check engine Hyundai Accent 2006 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Accent, Model: Hyundai Accent 2006Pages: 599, PDF Size: 17.59 MB

Page 565 of 599

6

OWNER MAINTENANCE

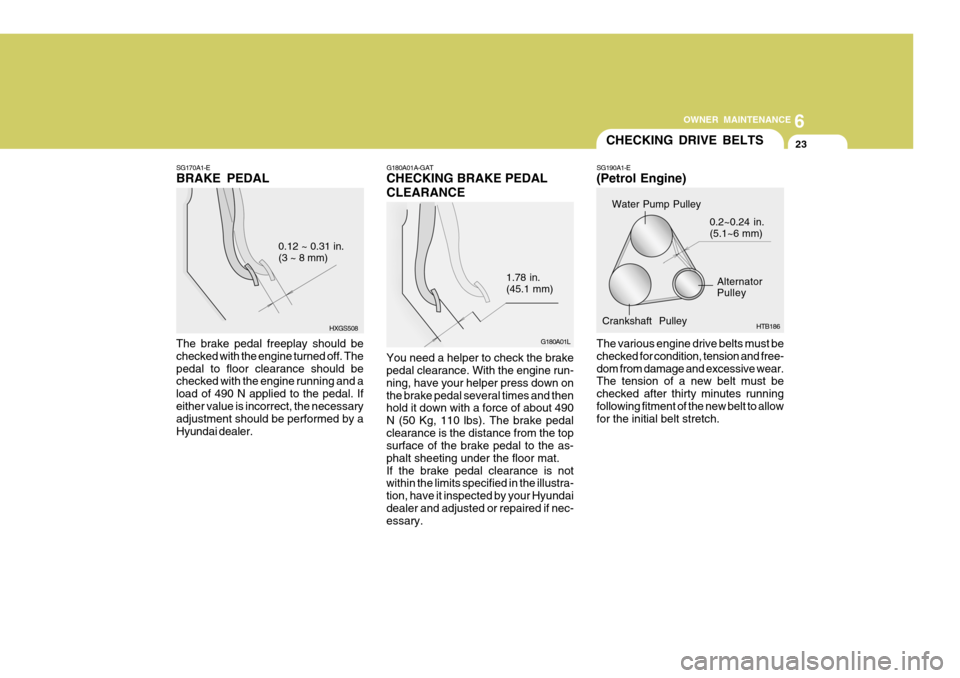

23CHECKING DRIVE BELTS

Water Pump Pulley

Alternator Pulley

Crankshaft Pulley

HTB186

G180A01L

HXGS508 G180A01A-GAT CHECKING BRAKE PEDAL CLEARANCE

You need a helper to check the brake pedal clearance. With the engine run- ning, have your helper press down onthe brake pedal several times and then hold it down with a force of about 490 N (50 Kg, 110 lbs). The brake pedalclearance is the distance from the top surface of the brake pedal to the as- phalt sheeting under the floor mat.If the brake pedal clearance is not within the limits specified in the illustra- tion, have it inspected by your Hyundaidealer and adjusted or repaired if nec- essary. 1.78 in. (45.1 mm)

SG170A1-E BRAKE PEDAL The brake pedal freeplay should be checked with the engine turned off. Thepedal to floor clearance should be checked with the engine running and a load of 490 N applied to the pedal. Ifeither value is incorrect, the necessary adjustment should be performed by a Hyundai dealer. 0.12 ~ 0.31 in. (3 ~ 8 mm)

The various engine drive belts must be checked for condition, tension and free-dom from damage and excessive wear. The tension of a new belt must be checked after thirty minutes runningfollowing fitment of the new belt to allow for the initial belt stretch.

SG190A1-E (Petrol Engine)

0.2~0.24 in. (5.1~6 mm)

Page 566 of 599

6OWNER MAINTENANCE

24

!

FUSIBLE LINKS

WARNING:

Under no circumstances should a fusible link be replaced with any- thing other than a new link of thesame rating. The use of higher rated links or other means of connecting the circuit will create a potential firehazard.

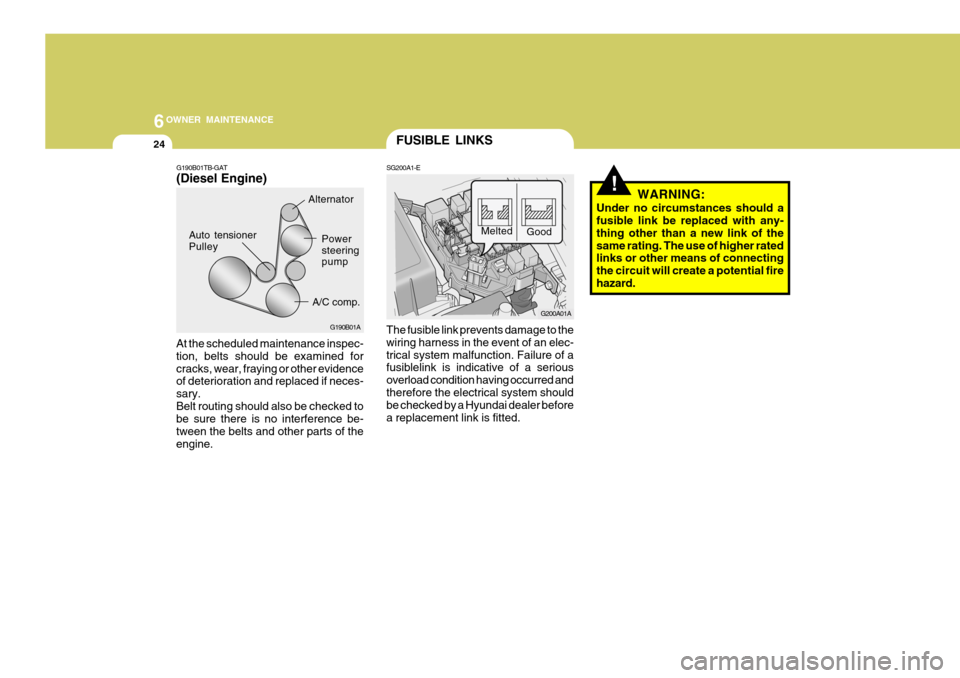

G190B01TB-GAT (Diesel Engine)

At the scheduled maintenance inspec- tion, belts should be examined forcracks, wear, fraying or other evidence of deterioration and replaced if neces- sary.Belt routing should also be checked to be sure there is no interference be- tween the belts and other parts of theengine. SG200A1-E The fusible link prevents damage to the wiring harness in the event of an elec-trical system malfunction. Failure of a fusiblelink is indicative of a serious overload condition having occurred andtherefore the electrical system should be checked by a Hyundai dealer before a replacement link is fitted.

A/C comp.

Auto tensioner Pulley

G190B01A

AlternatorPower steeringpump

G200A01A

Melted

Good

Page 569 of 599

6

OWNER MAINTENANCE

27REMOVAL OF WATER FROM THE FUEL FILTERPOWER STEERING FLUID LEVEL

G300A02B-GAT (DIESEL ENGINE)

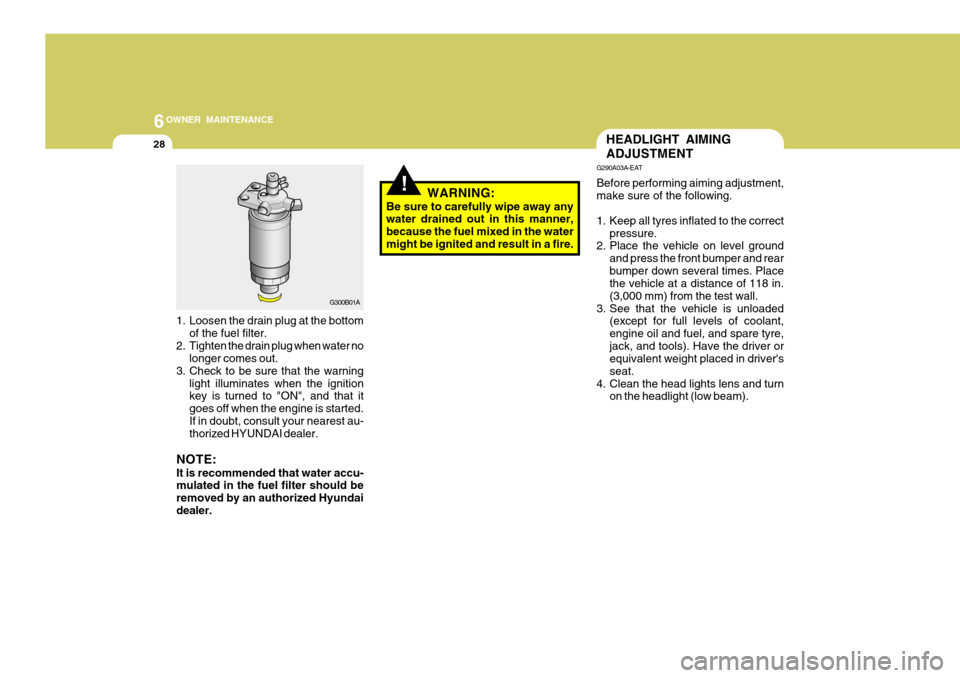

If the fuel filter warning light illuminates during driving, it indicates that waterhas accumulated in the fuel filter. If this occurs, remove the water as described below.

SG230B1-E POWER STEERING HOSES Power steering hoses should be checked for damage, deterioration andleakage at each service.

NOTE: Grinding noise from power steering pump may be heard immediately after the engine is started in extremelycold condition (below -4°F). If the noise stops during warm up, there is no abnormal function in the system.This is due to a power steering fluid characteristic in extremely cold con- ditions. FLUID RECOMMENDATION Only automatic transmission fluid meet- ing the specification of PSF-3 or Dexron 2 should be used in the power steering system.

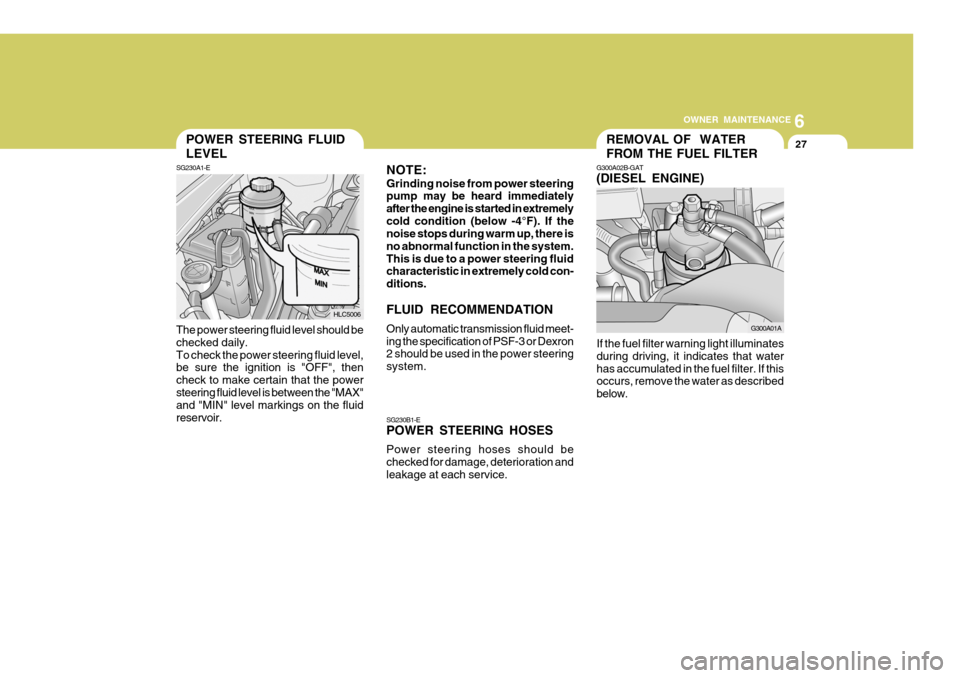

SG230A1-E The power steering fluid level should be checked daily.To check the power steering fluid level, be sure the ignition is "OFF", then check to make certain that the powersteering fluid level is between the "MAX" and "MIN" level markings on the fluid reservoir.

HLC5006

G300A01A

Page 570 of 599

6OWNER MAINTENANCE

28HEADLIGHT AIMING ADJUSTMENT

!

1. Loosen the drain plug at the bottom

of the fuel filter.

2. Tighten the drain plug when water no longer comes out.

3. Check to be sure that the warning light illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started.If in doubt, consult your nearest au- thorized HYUNDAI dealer.

NOTE: It is recommended that water accu- mulated in the fuel filter should be removed by an authorized Hyundaidealer. WARNING:

Be sure to carefully wipe away any water drained out in this manner, because the fuel mixed in the watermight be ignited and result in a fire. G290A03A-EAT Before performing aiming adjustment, make sure of the following.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground

and press the front bumper and rear bumper down several times. Place the vehicle at a distance of 118 in. (3,000 mm) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant,engine oil and fuel, and spare tyre,jack, and tools). Have the driver or equivalent weight placed in driver's seat.

4. Clean the head lights lens and turn on the headlight (low beam).

G300B01A

Page 571 of 599

6

OWNER MAINTENANCE

29

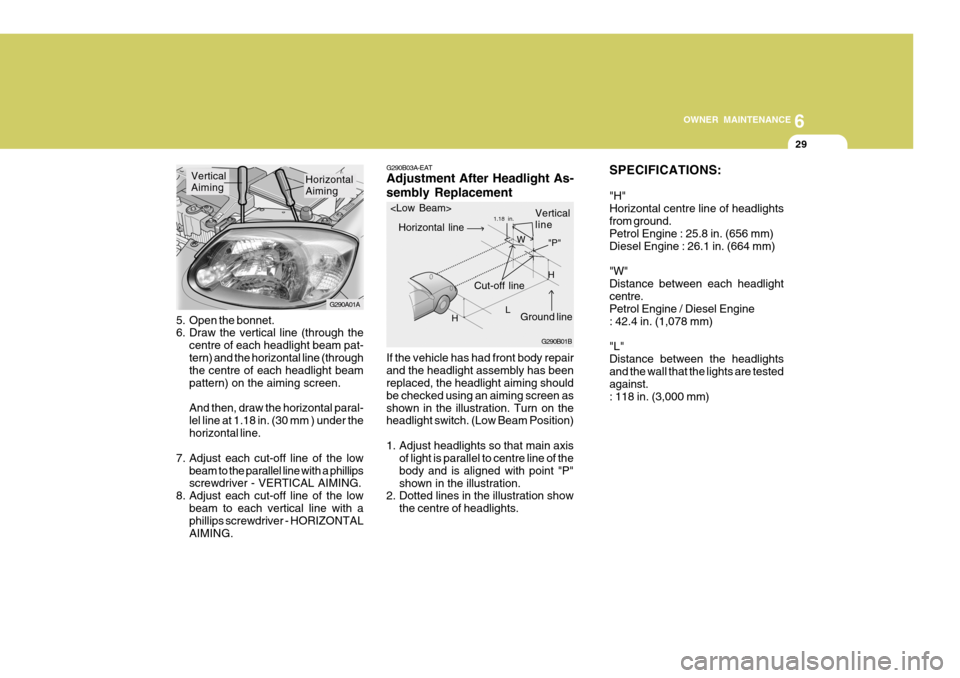

5. Open the bonnet.

6. Draw the vertical line (through the

centre of each headlight beam pat- tern) and the horizontal line (through the centre of each headlight beam pattern) on the aiming screen. And then, draw the horizontal paral- lel line at 1.18 in. (30 mm ) under thehorizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to each vertical line with aphillips screwdriver - HORIZONTAL AIMING.

G290A01A

Horizontal Aiming

Vertical Aiming

SPECIFICATIONS: "H" Horizontal centre line of headlightsfrom ground. Petrol Engine : 25.8 in. (656 mm) Diesel Engine : 26.1 in. (664 mm) "W" Distance between each headlightcentre. Petrol Engine / Diesel Engine : 42.4 in. (1,078 mm) "L" Distance between the headlightsand the wall that the lights are tested against. : 118 in. (3,000 mm)

If the vehicle has had front body repairand the headlight assembly has been replaced, the headlight aiming should be checked using an aiming screen asshown in the illustration. Turn on the headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis

of light is parallel to centre line of the body and is aligned with point "P"shown in the illustration.

2. Dotted lines in the illustration show

the centre of headlights.

G290B03A-EAT Adjustment After Headlight As- sembly Replacement

G290B01B

LW

Cut-off line Ground line

"P"

Horizontal line

Vertical line1.18 in.

H H

Page 579 of 599

6

OWNER MAINTENANCE

37FUSE PANEL DESCRIPTION

G200C02A-EAT Engine Compartment (Petrol Engine)

HLC5027

NOTE: Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label. FUSE RATING

120A50A 50A20A30A20A 30A 30A30A30A20A 10A 10A 10A 10A10A 10A10A15A 10A15A 15A 10A 25A PROTECTED COMPONENTS

Charging (Generator) Fuse 6, 7, 8, 9, Horn fuse, Room lamp fuse

Head lamp fuse, Front fog lamp fuse, Tail lamp relay, H/LP washer fuse

Engine control relay, Generator, Fuel pump relay, ECU #3 fuse Ignition power source, Start relayRadiator fan control Blower control ABS control, ABS bleeding connectorABS control, ABS bleeding connector Power window Condenser fan controlRadiator fan, Condenser fan, ECM, Oxygen sensor, Purge control valve,

SMATRA, Glow plug relay, Heater relay, Stop lamp switch A/C relayHorn relay Illumination lamps, Left rear combination lamp, License lamp, DRL control, Position lamp, H/LP washer relayRight rear combination lamp, License lamp, Position lamp Left head lamp, DRL control, Instrument cluster Right head lampFront fog lamp relay

Instrument cluster, Courtesy lamp, Trunk room lamp, ETACM, DLC, Door warning, Multipurpose check connectorAudio, Digital clock, Power antenna, A/C switch, Rear fog lamp switch Idle speed actuator, ECM, Camshaft position sensor, EGR actuator, Throttle plate actuatorECM Head lamp washer motor

Fuel pump relay, Fuel pump motor

ALT

BATTERY LAMPECU

IGN

RAD FAN

BLOWER

ABS ABS

P/WDW

COND FAN

ECU #1

A/CON COMP HORN

TAIL LH

TAIL RH

H/LP LH

H/LP RH

FRONT FOG

ROOM LP AUDIO

ECU #2 ECU#3

H/L WASHER

FUSIBLE

LINK

FUSE

DESCRIPTION

F/PUMP CHK (E50)

Page 580 of 599

6OWNER MAINTENANCE

38

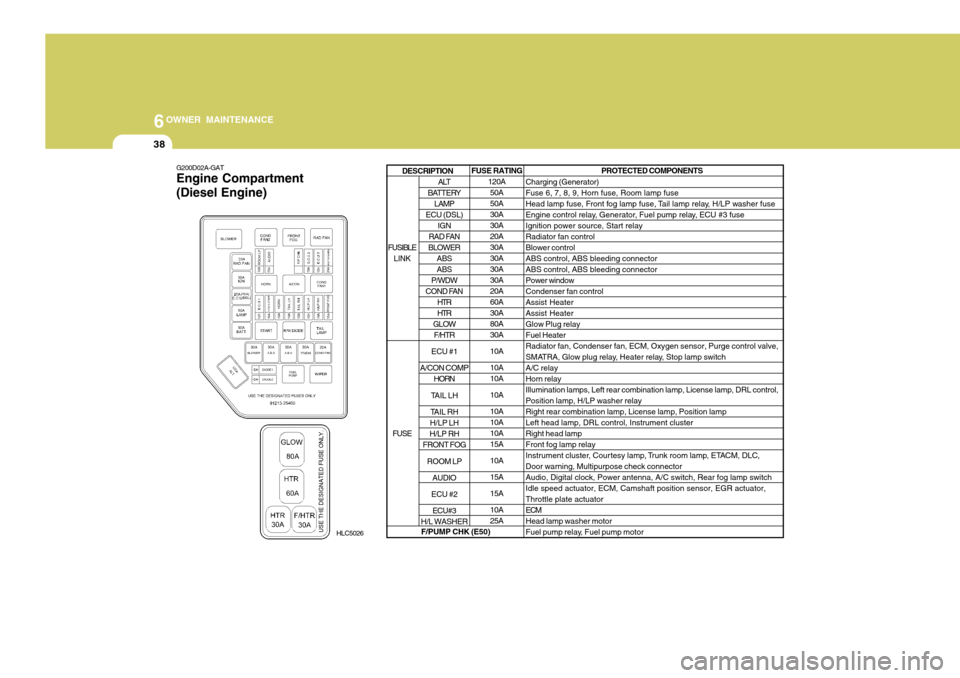

PROTECTED COMPONENTS

Charging (Generator) Fuse 6, 7, 8, 9, Horn fuse, Room lamp fuse

Head lamp fuse, Front fog lamp fuse, Tail lamp relay, H/LP washer fuse

Engine control relay, Generator, Fuel pump relay, ECU #3 fuseIgnition power source, Start relayRadiator fan controlBlower controlABS control, ABS bleeding connectorABS control, ABS bleeding connectorPower windowCondenser fan controlAssist HeaterAssist HeaterGlow Plug relayFuel HeaterRadiator fan, Condenser fan, ECM, Oxygen sensor, Purge control valve,

SMATRA, Glow plug relay, Heater relay, Stop lamp switchA/C relayHorn relayIllumination lamps, Left rear combination lamp, License lamp, DRL control,Position lamp, H/LP washer relayRight rear combination lamp, License lamp, Position lampLeft head lamp, DRL control, Instrument clusterRight head lampFront fog lamp relay

Instrument cluster, Cour tesy lamp, Trunk room lamp, ETACM, DLC,Door warning, Multipurpose check connectorAudio, Digital clock, Power antenna, A/C switch, Rear fog lamp switchIdle speed actuator, ECM, Camshaft position sensor, EGR actuator,Throttle plate actuatorECMHead lamp washer motor

Fuel pump relay, Fuel pump motor

HLC5026 FUSE RATING

120A

50A50A30A30A20A30A30A30A30A20A60A30A80A30A 10A10A 10A 10A10A 10A10A15A 10A15A15A10A 25A

ALT

BATTERY

LAMP

ECU (DSL)

IGN

RAD FAN

BLOWER ABS ABS

P/WDW

COND FAN HTRHTR

GLOW F/HTR

ECU #1

A/CON COMP HORN

TAIL LH

TAIL RH

H/LP LH

H/LP RH

FRONT FOG

ROOM LP

AUDIO

ECU #2 ECU#3

H/L WASHER

FUSIBLE

LINK

FUSEDESCRIPTION

F/PUMP CHK (E50)G200D02A-GAT Engine Compartment (Diesel Engine)