ECU Hyundai Getz 2008 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Getz, Model: Hyundai Getz 2008Pages: 383, PDF Size: 9.23 MB

Page 222 of 383

DO-IT-YOURSELF MAINTENANCE 6- 27

NOTE: Grinding noise from the power steering pump may be heard imme- diately after the engine is started inextremely cold conditions (below - 20°C). If the noise stops during warm up, there is no abnormal function inthe system. It is due to a power steering fluid characteristic in ex- tremely cold conditions. Recommended Fluid Use PSF-3 type fluid NOTE: Do not start the engine when the power steering oil reservoir is empty.G230A03A-GAT POWER STEERING FLUID LEVEL The power steering fluid level should be checked regularly.To check the power steering fluid level, be sure the ignition is "OFF", then check to make certain that the powersteering fluid level is between the "MAX" and "MIN" level markings on the fluid reservoir. HTB163

G220B01A-AAT Checking Engine Cooling Fan The engine coolant fan should come on automatically if the engine coolanttemperature is high. G220C01TB-AAT Checking Condenser Cooling Fan When the air conditioning is in opera- tion, the condenser cooling fan comes on automatically to be controlled by

ECU.

Page 231 of 383

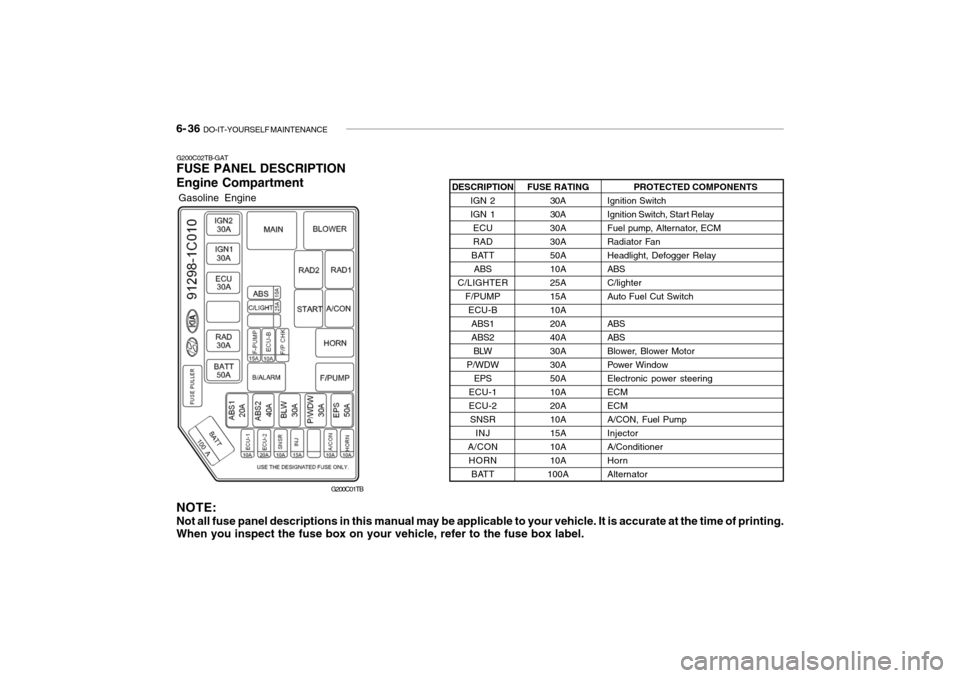

6- 36 DO-IT-YOURSELF MAINTENANCE

G200C02TB-GAT FUSE PANEL DESCRIPTION Engine Compartment

PROTECTED COMPONENTS

Ignition Switch

Ignition Switch, Start Relay

Fuel pump, Alternator, ECM

Radiator FanHeadlight, Defogger RelayABSC/lighterAuto Fuel Cut Switch ABS ABS

Blower, Blower Motor

Power WindowElectronic power steeringECMECMA/CON, Fuel PumpInjectorA/ConditionerHornAlternator

FUSE RATING

30A30A

30A30A50A10A25A15A10A20A40A30A30A50A10A20A10A15A10A10A

100A

DESCRIPTION

IGN 2IGN 1ECURAD

BATT ABS

C/LIGHTER F/PUMPECU-B ABS1ABS2BLW

P/WDW EPS

ECU-1ECU-2 SNSR INJ

A/CON HORN BATT

NOTE:

Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

Gasoline Engine

G200C01TB

Page 232 of 383

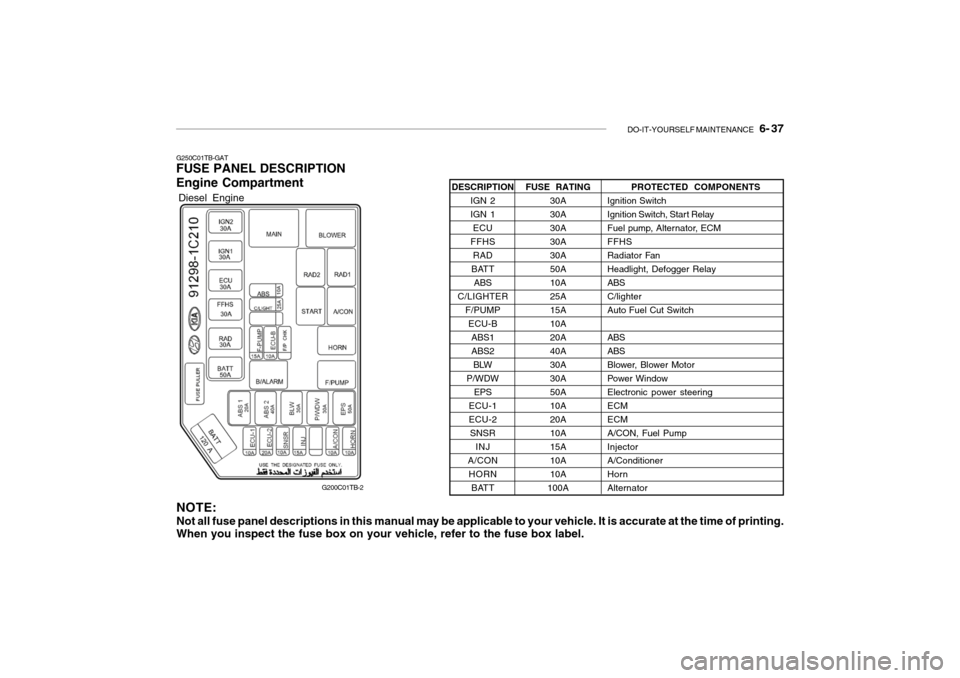

DO-IT-YOURSELF MAINTENANCE 6- 37

G250C01TB-GAT FUSE PANEL DESCRIPTION Engine Compartment

PROTECTED COMPONENTS

Ignition Switch

Ignition Switch, Start Relay

Fuel pump, Alternator, ECMFFHS

Radiator FanHeadlight, Defogger RelayABSC/lighterAuto Fuel Cut Switch ABS ABS

Blower, Blower Motor

Power WindowElectronic power steeringECMECMA/CON, Fuel PumpInjectorA/ConditionerHornAlternator

FUSE RATING

30A30A30A30A30A50A10A25A15A10A20A40A30A30A50A10A20A10A15A10A10A

100A

DESCRIPTION

IGN 2IGN 1ECU

FFHS RAD

BATT ABS

C/LIGHTER F/PUMPECU-BABS1ABS2BLW

P/WDW EPS

ECU-1ECU-2 SNSR INJ

A/CON HORN BATT

NOTE: Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

Diesel Engine

G200C01TB-2

Page 233 of 383

6- 38 DO-IT-YOURSELF MAINTENANCE

PROTECTED COMPONENTS

Room Lamp, Audio, Cluster

High Beam Light Indicator, Headlight (LH)

Front Fog LightHeadlight (RH)

Rear window Defroster

Blower, Sunroof

Fog light, ETACM, Power Window,Headlight leveling Device

Rear Fog Light

Front Wiper Motor

Hazard Warning Light, ETACM

Stop Light, Power Window ECM

Rear window Defroster

Seat Warmer

Daytime Running Light

Start Relay, Theft alarm system

Rear Wiper Motor

Door Lock System, SunroofAir BagPCM, ABS control

Power outletCluster

STOP/Tail Light (RH)

Turn Signal Light, Back-up Light

Audio, Electronic Outside MirrorA/Bag, Indicator

Stop/Tail Light (LH)Air conditioner

G200D02TB-GAT Inner Panel (Left hand drive type)

G200D01TBFUSE RATING15A 15A 10A 15A30A10A10A10A 20A 15A15A15A10A20A 10A 10A15A20A10A10A 15A 10A10A10A15A10A 10A 10A

DESCRIPTION

POWER CONN & R/LP

H/LP LH

F/FOG

H/LP RH PR/HTD

BLOWER

IGNITION

R/FOG

FRT WPR

HAZARD STOPECU2

HTD MIR

S/HTDDRL

START

RR/WPR D/LOCK

A/BAGECU1

P/OUTLET

CLUSTER TAIL RH T/SIG

AUDIO

A/BAG IND TAIL LH

A/C SW

Page 234 of 383

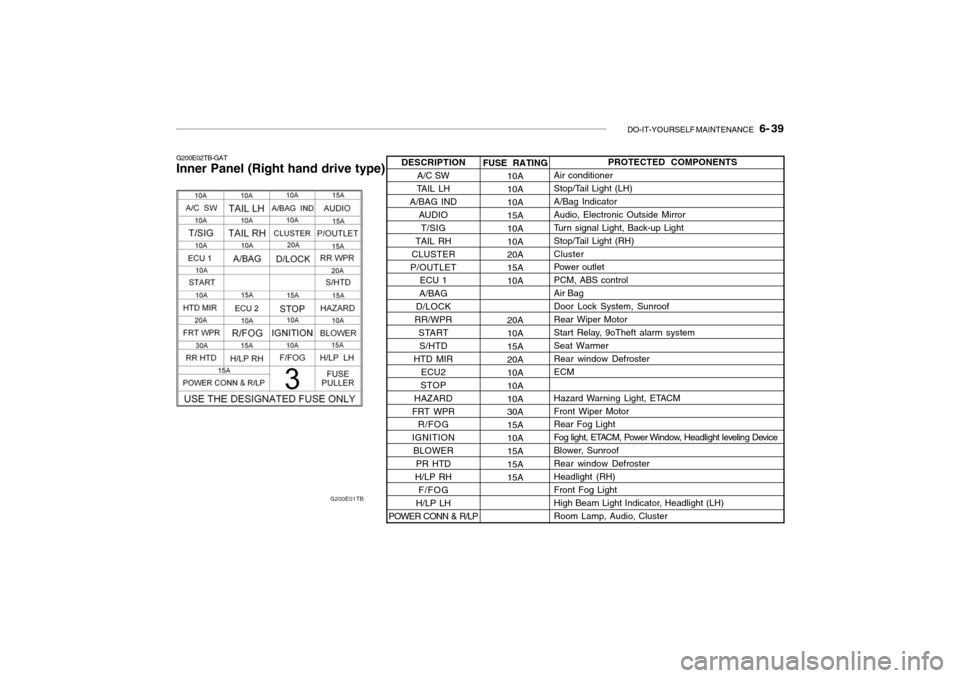

DO-IT-YOURSELF MAINTENANCE 6- 39

G200E02TB-GAT Inner Panel (Right hand drive type)

G200E01TBFUSE RATING10A 10A10A15A10A10A 20A 15A10A 20A 10A 15A20A10A10A10A 30A 15A10A15A15A15APROTECTED COMPONENTS

Air conditioner

Stop/Tail Light (LH) A/Bag IndicatorAudio, Electronic Outside Mirror

Turn signal Light, Back-up Light

Stop/Tail Light (RH)Cluster

Power outlet PCM, ABS controlAir BagDoor Lock System, SunroofRear Wiper Motor

Start Relay, 9oTheft alarm system Seat Warmer Rear window DefrosterECM

Hazard Warning Light, ETACM Front Wiper Motor Rear Fog Light

Fog light, ETACM, Power Window, Headlight leveling Device

Blower, SunroofRear window DefrosterHeadlight (RH)Front Fog Light

High Beam Light Indicator, Headlight (LH) Room Lamp, Audio, Cluster

DESCRIPTION

A/C SW

TAIL LH

A/BAG IND

AUDIO

T/SIG

TAIL RH

CLUSTER

P/OUTLET ECU 1

A/BAG

D/LOCK

RR/WPR STARTS/HTD

HTD MIR ECU2

STOP

HAZARD

FRT WPR R/FOG

IGNITION BLOWER PR HTD

H/LP RH F/FOG

H/LP LH

POWER CONN & R/LP

Page 299 of 383

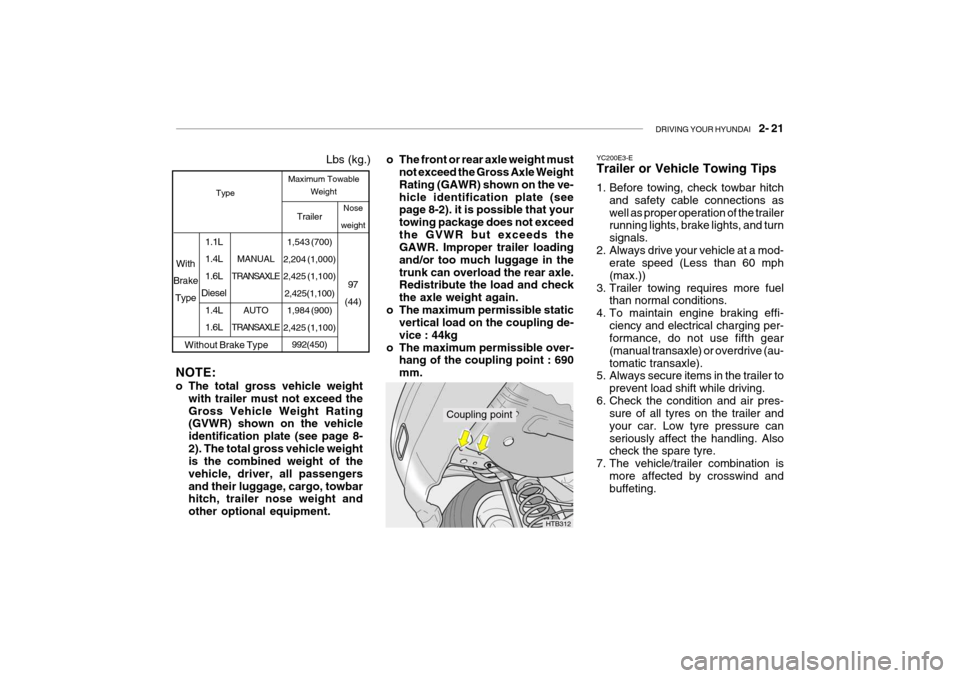

DRIVING YOUR HYUNDAI 2- 21

Coupling point

Nose

weight

97

(44)

Without Brake Type Trailer

1,543 (700)

2,204 (1,000) 2,425 (1,100) 2,425(1,100) 1,984 (900)

2,425 (1,100) 992(450)

MANUAL

TRANSAXLE

AUTO

TRANSAXLE

1.1L 1.4L1.6L

Diesel 1.4L1.6L

With

Brake Type Lbs (kg.)

Maximum Towable

Weight

Type

NOTE:

o The total gross vehicle weight with trailer must not exceed the Gross Vehicle Weight Rating (GVWR) shown on the vehicle identification plate (see page 8-2). The total gross vehicle weight is the combined weight of the vehicle, driver, all passengersand their luggage, cargo, towbar hitch, trailer nose weight and other optional equipment. o The front or rear axle weight must

not exceed the Gross Axle WeightRating (GAWR) shown on the ve-hicle identification plate (see page 8-2). it is possible that your towing package does not exceedthe GVWR but exceeds the GAWR. Improper trailer loading and/or too much luggage in thetrunk can overload the rear axle. Redistribute the load and check the axle weight again.

o The maximum permissible static vertical load on the coupling de-vice : 44kg

o The maximum permissible over- hang of the coupling point : 690mm. YC200E3-E Trailer or Vehicle Towing Tips

1. Before towing, check towbar hitch

and safety cable connections as well as proper operation of the trailer running lights, brake lights, and turn signals.

2. Always drive your vehicle at a mod- erate speed (Less than 60 mph(max.))

3. Trailer towing requires more fuel than normal conditions.

4. To maintain engine braking effi- ciency and electrical charging per- formance, do not use fifth gear (manual transaxle) or overdrive (au-tomatic transaxle).

5. Always secure items in the trailer to

prevent load shift while driving.

6. Check the condition and air pres- sure of all tyres on the trailer andyour car. Low tyre pressure canseriously affect the handling. Also check the spare tyre.

7. The vehicle/trailer combination is more affected by crosswind andbuffeting.

HTB312

Page 300 of 383

2- 22 DRIVING YOUR HYUNDAI

When being passed by a large ve- hicle, keep a constant speed and steer straight ahead. If there is toomuch wind buffeting slow down to get out of the other vehicle's air turbulence.

8. When parking your car and trailer, especially on a hill, be sure to followall the normal precautions. Turn yourfront wheel into the curb, set the parking brake firmly, and put the transaxle in 1st or Reverse (manual)or Park (automatic). In addition, we advise the use of wheel chocks at each of the trailer's tyres.

9. If the trailer has electric brakes, start your vehicle and trailer mov-ing, and then apply the trailer brakecontroller by hand to be sure the brakes are working. This lets you check your electrical connection atthe same time.

10. During your trip, check occasion-

ally to be sure that the load issecure, and that the lights and any trailer brakes are still working.

11. Avoid jerky starts, sudden accel- eration or sudden stops.

12. Avoid sharp turns and rapid lane

changes. 13. Avoid holding the brake pedal down

too long or too frequently. This could cause the brakes to over-heat, resulting in reduced braking efficiency.

14. When going down a hill, shift into a lower gear and use the enginebraking effect.When climbing a long grade, down-

shift the transaxle to a lower gearand reduce speed to reduce chances of engine overloading and/or overheating.

15. If you have to stop while going

uphill, do not hold the vehicle inplace by pressing on the accelera- tor. This can cause the automatic transaxle to overheat. Use the park-ing brake or footbrake.

NOTE: When towing check transaxle fluid more frequently. CAUTION:

If overheating should occur when towing, (temperature gauge reads near red zone), taking the followingaction may reduce or eliminate the problem.

1. Turn off the air conditioner.

2. Reduce highway speed.

3. Select a lower gear when going uphill.

4. While in stop and go traffic, place

the gear selection in park or neu- tral and idle the engine at a higher speed.

!

Page 305 of 383

WHAT TO DO IN AN EMERGENCY 3- 5

!

!

!

D040A01TB-EAT TEMPORARY SPARE TYRE (Not all models) The following instructions for the tem- porary spare tyre should be observed:

1. Check inflation pressure as soon as

practical after installing the spare tyre, and adjust to the specified pressure. The tyre pressure shouldbe periodically checked and main- tained at the specified pressure while the tyre is stored.

WARNING:

Whilst the engine is running, keep hands and clothing away from mov- ing parts such as the fan and drivebelts to prevent injury.

6. If the cause of the overheating can-not be found, wait until the enginetemperature has returned to normal. Then, if coolant has been lost, care- fully remove the radiator cap and addwater to bring the fluid level in the reservoir up to the base of the radia- tor fill opening. Fill the coolant ex-pansion tank to the halfway mark. To ensure the correct water to cool- ant mix is obtained after top up,testing by an authorised repairer is required. WARNING:

Do not remove the radiator cap whenthe engine is hot since steam and boiling water may be ejected fromthe radiator resulting in burns or scalding.

WARNING (Diesel only):

Never work on injection system withengine running or within 30 sec- onds after shutting off engine. Highpressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious in- jury, if it touches the body. Peopleusing pacemakers should not move closer than 30cm etc. to the ECU or wiring harness within the engineroom while engine is running, since the high currents in the Common Rail system produce considerablemagnetic fields. 5. If the water pump drive belt is broken

or coolant is leaking out, stop theengine immediately and call the near-est Hyundai authorised repairer for assistance.

! CAUTION:

Serious loss of coolant indicates there is a leak in the cooling system and this should be checked as soonas possible by a Hyundai authorised repairer.

7. Proceed with caution until it is estab-

lished that the engine is operating normally. If the engine overheatsrepeatedly, the advice of a Hyundai authorised repairer should be sought.

Page 326 of 383

VEHICLE MAINTENANCE REQUIREMENTS 5- 7

!

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

F060M01A-AAT

o Engine oil and filter

The engine oil and filter should be changed at the intervals specified inthe maintenance schedule. If the car is being driven in severe conditions, more frequent oil and filter changesare required. F060B01A-AAT

o Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oilsaturation and replace if necessary. Drive belts should be checked peri- odically for proper tension and ad-justed as necessary. F060C01A-GAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.

After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections.

F060D01TB-EAT

o Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Replace any damaged or leaking parts immediately. WARNING (Diesel only):

Never work on injection systemwith engine running or within 30 seconds after shutting off engine.High pressure pump, rail, injectors and high pressure pipes are sub- jected to high pressure even afterthe engine has been switched off. The fuel jet produced by fuel leaks may cause serious injury, if it con-tacts with the body. People using pacemakers should not move closer than 30cm to the ECU orwiring harness within the engine room with the engine running, since the high currents in the CommonRail system produce considerable magnetic fields.

Page 327 of 383

5- 8 VEHICLE MAINTENANCE REQUIREMENTS

F060H01A-AAT

o Air cleaner filter

A Genuine Hyundai air cleaner filter is recommended when filter is replaced. F060J01A-AAT

o Spark plugs

Make sure to install new spark plugs of the correct heat range.

F060G01A-EAT o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched- ule. Make sure that a new vapourhose or fuel filler cap is correctly re- placed. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evi- dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessive swelling indicate deterioration. Par-ticular attention should be paid to ex- amining those hose surfaces nearest to high heat sources, such as theexhaust manifold.Inspect the hose routing to assurethat the hoses do not come in contact with any heat source, sharp edges or moving component which might causeheat damage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make surethey are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidence ofdeterioration or damage. F060N01X-GAT

o Valve clearances (1.1 L)

Incorrect valve clearance will not onlyresult in unsteady engine operation, but will also cause excessive noise and reduced engine performance. In-spect valve clearance and adjust as required while the engine is hot. Valve-to-rocker arm clearance Intake valves ..... 0.2 mm (0.008 in.) Exhaust valves ... 0.25 mm (0.010 in.)

F060E01A-AAT o Timing belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately.