cooling Hyundai Genesis 2013 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2013, Model line: Genesis, Model: Hyundai Genesis 2013Pages: 429, PDF Size: 8.94 MB

Page 348 of 429

Maintenance

14

7

G050900AUN

Spark plugs

Make sure to install new spark plugs of

the correct heat range.

G051000AEN

Valve clearance (3.8L)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized HYUNDAI dealer should

perform the operation.

G051100AUN

Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

G051200AUN

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

Automatic transmission fluid

Automatic transmission fluid should not be

checked under normal usage conditions.

But in severe conditions, the fluid should

be changed at an authorized HYUNDAI

dealer in accordance to the scheduled

maintenance at the beginning of this

chapter.

✽ ✽

NOTICE

Automatic transmission fluid color is

basically red.

As the vehicle is driven, the automatic

transmission fluid will begin to look

darker.

This is normal condition and you should

not judge the need to replace the fluid

based upon the changed color.

G051500AUN

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

G051600AUN

Brake fluid

Check brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4

specification.

Never mix different types of fluid.

G051700AUN

Parking brake

Inspect the parking brake system includ-

ing the parking brake pedal and cables.CAUTION

The use of a non-specified fluid

could result in transmission mal-function and failure.

Use only specified automatic trans-mission fluid. (Refer to“Recommended lubricants andcapacities” in section 8.)

Page 352 of 429

Maintenance

18

7

G070000AUN

The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at the

beginning of the winter season, and

before traveling to a colder climate.

G070100AEN

Checking the coolant level

ENGINE COOLANT

WARNING

Removing radiator

cap

Never attempt to remove the radi-

ator cap while the engine is oper-

ating or hot. Doing so might lead

to cooling system and engine

damage and could result in seri-

ous personal injury from escap-

ing hot coolant or steam.

Turn the engine off and wait until it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the cool-

ing system. When you are sure all

the pressure has been released,

press down on the cap, using a

thick towel, and continue turning

counterclockwise to remove it.

(Continued)

(Continued)

Even if the engine is not operat-ing, do not remove the radiator

cap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

WARNING

The electric motor

(cooling fan) is con-

trolled by engine

coolant temperature,

refrigerant pressure

and vehicle speed. It may some-

times operate even when the

engine is not running. Use extreme

caution when working near the

blades of the cooling fan so that

you are not injured by a rotating fan

blades. As the engine coolant tem-

perature decreases, the electric

motor will automatically shut off.

This is a normal condition. If your

vehicle is equipped with GDI, the

electric motor (cooling fan) may

operate until you disconnect the

negative battery cable.

Page 353 of 429

719

Maintenance

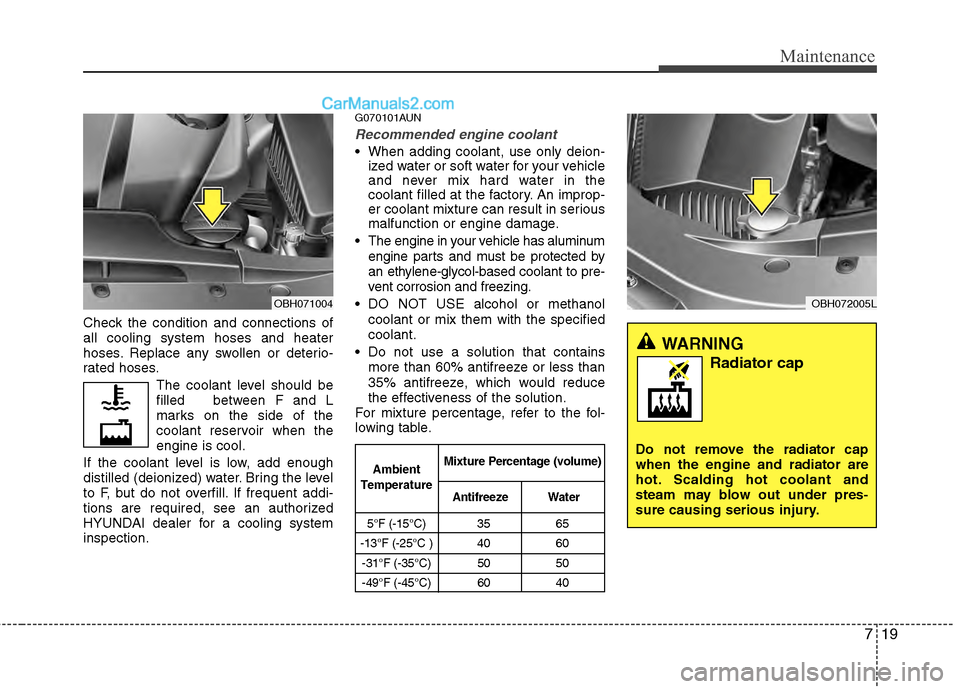

Check the condition and connections of

all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.The coolant level should be

filled between F and L

marks on the side of the

coolant reservoir when the

engine is cool.

If the coolant level is low, add enough

distilled (deionized) water. Bring the level

to F, but do not overfill. If frequent addi-

tions are required, see an authorized

HYUNDAI dealer for a cooling system

inspection.

G070101AUN

Recommended engine coolant

When adding coolant, use only deion- ized water or soft water for your vehicle

and never mix hard water in the

coolant filled at the factory. An improp-

er coolant mixture can result in serious

malfunction or engine damage.

The engine in your vehicle has aluminum engine parts and must be protected by

an ethylene-glycol-based coolant to pre-

vent corrosion and freezing.

DO NOT USE alcohol or methanol coolant or mix them with the specified

coolant.

Do not use a solution that contains more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution.

For mixture percentage, refer to the fol-

lowing table.

5°F (-15°C) 35 65

-13°F (-25°C ) 40 60

-31°F (-35°C) 50 50

-49°F (-45°C) 60 40

Ambient

Temperature Mixture Percentage (volume)

Antifreeze Water

OBH071004

WARNING

Radiator cap

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot coolant and

steam may blow out under pres-

sure causing serious injury.

OBH072005L

Page 391 of 429

757

Maintenance

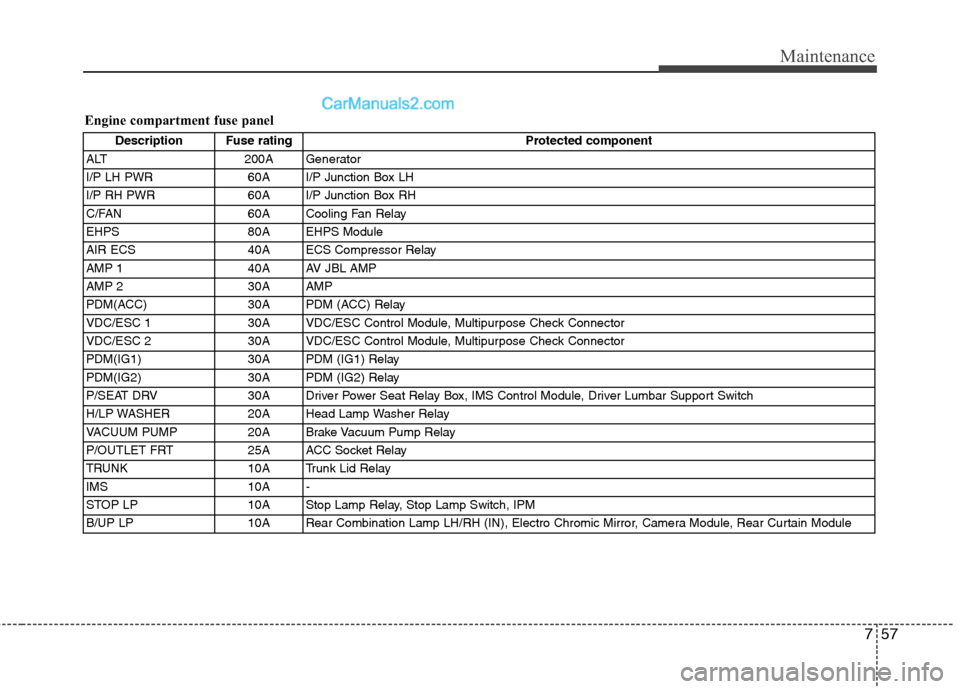

Description Fuse ratingProtected component

ALT 200A Generator

I/P LH PWR 60A I/P Junction Box LH

I/P RH PWR 60A I/P Junction Box RH

C/FAN 60A Cooling Fan Relay

EHPS 80A EHPS Module

AIR ECS 40A ECS Compressor Relay

AMP 1 40A AV JBL AMP

AMP 2 30A AMP

PDM(ACC) 30A PDM (ACC) Relay

VDC/ESC 1 30A VDC/ESC Control Module, Multipurpose Check Connector

VDC/ESC 2 30A VDC/ESC Control Module, Multipurpose Check Connector

PDM(IG1) 30A PDM (IG1) Relay

PDM(IG2) 30A PDM (IG2) Relay

P/SEAT DRV 30A Driver Power Seat Relay Box, IMS Control Module, Driver Lumbar Support Switch

H/LP WASHER 20A Head Lamp Washer Relay

VACUUM PUMP 20A Brake Vacuum Pump Relay

P/OUTLET FRT 25A ACC Socket Relay

TRUNK 10A Trunk Lid Relay

IMS 10A -

STOP LP 10A Stop Lamp Relay, Stop Lamp Switch, IPM

B/UP LP 10A Rear Combination Lamp LH/RH (IN), Electro Chromic Mirror, Camera Module, Rear Curtain Module

Engine compartment fuse panel

Page 393 of 429

759

Maintenance

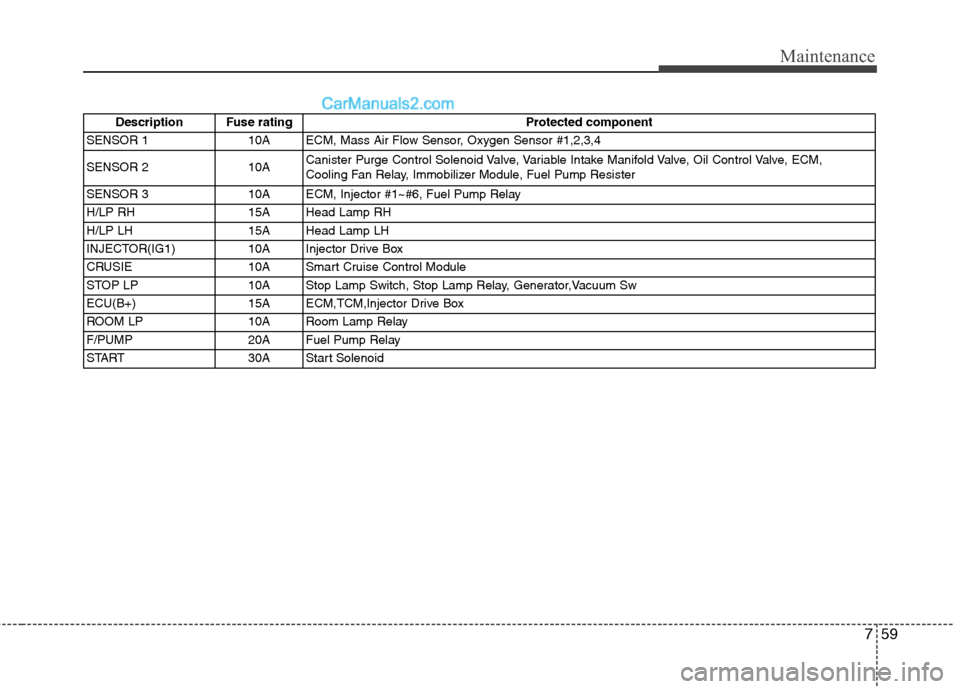

Description Fuse ratingProtected component

SENSOR 110AECM, Mass Air Flow Sensor, Oxygen Sensor #1,2,3,4

SENSOR 2 10A Canister Purge Control Solenoid Valve, Variable Intake Manifold Valve, Oil Control Valve, ECM,

Cooling Fan Relay, Immobilizer Module, Fuel Pump Resister

SENSOR 3 10A ECM, Injector #1~#6, Fuel Pump Relay

H/LP RH 15A Head Lamp RH

H/LP LH 15A Head Lamp LH

INJECTOR(IG1) 10A Injector Drive Box

CRUSIE 10A Smart Cruise Control Module

STOP LP 10A Stop Lamp Switch, Stop Lamp Relay, Generator,Vacuum Sw

ECU(B+) 15A ECM,TCM,Injector Drive Box

ROOM LP 10A Room Lamp Relay

F/PUMP 20A Fuel Pump Relay

START 30A Start Solenoid