engine coolant Hyundai Getz 2004 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Getz, Model: Hyundai Getz 2004Pages: 445, PDF Size: 12.16 MB

Page 394 of 445

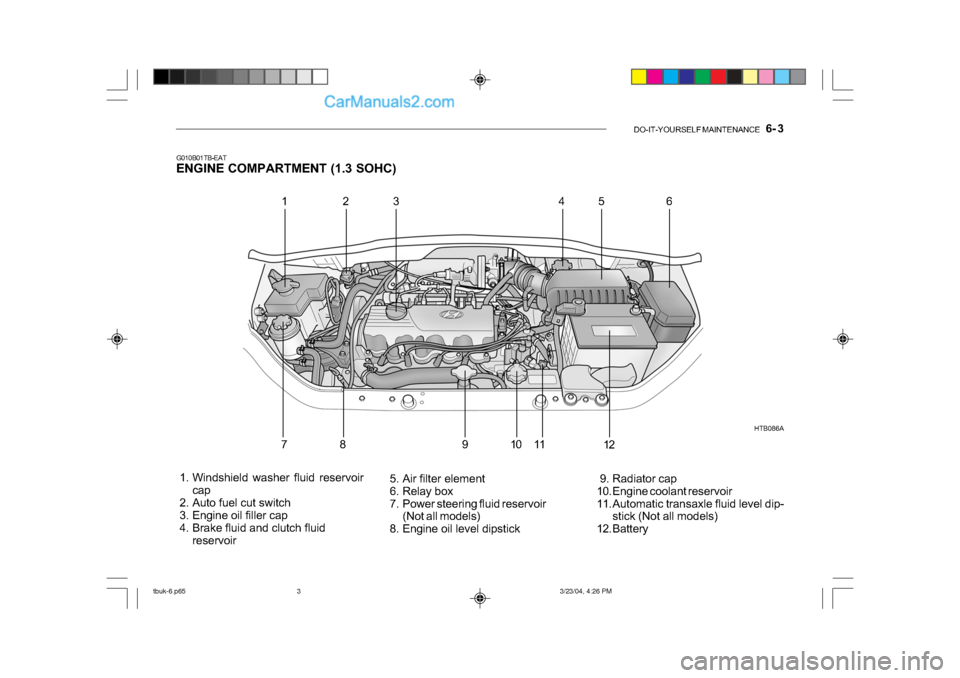

DO-IT-YOURSELF MAINTENANCE 6- 3

G010B01TB-EAT

ENGINE COMPARTMENT (1.3 SOHC)

1. Windshield washer fluid reservoir

cap

2. Auto fuel cut switch

3. Engine oil filler cap

4. Brake fluid and clutch fluid reservoir 5. Air filter element

6. Relay box

7. Power steering fluid reservoir

(Not all models)

8. Engine oil level dipstick 9. Radiator cap

10. Engine coolant reservoir

11. Automatic transaxle fluid level dip-

stick (Not all models)

12. Battery HTB086A

123

456

78 91 011

12

tbuk-6.p65 3/23/04, 4:26 PM

3

Page 395 of 445

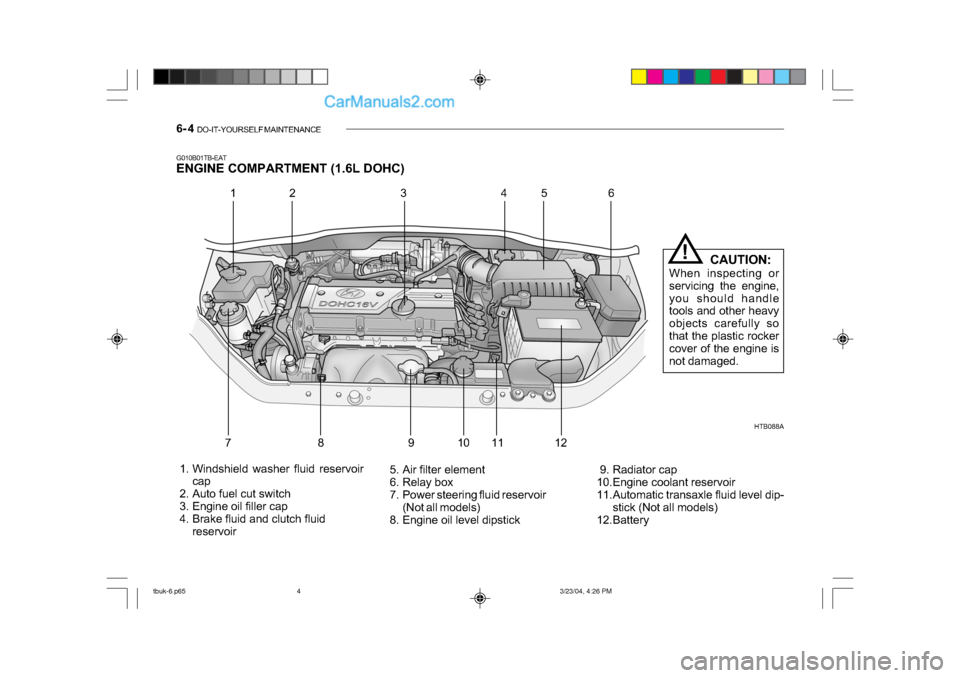

6- 4 DO-IT-YOURSELF MAINTENANCE

G010B01TB-EAT

ENGINE COMPARTMENT (1.6L DOHC)

HTB088A

1. Windshield washer fluid reservoir cap

2. Auto fuel cut switch

3. Engine oil filler cap

4. Brake fluid and clutch fluid reservoir 5. Air filter element

6. Relay box

7. Power steering fluid reservoir

(Not all models)

8. Engine oil level dipstick 9. Radiator cap

10.Engine coolant reservoir

11.Automatic transaxle fluid level dip-

stick (Not all models)

12.Battery

1 2 34

56

789 10 11 12 CAUTION:

When inspecting or

servicing the engine,

you should handle

tools and other heavy

objects carefully so

that the plastic rocker

cover of the engine is

not damaged.

!

tbuk-6.p65 3/23/04, 4:26 PM

4

Page 396 of 445

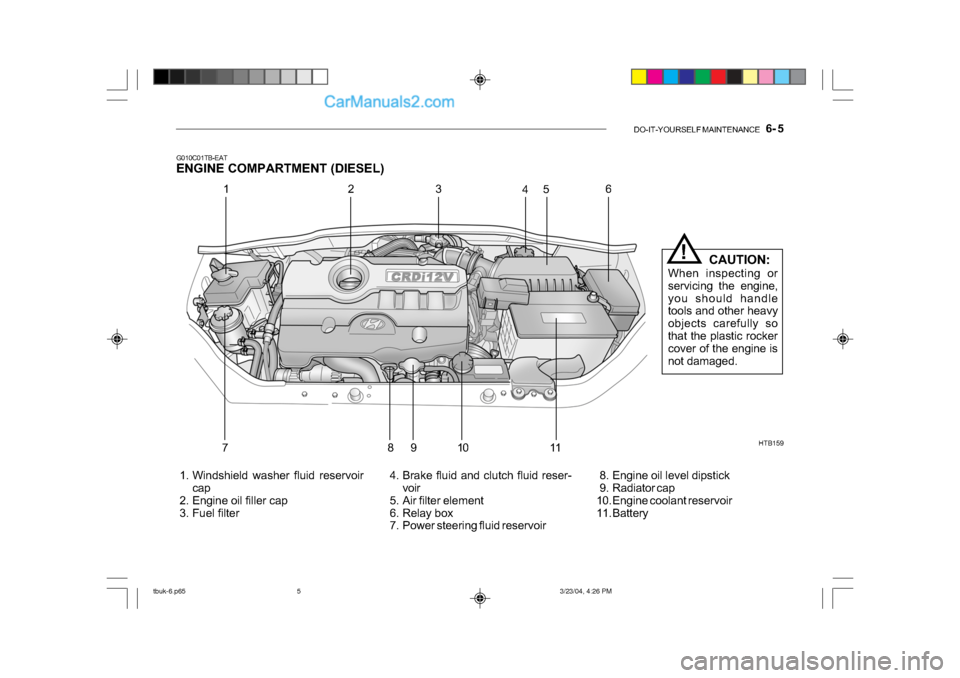

DO-IT-YOURSELF MAINTENANCE 6- 5

G010C01TB-EAT

ENGINE COMPARTMENT (DIESEL)

HTB159

1. Windshield washer fluid reservoir cap

2. Engine oil filler cap

3. Fuel filter 4. Brake fluid and clutch fluid reser-

voir

5. Air filter element

6. Relay box

7. Power steering fluid reservoir 8. Engine oil level dipstick

9. Radiator cap

10. Engine coolant reservoir

11. Battery

12

3

45 6

78 910

11 CAUTION:

When inspecting or

servicing the engine,

you should handle

tools and other heavy

objects carefully so

that the plastic rocker

cover of the engine is

not damaged.

!

tbuk-6.p65 3/23/04, 4:26 PM

5

Page 397 of 445

6- 6 DO-IT-YOURSELF MAINTENANCE

SG020B1-E

DAILY OPERATING CHECKS

The following items should be checked

on a daily basis or whenever the vehicle

is refuelled, whichever occurs sooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all light-

ing equipment.

o Windscreen wiper and washer opera- tion.

o Horn operation.

o Warning light operation.

o Adjustment and cleanliness of mir- rors.

o Seat and seat belt adjustment and operation.

o Fluid leakage.

The vehicle must not be driven if the

daily operating checks indicate that

any item of equipment related to the

safety or roadworthiness of the vehicle

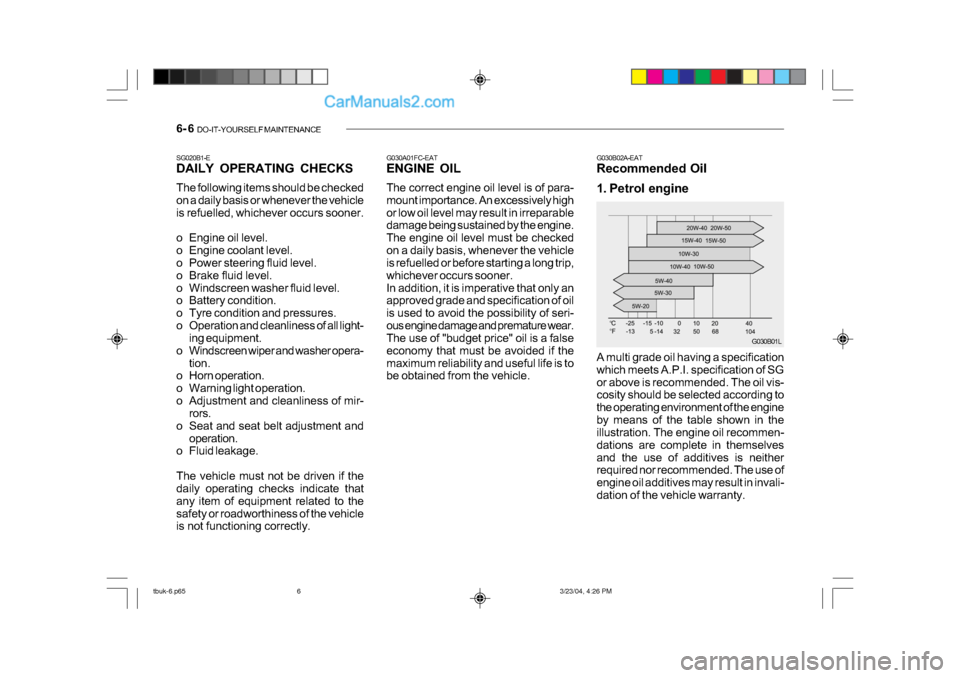

is not functioning correctly. G030B02A-EAT

Recommended Oil

1. Petrol engine

A multi grade oil having a specification

which meets A.P.I. specification of SG

or above is recommended. The oil vis-

cosity should be selected according to

the operating environment of the engine

by means of the table shown in the

illustration. The engine oil recommen-

dations are complete in themselves

and the use of additives is neither

required nor recommended. The use of

engine oil additives may result in invali-

dation of the vehicle warranty.

G030A01FC-EAT

ENGINE OIL

The correct engine oil level is of para-

mount importance. An excessively high

or low oil level may result in irreparable

damage being sustained by the engine.

The engine oil level must be checked

on a daily basis, whenever the vehicle

is refuelled or before starting a long trip,

whichever occurs sooner.

In addition, it is imperative that only an

approved grade and specification of oil

is used to avoid the possibility of seri-

ous engine damage and premature wear.

The use of "budget price" oil is a false

economy that must be avoided if the

maximum reliability and useful life is to

be obtained from the vehicle.

G030B01L

tbuk-6.p65

3/23/04, 4:26 PM

6

Page 401 of 445

6- 10 DO-IT-YOURSELF MAINTENANCE

!

!

HTB170

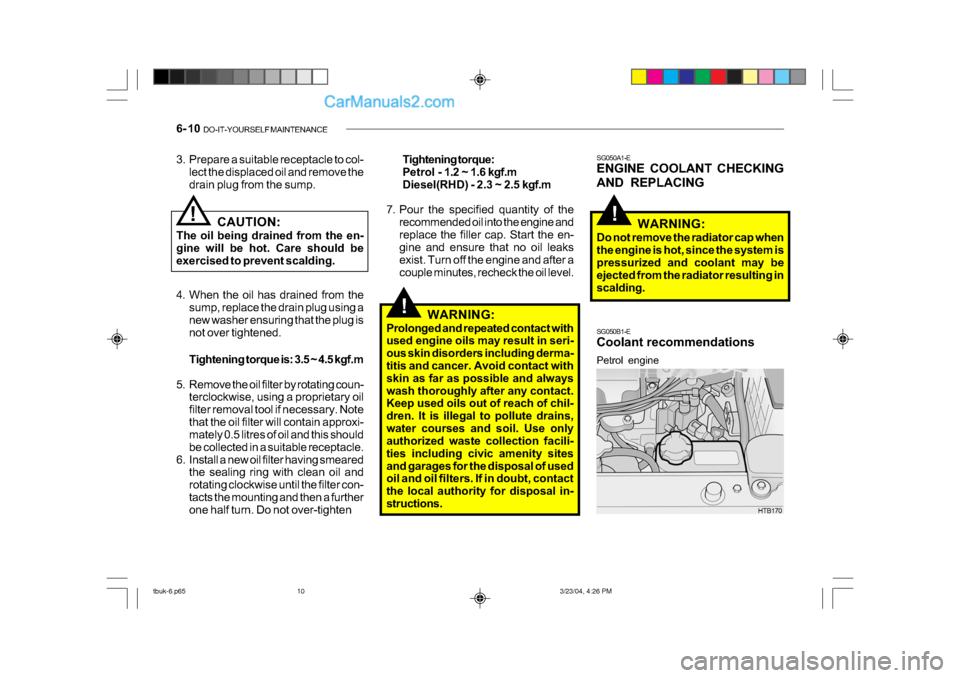

Petrol engine SG050A1-E

ENGINE COOLANT CHECKING

AND REPLACING

SG050B1-E

Coolant recommendations WARNING:

Do not remove the radiator cap when

the engine is hot, since the system is

pressurized and coolant may be

ejected from the radiator resulting in

scalding.

3. Prepare a suitable receptacle to col-

lect the displaced oil and remove the

drain plug from the sump.

4. When the oil has drained from the sump, replace the drain plug using a

new washer ensuring that the plug is

not over tightened.

Tightening torque is: 3.5 ~ 4.5 kgf.m

5. Remove the oil filter by rotating coun- terclockwise, using a proprietary oil

filter removal tool if necessary. Note

that the oil filter will contain approxi-

mately 0.5 litres of oil and this should

be collected in a suitable receptacle.

6. Install a new oil filter having smeared the sealing ring with clean oil and

rotating clockwise until the filter con-

tacts the mounting and then a further

one half turn. Do not over-tighten CAUTION:

The oil being drained from the en-

gine will be hot. Care should be

exercised to prevent scalding.

! Tightening torque:

Petrol -

1.2 ~ 1.6 kgf.m

Diesel(RHD) - 2.3 ~ 2.5 kgf.m

7. Pour the specified quantity of the recommended oil into the engine and

replace the filler cap. Start the en-

gine and ensure that no oil leaks

exist. Turn off the engine and after a

couple minutes, recheck the oil level.

WARNING:

Prolonged and repeated contact with

used engine oils may result in seri-

ous skin disorders including derma-

titis and cancer. Avoid contact with

skin as far as possible and always

wash thoroughly after any contact.

Keep used oils out of reach of chil-

dren. It is illegal to pollute drains,

water courses and soil. Use only

authorized waste collection facili-

ties including civic amenity sites

and garages for the disposal of used

oil and oil filters. If in doubt, contact

the local authority for disposal in-

structions.

tbuk-6.p65 3/23/04, 4:26 PM

10

Page 402 of 445

DO-IT-YOURSELF MAINTENANCE 6- 11

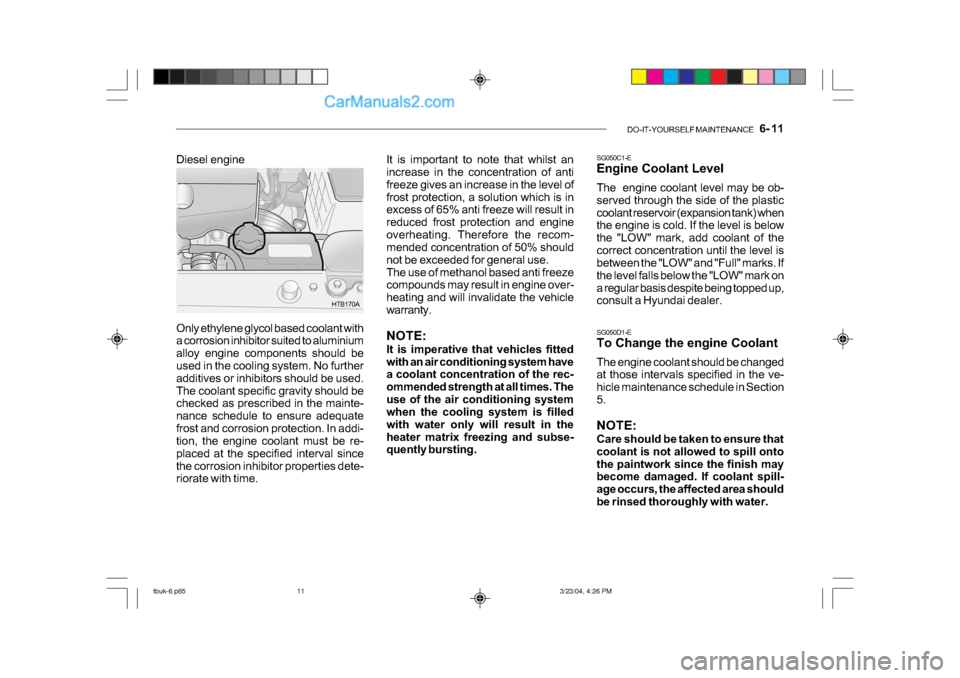

HTB170A

Diesel engine

Only ethylene glycol based coolant with

a corrosion inhibitor suited to aluminium

alloy engine components should be

used in the cooling system. No further

additives or inhibitors should be used.

The coolant specific gravity should be

checked as prescribed in the mainte-

nance schedule to ensure adequate

frost and corrosion protection. In addi-

tion, the engine coolant must be re-

placed at the specified interval since

the corrosion inhibitor properties dete-

riorate with time. It is important to note that whilst an

increase in the concentration of anti

freeze gives an increase in the level of

frost protection, a solution which is in

excess of 65% anti freeze will result in

reduced frost protection and engine

overheating. Therefore the recom-

mended concentration of 50% should

not be exceeded for general use.

The use of methanol based anti freeze

compounds may result in engine over-

heating and will invalidate the vehicle

warranty.

NOTE:

It is imperative that vehicles fitted

with an air conditioning system have

a coolant concentration of the rec-

ommended strength at all times. The

use of the air conditioning system

when the cooling system is filled

with water only will result in the

heater matrix freezing and subse-

quently bursting.

SG050C1-E

Engine Coolant Level

The engine coolant level may be ob-

served through the side of the plastic

coolant reservoir (expansion tank) when

the engine is cold. If the level is below

the "LOW" mark, add coolant of the

correct concentration until the level is

between the "LOW" and "Full" marks. If

the level falls below the "LOW" mark on

a regular basis despite being topped up,

consult a Hyundai dealer.

SG050D1-E

To Change the engine Coolant

The engine coolant should be changed

at those intervals specified in the ve-

hicle maintenance schedule in Section

5.

NOTE:

Care should be taken to ensure that

coolant is not allowed to spill onto

the paintwork since the finish may

become damaged. If coolant spill-

age occurs, the affected area should

be rinsed thoroughly with water.

tbuk-6.p65

3/23/04, 4:26 PM

11

Page 403 of 445

6- 12 DO-IT-YOURSELF MAINTENANCE

!

HTB172

HTB171

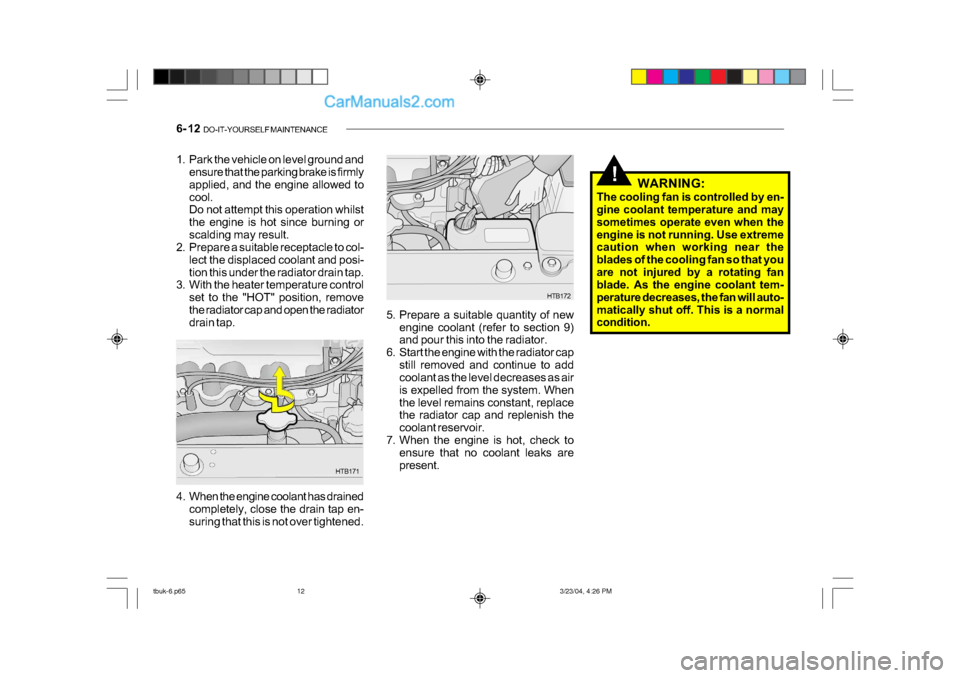

1. Park the vehicle on level ground and

ensure that the parking brake is firmly

applied, and the engine allowed to

cool.

Do not attempt this operation whilst

the engine is hot since burning or

scalding may result.

2. Prepare a suitable receptacle to col-

lect the displaced coolant and posi-

tion this under the radiator drain tap.

3. With the heater temperature control

set to the "HOT" position, remove

the radiator cap and open the radiator

drain tap. 5. Prepare a suitable quantity of new

engine coolant (refer to section 9)

and pour this into the radiator.

6. Start the engine with the radiator cap

still removed and continue to add

coolant as the level decreases as air

is expelled from the system. When

the level remains constant, replace

the radiator cap and replenish the

coolant reservoir.

7. When the engine is hot, check to ensure that no coolant leaks are

present.

4. When the engine coolant has drained completely, close the drain tap en-

suring that this is not over tightened. WARNING:

The cooling fan is controlled by en-

gine coolant temperature and may

sometimes operate even when the

engine is not running. Use extreme

caution when working near the

blades of the cooling fan so that you

are not injured by a rotating fan

blade. As the engine coolant tem-

perature decreases, the fan will auto-

matically shut off. This is a normal

condition.

tbuk-6.p65 3/23/04, 4:26 PM

12

Page 406 of 445

DO-IT-YOURSELF MAINTENANCE 6- 15

!

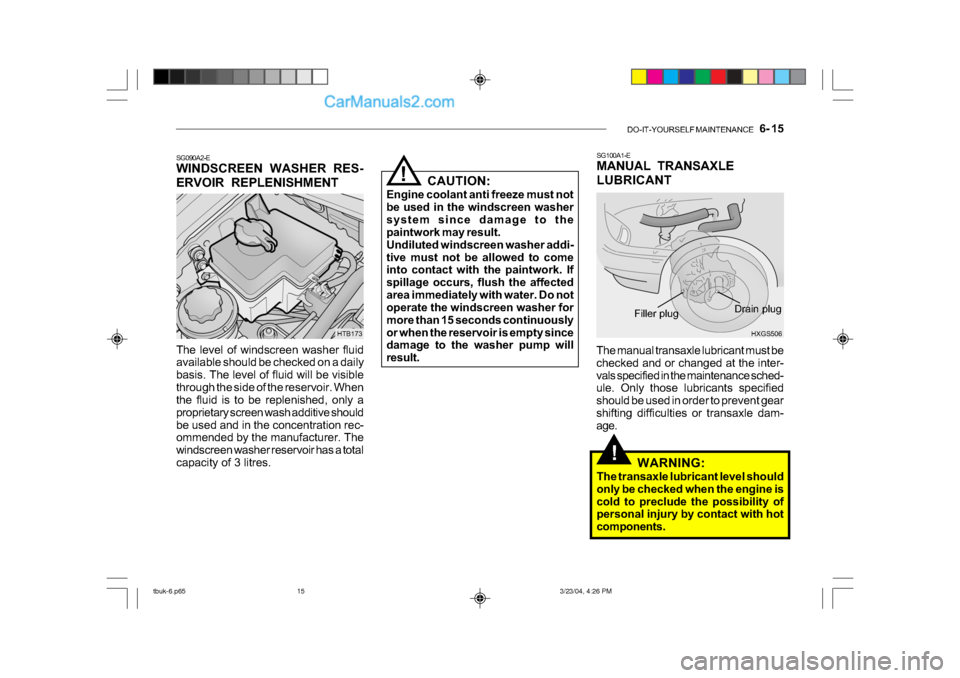

SG100A1-E

MANUAL TRANSAXLE

LUBRICANT

SG090A2-E

WINDSCREEN WASHER RES-

ERVOIR REPLENISHMENT

The level of windscreen washer fluid

available should be checked on a daily

basis. The level of fluid will be visible

through the side of the reservoir. When

the fluid is to be replenished, only a

proprietary screen wash additive should

be used and in the concentration rec-

ommended by the manufacturer. The

windscreen washer reservoir has a total

capacity of 3 litres. CAUTION:

Engine coolant anti freeze must not

be used in the windscreen washer

system since damage to the

paintwork may result.

Undiluted windscreen washer addi-

tive must not be allowed to come

into contact with the paintwork. If

spillage occurs, flush the affected

area immediately with water. Do not

operate the windscreen washer for

more than 15 seconds continuously

or when the reservoir is empty since

damage to the washer pump will

result.

!

HTB173

HXGS506

Drain plug

Filler plug

The manual transaxle lubricant must be

checked and or changed at the inter-

vals specified in the maintenance sched-

ule. Only those lubricants specified

should be used in order to prevent gear

shifting difficulties or transaxle dam-

age.

WARNING:

The transaxle lubricant level should

only be checked when the engine is

cold to preclude the possibility of

personal injury by contact with hot

components.

tbuk-6.p65 3/23/04, 4:26 PM

15

Page 408 of 445

DO-IT-YOURSELF MAINTENANCE 6- 17

!

!

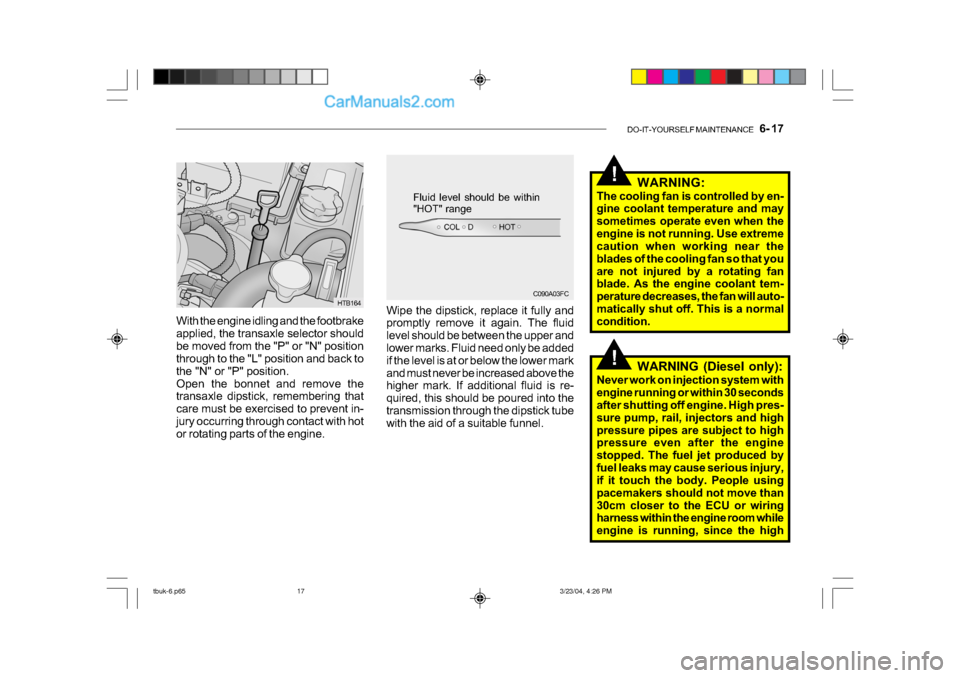

With the engine idling and the footbrake

applied, the transaxle selector should

be moved from the "P" or "N" position

through to the "L" position and back to

the "N" or "P" position.

Open the bonnet and remove the

transaxle dipstick, remembering that

care must be exercised to prevent in-

jury occurring through contact with hot

or rotating parts of the engine.

C090A03FC

Fluid level should be within

"HOT" range

HTB164 Wipe the dipstick, replace it fully and

promptly remove it again. The fluid

level should be between the upper and

lower marks. Fluid need only be added

if the level is at or below the lower mark

and must never be increased above the

higher mark. If additional fluid is re-

quired, this should be poured into the

transmission through the dipstick tube

with the aid of a suitable funnel. WARNING:

The cooling fan is controlled by en-

gine coolant temperature and may

sometimes operate even when the

engine is not running. Use extreme

caution when working near the

blades of the cooling fan so that you

are not injured by a rotating fan

blade. As the engine coolant tem-

perature decreases, the fan will auto-

matically shut off. This is a normal

condition.

WARNING (Diesel only):

Never work on injection system with

engine running or within 30 seconds

after shutting off engine. High pres-

sure pump, rail, injectors and high

pressure pipes are subject to high

pressure even after the engine

stopped. The fuel jet produced by

fuel leaks may cause serious injury,

if it touch the body. People using

pacemakers should not move than

30cm closer to the ECU or wiring

harness within the engine room while

engine is running, since the high

tbuk-6.p65 3/23/04, 4:26 PM

17

Page 416 of 445

DO-IT-YOURSELF MAINTENANCE 6- 25

!

!

o If battery electrolyte is spilled onto

skin or into eyes, the effected area

must be flushed with copious

amounts of water and medical assis-

tance sought.

o If battery electrolyte is ingested, copious amounts of water or milk

followed by an ant-acid (raw egg or

milk of magnesia) must be drunk.

Vomiting should not be induced and

medical assistance must be sought.

o Batteries must only be charged in well venti-lated areas from which

naked lights or sources of sparks are

excluded.

o Ensure that children, pets or other unauthorized persons are kept away

from batteries.

o Do not allow anything to bridge the positive (+) and negative (-) termi-

nals of the battery.

o Never invert the battery.

The battery fitted during production is of

the "Maintenance Free" type.

SG210A1-E

BATTERY MAINTENANCE

WARNING:

Motor vehicle batteries contain

sulphuric acid which is corrosive

and poisonous. Hydrogen gas is

emitted from the battery which is

explosive when combined with oxy-

gen. The following precautions must

be strictly observed to avoid per-

sonal injury or damage to the ve-

hicle.

HTB165 SG220A1-E

ELECTRIC COOLING FANS

WARNING:

The cooling fan is controlled by en-

gine coolant temperature and may

sometimes operate even when the

engine is not running. Use extreme

caution when working near the

blades of the cooling fan so that you

are not injured by a rotating fan

blade. As the engine coolant tem-

perature decreases, the fan will auto-

matically shut off. This is a normal

condition.

The engine cooling fan should operate

before the temperature gauge reaches

the upper portion of the scale and the

condenser fan should operate when-

ever the air conditioning is in use.

tbuk-6.p65 3/23/04, 4:27 PM

25