check engine light Hyundai Getz 2004 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Getz, Model: Hyundai Getz 2004Pages: 445, PDF Size: 12.16 MB

Page 409 of 445

6- 18 DO-IT-YOURSELF MAINTENANCE

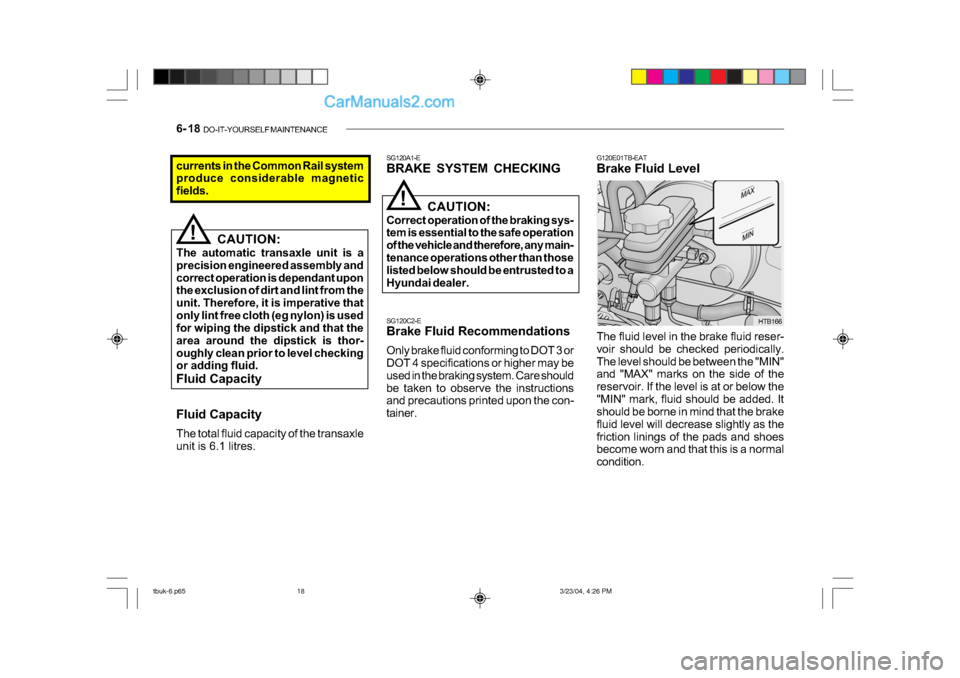

G120E01TB-EAT

Brake Fluid Level

SG120A1-E

BRAKE SYSTEM CHECKINGcurrents in the Common Rail system

produce considerable magnetic

fields.

!

CAUTION:

The automatic transaxle unit is a

precision engineered assembly and

correct operation is dependant upon

the exclusion of dirt and lint from the

unit. Therefore, it is imperative that

only lint free cloth (eg nylon) is used

for wiping the dipstick and that the

area around the dipstick is thor-

oughly clean prior to level checking

or adding fluid.

Fluid Capacity

Fluid Capacity

The total fluid capacity of the transaxle

unit is 6.1 litres. SG120C2-E

Brake Fluid Recommendations

Only brake fluid conforming to DOT 3 or

DOT 4 specifications or higher may be

used in the braking system. Care should

be taken to observe the instructions

and precautions printed upon the con-

tainer.

!

CAUTION:

Correct operation of the braking sys-

tem is essential to the safe operation

of the vehicle and therefore, any main-

tenance operations other than those

listed below should be entrusted to a

Hyundai dealer.

The fluid level in the brake fluid reser-

voir should be checked periodically.

The level should be between the "MIN"

and "MAX" marks on the side of the

reservoir. If the level is at or below the

"MIN" mark, fluid should be added. It

should be borne in mind that the brake

fluid level will decrease slightly as the

friction linings of the pads and shoes

become worn and that this is a normal

condition.

HTB166

tbuk-6.p65 3/23/04, 4:26 PM

18

Page 418 of 445

DO-IT-YOURSELF MAINTENANCE 6- 27

!

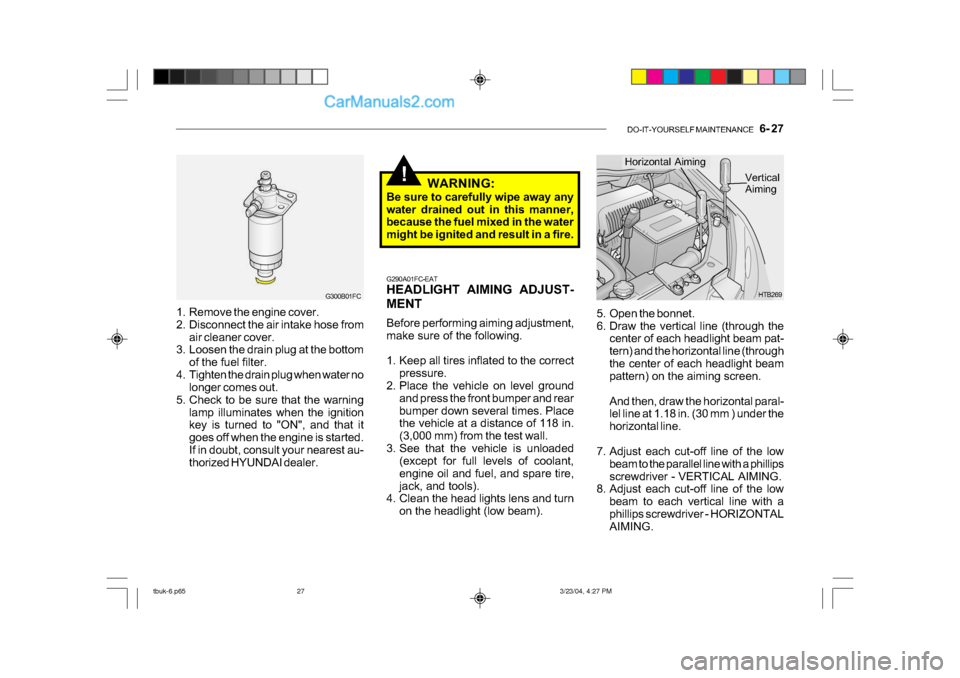

5. Open the bonnet.

6. Draw the vertical line (through the

center of each headlight beam pat-

tern) and the horizontal line (through

the center of each headlight beam

pattern) on the aiming screen.

And then, draw the horizontal paral-

lel line at 1.18 in. (30 mm ) under the

horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips

screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low

beam to each vertical line with a

phillips screwdriver - HORIZONTAL

AIMING. HTB269

Horizontal Aiming

Vertical

Aiming

G290A01FC-EAT

HEADLIGHT AIMING ADJUST-

MENT

Before performing aiming adjustment,

make sure of the following.

1. Keep all tires inflated to the correct pressure.

2. Place the vehicle on level ground

and press the front bumper and rear

bumper down several times. Place

the vehicle at a distance of 118 in.

(3,000 mm) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant,

engine oil and fuel, and spare tire,

jack, and tools).

4. Clean the head lights lens and turn

on the headlight (low beam). WARNING:

Be sure to carefully wipe away any

water drained out in this manner,

because the fuel mixed in the water

might be ignited and result in a fire.

1. Remove the engine cover.

2. Disconnect the air intake hose from air cleaner cover.

3. Loosen the drain plug at the bottom

of the fuel filter.

4. Tighten the drain plug when water no longer comes out.

5. Check to be sure that the warning lamp illuminates when the ignition

key is turned to "ON", and that it

goes off when the engine is started.

If in doubt, consult your nearest au-

thorized HYUNDAI dealer.

G300B01FC

tbuk-6.p65 3/23/04, 4:27 PM

27

Page 442 of 445

10- 2 INDEX

A

AIR BAG ................................................... ................1-30

AIR CONDITIONING SWI TCH ................................. 1-74

AIR CONDITIONING SYSTEM MAINTENANCE .....6-19

AIR CLEANER FILTER ............................................. 6-14

ANTENNA ................................................... ..............1-84

ANTI-LOCK BRAKE SYSTEM .................................. 2-13

ANTI-THEFT ALARM SYSTEM .................................. 1-7

ASHTRAY ................................................... ..............1-54

AUTO FUEL CUT SWITCH...................................... 1-68

AUTOMATIC TRANSAXLE ......................................... 2-9

AUTOMATIC TRANSAXLE FLUID .......................... .6-16

B

BATTERY MAINTENANCE ......................................6-25

BEFORE STARTING THE ENGINE........................... 2-3

BONNET RELEASE .................................................. 1-62

BRAKE PEDAL FREEPLAY ..................................... 6-22

BRAKE SYSTEM CHECKI NG ..................................6-18

C

CARE OF DI SC ................................................. ........1-82

CARE OF SEAT BELTS ........................................... 1-19

CARGO AREA COVER ............................................ 1-66

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ................................................... ... 7-3

CENTRAL DOOR LOCKS .......................................... 1-5

CHANGING A FLAT TYRE ......................................... 3-6 CHILD-PROOF REAR DOOR LOCK

.......................... 1-5

CHILD RESTRAINT SYST EM ..................................1-22

CIGAR LIGHTER ................................................... ...1-53

CLUTCH PEDAL FREEPLAY ...................................6-22

COMBINATION IGNITION SWITCH AND STEERING LOCK ................................................... 2-3

CONSOLE TRAY ................................................... ...1-54

COOLANT TEMPERATURE GAUGE .......................1-44

D

DAILY OPERATING CHECKS .................................... 6-6

DIGITAL CLOCK ........ ............................................... 1-53

DOOR LOCKS ................................................... ......... 1-5

DOOR WINDOWS ................................................... .1-10

DRINK HOLDER ... ................................................... .1-54

DRIVE BELTS ................................................... ........6-23

DRIVING FOR ECONOMY .......................................2-14

E

EFFECTIVE BRAKING ............................................. 2-13

ELECTRIC COOLING FANS ....................................6-25

EMERGENCY TOWI NG ........................................... 3-12

EMISSION CONTROL SYSTEM ................................ 7-2

ENGINE COM PARTMENT......................................... 6-2

ENGINE COOLANT CHECKING AND REPLACI NG ................................................. ........6-10

ENGINE OIL AND FILTER REPLACEMENT .............. 6-9

ENGINE OIL CO NSUMPTION................................... 6-8

tbuk-10.p65 3/23/04, 4:31 PM

2