fuel HUMMER H2 2006 Owner's Guide

[x] Cancel search | Manufacturer: HUMMER, Model Year: 2006, Model line: H2, Model: HUMMER H2 2006Pages: 502, PDF Size: 3.35 MB

Page 389 of 502

Treadwear Indicators:Narrow bands, sometimes

called wear bars, that show across the tread of a tire

when only 1/16 inch (1.6 mm) of tread remains.

SeeWhen It Is Time for New Tires on page 5-62.

UTQGS (Uniform Tire Quality Grading Standards):A

tire information system that provides consumers with

ratings for a tire’s traction, temperature, and treadwear.

Ratings are determined by tire manufacturers using

government testing procedures. The ratings are molded

into the sidewall of the tire. SeeUniform Tire Quality

Grading on page 5-65.

Vehicle Capacity Weight:The number of designated

seating positions multiplied by 150 lbs (68 kg) plus

the rated cargo load. SeeLoading Your Vehicle

on page 4-55.

Vehicle Maximum Load on the Tire:Load on an

individual tire due to curb weight, accessory weight,

occupant weight, and cargo weight.

Vehicle Placard:A label permanently attached to a

vehicle showing the vehicle’s capacity weight and

the original equipment tire size and recommended

in�ation pressure. See “Tire and Loading Information

Label” underLoading Your Vehicle on page 4-55.In�ation - Tire Pressure

Tires need the correct amount of air pressure to

operate effectively.

Notice:Do not let anyone tell you that

under-in�ation or over-in�ation is all right. It is not.

If your tires do not have enough air (under-in�ation),

you can get the following:

Too much �exing

Too much heat

Tire overloading

Premature or irregular wear

Poor handling

Reduced fuel economy

If your tires have too much air (over-in�ation), you

can get the following:

Unusual wear

Poor handling

Rough ride

Needless damage from road hazards

5-59

Page 442 of 502

Sheet Metal Damage

If the vehicle is damaged and requires sheet metal

repair or replacement, make sure the body repair shop

applies anti-corrosion material to parts repaired or

replaced to restore corrosion protection.

Original manufacturer replacement parts will provide the

corrosion protection while maintaining the warranty.

Finish Damage

Any stone chips, fractures or deep scratches in the

�nish should be repaired right away. Bare metal

will corrode quickly and may develop into major repair

expense.

Minor chips and scratches can be repaired with

touch-up materials available from your GM dealer.

Larger areas of �nish damage can be corrected in

your GM dealer’s body and paint shop.

Underbody Maintenance

Chemicals used for ice and snow removal and dust

control can collect on the underbody. If these are not

removed, corrosion and rust can develop on the

underbody parts such as fuel lines, frame, �oor pan, and

exhaust system even though they have corrosion

protection.

At least every spring, �ush these materials from the

underbody with plain water. Clean any areas where mud

and debris can collect. Dirt packed in close areas of

the frame should be loosened before being �ushed.

Your dealer or an underbody car washing system can

do this for you.

Chemical Paint Spotting

Some weather and atmospheric conditions can create a

chemical fallout. Airborne pollutants can fall upon and

attack painted surfaces on the vehicle. This damage can

take two forms: blotchy, ring-shaped discolorations,

and small, irregular dark spots etched into the

paint surface.

Although no defect in the paint job causes this, GM will

repair, at no charge to the owner, the surfaces of

new vehicles damaged by this fallout condition within

12 months or 12,000 miles (20 000 km) of purchase,

whichever occurs �rst.

5-112

Page 451 of 502

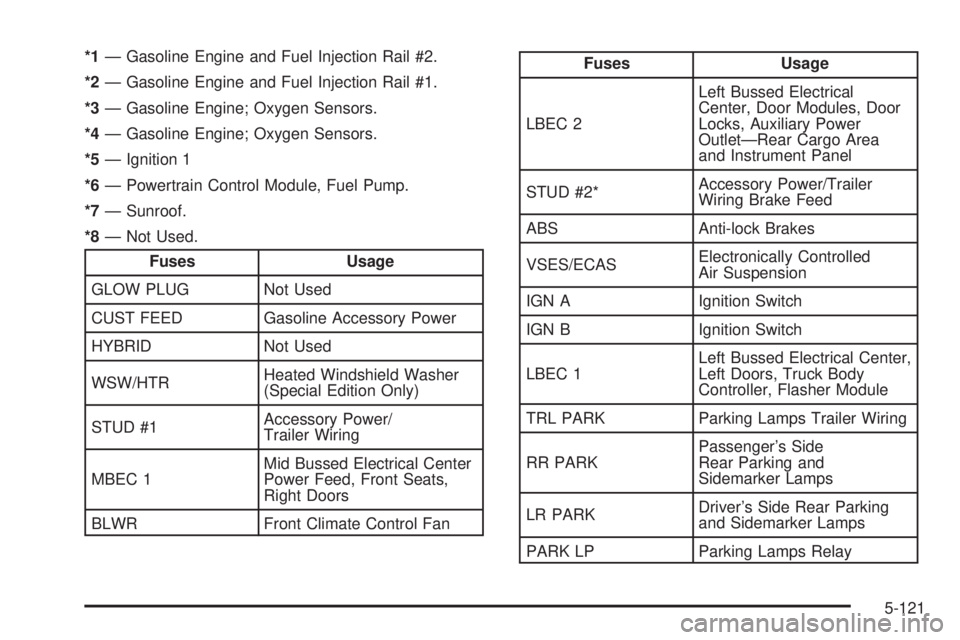

*1— Gasoline Engine and Fuel Injection Rail #2.

*2— Gasoline Engine and Fuel Injection Rail #1.

*3— Gasoline Engine; Oxygen Sensors.

*4— Gasoline Engine; Oxygen Sensors.

*5— Ignition 1

*6— Powertrain Control Module, Fuel Pump.

*7— Sunroof.

*8— Not Used.

Fuses Usage

GLOW PLUG Not Used

CUST FEED Gasoline Accessory Power

HYBRID Not Used

WSW/HTRHeated Windshield Washer

(Special Edition Only)

STUD #1Accessory Power/

Trailer Wiring

MBEC 1Mid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLWR Front Climate Control Fan

Fuses Usage

LBEC 2Left Bussed Electrical

Center, Door Modules, Door

Locks, Auxiliary Power

Outlet—Rear Cargo Area

and Instrument Panel

STUD #2*Accessory Power/Trailer

Wiring Brake Feed

ABS Anti-lock Brakes

VSES/ECASElectronically Controlled

Air Suspension

IGN A Ignition Switch

IGN B Ignition Switch

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKPassenger’s Side

Rear Parking and

Sidemarker Lamps

LR PARKDriver’s Side Rear Parking

and Sidemarker Lamps

PARK LP Parking Lamps Relay

5-121

Page 452 of 502

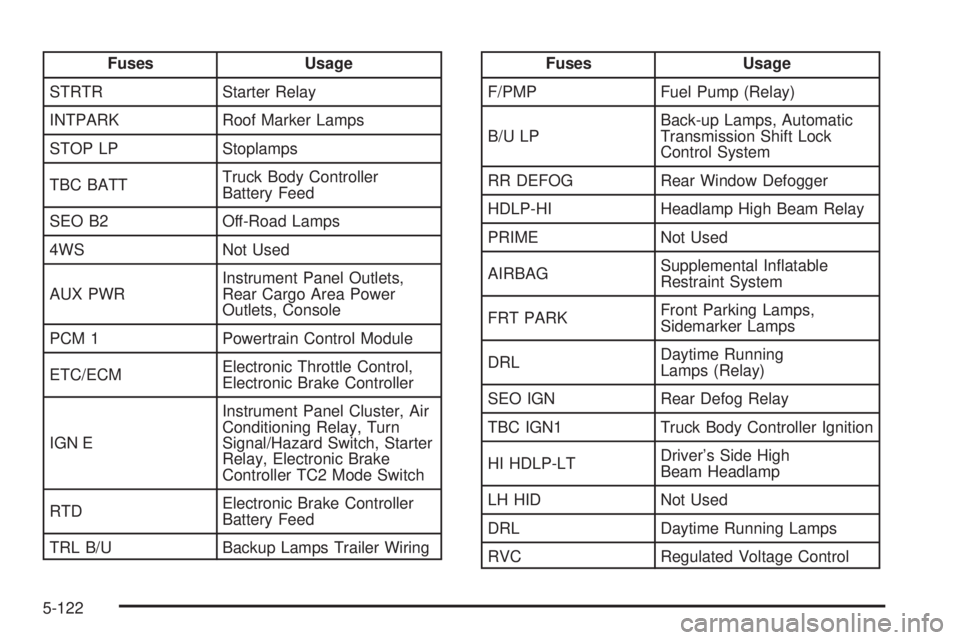

Fuses Usage

STRTR Starter Relay

INTPARK Roof Marker Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller

Battery Feed

SEO B2 Off-Road Lamps

4WS Not Used

AUX PWRInstrument Panel Outlets,

Rear Cargo Area Power

Outlets, Console

PCM 1 Powertrain Control Module

ETC/ECMElectronic Throttle Control,

Electronic Brake Controller

IGN EInstrument Panel Cluster, Air

Conditioning Relay, Turn

Signal/Hazard Switch, Starter

Relay, Electronic Brake

Controller TC2 Mode Switch

RTDElectronic Brake Controller

Battery Feed

TRL B/U Backup Lamps Trailer WiringFuses Usage

F/PMP Fuel Pump (Relay)

B/U LPBack-up Lamps, Automatic

Transmission Shift Lock

Control System

RR DEFOG Rear Window Defogger

HDLP-HI Headlamp High Beam Relay

PRIME Not Used

AIRBAGSupplemental In�atable

Restraint System

FRT PARKFront Parking Lamps,

Sidemarker Lamps

DRLDaytime Running

Lamps (Relay)

SEO IGN Rear Defog Relay

TBC IGN1 Truck Body Controller Ignition

HI HDLP-LTDriver’s Side High

Beam Headlamp

LH HID Not Used

DRL Daytime Running Lamps

RVC Regulated Voltage Control

5-122

Page 454 of 502

Capacities and Speci�cations

The following approximate capacities are given in English and metric. Please refer toRecommended Fluids and

Lubricants on page 6-12for more information.

Capacities and Speci�cations

ApplicationCapacities

English Metric

Cooling System

117.2 qt 16.3 L

Engine Oil with Filter

26.0 qt 5.7 L

Fuel Tank 32.0 gal 121.0 L

Transfer Case Fluid 2.0 qt 1.9 L

Wheel Nut Torque 140 lb ft 190Y

1After re�ll, the level must be rechecked. SeeCooling System on page 5-29.2After re�ll, the level must be rechecked. Add enough engine oil so that the �uid is within the proper operating

range. SeeEngine Oil on page 5-14.

All capacities are approximate. When adding, be sure to �ll to the appropriate level, as recommended in

this manual.

Engine Speci�cations

Engine VIN Code Transmission Spark Plug Gap

VORTEC™ 6.0L V8 U Automatic 0.040 inches (1.01 mm)

5-124

Page 455 of 502

Maintenance Schedule......................................6-2

Introduction...................................................6-2

Maintenance Requirements..............................6-2

Your Vehicle and the Environment....................6-2

Using the Maintenance Schedule......................6-2

Scheduled Maintenance...................................6-4

Additional Required Services............................6-6

Maintenance Footnotes...................................6-7Owner Checks and Services............................6-8

At Each Fuel Fill............................................6-8

At Least Once a Month...................................6-9

At Least Once a Year...................................6-10

Recommended Fluids and Lubricants...............6-12

Normal Maintenance Replacement Parts..........6-14

Engine Drive Belt Routing..............................6-15

Maintenance Record.....................................6-16

Section 6 Maintenance Schedule

6-1

Page 457 of 502

Because of all the different ways people use their

vehicles, maintenance needs vary. You may need more

frequent checks and replacements. So please read

the following and note how you drive. If you have any

questions on how to keep your vehicle in good condition,

see your GM Goodwrench

®dealer.

This schedule is for vehicles that:

carry passengers and cargo within recommended

limits. You will �nd these limits on the tire and

loading information label. SeeLoading Your Vehicle

on page 4-55.

are driven on reasonable road surfaces within legal

driving limits.

are driven off-road in the recommended manner.

SeeOff-Road Driving on page 4-16.

use the recommended fuel. SeeGasoline Octane

on page 5-5.

The services inScheduled Maintenance on page 6-4

should be performed when indicated. SeeAdditional

Required Services on page 6-6andMaintenance

Footnotes on page 6-7for further information.

{CAUTION:

Performing maintenance work on a vehicle can

be dangerous. In trying to do some jobs, you

can be seriously injured. Do your own

maintenance work only if you have the

required know-how and the proper tools and

equipment for the job. If you have any doubt,

see your GM Goodwrench

®dealer to have a

quali�ed technician do the work. SeeDoing

Your Own Service Work on page 5-4.

Some maintenance services can be complex.

So, unless you are technically quali�ed and have

the necessary equipment, you should have your

GM Goodwrench

®dealer do these jobs.

When you go to your GM Goodwrench

®dealer for your

service needs, you will know that GM-trained and

supported service technicians will perform the work

using genuine GM parts.

If you want to purchase service information, seeService

Publications Ordering Information on page 7-15.

6-3

Page 460 of 502

Additional Required Services

The following services should be performed at the �rst maintenance service (IorII) after the indicated miles

(kilometers) shown for each item.

Additional Required Services

Service and Miles (Kilometers)25,000

(41 500)50,000

(83 000)75,000

(125 000)100,000

(166 000)125,000

(207 500)150,000

(240 000)

Inspect fuel system for damage or leaks.• •••••

Inspect exhaust system for loose or

damaged components.• •••••

Replace engine air cleaner �lter. SeeEngine

Air Cleaner/Filter on page 5-19.•

Change automatic transmission �uid and �lter

(severe service).See footnote (h).•••

Change automatic transmission �uid and �lter

(normal service).•

Change transfer case �uid.See footnote (g).•••

Replace spark plugs and inspect spark plug

wires.An Emission Control Service.•

Engine cooling system service (or every

�ve years, whichever occurs �rst).An

Emission Control Service. See footnote (i).•

Inspect engine accessory drive belt.An

Emission Control Service. See footnote (k).•

6-6

Page 461 of 502

Maintenance Footnotes

#Lubricate the front suspension, ball joints, steering

linkage, transmission shift linkage, and parking

brake cable guides. Ball joints should not be lubricated

unless their temperature is 10°F (-12°C) or higher,

or they could be damaged.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, cha�ng, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect other brake parts, including calipers,

parking brake, etc.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose, or missing parts,

signs of wear or lack of lubrication. Inspect power

steering lines and hoses for proper hook-up, binding,

leaks, cracks, cha�ng, etc. Visually check constant

velocity joints, rubber boots and axle seals for leaks.

(c)Visually inspect hoses and have them replaced

if they are cracked, swollen, or deteriorated. Inspect

all pipes, �ttings, and clamps; replace with genuine

GM parts as needed. To help ensure proper operation,

a pressure test of the cooling system and pressure

cap and cleaning the outside of the radiator and

air conditioning condenser is recommended at least

once a year.

(d)Visually inspect wiper blades for wear or cracking.

Replace wiper blades that appear worn or damaged

or that streak or miss areas of the windshield.(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors, and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken airbag

coverings, and have them repaired or replaced.

The airbag system does not need regular maintenance.

(f)Lubricate all key lock cylinders, hood latch

assembly, secondary latch, pivots, spring anchor,

release pawl, rear compartment hinges, outer liftgate

handle pivot points, rear door detent link, roller

mechanism, liftgate handle pivot points, latch bolt, fuel

door hinge, cargo door hinge, locks, and folding

seat hardware. More frequent lubrication may be

required when exposed to a corrosive environment.

Applying silicone grease on weatherstrips with a clean

cloth will make them last longer, seal better, and

not stick or squeak.

Spare tire carrier hinge and latch: Inspect for leaks and

lubricate if required. Remove the setscrew at the

hinge casting and add lubricant, moving the hinge back

and forth periodically, until lubricant can be seen

coming from the setscrew opening. Install setscrew and

tighten to 7 ft lb (9Y). SeeRecommended Fluids

and Lubricants on page 6-12for what lubricant to use.

(g)Check vent hose at transfer case for kinks and

proper installation.

6-7

Page 462 of 502

(h)Change automatic transmission �uid and �lter if the

vehicle is mainly driven under one or more of these

conditions:

�In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

�In hilly or mountainous terrain.

�When doing frequent trailer towing.

�Uses such as found in taxi, police, or delivery

service.

(i)Drain, �ush, and re�ll cooling system. This service

can be complex; you should have your dealer perform

this service. See Engine Coolant on page 5-24 for

what to use. Inspect hoses. Clean radiator, condenser,

pressure cap, and �ller neck. Pressure test the

cooling system and pressure cap.

(j)A �uid loss in any vehicle system could indicate a

problem. Have the system inspected and repaired and

the �uid level checked. Add �uid if needed.

(k)Visually inspect belt for fraying, excessive cracks, or

obvious damage. Replace belt if necessary.Owner Checks and Services

These owner checks and services should be performed

at the intervals speci�ed to help ensure the safety,

dependability, and emission control performance of your

vehicle. Your GM Goodwrench

®dealer can assist you

with these checks and services.

Be sure any necessary repairs are completed at once.

Whenever any �uids or lubricants are added to your

vehicle, make sure they are the proper ones, as shown

inRecommended Fluids and Lubricants on page 6-12.

At Each Fuel Fill

It is important to perform these underhood checks at

each fuel �ll.

6-8