clock HUMMER H3 2010 User Guide

[x] Cancel search | Manufacturer: HUMMER, Model Year: 2010, Model line: H3, Model: HUMMER H3 2010Pages: 410, PDF Size: 2.24 MB

Page 252 of 410

9-68 Driving and Operating

Filling the Tank

{WARNING

Fuel vapor burns violently and a

fuel fire can cause bad injuries.

To help avoid injuries to you and

others, read and follow all the

instructions on the fuel pump

island. Turn off the engine when

refueling. Do not smoke near fuel

or when refueling the vehicle. Do

not use cellular phones. Keep

sparks, flames, and smoking

materials away from fuel. Do not

leave the fuel pump unattended

when refueling the vehicle. This is

against the law in some places.

Do not re-enter the vehicle while

pumping fuel. Keep children away

from the fuel pump; never let

children pump fuel.

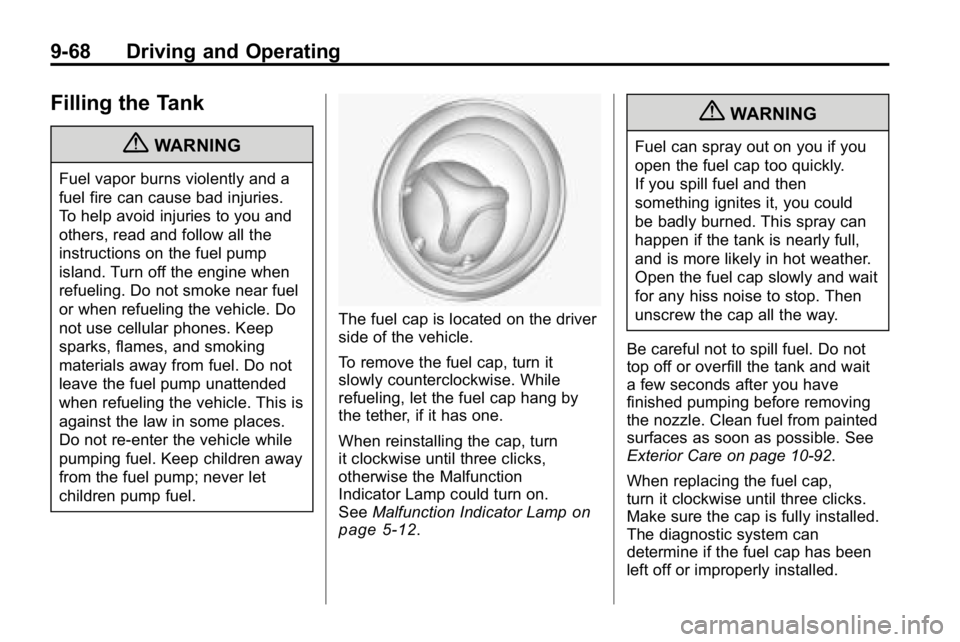

The fuel cap is located on the driver

side of the vehicle.

To remove the fuel cap, turn it

slowly counterclockwise. While

refueling, let the fuel cap hang by

the tether, if it has one.

When reinstalling the cap, turn

it clockwise until three clicks,

otherwise the Malfunction

Indicator Lamp could turn on.

SeeMalfunction Indicator Lamp

on

page 5‑12.

{WARNING

Fuel can spray out on you if you

open the fuel cap too quickly.

If you spill fuel and then

something ignites it, you could

be badly burned. This spray can

happen if the tank is nearly full,

and is more likely in hot weather.

Open the fuel cap slowly and wait

for any hiss noise to stop. Then

unscrew the cap all the way.

Be careful not to spill fuel. Do not

top off or overfill the tank and wait

a few seconds after you have

finished pumping before removing

the nozzle. Clean fuel from painted

surfaces as soon as possible. See

Exterior Care on page 10‑92.

When replacing the fuel cap,

turn it clockwise until three clicks.

Make sure the cap is fully installed.

The diagnostic system can

determine if the fuel cap has been

left off or improperly installed.

Page 287 of 410

Vehicle Care 10-21

{WARNING

Steam and scalding liquids from

a hot cooling system can blow

out and burn you badly. They

are under pressure, and if you

turn the surge tank pressure

cap—even a little —they can

come out at high speed. Never

turn the cap when the cooling

system, including the surge tank

pressure cap, is hot. Wait for the

cooling system and surge tank

pressure cap to cool if you ever

have to turn the pressure cap.

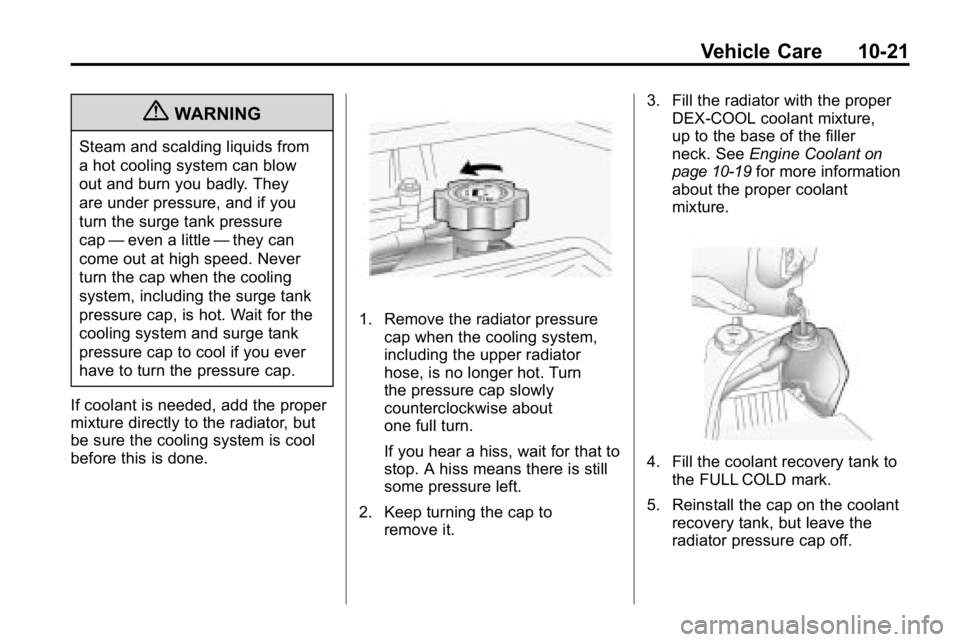

If coolant is needed, add the proper

mixture directly to the radiator, but

be sure the cooling system is cool

before this is done.

1. Remove the radiator pressure cap when the cooling system,

including the upper radiator

hose, is no longer hot. Turn

the pressure cap slowly

counterclockwise about

one full turn.

If you hear a hiss, wait for that to

stop. A hiss means there is still

some pressure left.

2. Keep turning the cap to remove it. 3. Fill the radiator with the proper

DEX‐COOL coolant mixture,

up to the base of the filler

neck. See Engine Coolant

on

page 10‑19for more information

about the proper coolant

mixture.

4. Fill the coolant recovery tank to

the FULL COLD mark.

5. Reinstall the cap on the coolant recovery tank, but leave the

radiator pressure cap off.

Page 300 of 410

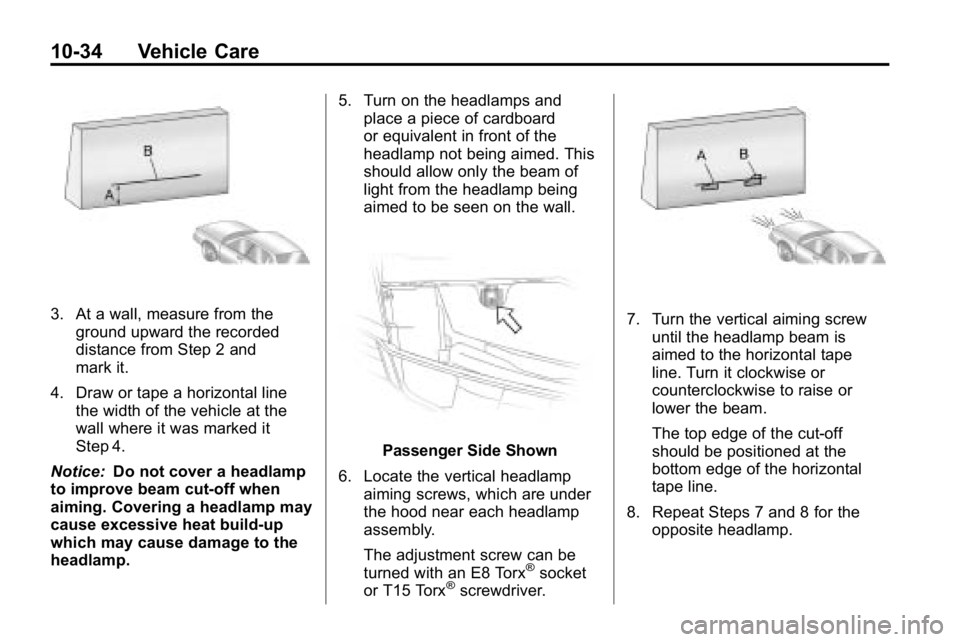

10-34 Vehicle Care

3. At a wall, measure from theground upward the recorded

distance from Step 2 and

mark it.

4. Draw or tape a horizontal line the width of the vehicle at the

wall where it was marked it

Step 4.

Notice: Do not cover a headlamp

to improve beam cut-off when

aiming. Covering a headlamp may

cause excessive heat build-up

which may cause damage to the

headlamp. 5. Turn on the headlamps and

place a piece of cardboard

or equivalent in front of the

headlamp not being aimed. This

should allow only the beam of

light from the headlamp being

aimed to be seen on the wall.

Passenger Side Shown

6. Locate the vertical headlamp aiming screws, which are under

the hood near each headlamp

assembly.

The adjustment screw can be

turned with an E8 Torx

®socket

or T15 Torx®screwdriver.

7. Turn the vertical aiming screw

until the headlamp beam is

aimed to the horizontal tape

line. Turn it clockwise or

counterclockwise to raise or

lower the beam.

The top edge of the cut-off

should be positioned at the

bottom edge of the horizontal

tape line.

8. Repeat Steps 7 and 8 for the opposite headlamp.

Page 301 of 410

Vehicle Care 10-35

Bulb Replacement

For the proper type of replacement

bulbs, seeReplacement Bulbson

page 10‑37.

For any bulb changing procedure

not listed in this section, contact

your dealer.

Halogen Bulbs

{WARNING

Halogen bulbs have pressurized

gas inside and can burst if you

drop or scratch the bulb. You or

others could be injured. Be sure

to read and follow the instructions

on the bulb package.

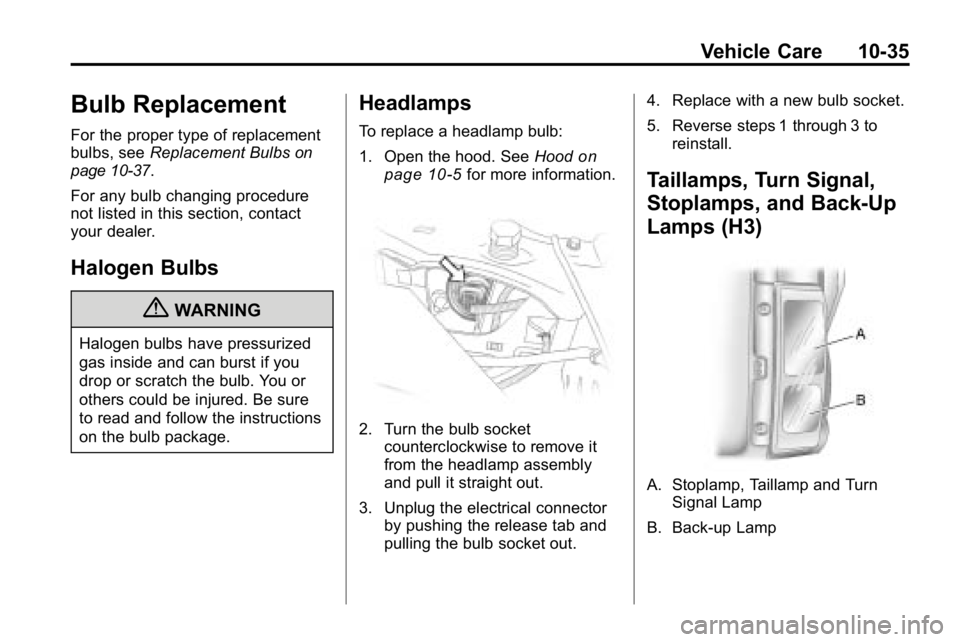

Headlamps

To replace a headlamp bulb:

1. Open the hood. See Hood

on

page 10‑5for more information.

2. Turn the bulb socket counterclockwise to remove it

from the headlamp assembly

and pull it straight out.

3. Unplug the electrical connector by pushing the release tab and

pulling the bulb socket out. 4. Replace with a new bulb socket.

5. Reverse steps 1 through 3 to

reinstall.

Taillamps, Turn Signal,

Stoplamps, and Back-Up

Lamps (H3)

A. Stoplamp, Taillamp and TurnSignal Lamp

B. Back-up Lamp

Page 302 of 410

10-36 Vehicle Care

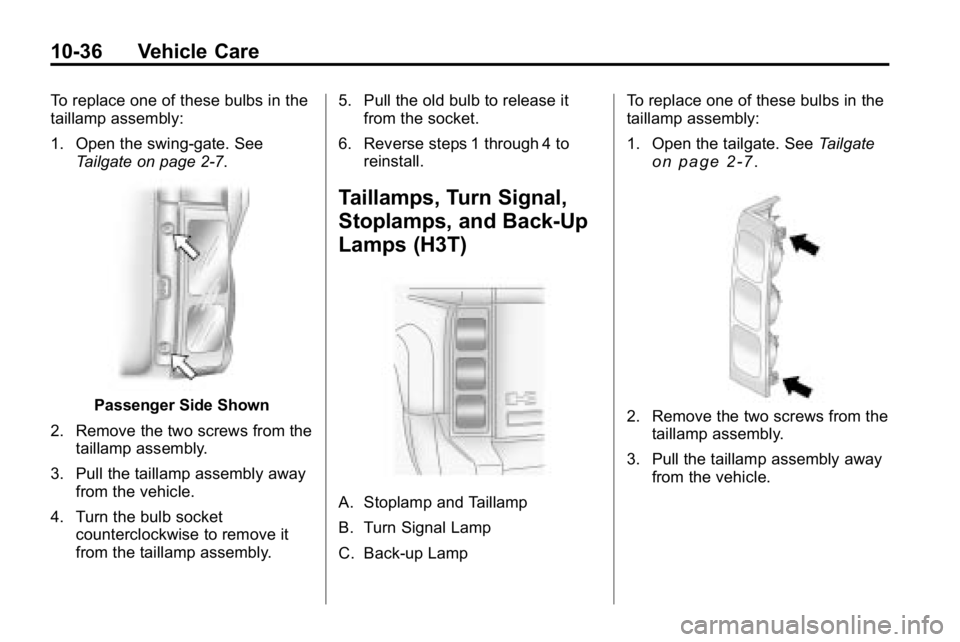

To replace one of these bulbs in the

taillamp assembly:

1. Open the swing-gate. SeeTailgate on page 2‑7.

Passenger Side Shown

2. Remove the two screws from the taillamp assembly.

3. Pull the taillamp assembly away from the vehicle.

4. Turn the bulb socket counterclockwise to remove it

from the taillamp assembly. 5. Pull the old bulb to release it

from the socket.

6. Reverse steps 1 through 4 to reinstall.

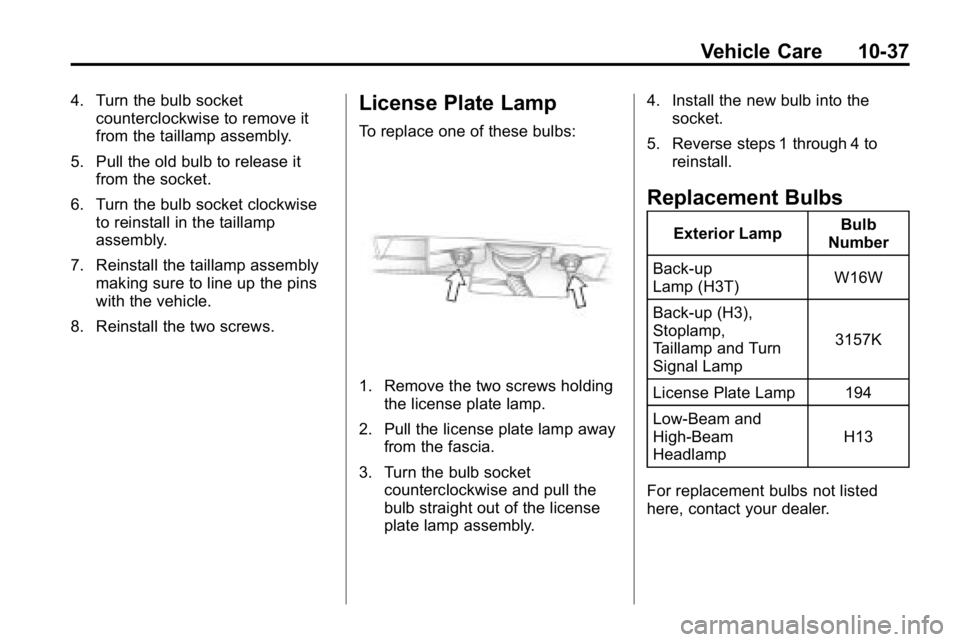

Taillamps, Turn Signal,

Stoplamps, and Back-Up

Lamps (H3T)

A. Stoplamp and Taillamp

B. Turn Signal Lamp

C. Back-up Lamp To replace one of these bulbs in the

taillamp assembly:

1. Open the tailgate. See

Tailgate

on page 2‑7.

2. Remove the two screws from the

taillamp assembly.

3. Pull the taillamp assembly away from the vehicle.

Page 303 of 410

Vehicle Care 10-37

4. Turn the bulb socketcounterclockwise to remove it

from the taillamp assembly.

5. Pull the old bulb to release it from the socket.

6. Turn the bulb socket clockwise to reinstall in the taillamp

assembly.

7. Reinstall the taillamp assembly making sure to line up the pins

with the vehicle.

8. Reinstall the two screws.License Plate Lamp

To replace one of these bulbs:

1. Remove the two screws holding the license plate lamp.

2. Pull the license plate lamp away from the fascia.

3. Turn the bulb socket counterclockwise and pull the

bulb straight out of the license

plate lamp assembly. 4. Install the new bulb into the

socket.

5. Reverse steps 1 through 4 to reinstall.

Replacement Bulbs

Exterior Lamp Bulb

Number

Back-up

Lamp (H3T) W16W

Back-up (H3),

Stoplamp,

Taillamp and Turn

Signal Lamp 3157K

License Plate Lamp 194

Low-Beam and

High-Beam

Headlamp H13

For replacement bulbs not listed

here, contact your dealer.

Page 332 of 410

10-66 Vehicle Care

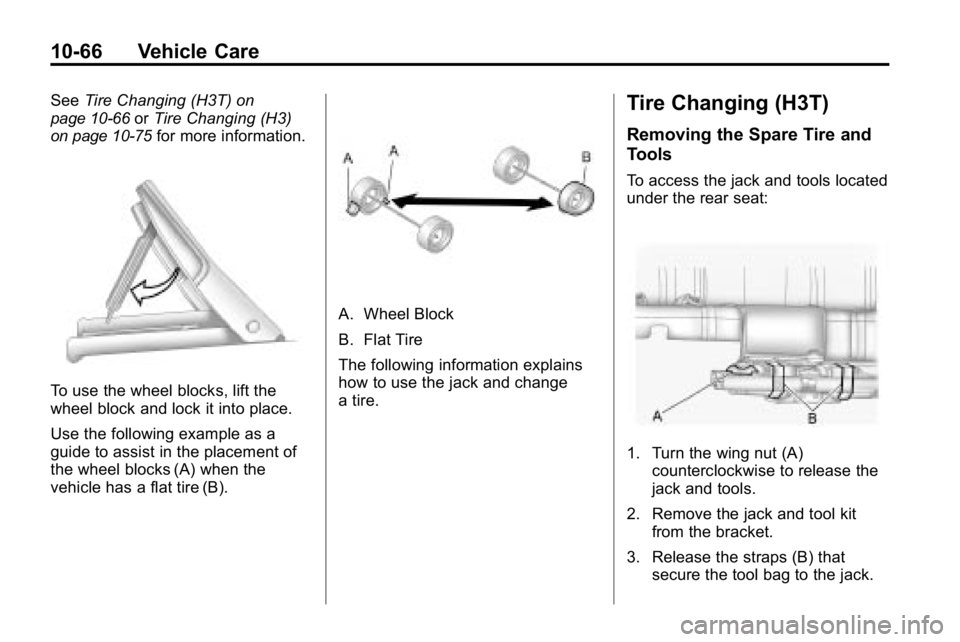

SeeTire Changing (H3T)on

page 10‑66or Tire Changing (H3)on page 10‑75for more information.

To use the wheel blocks, lift the

wheel block and lock it into place.

Use the following example as a

guide to assist in the placement of

the wheel blocks (A) when the

vehicle has a flat tire (B).

A. Wheel Block

B. Flat Tire

The following information explains

how to use the jack and change

a tire.

Tire Changing (H3T)

Removing the Spare Tire and

Tools

To access the jack and tools located

under the rear seat:

1. Turn the wing nut (A)

counterclockwise to release the

jack and tools.

2. Remove the jack and tool kit from the bracket.

3. Release the straps (B) that secure the tool bag to the jack.

Page 334 of 410

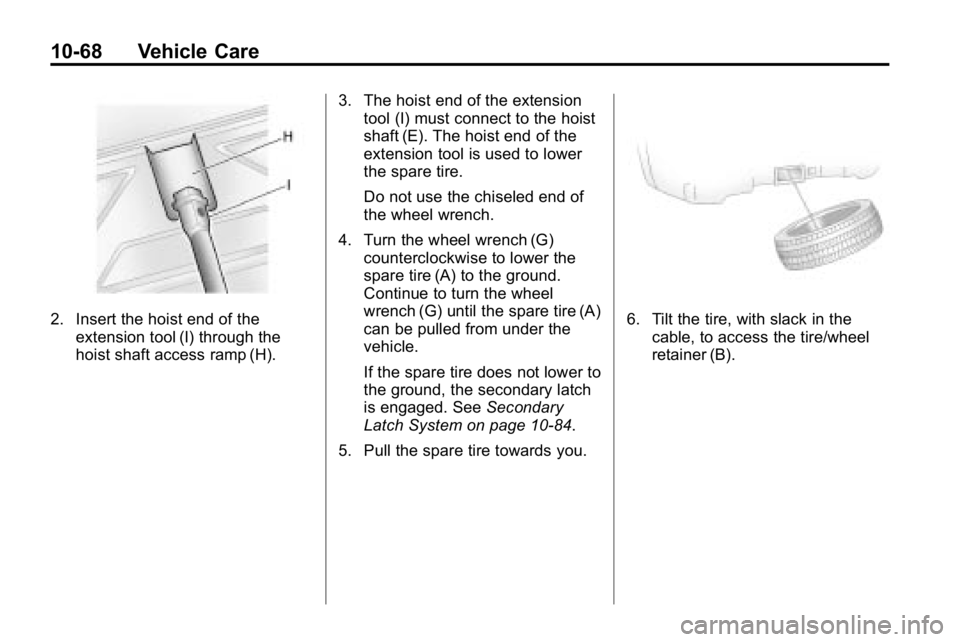

10-68 Vehicle Care

2. Insert the hoist end of theextension tool (I) through the

hoist shaft access ramp (H). 3. The hoist end of the extension

tool (I) must connect to the hoist

shaft (E). The hoist end of the

extension tool is used to lower

the spare tire.

Do not use the chiseled end of

the wheel wrench.

4. Turn the wheel wrench (G) counterclockwise to lower the

spare tire (A) to the ground.

Continue to turn the wheel

wrench (G) until the spare tire (A)

can be pulled from under the

vehicle.

If the spare tire does not lower to

the ground, the secondary latch

is engaged. See Secondary

Latch System on page 10‑84.

5. Pull the spare tire towards you.6. Tilt the tire, with slack in the cable, to access the tire/wheel

retainer (B).

Page 335 of 410

Vehicle Care 10-69

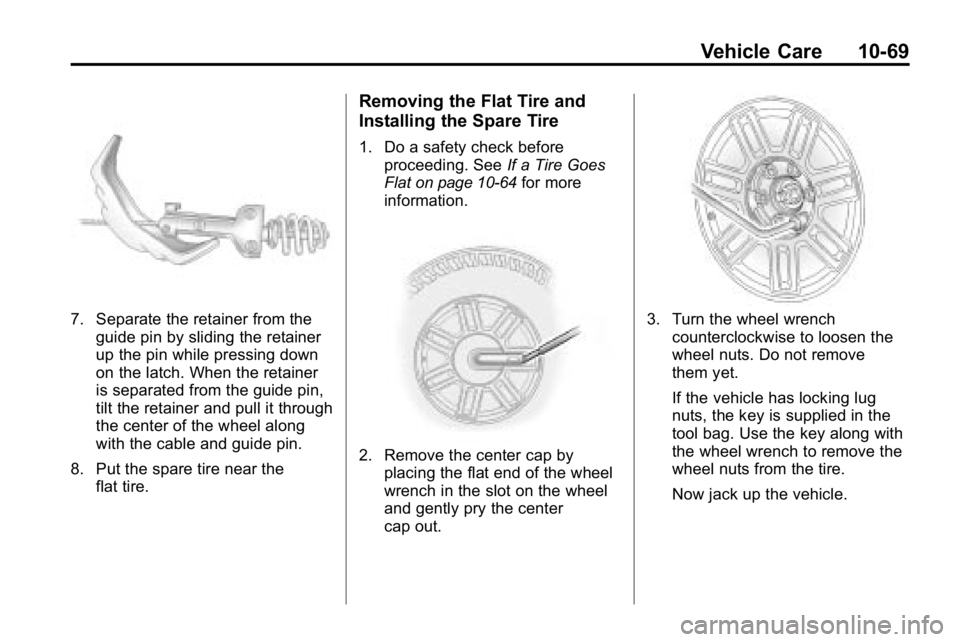

7. Separate the retainer from theguide pin by sliding the retainer

up the pin while pressing down

on the latch. When the retainer

is separated from the guide pin,

tilt the retainer and pull it through

the center of the wheel along

with the cable and guide pin.

8. Put the spare tire near the flat tire.

Removing the Flat Tire and

Installing the Spare Tire

1. Do a safety check before

proceeding. See If a Tire Goes

Flat

on page 10‑64for more

information.

2. Remove the center cap by placing the flat end of the wheel

wrench in the slot on the wheel

and gently pry the center

cap out.

3. Turn the wheel wrench

counterclockwise to loosen the

wheel nuts. Do not remove

them yet.

If the vehicle has locking lug

nuts, the key is supplied in the

tool bag. Use the key along with

the wheel wrench to remove the

wheel nuts from the tire.

Now jack up the vehicle.

Page 336 of 410

10-70 Vehicle Care

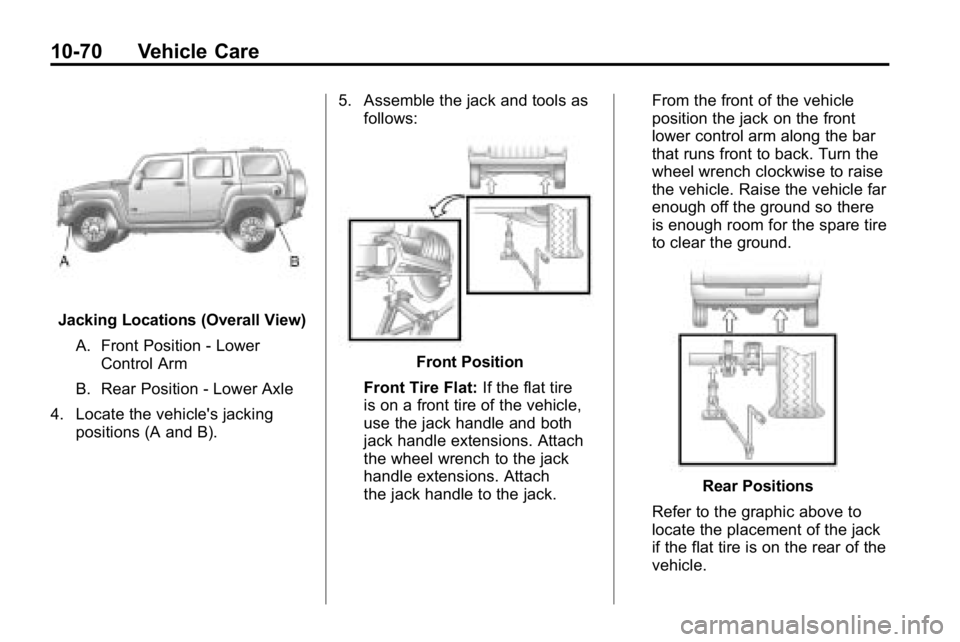

Jacking Locations (Overall View)A. Front Position - Lower Control Arm

B. Rear Position - Lower Axle

4. Locate the vehicle's jacking positions (A and B). 5. Assemble the jack and tools as

follows:

Front Position

Front Tire Flat: If the flat tire

is on a front tire of the vehicle,

use the jack handle and both

jack handle extensions. Attach

the wheel wrench to the jack

handle extensions. Attach

the jack handle to the jack. From the front of the vehicle

position the jack on the front

lower control arm along the bar

that runs front to back. Turn the

wheel wrench clockwise to raise

the vehicle. Raise the vehicle far

enough off the ground so there

is enough room for the spare tire

to clear the ground.

Rear Positions

Refer to the graphic above to

locate the placement of the jack

if the flat tire is on the rear of the

vehicle.