sensor Hyundai Accent 2016 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: Accent, Model: Hyundai Accent 2016Pages: 456, PDF Size: 16.41 MB

Page 338 of 456

615

What to do in an emergency

Changing a tire with TPMS

If you have a flat tire, the Low Tire

Pressure and Position telltales will

come on. Have the flat tire repaired

by an authorized HYUNDAI dealer

as soon as possible or replace the

flat tire with the spare tire (if

equipped).

The spare tire (if equipped) does not

come with a tire pressure monitoring

sensor. When the low pressure tire or

the flat tire is replaced with the spare

tire, the Low Tire Pressure Telltale

will remain on.Also, the TPMS Malfunction Indicator

will illuminate after blinking for one

minute if the vehicle is driven at

speed above 15.5 mph (25 km/h) for

approximately 20 minutes.

Once the original tire equipped with

a tire pressure monitoring sensor is

reinflated to the recommended pres-

sure and reinstalled on the vehicle,

the Low Tire Pressure Telltale and

TPMS Malfunction Indicator will go

off within a few minutes.

If the indicators do not extinguish

after a few minutes, please visit an

authorized HYUNDAI dealer.

Each wheel is equipped with a tire

pressure sensor mounted inside the

tire behind the valve stem (except for

the spare tire). You must use TPMS

specific wheels. It is recommended

that you always have your tires serv-

iced by an authorized HYUNDAI

dealer as soon as possible.CAUTION

The TPMS malfunction indica-

tor may blink for approximate-ly 1 minute and then remaincontinuously illuminated if thevehicle is moving around elec-tric power supply cables orradio transmitter such as atpolice stations, governmentand public offices, broadcast-ing stations, military installa-tions, airports, or transmittingtowers, etc. This can interferewith normal operation of theTire Pressure MonitoringSystem (TPMS).

The TPMS malfunction indica- tor may blink for approximate-ly 1 minute and then remaincontinuously illuminated if thesnow chains are used or someseparate electronic devicessuch as notebook computer,mobile charger, remote starteror navigation etc., are used inthe vehicle. This can interferewith normal operation of theTire Pressure MonitoringSystem (TPMS).

CAUTION

Never use a puncture-repairingagent not approved by HYUNDAIto repair and/or inflate a lowpressure tire. The tire sealant notapproved by HYUNDAI may dam-age the tire pressure sensor.

The sealant on the tire pressuresensor and wheel shall be elim-inated when you replace the tirewith a new one.

Page 339 of 456

What to do in an emergency

16

6

You may not be able to identify a tire

with low pressure by simply looking

at it. Always use a good quality tire

pressure gauge to measure. Please

note that a tire that is hot (from being

driven) will have a higher pressure

measurement than a tire that is cold.

A cold tire means the vehicle has

been sitting for 3 hours and driven for

less than 1 mile (1.6 km) in that 3 hour

period.

Allow the tire to cool before measur-

ing the inflation pressure. Always be

sure the tire is cold before inflating to

the recommended pressure. This device complies with Part 15

of the FCC rules.

Operation is subject to the following

two conditions:

1. This device may not cause harm-

ful interference, and

2. This device must accept any inter- ference received, including inter-

ference that may cause undesired

operation.

WARNING- ProtectingTPMS

Tampering with, modifying, or

disabling the Tire Pressure

Monitoring System (TPMS) com-

ponents may interfere with the

system's ability to warn the driv-

er of low tire pressure condi-

tions and/or TPMS malfunctions.

Tampering with, modifying, or

disabling the Tire Pressure

Monitoring System (TPMS) com-

ponents may void the warranty

for that portion of the vehicle.

WARNING- TPMS

The TPMS cannot alert you to severe and sudden tire dam-

age caused by external factors

such as nails or road debris.

If you feel any vehicle instabil- ity, immediately take your foot

off the accelerator, apply the

brakes gradually with light

force, and slowly move to a

safe position off the road.

WARNING

Changes or modifications not

expressly approved by the party

responsible for compliance could

void the user’s authority to operate

the equipment.

CAUTION

Do not use any tire sealantexcept the Tire Mobility Kitapproved by HYUNDAI if yourvehicle is equipped with a TirePressure Monitoring System.The liquid sealant can damagethe tire pressure sensors.

Page 353 of 456

What to do in an emergency

30

6

9. Switch off the compressor.

10. Detach the hoses from the

sealant bottle connector and

from the tire valve.

Return the Tire Mobility Kit to its stor-

age location in the vehicle. Distributing the sealant

Immediately drive approximately

4~6miles (7~10km or, about 10min)

to evenly distribute the sealant in the

tire.

Do not exceed a speed of 50 mph

(80 km/h). If possible, do not fall

below a speed of 12 mph (20 km/h).

While driving, if you experience any

unusual vibration, ride disturbance or

noise, reduce your speed and drive

with caution until you can safely pull

off of the side of the road.

Call for road side service or towing.

When you use the Tire Mobility Kit,

the tire pressure sensors and wheel

may be damaged by sealant, remove

the sealant stained with tire pressure

sensors and wheel and inspect in

authorized dealer.Checking the tire inflation pres-

sure

1. After driving approximately 4 ~ 6

miles (7 ~ 10 km or about 10min),

stop at a safe location.

2. Connect the filling hose (2) of the compressor (clip mounted side)

directly and then connect the fill-

ing hose (2) (opposite side) to the

tire valve.

3. Connect between compressor and the vehicle power outlet using the

cable and connectors.

4. Adjust the tire inflation pressure to the recomended tire inflation.

With the ignition swithched on, proceed as follows.

- To increase the inflation pres- sure : Switch on the compres-

sor, position I. To check the cur-

rent inflation pressure setting,

briefly switch off the compressor.

CAUTION - Tire pressure

Do not attempt to drive your vehicle if the tire pressure isbelow 200kpa (29 PSI). Thiscould result in an accident dueto sudden tire failure.

WARNING - Carbon monoxide

Do not leave your vehicle run-

ning in a poorly ventilated area

for extended periods of time.

Carbon monoxide poisoning

and suffocation can occur.

Page 354 of 456

631

What to do in an emergency

✽

✽NOTICE

The pressure gauge may show high-

er than actual reading when the

compressor is running. To get an

accurate tire pressure, the compres-

sor needs to be turned off.

- To reduce the inflation pres-

sure: Press the button (8) on the

compressor hose. Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 10 A ± 1A

Suitable for use at temperatures:

-22 ~ +158°F (-30 ~ +70°C)

Max. working pressure: 6 bar (87 psi)

Size

Compressor: 6.3 x 5.9 x 2.2 in. (161 x 150 x 55.8 mm)

Sealant bottle: ø 3.3 x 3.1 in. (ø 85 x 81 mm)

Compressor weight: 1.62 lbs ± 0.06 lbs (735 g ± 25 g)

Sealant volume: 12.2 cu. in. (200 ml)

CAUTION - Tire pressuresensor

When you use the Tire MobilityKit including sealant notapproved by HYUNDAI, the tirepressure sensors may be dam-aged by sealant. The sealant onthe tire pressure sensor andwheel should be removed whenyou replace the tire with a newone and inspect the tire pressuresensors in authorized dealer.

Page 387 of 456

729

Maintenance

Replace the filter according to the

Maintenance Schedule.

If the vehicle is operated in extremelydusty or sandy areas, replace the ele-ment more often than the usual recom-mended intervals. (Refer to“Maintenance under severe usage condi-tions” in this section.)

Filter inspection

The climate control air filter should be

replaced according to the Maintenance

Schedule. If the vehicle is operated in

severely air-polluted cities or on dusty

rough roads for a long period, it should

be inspected more frequently and

replaced earlier. When you replace the

climate control air filter, replace it per-

forming the following procedure, and be

careful to avoid damaging other compo-

nents.

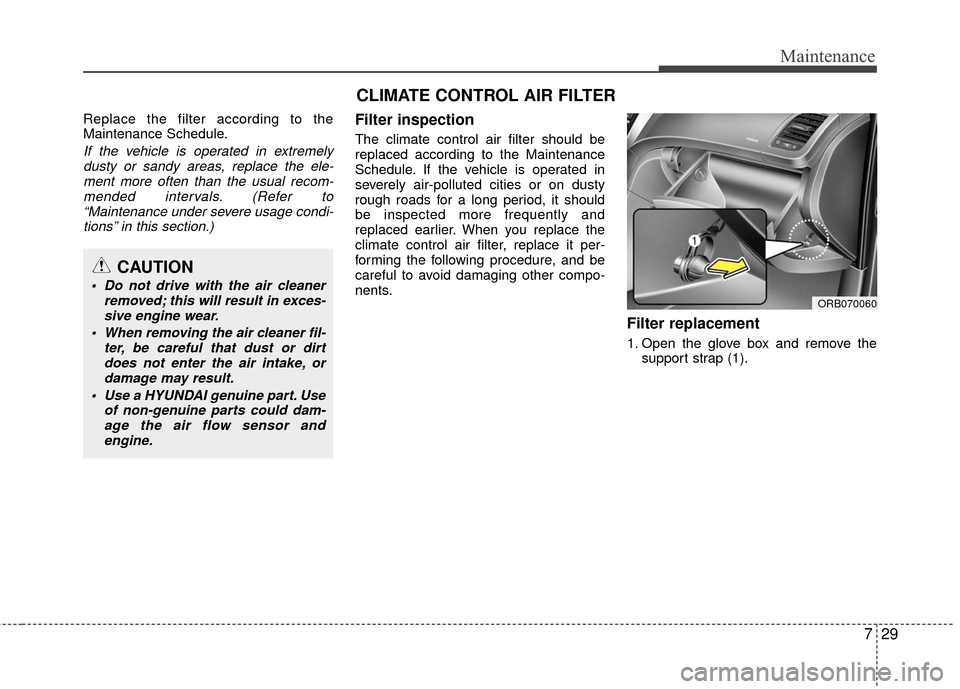

Filter replacement

1. Open the glove box and remove the support strap (1).

CAUTION

Do not drive with the air cleaner removed; this will result in exces-sive engine wear.

When removing the air cleaner fil- ter, be careful that dust or dirtdoes not enter the air intake, ordamage may result.

Use a HYUNDAI genuine part. Use of non-genuine parts could dam-age the air flow sensor andengine.

CLIMATE CONTROL AIR FILTER

ORB070060

Page 415 of 456

57

Maintenance

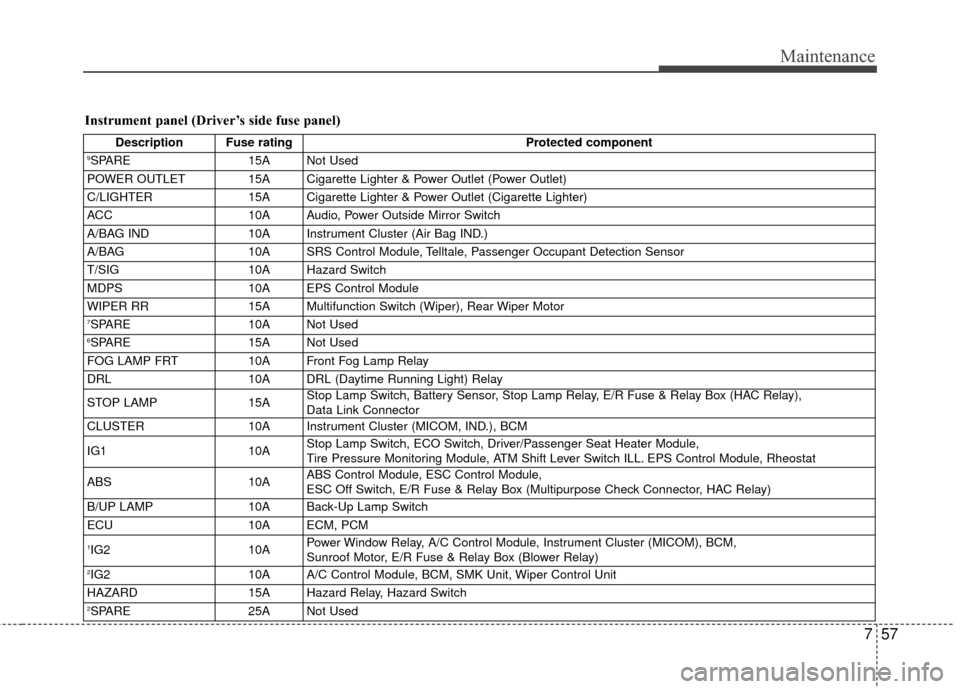

Instrument panel (Driver’s side fuse panel)

Description Fuse ratingProtected component9SPARE15A Not Used

POWER OUTLET 15A Cigarette Lighter & Power Outlet (Power Outlet)

C/LIGHTER 15A Cigarette Lighter & Power Outlet (Cigarette Lighter)

ACC 10A Audio, Power Outside Mirror Switch

A/BAG IND 10A Instrument Cluster (Air Bag IND.)

A/BAG 10A SRS Control Module, Telltale, Passenger Occupant Detection Sensor

T/SIG 10A Hazard Switch

MDPS 10A EPS Control Module

WIPER RR 15A Multifunction Switch (Wiper), Rear Wiper Motor

7SPARE10A Not Used6SPARE 15A Not Used

FOG LAMP FRT 10A Front Fog Lamp Relay

DRL 10A DRL (Daytime Running Light) Relay

STOP LAMP 15AStop Lamp Switch, Battery Sensor, Stop Lamp Relay, E/R Fuse & Relay Box (HAC Relay),

Data Link Connector

CLUSTER 10A Instrument Cluster (MICOM, IND.), BCM

IG1 10AStop Lamp Switch, ECO Switch, Driver/Passenger Seat Heater Module,

Tire Pressure Monitoring Module, ATM Shift Lever Switch ILL. EPS Control Module, Rheostat

ABS 10AABS Control Module, ESC Control Module,

ESC Off Switch, E/R Fuse & Relay Box (Multipurpose Check Connector, HAC Relay)

B/UP LAMP 10A Back-Up Lamp Switch

ECU 10A ECM, PCM

1IG210APower Window Relay, A/C Control Module, Instrument Cluster (MICOM), BCM,

Sunroof Motor, E/R Fuse & Relay Box (Blower Relay)

2IG2

10A A/C Control Module, BCM, SMK Unit, Wiper Control Unit

HAZARD 15A Hazard Relay, Hazard Switch

2SPARE25A Not Used

7

Page 416 of 456

Maintenance

7

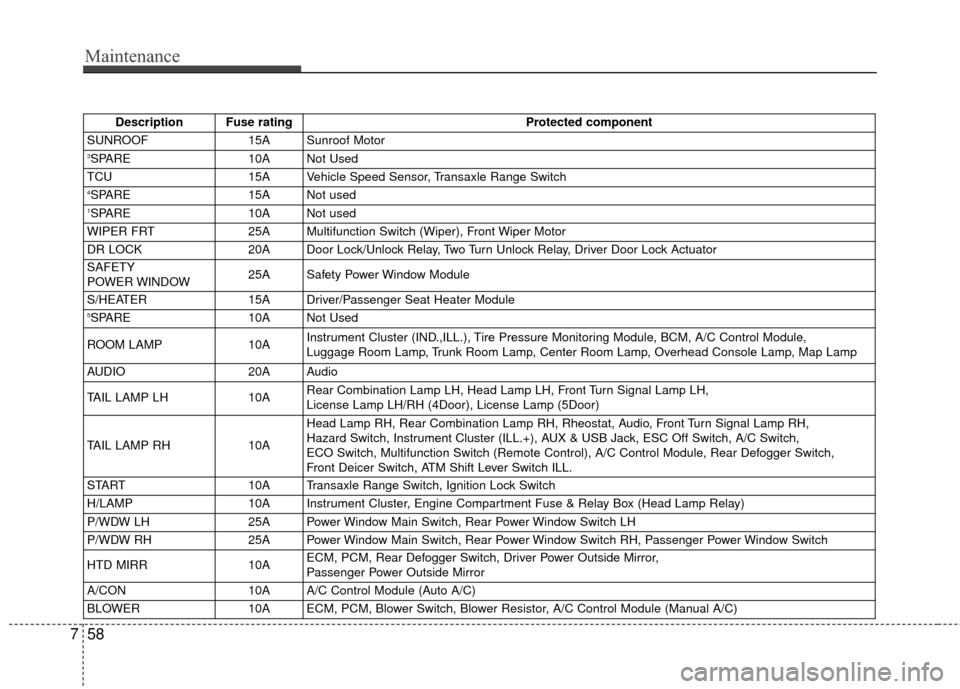

Description Fuse ratingProtected component

SUNROOF 15A Sunroof Motor

3SPARE10A Not Used

TCU 15A Vehicle Speed Sensor, Transaxle Range Switch

4SPARE15A Not used1SPARE10A Not used

WIPER FRT 25A Multifunction Switch (Wiper), Front Wiper Motor

DR LOCK 20A Door Lock/Unlock Relay, Two Turn Unlock Relay, Driver Door Lock Actuator

SAFETY

POWER WINDOW 25A Safety Power Window Module

S/HEATER 15A Driver/Passenger Seat Heater Module

5SPARE10A Not Used

ROOM LAMP 10AInstrument Cluster (IND.,ILL.), Tire Pressure Monitoring Module, BCM, A/C Control Module,

Luggage Room Lamp, Trunk Room Lamp, Center Room Lamp, Overhead Console Lamp, Map Lamp

AUDIO 20A Audio

TAIL LAMP LH 10ARear Combination Lamp LH, Head Lamp LH, Front Turn Signal Lamp LH,

License Lamp LH/RH (4Door), License Lamp (5Door)

TAIL LAMP RH 10AHead Lamp RH, Rear Combination Lamp RH, Rheostat, Audio, Front Turn Signal Lamp RH,

Hazard Switch, Instrument Cluster (ILL.+), AUX & USB Jack, ESC Off Switch, A/C Switch,

ECO Switch, Multifunction Switch (Remote Control), A/C Control Module, Rear Defogger Switch,

Front Deicer Switch, ATM Shift Lever Switch ILL.

START 10A Transaxle Range Switch, Ignition Lock Switch

H/LAMP 10A Instrument Cluster, Engine Compartment Fuse & Relay Box (Head Lamp Relay)

P/WDW LH 25A Power Window Main Switch, Rear Power Window Switch LH

P/WDW RH 25A Power Window Main Switch, Rear Power Window Switch RH, Passenger Power Window Switch

HTD MIRR 10AECM, PCM, Rear Defogger Switch, Driver Power Outside Mirror,

Passenger Power Outside Mirror

A/CON 10A A/C Control Module (Auto A/C)

BLOWER 10A ECM, PCM, Blower Switch, Blower Resistor, A/C Control Module (Manual A/C)

58

Page 418 of 456

Maintenance

7

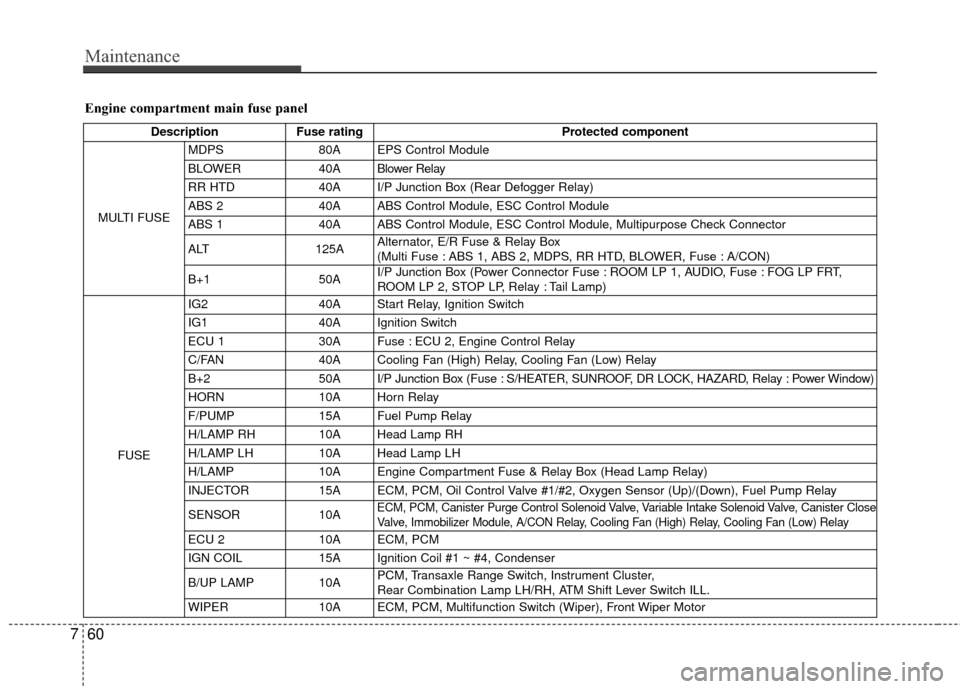

Engine compartment main fuse panel

DescriptionFuse rating Protected component

MULTI FUSE MDPS

80A EPS Control Module

BLOWER 40A Blower Relay

RR HTD 40A I/P Junction Box (Rear Defogger Relay)

ABS 2 40A ABS Control Module, ESC Control Module

ABS 1 40A ABS Control Module, ESC Control Module, Multipurpose Check Connector

ALT 125AAlternator, E/R Fuse & Relay Box

(Multi Fuse : ABS 1, ABS 2, MDPS, RR HTD, BLOWER, Fuse : A/CON)

B+1 50AI/P Junction Box (Power Connector Fuse : ROOM LP 1, AUDIO, Fuse : FOG LP FRT,

ROOM LP 2, STOP LP, Relay : Tail Lamp)

FUSE

IG240AStart Relay, Ignition Switch

IG140AIgnition Switch

ECU 1 30A Fuse : ECU 2, Engine Control Relay

C/FAN 40A Cooling Fan (High) Relay, Cooling Fan (Low) Relay

B+2 50A I/P Junction Box (Fuse : S/HEATER, SUNROOF, DR LOCK, HAZARD, Relay : Power Window)

HORN 10A Horn Relay

F/PUMP 15A Fuel Pump Relay

H/LAMP RH 10A Head Lamp RH

H/LAMP LH 10A Head Lamp LH

H/LAMP 10A Engine Compartment Fuse & Relay Box (Head Lamp Relay)

INJECTOR 15A ECM, PCM, Oil Control Valve #1/#2, Oxygen Sensor (Up)/(Down), Fuel Pump Relay

SENSOR 10A

ECM, PCM, Canister Purge Control Solenoid Valve, Variable Intake Solenoid Valve, Canister Close

Valve, Immobilizer Module, A/CON Relay, Cooling Fan (High) Relay, Cooling Fan (Low) Relay

ECU 210A ECM, PCM

IGN COIL 15A Ignition Coil #1 ~ #4, Condenser

B/UP LAMP 10APCM, Transaxle Range Switch, Instrument Cluster,

Rear Combination Lamp LH/RH, ATM Shift Lever Switch ILL.

WIPER 10A ECM, PCM, Multifunction Switch (Wiper), Front Wiper Motor

60

Page 429 of 456

771

Maintenance

APPEARANCE CARE

Exterior care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning and

caution statements that appear on the

label.

High-pressure washing

When using high-pressure washers,make sure to maintain sufficient dis-

tance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component dam-

age or water penetration.

Do not spray the camera, sensors or its surrounding area directly with a high

pressure washer. Shock applied from

high pressure water may cause the

device to not operate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or con-

nectors as they may be damaged if

they come into contact with high pres-

sure water.

Finish maintenance

Washing

To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are kept

clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.CAUTION

Do not use strong soap, chemical detergents or hot water, and donot wash the vehicle in direct sunlight or when the body of thevehicle is warm.

Be careful when washing the side windows of your vehicle.

Especially, with high-pressurewater, water may leak through thewindows and wet the interior.

To prevent damage to the plastic parts and lamps, do not cleanwith chemical solvents or strongdetergents.

WARNING - Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.