cooling Hyundai Accent 2015 - RHD (UK. Australia) User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2015, Model line: Accent, Model: Hyundai Accent 2015Pages: 425, PDF Size: 8.62 MB

Page 317 of 425

67

What to do in an emergency

IF THE ENGINE OVERHEATS

If your temperature gauge indicates over-

heating, you experience a loss of power

or knocking, the engine is probably too

hot. If this happens, you should:

1. Pull off the road and stop as soon as it

is safe to do so.

2. Place the shift lever in P (automatic

transaxle / Continuously Variable

Transaxle / Dual clutch transmission)

or neutral (manual transaxle) and set

the parking brake. If the air condition-

ing is on, turn it off.

3. If engine coolant is running out under

the car or steam is coming out from

the bonnet, stop the engine. Do not

open the bonnet until the coolant has

stopped running or the steaming has

stopped. If there is no visible loss of

engine coolant and no steam, leave

the engine running and check to be

sure the engine cooling fan is operat-

ing. If the fan is not running, turn the

engine off.4. With the engine turned off, check to

see if the water pump drive belt is

missing. If it is not missing, check to

see that it is tight. If the drive belt

seems to be satisfactory, check for

coolant leaking from the radiator,

hoses or under the car. (If the air con-

ditioning had been in use, it is normal

for cold water to be draining from it

when you stop.)

5. If the water pump drive belt is broken

or engine coolant is leaking out, stop

the engine immediately and call the

nearest authorised HYUNDAI dealer

for assistance.6. If you cannot find the cause of the

overheating, wait until the engine tem-

perature has returned to normal. Then,

if coolant has been lost, carefully add

coolant to the reservoir to bring the

fluid level in the reservoir up to the

halfway mark.

7. Proceed with caution, keeping alert for

further signs of overheating. If over-

heating happens again, call an autho-

rised HYUNDAI dealer for assistance.

WARNING

Whilst the engine is running, keep

hair, hands and clothing away from

moving parts such as the fan and

drive belts to prevent injury.

WARNING

Do not remove the radiator cap

when the engine is hot. This can

allow coolant to be blown out of the

opening and cause serious burns.

CAUTION

• Serious loss of coolant indicates

there is a leak in the cooling sys-

tem and this should be checked

as soon as possible by an autho-

rised HYUNDAI dealer.

• When the engine overheats from

low engine coolant, suddenly

adding engine coolant may cause

cracks in the engine. To prevent

damage, add engine coolant

slowly in small quantities.

Page 333 of 425

75

Maintenance

Engine compartment precautions

(Diesel engine)

• Follow the safety tips provided below,

when you are checking the engine bay

whilst the engine is running.

- Do not touch the injector, injector

wirings, and the engine computer

whilst the engine is running.

- Do not remove the injector connector

whilst the engine is running.

- People using pacemakers must not

go near the engine whilst the engine

is starting or running.

WARNING- Maintenance

work

• Performing maintenance work on

a vehicle can be dangerous. You

can be seriously injured whilst

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, have it done by an

authorised HYUNDAI dealer.

• Working under the bonnet with

the engine running is dangerous.

It becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine whilst work-

ing under the bonnet, make cer-

tain that you remove all jewelry

(especially rings, bracelets,

watches, and necklaces) and all

neckties, scarves, and similar

loose clothing before getting

near the engine or cooling fans.

WARNING- Diesel Engine

Never work on injection system

with engine running or within 30

seconds after shutting off engine.

High-pressure pump, rail, injectors

and high-pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touches the body.

People using pacemakers should

not move within 30cm of the ECU or

wiring harness within the engine

room whilst engine is running, high

currents used in the electronic

engine control system produce

considerable magnetic fields.

CAUTION

• Do not put heavy objects or apply

excessive force on top of the

engine cover (if equipped) or fuel

related parts.

• When you inspect the fuel system

(fuel lines and fuel injection

devices), we recommend that you

contact an authorised HYUNDAI

dealer.

• Do not drive long time with the

engine cover (if equipped)

removed.

• When checking the engine room,

do not go near fire. Fuel, washer

fluid, etc. are flammable oils that

may cause fire.

• Before touching the battery, igni-

tion cables and electrical wiring,

you should disconnect the bat-

tery "-" terminal. You may get an

electric shock from the electric

current.

• When you remove the interior

trim cover with a flat head (-) driv-

er, be careful not to damage the

cover.

• Be careful when you replace and

clean bulbs to avoid burns or

electrical shock.

Page 340 of 425

Maintenance

12 7

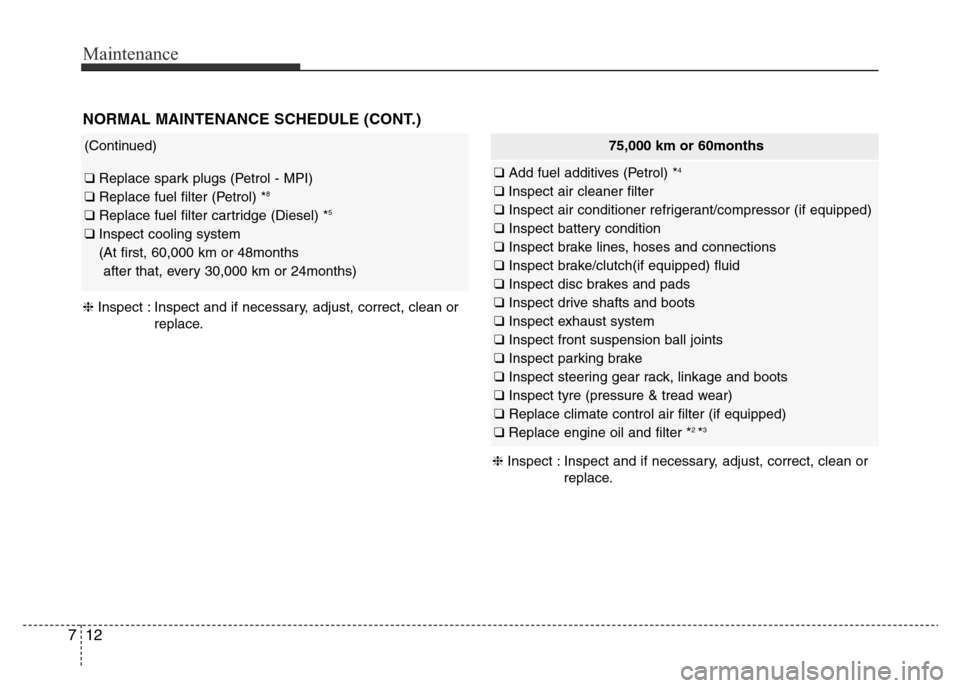

NORMAL MAINTENANCE SCHEDULE (CONT.)

(Continued)

❑ Replace spark plugs (Petrol - MPI)

❑ Replace fuel filter (Petrol) *8

❑ Replace fuel filter cartridge (Diesel) *5

❑ Inspect cooling system

(At first, 60,000 km or 48months

after that, every 30,000 km or 24months)

75,000 km or 60months

❑ Add fuel additives (Petrol) *4

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter *

2 *3

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 341 of 425

713

Maintenance

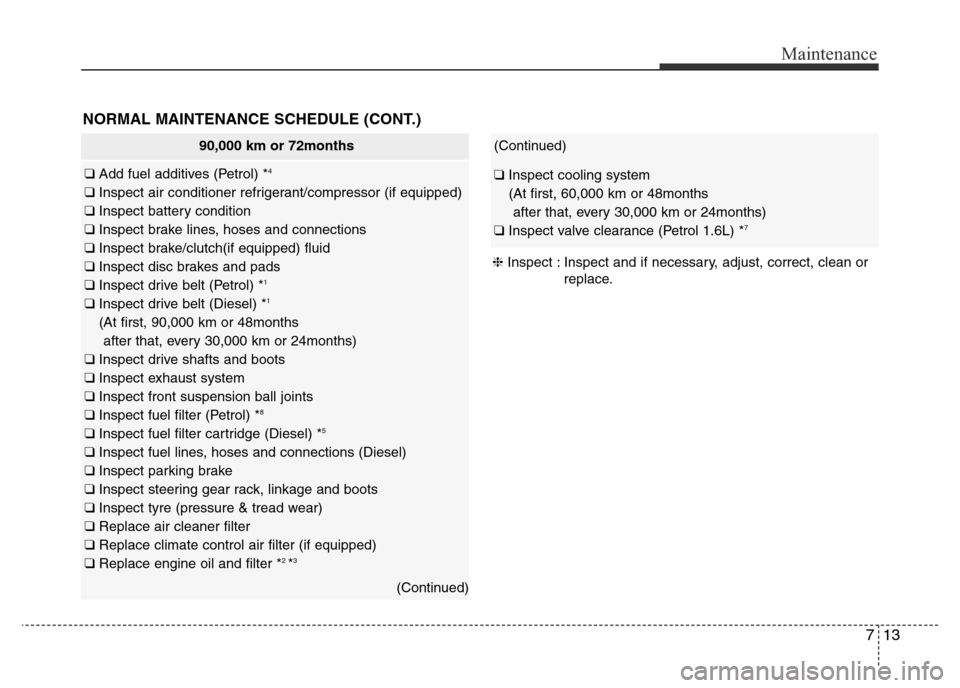

NORMAL MAINTENANCE SCHEDULE (CONT.)

90,000 km or 72months

❑ Add fuel additives (Petrol) *4

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) *

1

❑ Inspect drive belt (Diesel) *1

(At first, 90,000 km or 48months

after that, every 30,000 km or 24months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter (Petrol) *

8

❑ Inspect fuel filter cartridge (Diesel) *5

❑ Inspect fuel lines, hoses and connections (Diesel)

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace air cleaner filter

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter *

2 *3

(Continued)

(Continued)

❑ Inspect cooling system

(At first, 60,000 km or 48months

after that, every 30,000 km or 24months)

❑ Inspect valve clearance (Petrol 1.6L) *

7

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 343 of 425

715

Maintenance

NORMAL MAINTENANCE SCHEDULE (CONT.)

(Continued)

❑ Inspect vapour hose and fuel filler cap (Petrol)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter *

2 *3

❑ Replace fuel filter (Petrol) *8

❑ Replace fuel filter cartridge (Diesel) *5

❑ Replace spark plugs (Petrol - MPI)

❑ Replace spark plugs (Petrol - GDI)

(Every 150,000 km or 120 months)

❑ Replace coolant *

9

(At first, 210,000 km or 120months

after that, every 30,000 km or 24months *6)

❑ Inspect cooling system

(At first, 60,000 km or 48months

after that, every 30,000 km or 24months)

No check, No service required

❑Automatic transaxle fluid (6 A/T) (if equipped)

❑Continuously Variable Transaxle fluid (if equipped)

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 347 of 425

719

Maintenance

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuel

filler cap is correctly replaced.

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Air cleaner filter

A Genuine HYUNDAI air cleaner filter is

recommended when the filter is

replaced.

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range.

Valve clearance (Petrol 1.6L)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorised HYUNDAI dealer should

perform the operation.

Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

WARNING

Do not disconnect and inspect

spark plugs when the engine is hot.

You may burn yourself.

Page 352 of 425

Maintenance

24 7

ENGINE COOLANT

The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at the

beginning of the winter season, and

before travelling to a colder climate.Checking the coolant level

WARNING

Removing radiator

cap

• Never attempt to remove the radi-

ator cap whilst the engine is

operating or hot. Doing so might

lead to cooling system and

engine damage and could result

in serious personal injury from

escaping hot coolant or steam.

• Turn the engine off and wait until

it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back whilst

the pressure is released from the

cooling system. When you are

sure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

(Continued)

WARNING

The electric motor (cool-

ing fan) is controlled by

engine coolant tempera-

ture, refrigerant pres-

sure and vehicle speed.

It may sometimes operate even

when the engine is not running.

Use extreme caution when working

near the blades of the cooling fan

so that you are not injured by rotat-

ing fan blades. As the engine

coolant temperature decreases, the

electric motor will automatically

shut off. This is a normal condition.

If your vehicle is equipped with

GDI, the electric motor (cooling fan)

may operate until you disconnect

the negative battery cable.

(Continued)

• Even if the engine is not operat-

ing, do not remove the radiator

cap or the drain plug whilst the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

CAUTION

• Do not drive with no engine

coolant. It may cause water pump

failure and engine seizure, etc.

• When the engine overheats from

low engine coolant, suddenly

adding engine coolant may cause

cracks in the engine. To prevent

damage, add engine coolant

slowly in small quantities.

Page 353 of 425

725

Maintenance

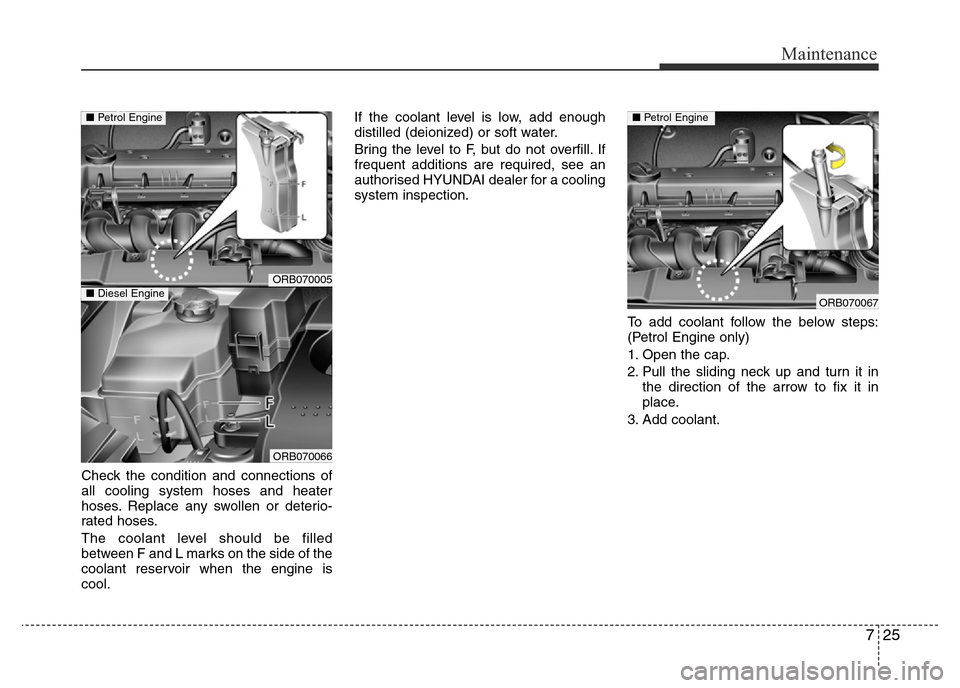

Check the condition and connections of

all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F and L marks on the side of the

coolant reservoir when the engine is

cool.If the coolant level is low, add enough

distilled (deionized) or soft water.

Bring the level to F, but do not overfill. If

frequent additions are required, see an

authorised HYUNDAI dealer for a cooling

system inspection.

To add coolant follow the below steps:

(Petrol Engine only)

1. Open the cap.

2. Pull the sliding neck up and turn it in

the direction of the arrow to fix it in

place.

3. Add coolant.

ORB070067

■ Petrol Engine

ORB070005

ORB070066

■ Petrol Engine

■ Diesel Engine

Page 392 of 425

Maintenance

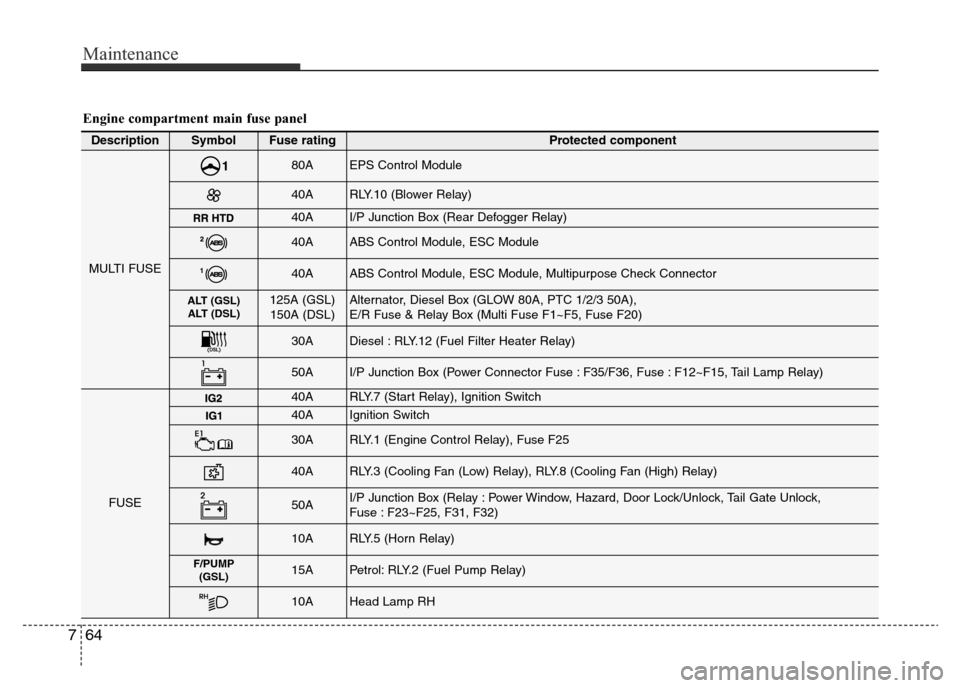

64 7

DescriptionSymbolFuse ratingProtected component

MULTI FUSE

80AEPS Control Module

40ARLY.10 (Blower Relay)

40AI/P Junction Box (Rear Defogger Relay)

40AABS Control Module, ESC Module

40AABS Control Module, ESC Module, Multipurpose Check Connector

ALT (GSL)

ALT (DSL)125A (GSL)

150A (DSL)Alternator, Diesel Box (GLOW 80A, PTC 1/2/3 50A),

E/R Fuse & Relay Box (Multi Fuse F1~F5, Fuse F20)

30ADiesel : RLY.12 (Fuel Filter Heater Relay)

50AI/P Junction Box (Power Connector Fuse : F35/F36, Fuse : F12~F15, Tail Lamp Relay)

FUSE

40ARLY.7 (Start Relay), Ignition Switch

40AIgnition Switch

30ARLY.1 (Engine Control Relay), Fuse F25

40ARLY.3 (Cooling Fan (Low) Relay), RLY.8 (Cooling Fan (High) Relay)

50AI/P Junction Box (Relay : Power Window, Hazard, Door Lock/Unlock, Tail Gate Unlock,

Fuse : F23~F25, F31, F32)

10ARLY.5 (Horn Relay)

F/PUMP

(GSL)15APetrol: RLY.2 (Fuel Pump Relay)

10AHead Lamp RH

Engine compartment main fuse panel

Page 393 of 425

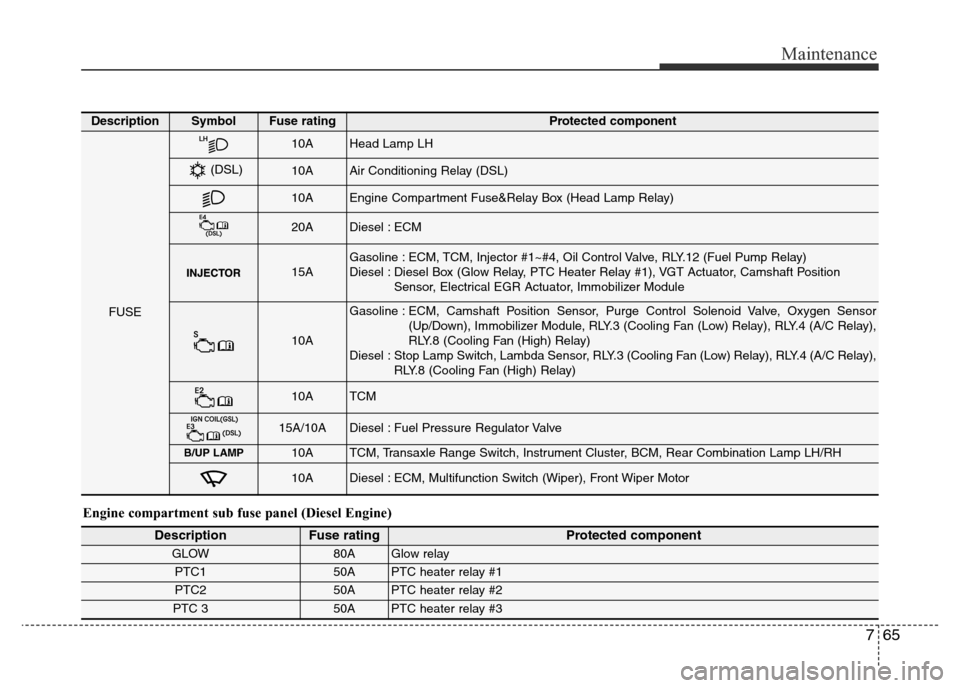

765

Maintenance

Engine compartment sub fuse panel (Diesel Engine)

DescriptionFuse ratingProtected component

GLOW80A Glow relay

PTC150A PTC heater relay #1

PTC250A PTC heater relay #2

PTC 350A PTC heater relay #3

DescriptionSymbolFuse ratingProtected component

FUSE

10AHead Lamp LH

10AAir Conditioning Relay (DSL)

10AEngine Compartment Fuse&Relay Box (Head Lamp Relay)

20ADiesel : ECM

15AGasoline : ECM, TCM, Injector #1~#4, Oil Control Valve, RLY.12 (Fuel Pump Relay)

Diesel : Diesel Box (Glow Relay, PTC Heater Relay #1), VGT Actuator, Camshaft Position

Sensor, Electrical EGR Actuator, Immobilizer Module

10A

Gasoline : ECM, Camshaft Position Sensor, Purge Control Solenoid Valve, Oxygen Sensor

(Up/Down), Immobilizer Module, RLY.3 (Cooling Fan (Low) Relay), RLY.4 (A/C Relay),

RLY.8 (Cooling Fan (High) Relay)

Diesel : Stop Lamp Switch, Lambda Sensor, RLY.3 (Cooling Fan (Low) Relay), RLY.4 (A/C Relay),

RLY.8 (Cooling Fan (High) Relay)

10ATCM

15A/10ADiesel : Fuel Pressure Regulator Valve

B/UP LAMP10ATCM, Transaxle Range Switch, Instrument Cluster, BCM, Rear Combination Lamp LH/RH

10ADiesel : ECM, Multifunction Switch (Wiper), Front Wiper Motor

(DSL)