Hyundai Elantra 2014 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2014, Model line: Elantra, Model: Hyundai Elantra 2014Pages: 668, PDF Size: 35.58 MB

Page 541 of 668

What to do in an emergency

24

6

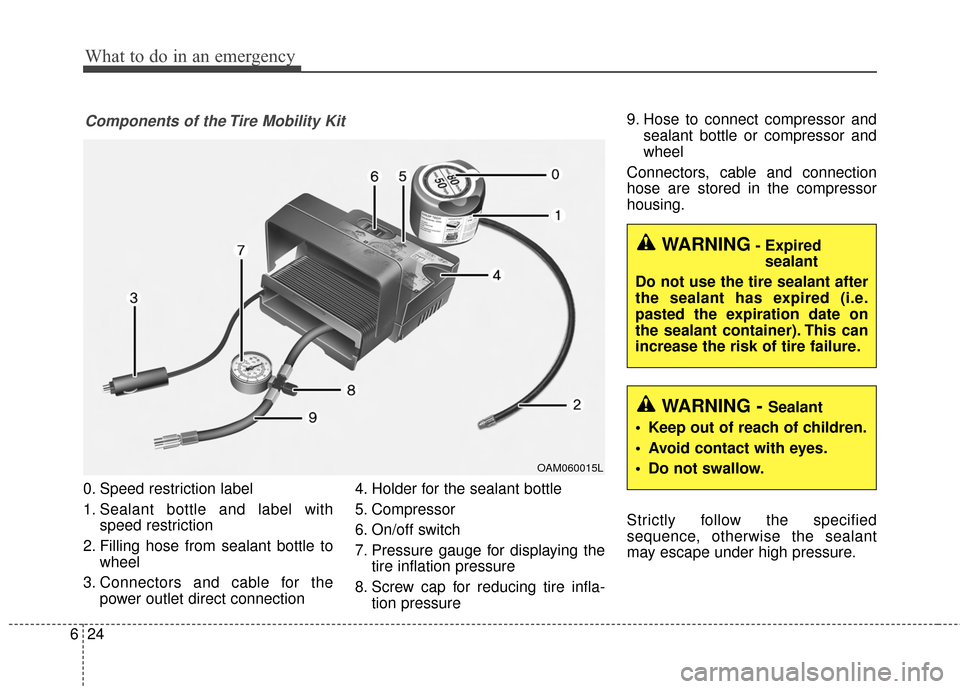

0. Speed restriction label

1. Sealant bottle and label with

speed restriction

2. Filling hose from sealant bottle to wheel

3. Connectors and cable for the power outlet direct connection 4. Holder for the sealant bottle

5. Compressor

6. On/off switch

7. Pressure gauge for displaying the

tire inflation pressure

8. Screw cap for reducing tire infla- tion pressure 9. Hose to connect compressor and

sealant bottle or compressor and

wheel

Connectors, cable and connection

hose are stored in the compressor

housing.

Strictly follow the specified

sequence, otherwise the sealant

may escape under high pressure.

Components of the Tire Mobility Kit

OAM060015L

WARNING- Expired sealant

Do not use the tire sealant after

the sealant has expired (i.e.

pasted the expiration date on

the sealant container). This can

increase the risk of tire failure.

WARNING - Sealant

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

Page 542 of 668

625

What to do in an emergency

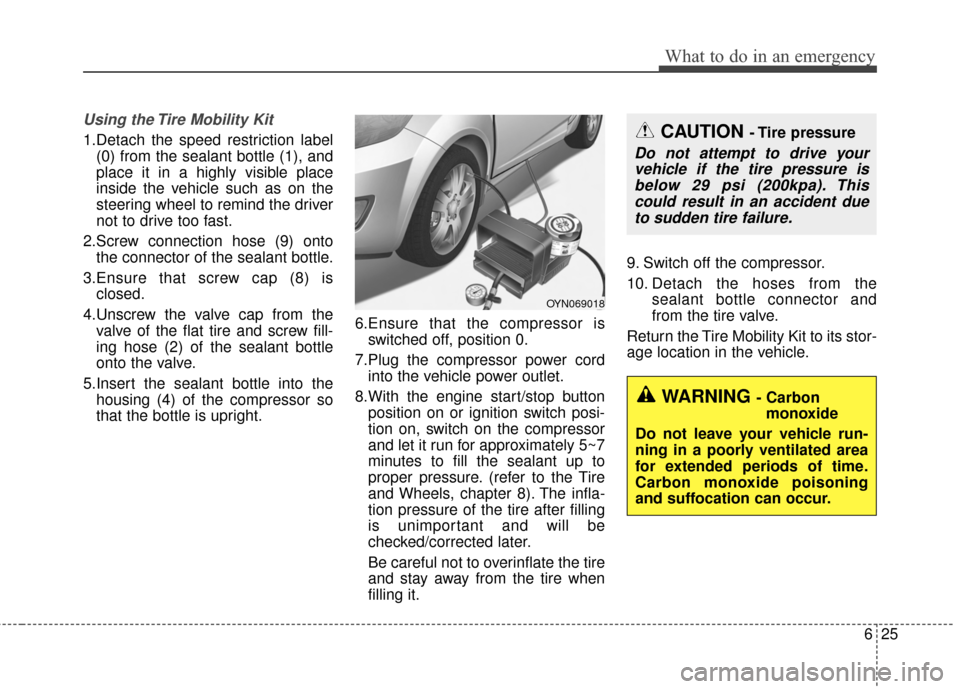

Using the Tire Mobility Kit

1.Detach the speed restriction label(0) from the sealant bottle (1), and

place it in a highly visible place

inside the vehicle such as on the

steering wheel to remind the driver

not to drive too fast.

2.Screw connection hose (9) onto the connector of the sealant bottle.

3.Ensure that screw cap (8) is closed.

4.Unscrew the valve cap from the valve of the flat tire and screw fill-

ing hose (2) of the sealant bottle

onto the valve.

5.Insert the sealant bottle into the housing (4) of the compressor so

that the bottle is upright. 6.Ensure that the compressor is

switched off, position 0.

7.Plug the compressor power cord into the vehicle power outlet.

8.With the engine start/stop button position on or ignition switch posi-

tion on, switch on the compressor

and let it run for approximately 5~7

minutes to fill the sealant up to

proper pressure. (refer to the Tire

and Wheels, chapter 8). The infla-

tion pressure of the tire after filling

is unimportant and will be

checked/corrected later.

Be careful not to overinflate the tire

and stay away from the tire when

filling it. 9. Switch off the compressor.

10. Detach the hoses from the

sealant bottle connector and

from the tire valve.

Return the Tire Mobility Kit to its stor-

age location in the vehicle.

OYN069018

CAUTION - Tire pressure

Do not attempt to drive your vehicle if the tire pressure isbelow 29 psi (200kpa). Thiscould result in an accident dueto sudden tire failure.

WARNING - Carbon monoxide

Do not leave your vehicle run-

ning in a poorly ventilated area

for extended periods of time.

Carbon monoxide poisoning

and suffocation can occur.

Page 543 of 668

What to do in an emergency

26

6

Distributing the sealant

11. Immediately drive approximately

4~6miles (7~10km or about 10

minutes) to evenly distribute the

sealant in the tire.

Do not exceed a speed of 50 mph

(80 km/h). If possible, do not fall

below a speed of 12 mph (20 km/h).

While driving, if you experience any

unusual vibration, ride disturbance or

noise, reduce your speed and drive

with caution until you can safely pull

off of the side of the road.

Call for road side service or towing.

When you use the Tire Mobility Kit,

the tire pressure sensors and wheel

may be damaged by sealant, remove

the sealant stained with tire pressure

sensors and wheel and inspect at an

authorized dealer. Checking the tire inflation pres-

sure

1.After driving approximately

4~6miles (7~10km or about

10 minutes), stop at a safety loca-

tion.

2.Connect connection hose (9) of the compressor directly to the tire

valve.

3.Plug the compressor power cord into the vehicle power outlet.

4.Adjust the tire inflation pressure to the recommended tire inflation.

With the ignition on, proceed as fol-

lows.

- To increase the inflation pressure: Switch on the compressor, posi-

tion I. To check the current infla-

tion pressure setting, briefly

switch off the compressor.

✽ ✽ NOTICE

The pressure gauge may show high-

er than actual reading when the

compressor is running. To get an

accurate tire pressure, the compres-

sor needs to be turned off.

- To reduce the inflation pressure:

Loosen the screw cap (8) on the

compressor hose.

Page 544 of 668

627

What to do in an emergency

Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 15 A

Suitable for use at temperatures:-22 ~ +158°F (-30 ~ +70°C)

Max. working pressure: 87 psi (6 bar)

Size

Compressor: 6.7 x 5.9 x 2.4 in. (170 x 150 x 60 mm)

Sealant bottle: 3.3 x 3.0 ø in. (85 x 77 ø mm)

Compressor weight: 1.8 lbs (0.8 kg)

Sealant volume: 12.2 cu. in. (200 ml)CAUTION - Tire pressuresensor

When you use the Tire MobilityKit including sealant notapproved by HYUNDAI, the tirepressure sensors may be dam-aged by sealant. The sealant onthe tire pressure sensor andwheel should be removed whenyou replace the tire with a newone and inspect the tire pres-sure sensors at an authorizeddealer.

Page 545 of 668

What to do in an emergency

28

6

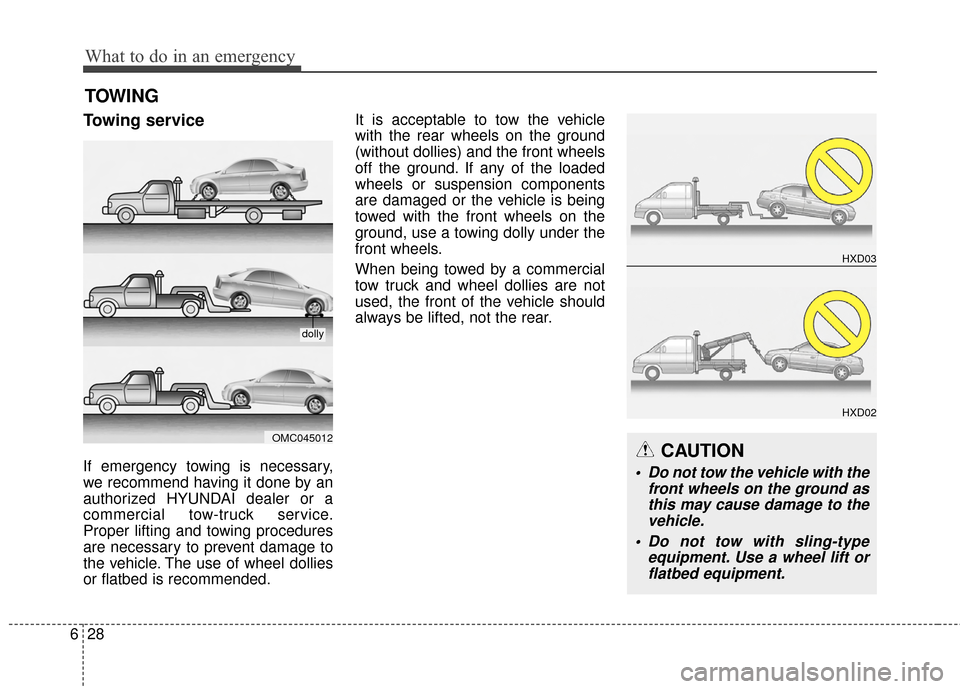

Towing service

If emergency towing is necessary,

we recommend having it done by an

authorized HYUNDAI dealer or a

commercial tow-truck service.

Proper lifting and towing procedures

are necessary to prevent damage to

the vehicle. The use of wheel dollies

or flatbed is recommended. It is acceptable to tow the vehicle

with the rear wheels on the ground

(without dollies) and the front wheels

off the ground. If any of the loaded

wheels or suspension components

are damaged or the vehicle is being

towed with the front wheels on the

ground, use a towing dolly under the

front wheels.

When being towed by a commercial

tow truck and wheel dollies are not

used, the front of the vehicle should

always be lifted, not the rear.

TOWING

OMC045012

HXD03

HXD02

dolly

CAUTION

Do not tow the vehicle with the

front wheels on the ground asthis may cause damage to thevehicle.

Do not tow with sling-type equipment. Use a wheel lift orflatbed equipment.

Page 546 of 668

629

What to do in an emergency

When towing your vehicle in an

emergency without wheel dollies:

1.Place the ignition switch in theACC position.

2.Place the shift lever in N (Neutral).

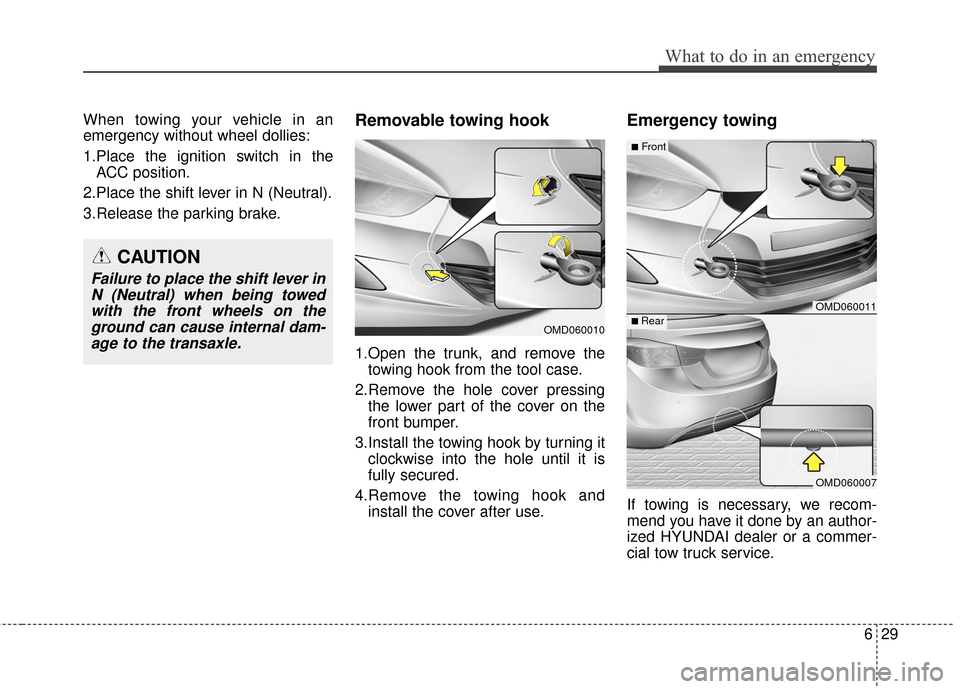

3.Release the parking brake.Removable towing hook

1.Open the trunk, and remove the towing hook from the tool case.

2.Remove the hole cover pressing the lower part of the cover on the

front bumper.

3.Install the towing hook by turning it clockwise into the hole until it is

fully secured.

4.Remove the towing hook and install the cover after use.

Emergency towing

If towing is necessary, we recom-

mend you have it done by an author-

ized HYUNDAI dealer or a commer-

cial tow truck service.

CAUTION

Failure to place the shift lever inN (Neutral) when being towedwith the front wheels on theground can cause internal dam-age to the transaxle.

OMD060010

OMD060011

OMD060007

■Front

■ Rear

Page 547 of 668

What to do in an emergency

30

6

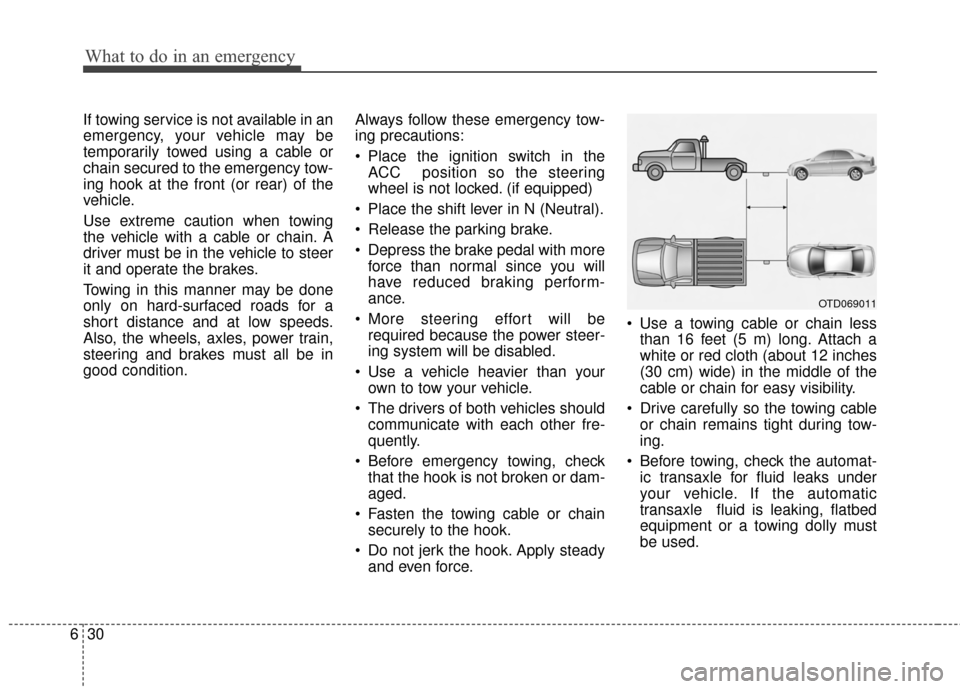

If towing service is not available in an

emergency, your vehicle may be

temporarily towed using a cable or

chain secured to the emergency tow-

ing hook at the front (or rear) of the

vehicle.

Use extreme caution when towing

the vehicle with a cable or chain. A

driver must be in the vehicle to steer

it and operate the brakes.

Towing in this manner may be done

only on hard-surfaced roads for a

short distance and at low speeds.

Also, the wheels, axles, power train,

steering and brakes must all be in

good condition. Always follow these emergency tow-

ing precautions:

Place the ignition switch in the

ACC position so the steering

wheel is not locked. (if equipped)

Place the shift lever in N (Neutral).

Release the parking brake.

Depress the brake pedal with more force than normal since you will

have reduced braking perform-

ance.

More steering effort will be required because the power steer-

ing system will be disabled.

Use a vehicle heavier than your own to tow your vehicle.

The drivers of both vehicles should communicate with each other fre-

quently.

Before emergency towing, check that the hook is not broken or dam-

aged.

Fasten the towing cable or chain securely to the hook.

Do not jerk the hook. Apply steady and even force. Use a towing cable or chain less

than 16 feet (5 m) long. Attach a

white or red cloth (about 12 inches

(30 cm) wide) in the middle of the

cable or chain for easy visibility.

Drive carefully so the towing cable or chain remains tight during tow-

ing.

Before towing, check the automat- ic transaxle for fluid leaks under

your vehicle. If the automatic

transaxle fluid is leaking, flatbed

equipment or a towing dolly must

be used.

OTD069011

Page 548 of 668

631

What to do in an emergency

CAUTION

To avoid damage to your vehicleand vehicle components whentowing:

Always pull straight ahead when using the towing hooks.Do not pull from the side or ata vertical angle.

Do not use the towing hooks to pull a vehicle out of mud,sand or other conditions fromwhich the vehicle cannot bedriven out under its ownpower.

Limit the vehicle speed to 10 mph (15 km/h) and driveless than 1 mile (1.5 km) whentowing to avoid serious dam-age to the automatic transaxle.

Page 549 of 668

Maintenance

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 7-4

• Owner’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

• Owner maintenance precautions . . . . . . . . . . . . . . . . . 7-4

Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

• Owner maintenance schedule. . . . . . . . . . . . . . . . . . . . 7-7

Scheduled maintenance services . . . . . . . . . . . . . . . 7-8

Explanation of scheduled maintenance items . . . 7-26

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

• Checking the engine oil level . . . . . . . . . . . . . . . . . . . 7-30

• Checking the engine oil and filter . . . . . . . . . . . . . . . 7-31

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

• Checking the engine coolant level . . . . . . . . . . . . . . . 7-32

• Changing engine coolant. . . . . . . . . . . . . . . . . . . . . . . 7-34

Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

• Checking the brake/clutch fluid level . . . . . . . . . . . . 7-35

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

• Checking the washer fluid level . . . . . . . . . . . . . . . . . 7-36

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

• Checking the parking brake. . . . . . . . . . . . . . . . . . . . 7-36

Air cleaner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

• Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Climate control air cleaner . . . . . . . . . . . . . . . . . . 7-39

• Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

• Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

• Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

43

• For best battery service . . . . . . . . . . . . . . . . . . . . . . . 7-44

• Battery recharging . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

• Reset features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Tires and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

• Tire care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

7-47

• Recommended cold tire inflation pressures . . . . . . . 7-48

• Check tire inflation pressure . . . . . . . . . . . . . . . . . . . 7-49

• Tire rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

• Wheel alignment and tire balance . . . . . . . . . . . . . . . 7-51

• Tire replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

• Wheel replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

• Tire traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

• Tire maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

• Tire sidewall labeling . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

• Tire terminology and definitions . . . . . . . . . . . . . . . . 7-57

• All season tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

• Summer tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

• Snow tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

60

• Radial-ply tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-61

• Low aspect ratio tires . . . . . . . . . . . . . . . . . . . . . . . . . 7-61

7

Page 550 of 668

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

7-63

• Instrument panel fuse replacement . . . . . . . . . . . . . . 7-64

• Memory fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-65

• Engine compartment panel fuse replacement . . . . . 7-66

• Fuse/relay panel description. . . . . . . . . . . . . . . . . . . . 7-68

Light bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-76

• Headlight, parking light, turn signal light, side marker and front fog light bulb

replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-76

• Side repeater light replacement . . . . . . . . . . . . . . . . . 7-80

• Rear combination light bulb replacement . . . . . . . . 7-81

• High mounted stop light replacement . . . . . . . . . . . . 7-84

• License plate light bulb replacement. . . . . . . . . . . . . 7-85

• Interior light bulb replacement . . . . . . . . . . . . . . . . . 7-85

Appearance care . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-87

• Exterior care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-87

• Interior care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-92

Emission control system . . . . . . . . . . . . . . . . . . . . 7-94

• Crankcase emission control system . . . . . . . . . . . . . . 7-94

• Evaporative emission control system including onboard refueling vapor recovery (ORVR). . . . . . 7-94

• Exhaust emission control system . . . . . . . . . . . . . . . . 7-95

California perchlorate notice . . . . . . . . . . . . . . . . 7-98

7