fuel Hyundai Atos 2002 Service Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2002, Model line: Atos, Model: Hyundai Atos 2002Pages: 249, PDF Size: 3.11 MB

Page 203 of 249

WHAT TO DO IN AN EMERGENCY

3-2 3. If coolant is running out under the car or

steam is coming out from under the bonnet stop the engine. Do not open the bonnetuntil the coolant has stopped running or thesteaming has stopped. If there is no visibleloss of coolant and no steam, leave theengine running and check to be sure theengine cooling fan is operating. If the fan isnot running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing, check to see thatit is tight. If the drive belt seems to besatisfactory, check for coolant leaking fromthe radiator, hoses or under the car. (If theair conditioner had been in use, it is normalfor cold water to be draining from it).

WARNING: While the engine is running, keep hands andclothing away from moving parts such asthe fan and drive belts to prevent injury.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine imme-diately and call the nearest Hyundai dealerfor assistance.

WARNING: Do not remove the radiator cap when theengine is hot since steam and boiling watermay be ejected from the radiator resulting inburns or scalding.

CAUTION:

Personal injury and damage to the vehicle

may occur if jump starting is not performedcorrectly. If any doubt exists as to how thisoperation should be performed, seek assis-tance from qualified personnel. WARNING:

Motor vehicle batteries contain sulphuric

acid and emit hydrogen gas. Protective cloth- ing should be worn and care exercised toprevent the acid from coming into contactwith skin or clothing and the vehicle. Nakedlights should not be permitted in the vicinityof the battery. Care should be exercised topreventsparks occurring during connection.If acid accidentally comes into contact withskin or eyes, the affected area should imme-diately be flushed with copious amounts ofwater and medical assistance sought.

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed in another vehicle, ensure that the two vehi-cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle provid- ing the jump start is running prior to connec-tion of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of thedischarged battery. 5. Attach the black jump cable to the negative

(-) terminal of the booster battery, and theother end to a ground point within the enginecompartment of the vehicle with the flat bat-tery. Do not connect to the negative batteryterminal of the flat battery since sparks maybe generated with the subsequent risk ofexplosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Remove jump cables in the reverse order of installation (black cable first).

NOTE: If the jump cable is incorrectly installed, damage to the vehicle electrical system mayoccur, in particular the electronic compo-nents such as the Fuel Injection systemcomputer and the Automatic Transaxle com-puter. The battery must never be discon-nected whilst the engine is running. XD040A1-E

IF THE ENGINE OVERHEATS If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transaxle, semi- automatic transalxe) and set the parkingbrake. If the air conditioner is on, turn it off.

Page 212 of 249

VEHICLE MAINTENANCE REQUIREMENTS 5-1

NOTE: The inspection and testing of certain elec-

tronic fuel injection/engine management and automatic transmission control systems re-quire specialised electronic equipment spe-cifically designed for Hyundai vehicles. Theuse of general purpose electrical test equip-ment may result in damage to the controlunit microprocessors. be sure these are equivalent to the quality ofthe original Hyundai parts. Your Service Pass-port provides further information about yourwarranty coverage.

DF020F1-E SERVICE HISTORYIt is important that all scheduled maintenance

services are recorded in the warranty and ser- vice passport to ensure that proof of mainte-nance is available when warranty service isrequired.

DF020A1-E MAINTENANCE AND SERVICING REQUIREMENTS To ensure the continued reliability and safety of

the vehicle, certain routine maintenance opera-tions are required at specific mileage or timeintervals.

It is the responsibility of the vehicle owner to

ensure that the maintenance schedules shownin both this Owners Manual and the Warrantyand Service Passport are adhered to.

The new vehicle warranty may be invalidated if

the routine maintenance operations are notperformed in line with the recommendationsoutlined and the safety and durability of thevehicle adversely affected.

It is recommended that all maintenance opera-

tions with the exception of the daily operatingchecks are entrusted to a Hyundai dealer toensure that the latest repair and maintenanceprocedures and specialized servicing tools areemployed. In addition, the use of genuineHyundai replacement parts will ensure that thevehicle safety and performance will not becompromised. ZF010A1-A

5. VEHICLE MAINTE-

NANCE REQUIRE- MENTS

SF020C1-B Specified Scheduled ProceduresThese are the procedures such as inspections,

adjustments and replacements that are listed in the maintenance charts starting on page 5-2.These procedures must be performed at theintervals shown in the maintenance scheduleto assure that your warranty remains in effect.Although it is strongly recommended that theybe performed by the factory-trained or distribu-tor-trained technicians at your Hyundai dealer,these procedures may be performed at anyqualified service facility.

It is suggested that genuine Hyundai service

parts be used for any required repairs or re-placements. Other parts of equivalent qualitysuch as engine oil, engine coolant, manual orauto transaxle oil, brake fluid and so on whichare not supplied by Hyundai Motor Company orits distributor may be used without affectingyour warranty coverage but you should always

5

Page 213 of 249

VEHICLE MAINTENANCE REQUIREMENTS

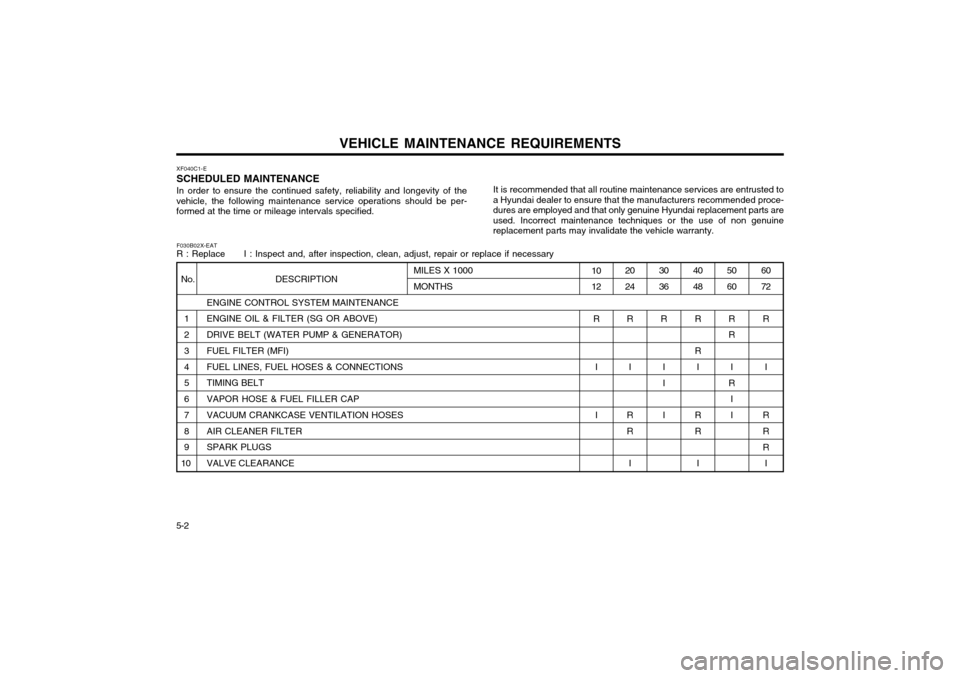

5-2 XF040C1-E SCHEDULED MAINTENANCEIn order to ensure the continued safety, reliability and longevity of the

vehicle, the following maintenance service operations should be per- formed at the time or mileage intervals specified. It is recommended that all routine maintenance services are entrusted to

a Hyundai dealer to ensure that the manufacturers recommended proce-dures are employed and that only genuine Hyundai replacement parts areused. Incorrect maintenance techniques or the use of non genuinereplacement parts may invalidate the vehicle warranty.

F030B02X-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

ENGINE CONTROL SYSTEM MAINTENANCE

1 ENGINE OIL & FILTER (SG OR ABOVE)

2 DRIVE BELT (WATER PUMP & GENERATOR)

3 FUEL FILTER (MFI)

4 FUEL LINES, FUEL HOSES & CONNECTIONS

5 TIMING BELT

6 VAPOR HOSE & FUEL FILLER CAP

7 VACUUM CRANKCASE VENTILATION HOSES

8 AIR CLEANER FILTER

9 SPARK PLUGS

10 VALVE CLEARANCE

No. DESCRIPTION60 72

R

I

R R R I

5060

R R I

R I I

4048

R R I

R R I

1012

R

I I

MILES X 1000 MONTHS30 36

R

II I

20 24

R

I

R R I

Page 216 of 249

VEHICLE MAINTENANCE REQUIREMENTS 5-5

F060A01A-AAT EXPLANATION OF SCHEDULED MAIN-

TENANCE ITEMS

F060M01A-AAT

o Engine oil and filterThe engine oil and filter should be changed at

the intervals specified in the maintenance sched- ule. If the car is being driven in severe condi-tions, more frequent oil and filter changes arerequired.

F060B01A-AAT

o Drive belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked periodically for proper tension andadjusted as necessary.

F060C01A-AAT

o Fuel filterA clogged filter can limit the speed at which the

vehicle may be driven, damage the emission system and cause hard starting. If an exces-sive amount of foreign matter accumulates in

the fuel tank, the filter may require replacementmore frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections. F060D01A-AAT

o Fuel lines, fuel hoses and connec-

tions

Check the fuel lines, fuel hoses and connec-

tions for leakage and damage. Replace anydamaged or leaking parts immediately.

F060E01A-AAT

o Timing beltInspect all parts related to the timing belt for

damage and deformation. Replace any dam- aged parts immediately.

F060G01A-AAT

o Vapour hose and fuel filler capThe vapor hose and fuel filler cap should be

inspected at those intervals specified in the maintenance schedule. Make sure that a new

vapour hose or fuel filler cap is correctly re-placed.

F060F01A-AAT

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of

heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abrasions,and excessive swelling indicate deterioration.Particular attention should be paid to examine

those hose surfaces nearest to high heat sourc-

es, such as the exhaust manifold. Inspect the hose routing to assure that the

hoses do not come in contact with any heatsource, sharp edges or moving component

which might cause heat damage or mechanicalwear. Inspect all hose connections, such as

clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses

should be replaced immediately if there is any

evidence of deterioration or damage.

F060H01A-AAT

o Air cleaner filter A Genuine Hyundai air cleaner filter is recom-

mended when filter is replaced.

F060J01A-AAT

o Spark plugsMake sure to install new spark plugs of the

correct heat range.

F060N01X-GAT

o Valve clearances Incorrect valve clearance will not only result in

unsteady engine operation, but will also cause excessive noise and reduced engine perfor-mance. Inspect valve clearance and adjust asrequired while the engine is hot.

Valve-to-rocker arm clearance Intake valves ..... 0.008 in. (0.2 mm)Exhaust valves .... 0.010 in. (0.25 mm)

Page 219 of 249

DO-IT-YOURSELF MAINTENANCE 6-1

ZG000A1-E

6. DO-IT-YOURSELF MAINTENANCE

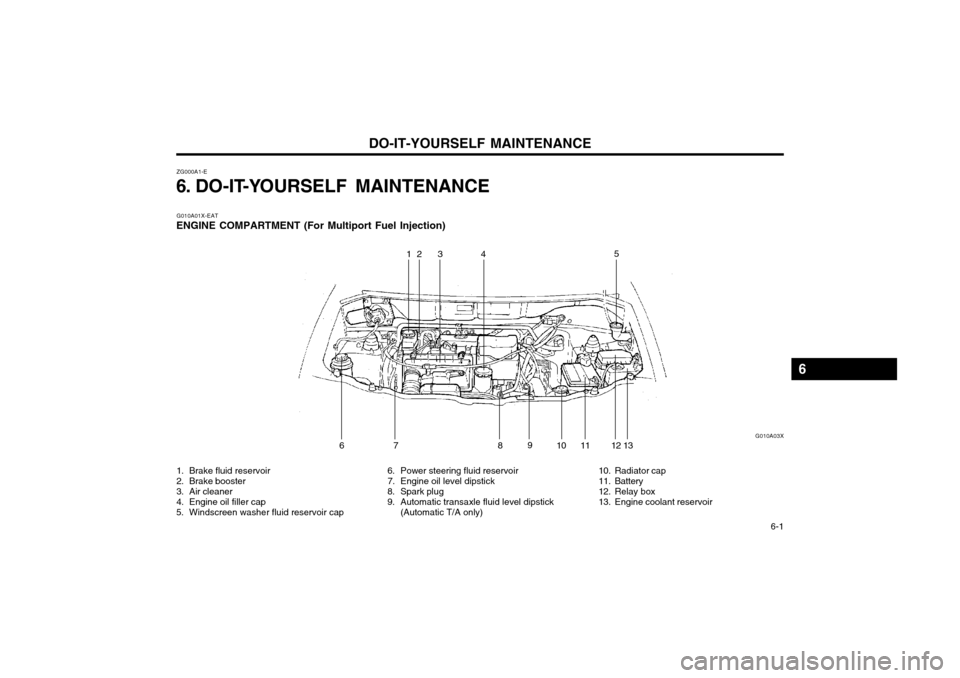

1. Brake fluid reservoir

2. Brake booster

3. Air cleaner

4. Engine oil filler cap

5. Windscreen washer fluid reservoir cap 6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Spark plug

9. Automatic transaxle fluid level dipstick

(Automatic T/A only) 10. Radiator cap

11. Battery

12. Relay box

13. Engine coolant reservoir

G010A01X-EAT

ENGINE COMPARTMENT (For Multiport Fuel Injection)

5

13

129

14

101186 G010A03X

23

7

6

Page 220 of 249

DO-IT-YOURSELF MAINTENANCE

6-2 ZG020B1-E

GENERAL CHECKS Engine Compartment

The following should be checked regularly:

o Engine oil level and condition

o Transaxle fluid level and condition

o Brake reservoir fluid level

o Engine coolant level

o Windscreen washer fluid level

o Accessory drive belt condition

o Coolant hose condition

o Fluid leaks (on or below components)

o Power steering fluid level

o Tyre pressure and condition (including spare)

o Battery condition ZG020C1-A

Vehicle Exterior

The following should be checked monthly:

o Overall appearance and condition

o Wheel condition and wheel nut tightness

o Exhaust system condition

o Light condition and operation

o Windscreen glass condition

o Wiper blade condition

o Paint condition and corrosion

o Fluid leaks

o Door and hood lock condition o Air filter element condition G020C02X-GAT

Vehicle Interior

The following should be checked each time

when the vehicle is driven:

o Lights operation

o Windscreen wipers operation

o Horn operation

o Defroster, heating system operation (and air conditioning, if installed)

o Steering operation and condition

o Mirror condition and operation

o Turn signal operation

o Accelerator pedal operation

o Brake operation, including parking brake

o Manual transaxle operation, including clutch operation

o Automatic transaxle operation, including "Park" mechanism operation

o Seat control condition and operation

o Seat belt condition and operation

o Sunvisor operation

If you notice anything that does not operate

correctly or appear to be functioning correctly, inspect it carefully and seek assistance fromyour Hyundai dealer if service is needed. ZG030A1-A

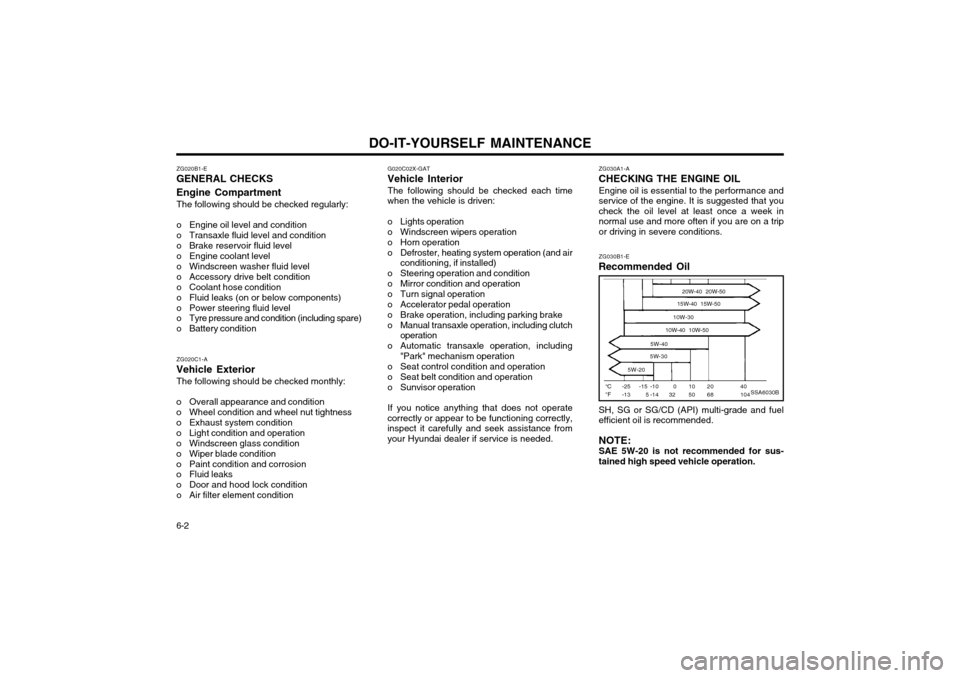

CHECKING THE ENGINE OIL

Engine oil is essential to the performance andservice of the engine. It is suggested that youcheck the oil level at least once a week innormal use and more often if you are on a tripor driving in severe conditions. ZG030B1-E

Recommended Oil

SSA6030B°C °F -25-13 20W-40 20W-50

15W-40 15W-50

10W-30

10W-40 10W-50

5W-40

5W-30

5W-20

40104

2068

1050

032

-15 5 -10-14

SH, SG or SG/CD (API) multi-grade and fuel efficient oil is recommended. NOTE: SAE 5W-20 is not recommended for sus-tained high speed vehicle operation.

Page 235 of 249

DO-IT-YOURSELF MAINTENANCE 6-17

WARNING: The halogen bulb contains gas under pres-

sure and if impacted could shatter, and re- sulting in flying fragments. Always wear eye

protection when servicing the bulb. Protectthe bulb against abrasions or scratches andagainst liquids when lighted. Turn on thebulb only when installing in a headlight.Replace the headlight if damaged or cracked.Keep the bulb out of the reach of childrenand dispose of the used bulb with care.

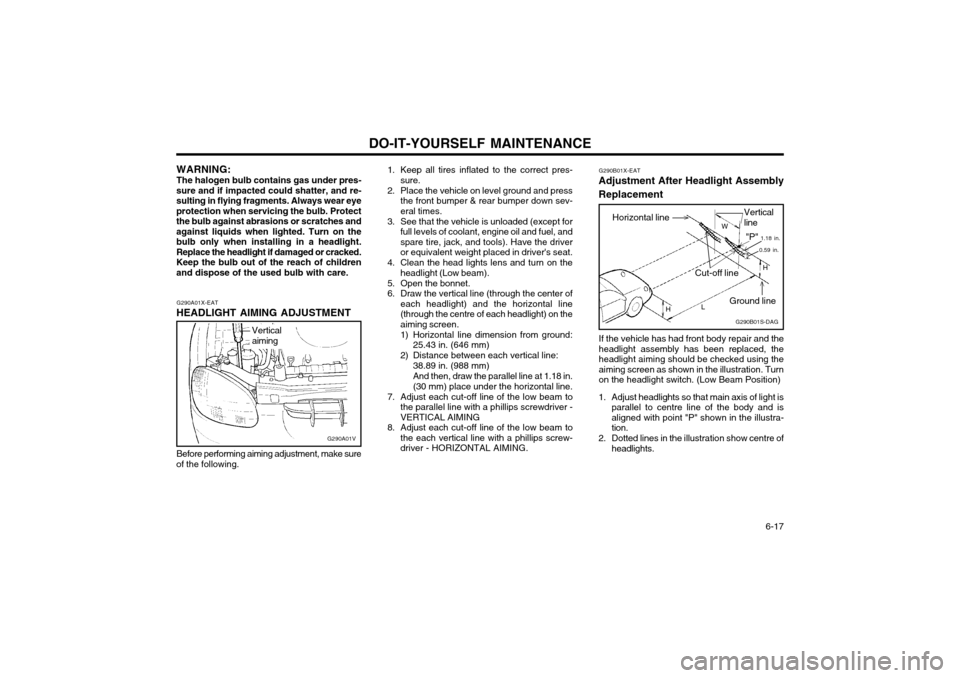

G290A01X-EAT

HEADLIGHT AIMING ADJUSTMENT

G290A01V

Before performing aiming adjustment, make sure

of the following.

Vertical aiming

1. Keep all tires inflated to the correct pres- sure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down sev- eral times.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, andspare tire, jack, and tools). Have the driveror equivalent weight placed in driver's seat.

4. Clean the head lights lens and turn on the headlight (Low beam).

5. Open the bonnet.

6. Draw the vertical line (through the center of each headlight) and the horizontal line(through the centre of each headlight) on theaiming screen.

1) Horizontal line dimension from ground:25.43 in. (646 mm)

2) Distance between each vertical line: 38.89 in. (988 mm)And then, draw the parallel line at 1.18 in. (30 mm) place under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver -VERTICAL AIMING

8. Adjust each cut-off line of the low beam to the each vertical line with a phillips screw-driver - HORIZONTAL AIMING. G290B01X-EAT

Adjustment After Headlight Assembly Replacement

If the vehicle has had front body repair and the headlight assembly has been replaced, theheadlight aiming should be checked using theaiming screen as shown in the illustration. Turnon the headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis of light is parallel to centre line of the body and isaligned with point "P" shown in the illustra-tion.

2. Dotted lines in the illustration show centre of headlights. G290B01S-DAG

Horizontal lineVertical line

W

0.59 in.

"P" 1.18 in.

Cut-off line

Ground line H

H L

Page 239 of 249

EMISSION CONTROL SYSTEMS 7-1

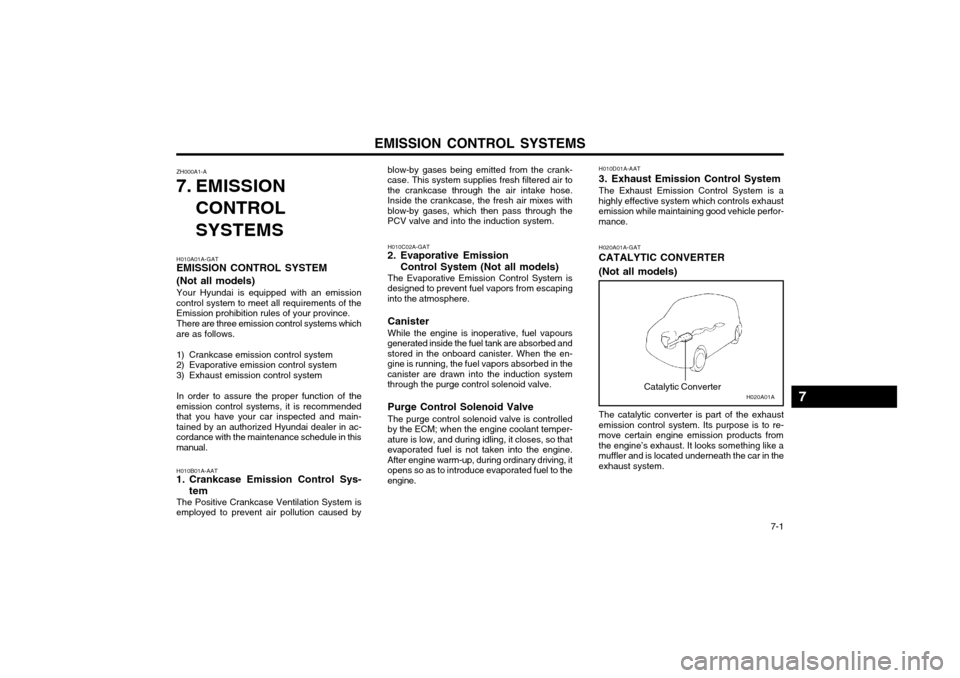

H010A01A-GAT EMISSION CONTROL SYSTEM (Not all models) Your Hyundai is equipped with an emission

control system to meet all requirements of the Emission prohibition rules of your province.

There are three emission control systems which

are as follows.

1) Crankcase emission control system

2) Evaporative emission control system

3) Exhaust emission control system In order to assure the proper function of the

emission control systems, it is recommended that you have your car inspected and main-tained by an authorized Hyundai dealer in ac-

cordance with the maintenance schedule in thismanual. ZH000A1-A

7. EMISSION

CONTROL SYSTEMS

H010B01A-AAT

1. Crankcase Emission Control Sys-

tem

The Positive Crankcase Ventilation System is

employed to prevent air pollution caused by blow-by gases being emitted from the crank- case. This system supplies fresh filtered air to

the crankcase through the air intake hose.Inside the crankcase, the fresh air mixes with

blow-by gases, which then pass through thePCV valve and into the induction system.

H010D01A-AAT

3. Exhaust Emission Control SystemThe Exhaust Emission Control System is a

highly effective system which controls exhaust

emission while maintaining good vehicle perfor-mance.

H010C02A-GAT

2. Evaporative Emission

Control System (Not all models)

The Evaporative Emission Control System is

designed to prevent fuel vapors from escapinginto the atmosphere.

Canister While the engine is inoperative, fuel vapours

generated inside the fuel tank are absorbed and stored in the onboard canister. When the en-gine is running, the fuel vapors absorbed in thecanister are drawn into the induction systemthrough the purge control solenoid valve.

Purge Control Solenoid Valve The purge control solenoid valve is controlled

by the ECM; when the engine coolant temper- ature is low, and during idling, it closes, so that

evaporated fuel is not taken into the engine.

After engine warm-up, during ordinary driving, itopens so as to introduce evaporated fuel to theengine.

H020A01ACatalytic Converter

H020A01A-GAT CATALYTIC CONVERTER (Not all models) The catalytic converter is part of the exhaust

emission control system. Its purpose is to re- move certain engine emission products from

the engine’s exhaust. It looks something like amuffler and is located underneath the car in theexhaust system.

7

Page 240 of 249

7-2EMISSION CONTROL SYSTEMS

H020B01A-GAT About the Catalytic ConverterExhaust gases passing through the catalytic

converter cause it to operate at very high tem- peratures. As a result, the introduction of large

amounts of unburned gasoline may cause it to

overheat and create a fire hazard. This can beavoided by observing the following:

o Use unleaded fuel only.

o Maintain your engine in good condition. Ex- tremely high converter temperatures can result from improper operation of the electri-cal, ignition or fuel injection systems.

o If your engine stalls, pings, knocks, or is hard to start, take your car to your Hyundaidealer as soon as possible and have thedifficulty corrected.

o Avoid driving with a very low fuel level. If your run out of gasoline, it could cause theengine to misfire and result in excessive

loading of the catalytic converter.

o Avoid idling the engine for periods longer than 10 minutes.

o Your Hyundai should not be either pushed or pulled to get it started. This can cause thecatalytic converter to overload.

o Take care not to stop your Hyundai over any combustible material such as grass, paper,leaves or rags. As these materials could

come in contact with the catalytic converterand could cause a fire. o Do not touch the catalytic converter or any

other part of the exhaust system while theengine is running as it is very hot and couldresult in burns.

o Remember that your Hyundai dealer is your best source of assistance.

Page 244 of 249

VEHICLE SPECIFICATIONS 9-1

Litres

35 J040A01X-GAT ELECTRICAL

Battery Alternator Starting motor

MF 12V 40AH

13.5V 60A

0.8 KW

J050A02X-GAT BRAKE

Dual hydraulic with brake booster Ventilated disc Drum Cable operated on rear wheel

J060A01X-EAT FUEL SYSTEM

lmp.gal 7.7

J020A01X-EAT POWER STEERING

Type Wheel free play Rack stroke Oil pump type Rack and pinion0 ~ 1.181 in. (0 ~ 30 mm) 5.354 in. (136 mm) Vane type

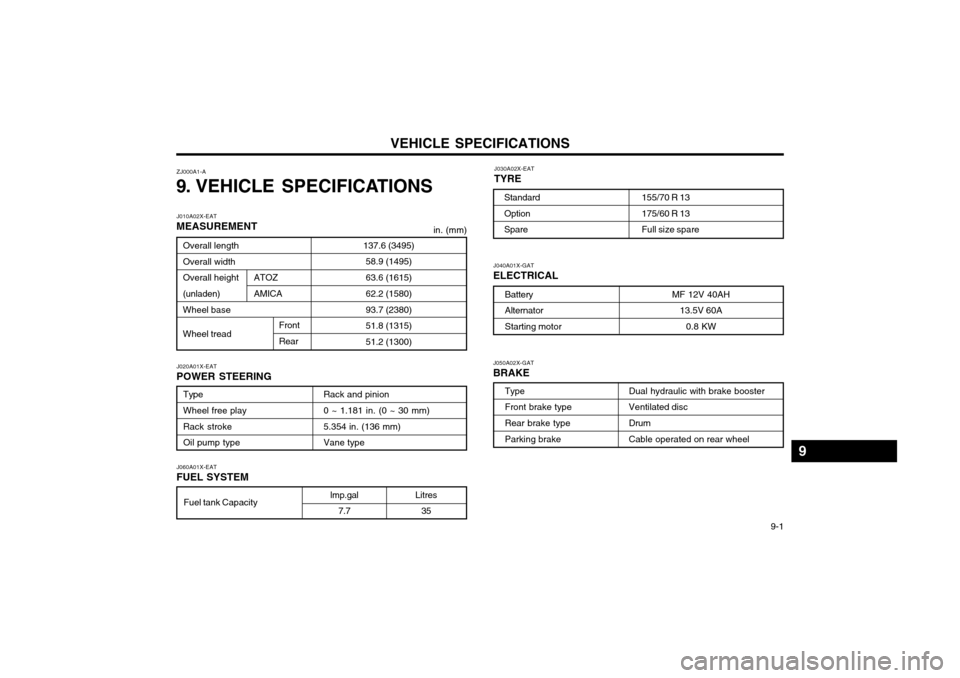

ZJ000A1-A

9. VEHICLE SPECIFICATIONS J030A02X-EAT TYRE

155/70 R 13 175/60 R 13 Full size spare

Standard Option Spare

J010A02X-EAT MEASUREMENT

137.6 (3495)58.9 (1495) 63.6 (1615) 62.2 (1580) 93.7 (2380) 51.8 (1315) 51.2 (1300)Overall length Overall width Overall height (unladen) Wheel base Wheel tread

in. (mm)

ATOZ AMICA

Front Rear

Fuel tank Capacity Type Front brake type Rear brake type Parking brake

9