n th e hoo d latc h assembl y wit h a

mil d cleaner , the n lubricat e i t wit h a

multipurpos e grease . Lubricat e al l

th e movin g parts , includin g th e pivot .

Follo w th e tim e an d distanc e

recommendation s i n th e

Maintenanc e Schedule . I f yo u ar e

no t sur e ho w to clea n an d greas e th e

latch , contac t you r Hond a dealer . Spar

k Plug s

Th e spar k plug s i n you r ca r ar e a

specia l platinum-tippe d desig n fo r

longe r life . The y onl y nee d t o b e

replace d ever y 7 year s o r 105,00 0

mile s (168,00 0 km) , whicheve r

come s first .

Replacement

1 . Remov e th e fou r hexago n socke t

hea d ca p bolt s holdin g th e ignitio n

coi l cover .

2 . Clea n u p an y dir t an d oi l tha t hav e

collecte d aroun d th e ignitio n coils .

Maintenanc e

PIVOT

S

Page 178 of 276

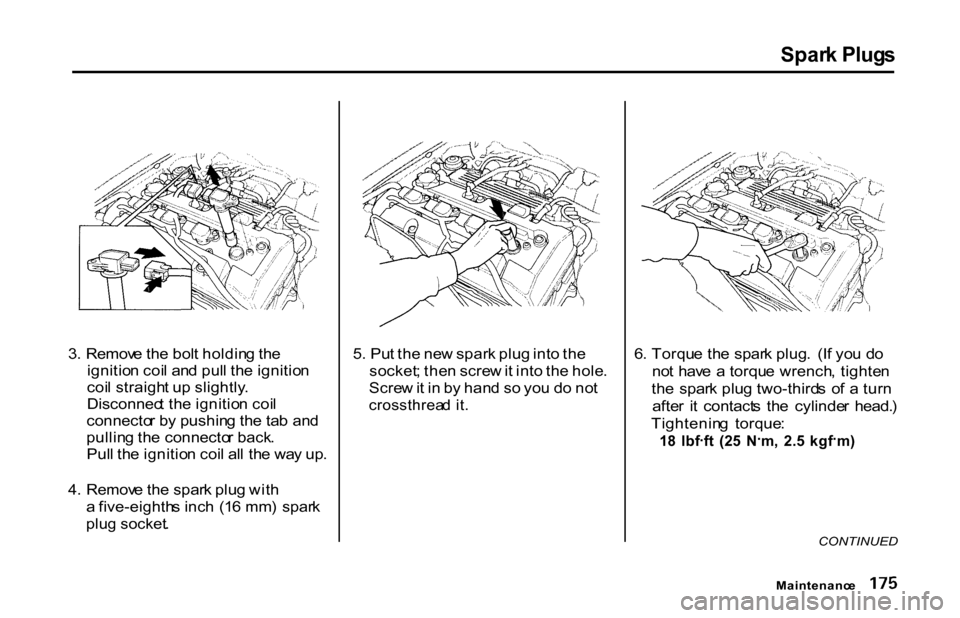

Spar

k Plug s

3 . Remov e th e bol t holdin g th e

ignitio n coi l an d pul l th e ignitio n

coi l straigh t u p slightly .

Disconnec t th e ignitio n coi l

connecto r b y pushin g th e ta b an d

pullin g th e connecto r back .

Pul l th e ignitio n coi l al l th e wa y up .

4 . Remov e th e spar k plu g wit h

a five-eighth s inc h (1 6 mm ) spar k

plu g socket . 5

. Pu t th e ne w spar k plu g int o th e

socket ; the n scre w it int o th e hole .

Scre w it i n b y han d s o yo u d o no t

crossthrea d it .

6

. Torqu e th e spar k plug . (I f yo u d o

no t hav e a torqu e wrench , tighte n

th e spar k plu g two-third s o f a tur n

afte r i t contact s th e cylinde r head. )

Tightenin g torque :

1 8 lbf .

f t (2 5 N .

m , 2. 5 kgf .

m )

CONTINUED

Maintenanc e

Page 179 of 276

Spar

k Plug s

Tighten the spark plugs carefully. A

spark plug that is too loose can

overheat and damage the engine.

Overtighlening can cause damage to

the threads in the cylinder head.

7 . Instal l th e ignitio n coil . Reinstal l

th e bolt .

8 . Repea t thi s procedur e fo r th e

othe r thre e spar k plugs .

9 . Reinstal l th e cove r o n th e cylinde r

bank . Reinstal l th e fou r hexago n

socke t hea d ca p bolts .

Specifications

:

NGK:

DENSO :

PFR7G-11 S

PK22PR-L11 S

Spark Plu g Gap :

0.04

3 in (1. 1 m m

Maintenanc e

NOTIC

E

Page 180 of 276

Batter

y

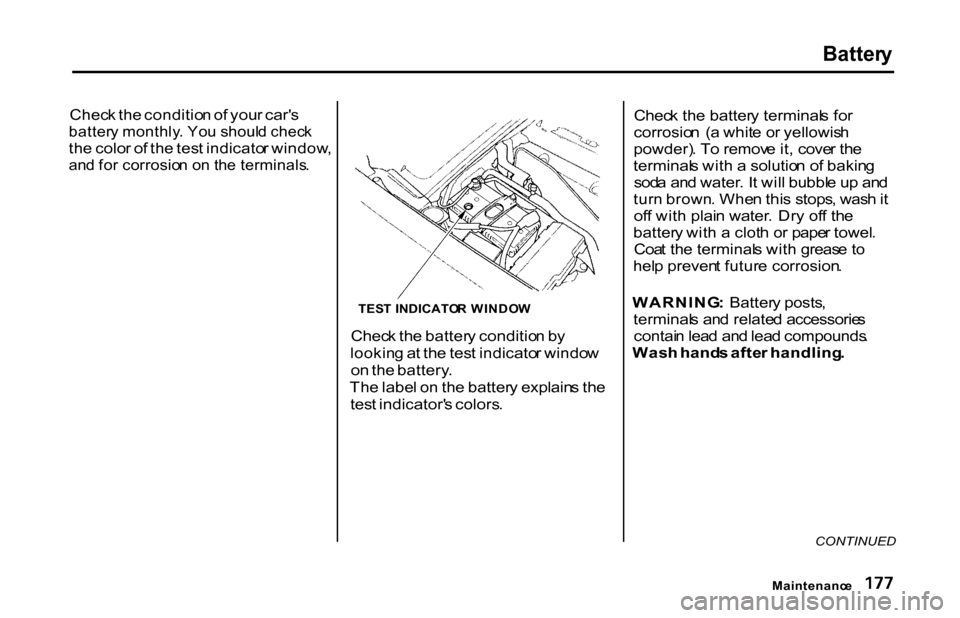

Chec k th e conditio n o f you r car' s

batter y monthly . Yo u shoul d chec k

th e colo r o f th e tes t indicato r window ,

an d fo r corrosio n o n th e terminals .

Check th e batter y conditio n b y

lookin g a t th e tes t indicato r windo w

o n th e battery .

Th e labe l o n th e batter y explain s th e

tes t indicator' s colors . Chec

k th e batter y terminal s fo r

corrosio n ( a whit e o r yellowis h

powder) . T o remov e it , cove r th e

terminal s wit h a solutio n o f bakin g

sod a an d water . I t wil l bubbl e u p an d

tur n brown . Whe n thi s stops , was h it

of f wit h plai n water . Dr y of f th e

batter y wit h a clot h o r pape r towel .

Coa t th e terminal s wit h greas e to

hel p preven t futur e corrosion .

WARNING : Batter y posts ,

terminal s an d relate d accessorie s

contai n lea d an d lea d compounds .

Was h hand s afte r handling .

CONTINUED

Maintenanc e

TES

T INDICATO R WINDO W