engine Hyundai Getz 2005 Manual PDF

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2005, Model line: Getz, Model: Hyundai Getz 2005Pages: 437, PDF Size: 11.19 MB

Page 162 of 437

DO-IT-YOURSELF MAINTENANCE 6- 17

!

!

With the engine idling and the footbrake applied, the transaxle selector shouldbe moved from the "P" or "N" position through to the "L" position and back to the "N" or "P" position.Open the bonnet and remove the transaxle dipstick, remembering that care must be exercised to prevent in-jury occurring through contact with hot or rotating parts of the engine.

C090A03FC

Fluid level should be within "HOT" range

HTB164 Wipe the dipstick, replace it fully and promptly remove it again. The fluid level should be between the upper and lower marks. Fluid need only be added if the level is at or below the lower markand must never be increased above the higher mark. If additional fluid is re- quired, this should be poured into thetransmission through the dipstick tube with the aid of a suitable funnel. WARNING:

The cooling fan is controlled by en-gine coolant temperature and may sometimes operate even when theengine is not running. Use extreme caution when working near the blades of the cooling fan so that youare not injured by a rotating fan blade. As the engine coolant tem- perature decreases, the fan will auto-matically shut off. This is a normal condition.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 seconds after shutting off engine. High pres- sure pump, rail, injectors and highpressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced byfuel leaks may cause serious injury, if it touch the body. People using pacemakers should not move than30cm closer to the ECU or wiring harness within the engine room while engine is running, since the high

Page 163 of 437

6- 18 DO-IT-YOURSELF MAINTENANCE

G120E01TB-EAT Brake Fluid Level

SG120A1-EBRAKE SYSTEM CHECKINGcurrents in the Common Rail system produce considerable magnetic fields.

!

CAUTION:

The automatic transaxle unit is a precision engineered assembly andcorrect operation is dependant upon the exclusion of dirt and lint from the unit. Therefore, it is imperative thatonly lint free cloth (eg nylon) is used for wiping the dipstick and that the area around the dipstick is thor-oughly clean prior to level checking or adding fluid. Fluid Capacity The total fluid capacity of the transaxle unit is 6.1 litres. SG120C2-E Brake Fluid Recommendations Only brake fluid conforming to DOT 3 or DOT 4 specifications or higher may be used in the braking system. Care shouldbe taken to observe the instructions and precautions printed upon the con- tainer.

!

CAUTION:

Correct operation of the braking sys- tem is essential to the safe operation of the vehicle and therefore, any main-tenance operations other than those listed below should be entrusted to a Hyundai authorised repairer.

The fluid level in the brake fluid reser-voir should be checked periodically.The level should be between the "MIN" and "MAX" marks on the side of the reservoir. If the level is at or below the"MIN" mark, fluid should be added. It should be borne in mind that the brake fluid level will decrease slightly as thefriction linings of the pads and shoes become worn and that this is a normal condition.

HTB166

Page 165 of 437

6- 20 DO-IT-YOURSELF MAINTENANCE

B145A01TB-EAT CHANGING THE POLLEN FIL-

TER (In Front of evaporator unit)(Not all models) The pollen filter is located in front of the evaporator unit behind the glove box. It operates to decrease pollutants fromentering the car and to filter the air.

1. Remove the adjusting pins on both

sides of the glove box to open half the glove box.

HTB290-D

SG140D1-E Off Season Maintenance The air conditioning must be run for ten minutes or so weekly during periodswhen the system would not normally be used to ensure that the compressor and seals are lubricated. If this precautionis not observed the compressor seals may become stuck to the compressor shaft and damaged when the system isnext used resulting in a loss of refriger- ant and damage to the compressor.

SG140C1-E Checking the Refrigerant

1. Start the engine and run at idle for

several minutes with the refrigera- tion system running at the coldest setting.

2. Open the bonnet and inspect the sight glass on the top of the receiverdryer.

3. If the refrigerant charge is insuffi- cient, a flow of bubbles will be ob-served through the sight glass.

4. If the refrigerant charge is satisfac- tory, no bubbles will be observedthrough the sight glass. CAUTION:

Running the air conditioning systemwith a low refrigerant level may dam-age the compressor.

!

The air conditioning compressor drive belt should be checked to ensure free- dom from damage or excessive wearand correct tension. The belt tension is correct when the belt deflects by about 0.3 inches (8 mm) (1.1L: 5 ~ 5.5 mm)when a force of 98 N is applied to the belt halfway between the compressor and crankshaft pulleys. Adjustment ofthe belt should be entrusted to a Hyundai authorised repairer.

Page 167 of 437

6- 22 DO-IT-YOURSELF MAINTENANCE

G180A01A-GAT CHECKING BRAKE PEDAL CLEARANCE

G180A01L

1.78 in. (45.1 mm)

You need a helper to check the brake pedal clearance. With the engine run- ning, have your helper press down on the brake pedal several times and thenhold it down with a force of about 490 N (50 Kg, 110 lbs). The brake pedal clearance is the distance from the topsurface of the brake pedal to the as- phalt sheeting under the floor mat. If the brake pedal clearance is notwithin the limits specified in the illustra- tion, have it inspected by your Hyundai authorised repairer and adjusted orrepairered if necessary.SG170A1-E BRAKE PEDAL FREEPLAY

HXGS508

0.12 ~ 0.31 in. (3 ~ 8 mm)

The brake pedal freeplay should be checked with the engine turned off. Thepedal to floor clearance should be checked with the engine running and a load of 490 N applied to the pedal. Ifeither value is incorrect, the necessary adjustment should be performed by a Hyundai authorised repairer. Pedal tofloor clearance: 1.97 in. (50 mm)SG160A1-E CLUTCH PEDAL FREEPLAY

G160A01E

0.24 ~ 0.51 in. (6 ~ 13 mm)

The clutch pedal freeplay should be checked against the specified value. If the freeplay is not correct, the clutch should be adjusted by a Hyundaiauthorised repairer.

Page 168 of 437

DO-IT-YOURSELF MAINTENANCE 6- 23

The various engine drive belts must be checked for condition, tension and free- dom from damage and excessive wear.The tension of a new belt must be checked after thirty minutes running following fitment of the new belt to allowfor the initial belt stretch. G190B01TB-GAT CHECKING DRIVE BELTS (Diesel)

A/C comp.

Auto tensioner Pulley

G190B01TB

AlternatorPower steering pump

At the scheduled maintenance inspec- tion, belts should be examined forcracks, wear, fraying or other evidence of deterioration and replaced if neces- sary.Belt routing should also be checked to be sure there is no interference be- tween the belts and other parts of theengine.

Crankshaft Pulley

SG190A1-E DRIVE BELTS (Gasoline)

1.1L

1.3L/1.6L Alternator

0.37 ~ 0.43 in. (9.5 ~11.0 mm)

Water Pump Pulley

Alternator Pulley

0.2~0.24 in.(5.1~6 mm)

HTB186

Crankshaft pulley

HTB220

Water Pump Pulley

Page 170 of 437

DO-IT-YOURSELF MAINTENANCE 6- 25

!

!

o If battery electrolyte is spilled onto

skin or into eyes, the effected area must be flushed with copiousamounts of water and medical assis- tance sought.

o If battery electrolyte is ingested, copious amounts of water or milkfollowed by an ant-acid (raw egg or milk of magnesia) must be drunk.Vomiting should not be induced and medical assistance must be sought.

o Batteries must only be charged in well venti-lated areas from whichnaked lights or sources of sparks are excluded.

o Ensure that children, pets or other unauthorized persons are kept awayfrom batteries.

o Do not allow anything to bridge the positive (+) and negative (-) termi-nals of the battery.

o Never invert the battery. The battery fitted during production is of the "Maintenance Free" type.

SG210A1-E BATTERY MAINTENANCE

WARNING:

Motor vehicle batteries contain sulphuric acid which is corrosive and poisonous. Hydrogen gas isemitted from the battery which is explosive when combined with oxy- gen. The following precautions mustbe strictly observed to avoid per- sonal injury or damage to the ve- hicle.

HTB165 SG220A1-E ELECTRIC COOLING FANS

WARNING:

The cooling fan is controlled by en- gine coolant temperature and maysometimes operate even when the engine is not running. Use extreme caution when working near theblades of the cooling fan so that you are not injured by a rotating fan blade. As the engine coolant tem-perature decreases, the fan will auto- matically shut off. This is a normal condition. The engine cooling fan should operate before the temperature gauge reachesthe upper portion of the scale and the condenser fan should operate when- ever the air conditioning is in use.

Page 171 of 437

6- 26 DO-IT-YOURSELF MAINTENANCE

HTB287

SG230B1-E POWER STEERING HOSES Power steering hoses should be checked for damage, deterioration andleakage at each service.

steering fluid level is between the "MAX" and "MIN" level markings on the fluid reservoir. NOTE: Grinding noise from power steering pump may be heard immediatelyafter the engine is started in extremely

cold condition (below -4°F). If the noise stops during warm up, there isno abnormal function in the system. This is due to a power steering fluid characteristic in extremely cold con-ditions. FLUID RECOMMENDATION Only automatic transmission fluid meet- ing the specification of Dexron 2 shouldbe used in the power steering system.

G300A01TB-GAT REMOVAL OF WATER FROM THE FUEL FILTER(DIESEL ENGINE) If the fuel filter warning lamp illuminates during driving, it indicates that waterhas accumulated in the fuel filter. If this occurs, remove the water as described.

SG230A2-E POWER STEERING FLUID LEVEL The power steering fluid level should be checked daily.To check the power steering fluid level, be sure the ignition is "OFF", then check to make certain that the power

HTB163

Page 172 of 437

DO-IT-YOURSELF MAINTENANCE 6- 27

!

5. Open the bonnet.

6. Draw the vertical line (through the

center of each headlight beam pat-tern) and the horizontal line (throughthe center of each headlight beam pattern) on the aiming screen. And then, draw the horizontal paral- lel line at 1.18 in. (30 mm ) under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillipsscrewdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low

beam to each vertical line with aphillips screwdriver - HORIZONTAL AIMING. HTB269

Horizontal Aiming

Vertical Aiming

G290A01FC-EAT HEADLIGHT AIMING ADJUST- MENT Before performing aiming adjustment, make sure of the following.

1. Keep all tyres inflated to the correct pressure.

2. Place the vehicle on level ground

and press the front bumper and rear bumper down several times. Place the vehicle at a distance of 118 in. (3,000 mm) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant,engine oil and fuel, and spare tyre,jack, and tools).

4. Clean the head lights lens and turn

on the headlight (low beam). WARNING:

Be sure to carefully wipe away anywater drained out in this manner, because the fuel mixed in the water might be ignited and result in a fire.

1. Remove the engine cover.

2. Disconnect the air intake hose from air cleaner cover.

3. Loosen the drain plug at the bottom

of the fuel filter.

4. Tighten the drain plug when water no longer comes out.

5. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started.If in doubt, consult your nearest Hyundai authorised repairer.

G300B01FC

Page 179 of 437

6- 34 DO-IT-YOURSELF MAINTENANCE

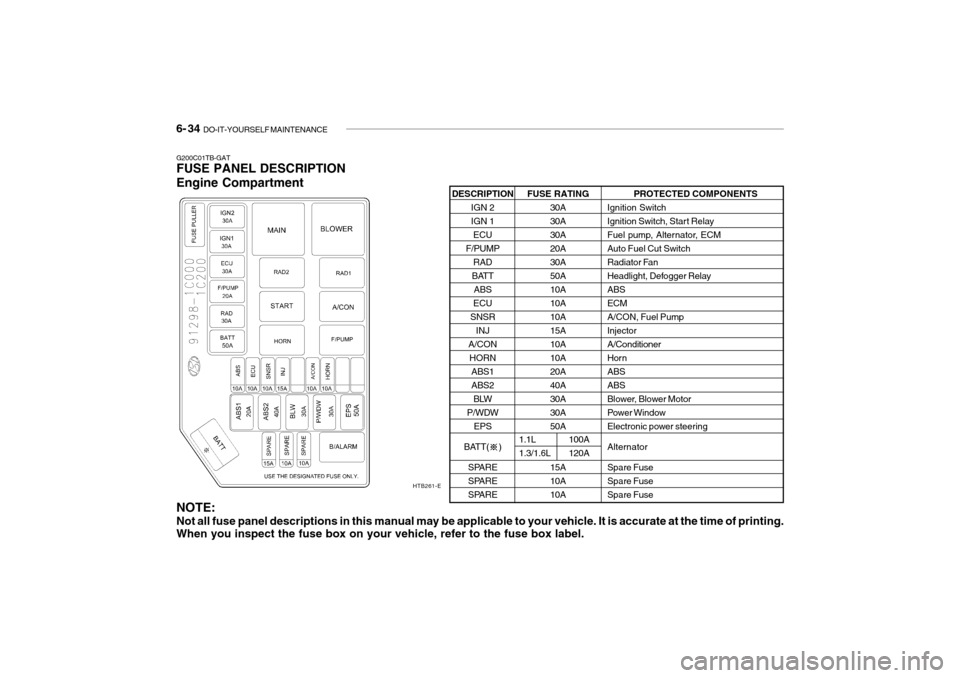

G200C01TB-GAT FUSE PANEL DESCRIPTION Engine Compartment

HTB261-EPROTECTED COMPONENTS

Ignition Switch

Ignition Switch, Start Relay

Fuel pump, Alternator, ECM

Auto Fuel Cut Switch

Radiator Fan

Headlight, Defogger RelayABSECMA/CON, Fuel PumpInjectorA/Conditioner

HornABSABS

Blower, Blower Motor

Power Window

Electronic power steering AlternatorSpare Fuse Spare FuseSpare Fuse

FUSE RATING

30A30A30A20A30A50A10A10A10A15A10A10A20A40A30A30A50A 15A 10A10A

DESCRIPTION

IGN 2IGN 1ECU

F/PUMP RAD

BATT ABS

ECU

SNSR INJ

A/CON HORN ABS1ABS2 BLW

P/WDW EPS

BATT( ) SPARE

SPARE

SPARE

NOTE:

Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

1.1L 1.3/1.6L 100A120A

Page 182 of 437

7- 2 EMISSION CONTROL SYSTEMS

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the vehicle is destined, the emissioncontrol system will comprise one or more of the following emission con- trol devices.

1) Crankcase emission control sys-

tem

2) Evaporative emission control sys-

tem

3) Exhaust emission control systemIn order that the proper functioning of the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintainedby a Hyundai authorised repairer in accordance with the maintenance schedule in this manual. SH010B1-E

1. CRANKCASE EMISSION

CONTROLSYSTEM

The positive crankcase ventilation

system is employed to prevent airpollution caused by blow-by gasesbeing emitted from the crankcase by introducing fresh air to the crankcase through the air cleaner where thismixes with blow-by gases and then passes through the PCV valve into the intake manifold from where it sub-sequently enters the combustion chamber and is burned.

SH010C1-E

2. EVAPORATIVE EMISSION

CONTROL SYSTEM

The Evaporative Emission Control

System is designed to prevent fuel vapours from escaping into the atmo- sphere through the fuel tank ventila- tion system.

Whilst the engine is not running, fuel

vapours generated inside the fuel tankare absorbed and stored in a char-coal canister. When the engine is started, the vapours stored in the canister are drawn into the induction SH010D1-E

3. EXHAUST EMISSION CON

TROL SYSTEM

The exhaust emission control system

is a highly effective system whichcontrols exhaust emission while main- taining good vehicle performance.

system through the purge control so-lenoid valve and are subsequently burned.

The purge control solenoid valve is

controlled by the ECU; when the en-gine coolant temperature is low or the engine is idling, the purge control valve is closed and fuel vapours re-main stored in the canister. Under normal running conditions when the engine is warm, the valve opens andthe vapours are drawn into the inlet tract and subsequently burned in the combustion chamber.