power steering fluid Hyundai Getz 2005 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2005, Model line: Getz, Model: Hyundai Getz 2005Pages: 437, PDF Size: 11.19 MB

Page 48 of 437

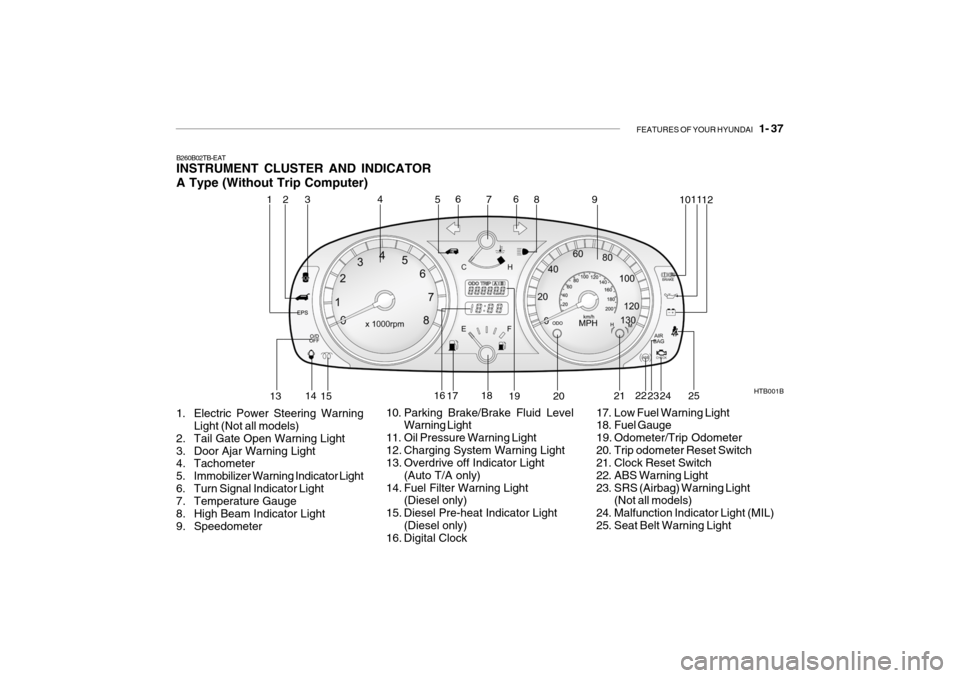

FEATURES OF YOUR HYUNDAI 1- 37

B260B02TB-EAT INSTRUMENT CLUSTER AND INDICATOR A Type (Without Trip Computer)

1. Electric Power Steering Warning Light (Not all models)

2. Tail Gate Open Warning Light

3. Door Ajar Warning Light

4. Tachometer

5. Immobilizer Warning Indicator Light

6. Turn Signal Indicator Light

7. Temperature Gauge

8. High Beam Indicator Light

9. Speedometer HTB001B

10. Parking Brake/Brake Fluid Level Warning Light

11. Oil Pressure Warning Light

12. Charging System Warning Light

13. Overdrive off Indicator Light (Auto T/A only)

14. Fuel Filter Warning Light (Diesel only)

15. Diesel Pre-heat Indicator Light (Diesel only)

16. Digital Clock 17. Low Fuel Warning Light

18. Fuel Gauge

19. Odometer/Trip Odometer

20. Trip odometer Reset Switch

21. Clock Reset Switch

22. ABS Warning Light

23. SRS (Airbag) Warning Light

(Not all models)

24. Malfunction Indicator Light (MIL)

25. Seat Belt Warning Light

1

2

4

53 6

7 8

9 1011

12

13 14

15 16

17 18

19 20 21

22

23 24

6

25

Page 49 of 437

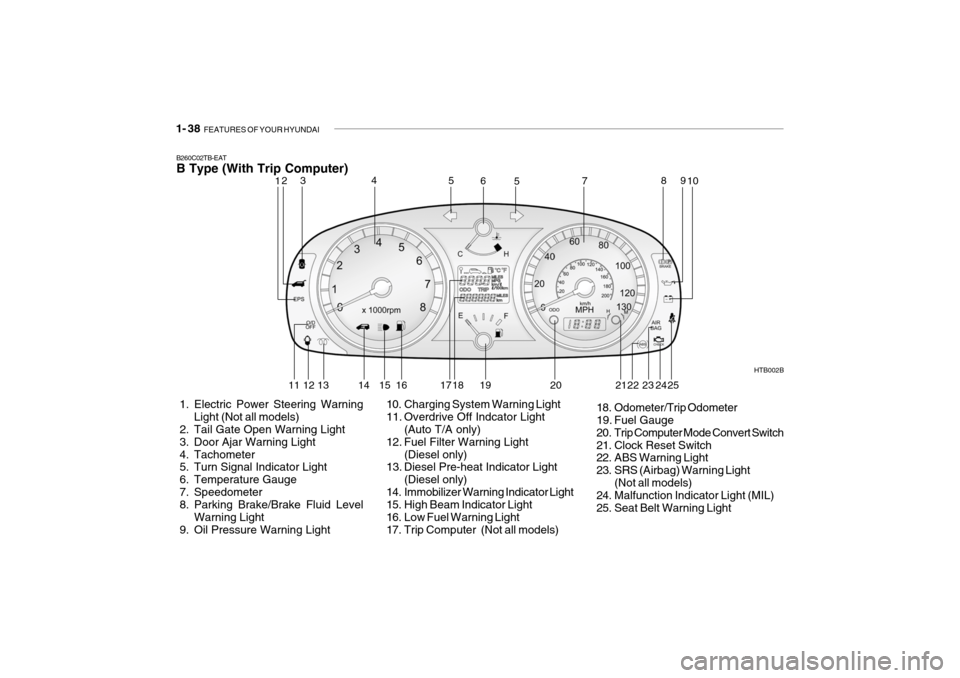

1- 38 FEATURES OF YOUR HYUNDAI

B260C02TB-EAT B Type (With Trip Computer)

1. Electric Power Steering Warning

Light (Not all models)

2. Tail Gate Open Warning Light

3. Door Ajar Warning Light

4. Tachometer

5. Turn Signal Indicator Light

6. Temperature Gauge

7. Speedometer

8. Parking Brake/Brake Fluid Level

Warning Light

9. Oil Pressure Warning Light HTB002B

10. Charging System Warning Light

11. Overdrive Off Indcator Light (Auto T/A only)

12. Fuel Filter Warning Light (Diesel only)

13. Diesel Pre-heat Indicator Light

(Diesel only)

14. Immobilizer Warning Indicator Light

15. High Beam Indicator Light

16. Low Fuel Warning Light

17. Trip Computer (Not all models) 18. Odometer/Trip Odometer

19. Fuel Gauge

20. Trip Computer Mode Convert Switch

21. Clock Reset Switch

22. ABS Warning Light

23. SRS (Airbag) Warning Light

(Not all models)

24. Malfunction Indicator Light (MIL)

25. Seat Belt Warning Light

12 3 4

5

5

6

78

910

11 12 13 14 15 16 17 18 19 20 22 23

242521

Page 144 of 437

VEHICLE MAINTENANCE REQUIREMENTS 5- 9

F070E03A-AAT

o Automatic transaxle fluid

The fluid level should be in the "HOT" range of the dipstick, after engine and transaxle are at normal operating tem- perature. Check the AutomaticTransaxle Fluid level with the engine running and the transaxle in neutral, with the parking brake properly ap-plied. Use DIAMOND ATF SP-III or SK ATF SP-III when adding or chang- ing fluid. 6ZF070F1-A

o Brake hoses and lines

Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replace any deteriorated ordamaged parts immediately. 6ZF070G2-A

o Brake fluid

Check brake fluid level in the brake fluid reservoir. The level should be between "MIN" and "MAX" marks on the side of the reservoir. Use onlyhydraulic brake fluid conforming to DOT 3 or DOT 4. 6ZF070H1-A

o Rear brake drums and linings/ parking brake

Check the rear brake drums and lin-

ings for scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parking brake system in- cluding the parking brake lever andcables. For detailed service proce- dures, refer to the Shop Manual.

6ZF070J1-A

o Brake pads, calipers and

rotors

Check the pads for excessive wear,

discs for run out and wear, and cali-pers for fluid leakage.

6ZF070K1-A

o Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete- rioration, or damage. Start the engine and listen carefully for any exhaust gas leakage. Tighten connections orreplace parts as necessary. 6ZF070L1-A o Suspension mounting bolts Check the suspension connections for looseness or damage. Retighten to the specified torque. 6ZF070M1-A o Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine off, check for excessive freeplay inthe steering wheel.Check the linkage for bends or dam-age. Check the dust boots and balljoints for deterioration, cracks, or dam- age. Replace any damaged parts. 6ZF070N1-A

o Power steering pump, belt and hoses

Check the power steering pump and hoses for leakage and damage. Re-place any damaged or leaking parts immediately. Inspect the power steer- ing belt for evidence of cuts, cracks,excessive wear, oiliness and proper tension. Replace or adjust it if neces- sary.

Page 146 of 437

6. Do-It-Yourself Maintenance

Engine compartment ........................................................................ 6-2

Daily operating checks ..................................................................... 6-6

Engine oil .......................................................................................... 6-6

Engine and filter Replacement ......................................................... 6-9

Engine coolant Checking and Replacing .......................................6-10

Spark plug Replacement ................................................................ 6-13

Changing the air cleaner filter ......................................................... 6-14

Manual Transaxle Lubricant........................................................... 6-15

Automatic Transaxle fluid ............................................................... 6-16

Brake System Checking ................................................................ 6-18

Air conditioning System .................................................................. 6-19

Drive belts ...................................................................................... 6-23

Individual Circuit Fuses .................................................................. 6-24

Power steering fluid level ............................................................... 6-26

Replacing Light Bulbs .................................................................... 6-28

Fuse panel description ................................................................... 6-34

6

Page 147 of 437

6- 2 DO-IT-YOURSELF MAINTENANCE

HTB160A

1. Windshield washer fluid reservoir cap

2. Auto fuel cut switch

3. Engine oil filler cap 4. Brake fluid and clutch fluid

reservoir

5. Air filter element

6. Relay box

7. Power steering fluid reservoir 8. Engine oil level dipstick

9. Radiator cap

10.Engine coolant reservoir

11.Battery

G010A01TB-EAT ENGINE COMPARTMENT (1.1 SOHC)

12 3

456

78 9 10 1 1

Page 148 of 437

DO-IT-YOURSELF MAINTENANCE 6- 3

G010B01TB-EAT ENGINE COMPARTMENT (1.3 SOHC)

1. Windshield washer fluid reservoir

cap

2. Auto fuel cut switch

3. Engine oil filler cap

4. Brake fluid and clutch fluid reservoir 5. Air filter element

6. Relay box

7. Power steering fluid reservoir

(Not all models)

8. Engine oil level dipstick 9. Radiator cap

10. Engine coolant reservoir

11. Automatic transaxle fluid level dip-

stick (Not all models)

12. Battery HTB086A

123

456

78 91 011

12

Page 149 of 437

6- 4 DO-IT-YOURSELF MAINTENANCE

G010B01TB-EAT ENGINE COMPARTMENT (1.6L DOHC)

HTB088A

1. Windshield washer fluid reservoir cap

2. Auto fuel cut switch

3. Engine oil filler cap

4. Brake fluid and clutch fluid reservoir 5. Air filter element

6. Relay box

7. Power steering fluid reservoir

(Not all models)

8. Engine oil level dipstick 9. Radiator cap

10.Engine coolant reservoir

11.Automatic transaxle fluid level dip-

stick (Not all models)

12.Battery

1 2 34

56

789 10 11 12 CAUTION:

When inspecting or servicing the engine,you should handle tools and other heavy objects carefully sothat the plastic rocker cover of the engine is not damaged.

!

Page 150 of 437

DO-IT-YOURSELF MAINTENANCE 6- 5

G010C01TB-EAT ENGINE COMPARTMENT (DIESEL)

HTB159

1. Windshield washer fluid reservoir cap

2. Engine oil filler cap

3. Fuel filter 4. Brake fluid and clutch fluid reser-

voir

5. Air filter element

6. Relay box

7. Power steering fluid reservoir 8. Engine oil level dipstick

9. Radiator cap

10. Engine coolant reservoir

11. Battery

12

3

45 6

78 910

11 CAUTION:

When inspecting or servicing the engine,you should handle tools and other heavy objects carefully sothat the plastic rocker cover of the engine is not damaged.

!

Page 151 of 437

6- 6 DO-IT-YOURSELF MAINTENANCE

SG020B1-E DAILY OPERATING CHECKS The following items should be checked on a daily basis or whenever the vehicleis refuelled, whichever occurs sooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all light-

ing equipment.

o Windscreen wiper and washer opera- tion.

o Horn operation.

o Warning light operation.

o Adjustment and cleanliness of mir- rors.

o Seat and seat belt adjustment and operation.

o Fluid leakage. The vehicle must not be driven if the daily operating checks indicate that any item of equipment related to thesafety or roadworthiness of the vehicle is not functioning correctly. G030B03A-EAT Recommended Oil

1. Petrol engine The engine oil quality should meet the following classification. API SJ, SL or ABOVE, ILSAC GF-3 or ABOVE The oil viscosity should be selected according to the operating environment of the engine by means of the table shown above. The engine oil recom-mendations are complete in themselves and the use of additives is neither required nor recommended. The use ofengine oil additives may result in invali- dation of the vehicle warranty.

G030A01FC-EAT ENGINE OIL The correct engine oil level is of para- mount importance. An excessively highor low oil level may result in irreparable damage being sustained by the engine. The engine oil level must be checkedon a daily basis, whenever the vehicle is refuelled or before starting a long trip, whichever occurs sooner.In addition, it is imperative that only an approved grade and specification of oil is used to avoid the possibility of seri-ous engine damage and premature wear. The use of "budget price" oil is a false economy that must be avoided if themaximum reliability and useful life is to be obtained from the vehicle.

G030B01L

Page 164 of 437

DO-IT-YOURSELF MAINTENANCE 6- 19

!WARNING:

Brake fluid is hygroscopic and should never be stored in an un- sealed container. The presence ofwater in the braking system will cause vapour locks and increase the possi- bility of brake fade along with pro-moting corrosion within the braking system. The brake fluid must be changed at the specified time or mile-age interval to ensure continued safe operation of the system. Brake fluid will cause rapid and serious damageto paintwork. If accidental spillage occurs, the affected area must be rinsed with water immediately. Donot allow brake fluid to come into SG140A1-E AIR CONDITIONING SYSTEM MAINTENANCECondenser Ensure that the condenser is periodi- cally inspected and that accumulationsof dirt, dead insects and leaves etc, are removed to ensure that the efficiency of the system is not impaired. Care mustbe exercised to ensure that the con- denser fins are not damaged during cleaning.

G140D01TB-EAT Compressor Drive BeltG140D01TB

Power steering

Crank pully

A/C pully

0.19 ~ 0.21 in. (5 ~ 5.5 mm)

1.1L

To add brake fluid;

1) If it is necessary, remove the air

cleaner cover.

2) Wipe away any dirt then unscrew the

fluid reservoir cap.

3) Slowly pour the recommended fluid into the reservoir using by a funnel. Do not overfill.

4) Carefully replace the cap on the res- ervoir and tighten. contact with the eyes or to be in-gested and ensure that fluid is safelystored away form the reach of chil- dren.

CRANK PULLEY

HTB219

A/C

TENSION PULLEY 0.315 in. (8mm)

1.3/1.6L