Maintenance Hyundai Elantra 2013 Manual PDF

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2013, Model line: Elantra, Model: Hyundai Elantra 2013Pages: 383, PDF Size: 8.94 MB

Page 348 of 383

Maintenance

60 7

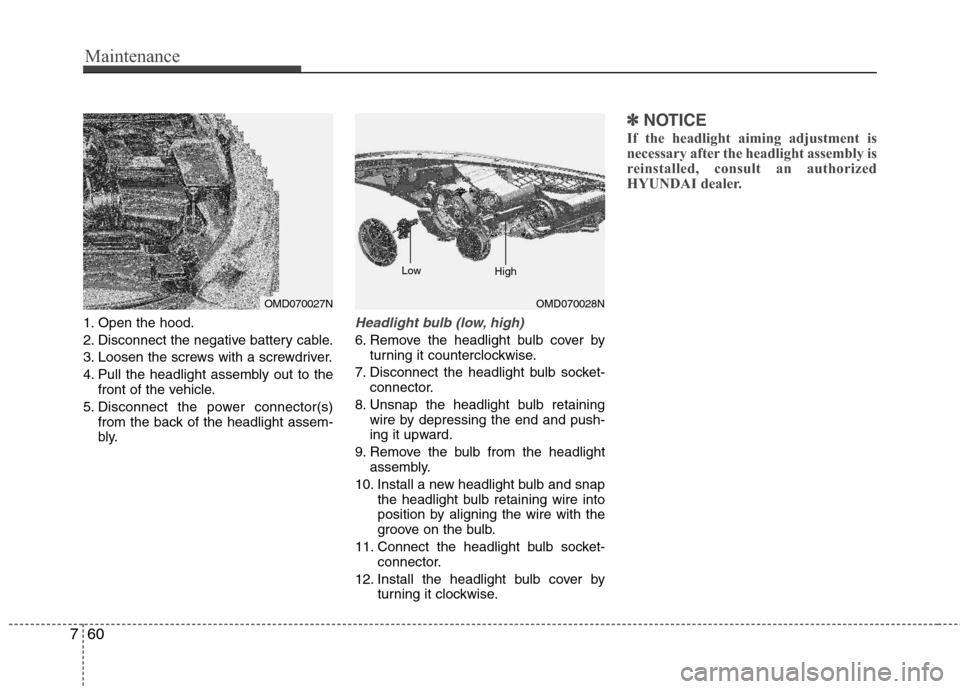

1. Open the hood.

2. Disconnect the negative battery cable.

3. Loosen the screws with a screwdriver.

4. Pull the headlight assembly out to the

front of the vehicle.

5. Disconnect the power connector(s)

from the back of the headlight assem-

bly.Headlight bulb (low, high)

6. Remove the headlight bulb cover by

turning it counterclockwise.

7. Disconnect the headlight bulb socket-

connector.

8. Unsnap the headlight bulb retaining

wire by depressing the end and push-

ing it upward.

9. Remove the bulb from the headlight

assembly.

10. Install a new headlight bulb and snap

the headlight bulb retaining wire into

position by aligning the wire with the

groove on the bulb.

11. Connect the headlight bulb socket-

connector.

12. Install the headlight bulb cover by

turning it clockwise.

✽ ✽

NOTICE

If the headlight aiming adjustment is

necessary after the headlight assembly is

reinstalled, consult an authorized

HYUNDAI dealer.

OMD070027NOMD070028N Low

High

Page 349 of 383

761

Maintenance

Front turn signal bulb

Follow steps 1 to 5 from previous page.

6. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

7. Remove the bulb from the socket by

pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.

8. Insert a new bulb by inserting it into the

socket and rotating it until it locks into

place.

9. Install the socket in the assembly by

aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

10.Reinstall the light assembly to the

body of the vehicle.

Front side marker

Follow steps 1 to 5 from previous page.

6. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

7. Remove the bulb from the socket by

pulling out the bulb.

8. Insert a new bulb.

9. Install the socket in the assembly by

aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

10. Reinstall the light assembly to the

body of the vehicle.

Fog light bulbs (if equipped)

If the light bulb is not operating, have the

vehicle checked by an authorized

HYUNDAI dealer.

OMD070055N Side marker

Turn signal

Page 350 of 383

Maintenance

62 7

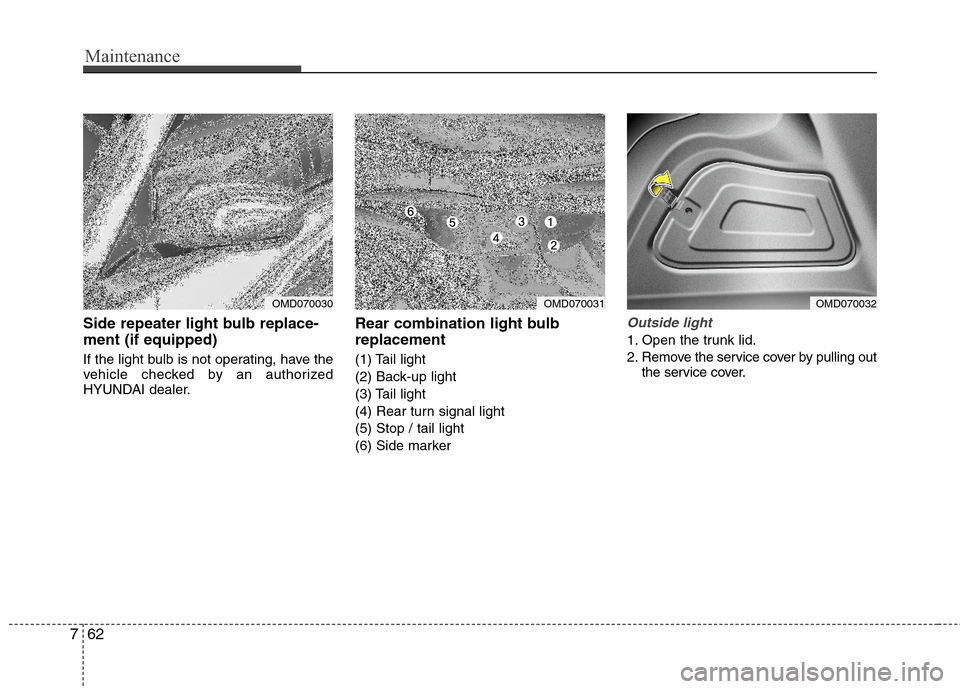

Side repeater light bulb replace-

ment (if equipped)

If the light bulb is not operating, have the

vehicle checked by an authorized

HYUNDAI dealer.

Rear combination light bulb

replacement

(1) Tail light

(2) Back-up light

(3) Tail light

(4) Rear turn signal light

(5) Stop / tail light

(6) Side marker

Outside light

1. Open the trunk lid.

2. Remove the service cover by pulling out

the service cover.

OMD070032OMD070031OMD070030

Page 351 of 383

763

Maintenance

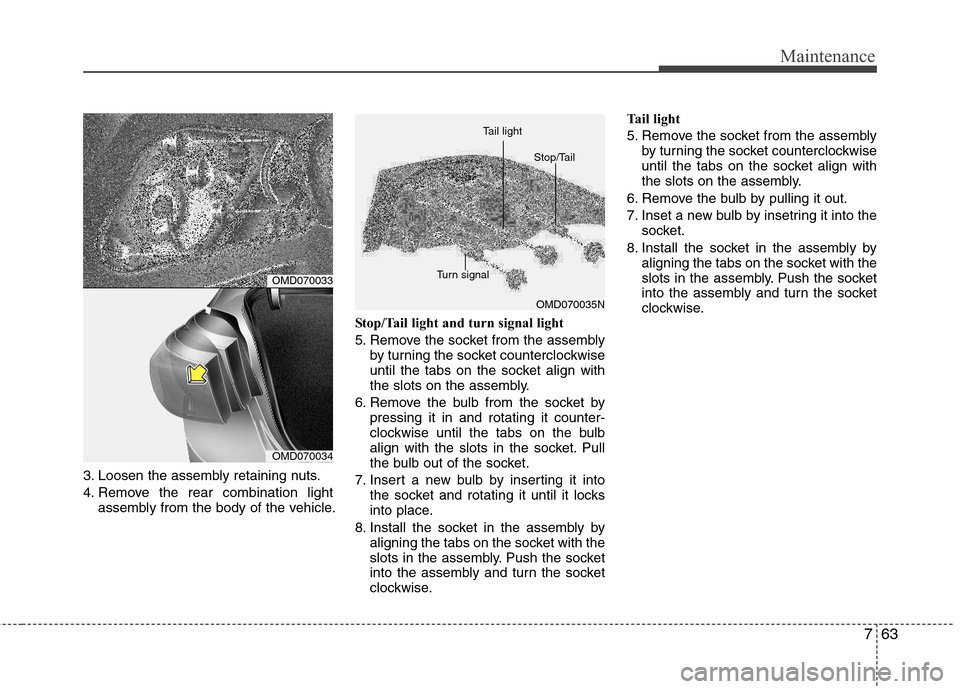

3. Loosen the assembly retaining nuts.

4. Remove the rear combination light

assembly from the body of the vehicle.Stop/Tail light and turn signal light

5. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

6. Remove the bulb from the socket by

pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.

7. Insert a new bulb by inserting it into

the socket and rotating it until it locks

into place.

8. Install the socket in the assembly by

aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.Tail light

5. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

6. Remove the bulb by pulling it out.

7. Inset a new bulb by insetring it into the

socket.

8. Install the socket in the assembly by

aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

OMD070035N

OMD070033

OMD070034Turn signalStop/Tail Tail light

Page 352 of 383

Maintenance

64 7

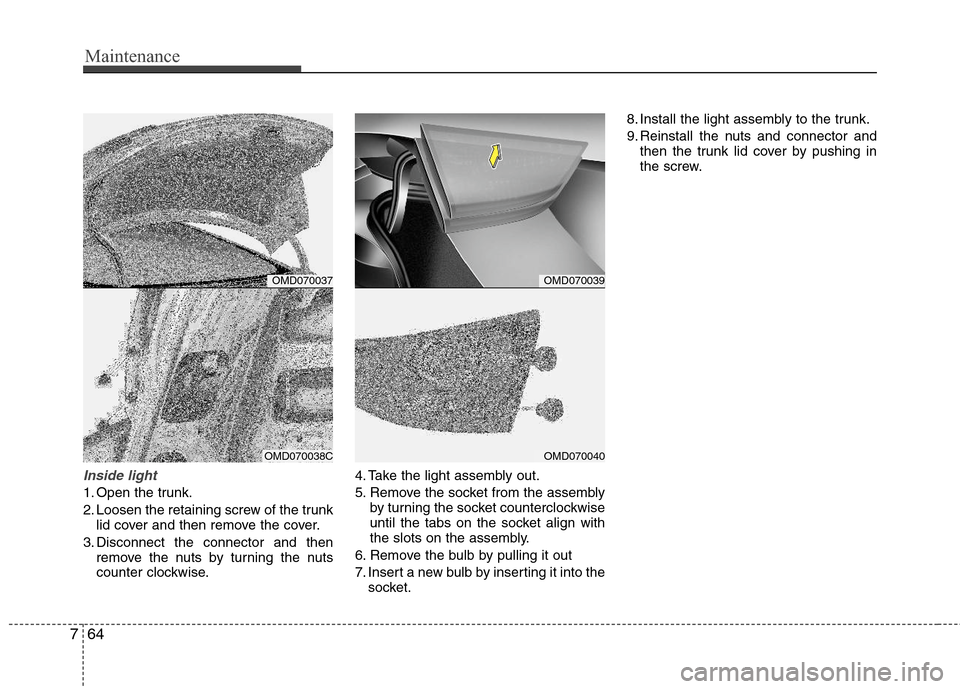

Inside light

1. Open the trunk.

2. Loosen the retaining screw of the trunk

lid cover and then remove the cover.

3. Disconnect the connector and then

remove the nuts by turning the nuts

counter clockwise.4. Take the light assembly out.

5. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

6. Remove the bulb by pulling it out

7. Insert a new bulb by inserting it into the

socket.8. Install the light assembly to the trunk.

9. Reinstall the nuts and connector and

then the trunk lid cover by pushing in

the screw.

OMD070039

OMD070040

OMD070037

OMD070038C

Page 353 of 383

765

Maintenance

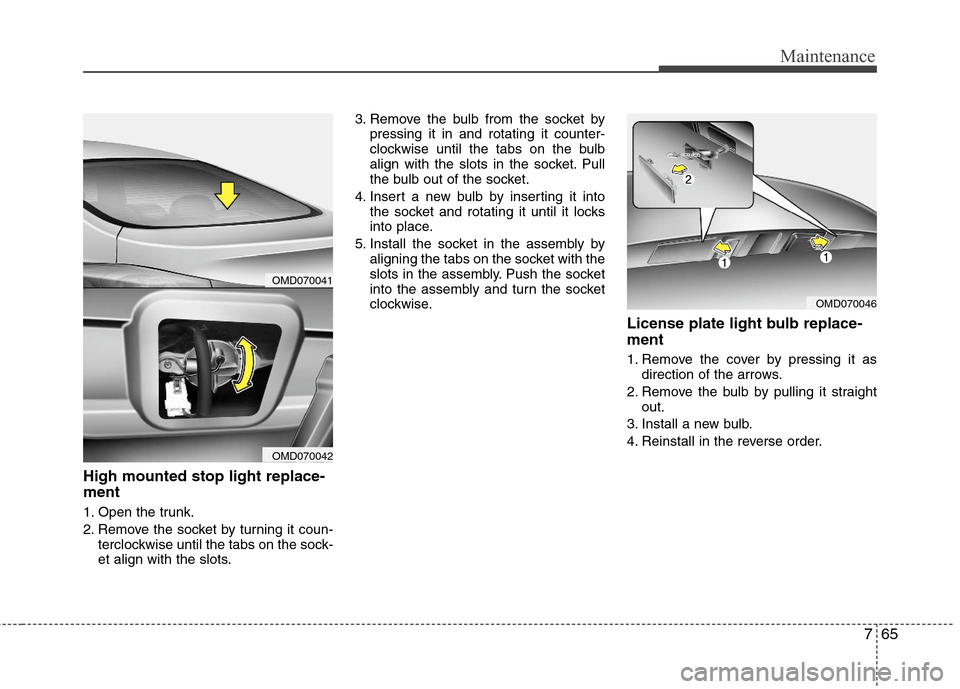

High mounted stop light replace-

ment

1. Open the trunk.

2. Remove the socket by turning it coun-

terclockwise until the tabs on the sock-

et align with the slots.3. Remove the bulb from the socket by

pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.

4. Insert a new bulb by inserting it into

the socket and rotating it until it locks

into place.

5. Install the socket in the assembly by

aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

License plate light bulb replace-

ment

1. Remove the cover by pressing it as

direction of the arrows.

2. Remove the bulb by pulling it straight

out.

3. Install a new bulb.

4. Reinstall in the reverse order.

OMD070046

OMD070041

OMD070042

Page 354 of 383

Maintenance

66 7

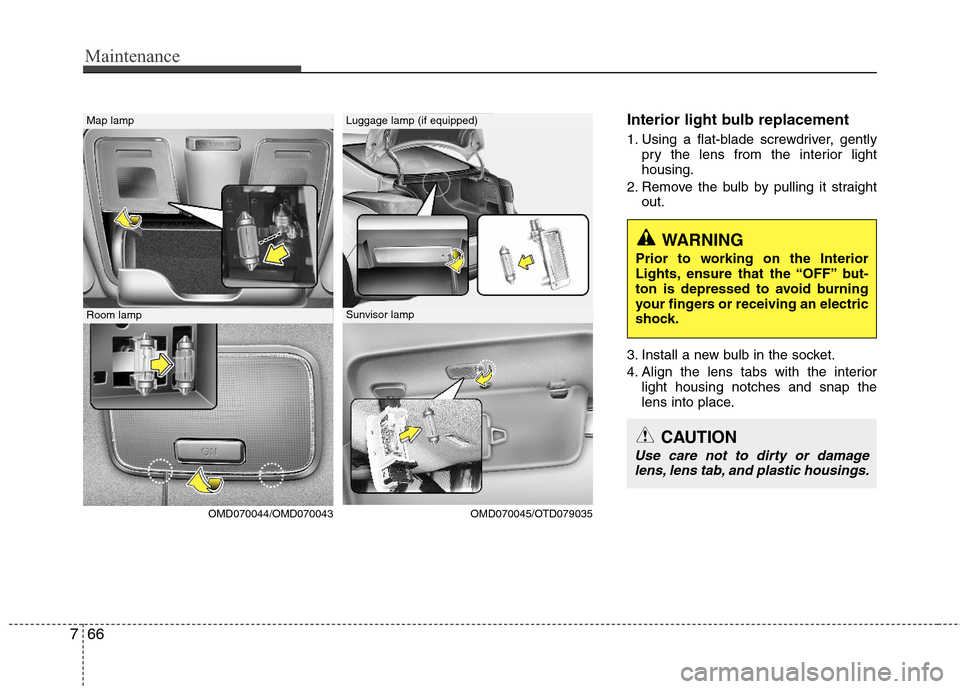

Interior light bulb replacement

1. Using a flat-blade screwdriver, gently

pry the lens from the interior light

housing.

2. Remove the bulb by pulling it straight

out.

3. Install a new bulb in the socket.

4. Align the lens tabs with the interior

light housing notches and snap the

lens into place.

WARNING

Prior to working on the Interior

Lights, ensure that the “OFF” but-

ton is depressed to avoid burning

your fingers or receiving an electric

shock.

CAUTION

Use care not to dirty or damage

lens, lens tab, and plastic housings.

Luggage lamp (if equipped)Map lamp

Sunvisor lamp Room lamp

OMD070044/OMD070043 OMD070045/OTD079035

Page 355 of 383

767

Maintenance

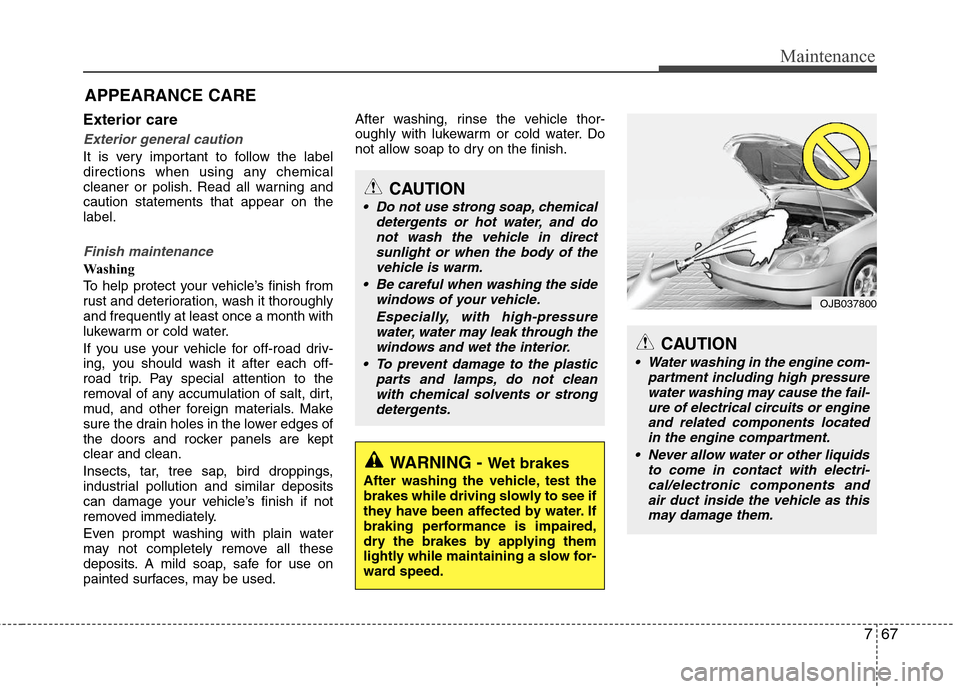

APPEARANCE CARE

Exterior care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning and

caution statements that appear on the

label.

Finish maintenance

Washing

To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are kept

clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.

CAUTION

Do not use strong soap, chemical

detergents or hot water, and do

not wash the vehicle in direct

sunlight or when the body of the

vehicle is warm.

Be careful when washing the side

windows of your vehicle.

Especially, with high-pressure

water, water may leak through the

windows and wet the interior.

To prevent damage to the plastic

parts and lamps, do not clean

with chemical solvents or strong

detergents.

WARNING - Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

CAUTION

Water washing in the engine com-

partment including high pressure

water washing may cause the fail-

ure of electrical circuits or engine

and related components located

in the engine compartment.

Never allow water or other liquids

to come in contact with electri-

cal/electronic components and

air duct inside the vehicle as this

may damage them.

OJB037800

Page 356 of 383

Maintenance

68 7

Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽ ✽

NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

Bright-metal maintenance

To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal

parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal

areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Pay

special attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting.

CAUTION

Wiping dust or dirt off the body

with a dry cloth will scratch the

finish.

Do not use steel wool, abrasive

cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plated

or anodized aluminum parts. This

may result in damage to the pro-

tective coating and cause discol-

oration or paint deterioration.

Page 357 of 383

769

Maintenance

Aluminum wheel maintenance

The aluminum wheels are coated with a

clear protective finish.

Do not use any abrasive cleaner, pol-

ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

Use only a mild soap or neutral deter-

gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

Avoid washing the wheels with high-

speed car wash brushes.

Do not use any cleaners containing

acid or acid detergents. It may damage

and corrode the aluminum wheels

coated with a clear protective finish.

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design and

construction practices to combat corro-

sion, we produce cars of the highest

quality. However, this is only part of the

job. To achieve the long-term corrosion

resistance your vehicle can deliver, the

owner's cooperation and assistance is

also required.

Common causes of corrosion

The most common causes of corrosion

on your car are:

allowed to accumulate underneath the

car.

Removal of paint or protective coatings

by stones, gravel, abrasion or minor

scrapes and dents which leave unpro-

tected metal exposed to corrosion.WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.