ECU Hyundai Coupe 2002 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2002, Model line: Coupe, Model: Hyundai Coupe 2002Pages: 140, PDF Size: 1.45 MB

Page 95 of 140

3-7

IN CASE OF EMERGENCY

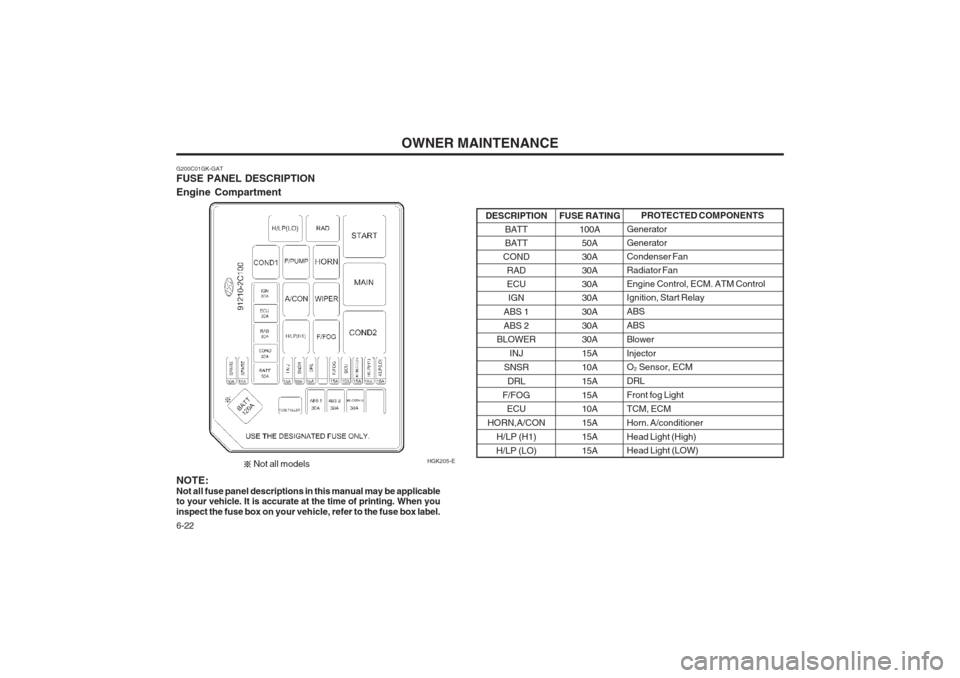

SD080A1-E VEHICLE TOWING OR RECOVERY

o OK FOR AUTOMATIC OR MANUALTRANSAXLE EQUIPPED VEHICLE

CAUTION: An incorrect tow or recovery could result in serious damage to the vehicle. If any damage to the suspension, steering or transmission is apparent or suspected, a towing ambu- lance must be used.

HGK194

SD070J1-E 8. Lower Vehicle and Tighten Nuts Lower the car to the ground turning the wheel nut wrench counterclockwise. When the vehicle is firmly on the ground, remove the jack and tighten the wheel nuts securely. At the first available opportunity, the wheel nut torque should be checked with a suitable torque wrench. Wheel nut tightening torque Steel wheel & aluminium alloy wheel: 900-1,100 kg.cm (65-80 lb.ft) SD070K1-E AFTER CHANGING WHEELS The pressure of the spare tyre should be checked at the first available opportunity. If any doubt exists as to the tyre pressure, the vehicle should be driven slowly to the nearest service station and the tyre pressure checked and adjusted as required. If the valve cap is lost from any of the valves, a replacement should be obtained and fitted at the first available opportunity. The valve cap pre- vents the ingress of dirt which may cause the valve to stick and therefore leak and is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly located in the boot of the vehicle to prevent damage and noise.

D080A01GK

HGK195

Page 103 of 140

VEHICLE MAINTENANCE REQUIREMENTS 5-5

6ZF060D1-A

o Fuel lines, fuel hoses and connec-

tions

Check the fuel lines, fuel hoses and connections for leakage and damage. Replace any damaged or leaking parts immediately. 6ZF060E1-A o Timing beltInspect all parts related to the timing belt for damage and deformation. Replace any dam- aged parts immediately. 6ZF060G1-A

o Vapour hose and fuel filler cap The vapor hose and fuel filler cap should be inspected at those intervals specified in the main- tenance schedule. Make sure that a new vapour hose or fuel filler cap is correctly replaced. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard and brittle rub- ber, cracking, tears, cuts, abrasions, and exces- sive swelling indicate deterioration. Particular attention should be paid to examining those hose surfaces nearest to high heat sources, such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with any heat source,sharp edges or moving component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clamps and cou- plings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidence of deteriora- tion or damage. 6ZF060H1-A

o Air cleaner filter A Genuine Hyundai air cleaner filter is recom- mended when filter is replaced. 6ZF060J1-A

o Spark plugs Make sure to install new spark plugs of the correct heat range.

6ZF060A1-A EXPLANATION OF SCHEDULED MAINTENANCE ITEMS 6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions, more frequent oil and filter changes are required. 6ZF060B2-A

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked peri- odically for proper tension and adjusted as nec- essary. 6ZF060C1-A

o Fuel filter A clogged filter can limit the speed at which the vehicle may be driven, damage the emission system and cause hard starting. If an excessive amount of foreign matter accumulates in the fuel tank, the filter may require replacement more frequently. After installing a new filter, run the engine for several minutes, and check for leaks at the connections.

F060N02E-EAT

o Valve Clearance Inspect excessive valve noise and/or engine vibration and adjust if necessary. A qualified technician should perform the operation.

Page 111 of 140

OWNER MAINTENANCE

6-6 CAUTION: The oil being drained from the engine will be hot. Care should be exercised to prevent scalding.

4. When the oil has drained from the sump,

replace the drain plug using a new washer ensuring that the plug is not over tightened.

Tightening torque :

4.5 ~ 4.0 kgf.m (1.6/2.0L)4.5 ~ 3.5 kgf.m (2.7L)

5. Remove the oil filter by rotating counterclock- wise, using a proprietary oil filter removal toolif necessary. Note that the oil filter will contain approximately 0.5 litres of oil and this should be collected in a suitable receptacle.

6. Install a new oil filter having smeared the

sealing ring with clean oil and rotating clock- wise until the filter contacts the mounting and then a further one half turn. Do not over- tighten. Tightening torque: 1.2 ~ 1.6 kgf.m.

7. Pour the specified quantity of the recom- mended oil into the engine and replace the filler cap. Start the engine and ensure that no oil leaks exist. Turn off the engine and after a couple minutes, recheck the oil level.

WARNING: Prolonged and repeated contact with used engine oils may result in serious skin disor- ders including dermatitis and cancer. Avoid contact with skin as far as possible and al-

G040A02GK-EAT ENGINE OIL AND FILTER REPLACEMENT The engine oil and filter must be changed at the time or mileage interval specified in the mainte- nance schedule. If the vehicle is operated under severe or adverse conditions, the oil and filter must be replaced more frequently. To replace the oil and filter, proceed as follows:

1. Ensure that the engine is at normal operating

temperature and park the vehicle on level ground with the parking brake securely ap- plied and the engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and remove the drain plug fromthe sump.

ZG030E1-A ENGINE OIL CONSUMPTION Function of engine oil Engine oil has the primary function of lubricating and cooling the inside of the engine. Engine oil consumption It is normal that an engine should consume some engine oil while normal driving. The cause of oil consumption in a normal engine are as follows;

o Engine oil is used to lubricate pistons, piston

rings and cylinders. A thin film of oil is left on the cylinder wall when a piston moves downwards in the cylinder. High negative pressure generated during en- gine operation sucks some of the oil into the combustion chamber. This oil with some oil of the cylinder wall is burned by the high temperature combustion gases during the combustion process.

o The engine oil consumption is strongly ef- fected by the viscosity and quality of oil, engine rpm and driving condition etc. The engine oil is more consumed under se- vere driving conditions such as high speeds and frequent acceleration and deceleration than normal driving condition.

G040A01GK

DOHC VVT V6

Page 127 of 140

OWNER MAINTENANCE

6-22

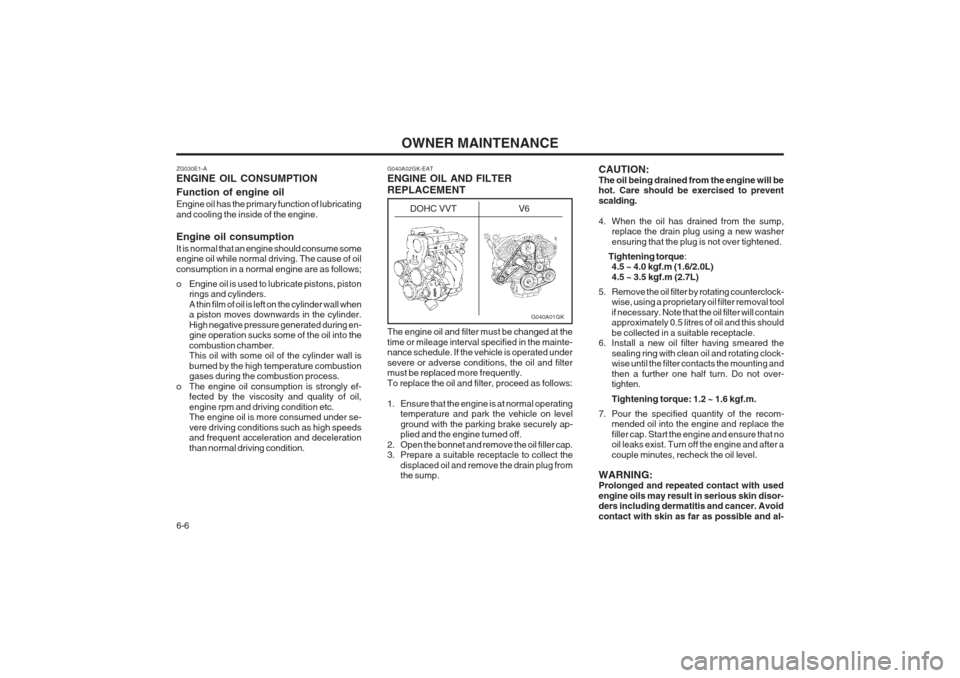

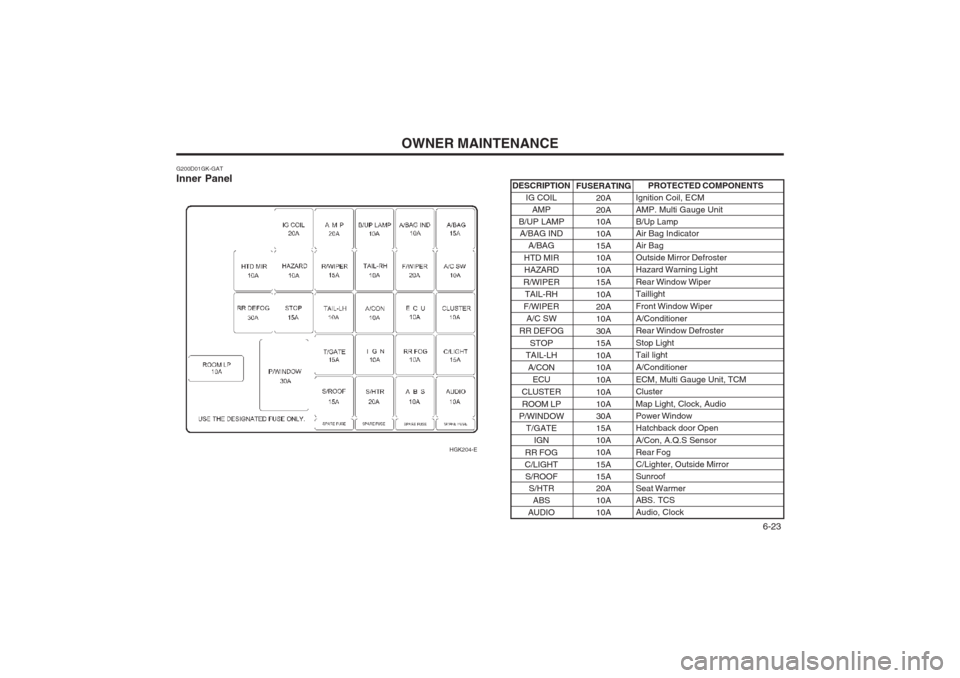

G200C01GK-GAT FUSE PANEL DESCRIPTION Engine Compartment HGK205-EPROTECTED COMPONENTS

GeneratorGeneratorCondenser FanRadiator FanEngine Control, ECM. ATM ControlIgnition, Start Relay ABSABSBlowerInjector O 2 Sensor, ECM

DRL Front fog LightTCM, ECMHorn. A/conditionerHead Light (High) Head Light (LOW)

FUSE RATING

100A50A30A30A30A30A 30A30A 30A 15A10A15A15A 10A 15A15A15A

DESCRIPTION

BATT BATT

COND RADECUIGN

ABS 1 ABS 2

BLOWER

INJ

SNSR DRL

F/FOG ECU

HORN,A/CON H/LP (H1)

H/LP (LO)

NOTE:

Not all fuse panel descriptions in this manual may be applicable

to your vehicle. It is accurate at the time of printing. When youinspect the fuse box on you r vehicle, refer to the fuse box label.

Not all models

Page 128 of 140

OWNER MAINTENANCE 6-23

DESCRIPTION

IG COILAMP

B/UP LAMP A/BAG IND

A/BAG

HTD MIR HAZARD

R/WIPER TAIL-RH

F/WIPER A/C SW

RR DEFOG STOP

TAIL-LH

A/CON ECU

CLUSTER ROOM LP

P/WINDOW T/GATE IGN

RR FOG

C/LIGHT S/ROOF S/HTR

ABS

AUDIO

G200D01GK-GAT Inner Panel

HGK204-E

PROTECTED COMPONENTS

Ignition Coil, ECM

AMP. Multi Gauge UnitB/Up Lamp Air Bag Indicator Air BagOutside Mirror DefrosterHazard Warning Light Rear Window Wiper Taillight Front Window WiperA/Conditioner Rear Window Defroster Stop Light Tail light A/Conditioner

ECM, Multi Gauge Unit, TCM Cluster Map Light, Clock, Audio Power WindowHatchback door Open A/Con, A.Q.S Sensor Rear FogC/Lighter, Outside MirrorSunroofSeat Warmer ABS. TCS Audio, Clock

FUSERATING

20A20A 10A 10A15A10A 10A 15A 10A20A 10A 30A 15A 10A 10A 10A10A 10A30A15A10A10A 15A 15A 20A 10A10A

Page 129 of 140

EMISSION CONTROL SYSTEM 7-1

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the vehicle is destined, the emission control system will comprise one or more of the following emission control devices. (1) Crankcase emission control system (2) Evaporative emission control system (3) Exhaust emission control system In order that the proper functioning of the emis- sion control systems may be ensured, it is recommended that the vehicle is inspected and maintained by an authorized Hyundai dealer in accordance with the maintenance schedule in this manual.

SH000A1-E

7. EMISSION

CONTROL SYSTEM

SH010B1-E

1. CRANKCASE EMISSION CONTROL SYSTEM

The positive crankcase ventilation system is employed to prevent air pollution caused by blow-by gases being emitted from the crankcase by introducing fresh air to the crankcase through the air cleaner where this mixes with blow-by gases and then passes through the PCV valve into the intake manifold from where it subse- quently enters the combustion chamber and is burned.

SH010D1-E

3. EXHAUST EMISSION CONTROL SYSTEM The exhaust emission control system is a highly effective system which controls exhaust emis- sion while maintaining good vehicle performance.

SH010C1-E

2. EVAPORATIVE EMISSION CONTROL SYSTEM

The Evaporative Emission Control System is designed to prevent fuel vapours from escaping into the atmosphere through the fuel tank venti- lation system. Whilst the engine is not running, fuel vapours generated inside the fuel tank are absorbed and stored in a charcoal canister. When the engine is started, the vapours stored in the canister are drawn into the induction system through the purge control solenoid valve and are subse- quently burned. The purge control solenoid valve is controlled by the ECU; when the engine coolant temperature is low or the engine is idling, the purge control valve is closed and fuel vapours remain stored in the canister. Under normal running conditions when the engine is warm, the valve opens and the vapours are drawn into the inlet tract and subsequently burned in the combustion cham- ber. SH020A1-E CATALYTIC CONVERTOR OPERATING PRECAUTIONS

JN70010A

Catalytic Converter

Hyundai Coupe models are fitted with catalytic convertors which require special operating con- siderations. The catalytic convertor serves to oxidize certain noxious elements of the exhaust gases leaving the engine to reduce the level of pollutants emitted from the vehicle and, provided that care is exercised to prevent damage, the catalyst will operate efficiently for the life of the vehicle. It is of the utmost importance that the following information is read and understood by the ve-7