maintenance schedule Hyundai Getz 2008 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Getz, Model: Hyundai Getz 2008Pages: 383, PDF Size: 9.23 MB

Page 321 of 383

5- 2 VEHICLE MAINTENANCE REQUIREMENTS

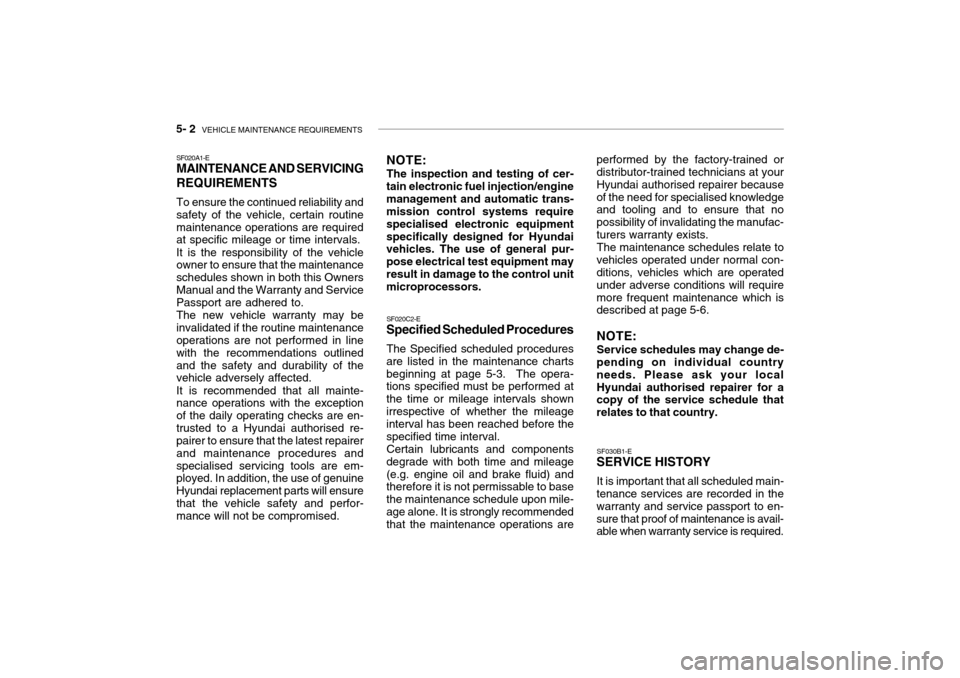

SF020A1-E MAINTENANCE AND SERVICING REQUIREMENTS To ensure the continued reliability and safety of the vehicle, certain routinemaintenance operations are required at specific mileage or time intervals. It is the responsibility of the vehicle owner to ensure that the maintenance schedules shown in both this OwnersManual and the Warranty and Service Passport are adhered to. The new vehicle warranty may be invalidated if the routine maintenance operations are not performed in line with the recommendations outlinedand the safety and durability of the vehicle adversely affected. It is recommended that all mainte- nance operations with the exception of the daily operating checks are en-trusted to a Hyundai authorised re- pairer to ensure that the latest repairer and maintenance procedures andspecialised servicing tools are em- ployed. In addition, the use of genuine Hyundai replacement parts will ensurethat the vehicle safety and perfor- mance will not be compromised. NOTE:

The inspection and testing of cer-

tain electronic fuel injection/engine management and automatic trans- mission control systems require specialised electronic equipmentspecifically designed for Hyundai vehicles. The use of general pur- pose electrical test equipment mayresult in damage to the control unit microprocessors.

SF020C2-E

Specified Scheduled Procedures

The Specified scheduled procedures

are listed in the maintenance charts beginning at page 5-3. The opera- tions specified must be performed at the time or mileage intervals shownirrespective of whether the mileage interval has been reached before the specified time interval. Certain lubricants and components

degrade with both time and mileage(e.g. engine oil and brake fluid) and therefore it is not permissable to base the maintenance schedule upon mile-age alone. It is strongly recommended that the maintenance operations are performed by the factory-trained ordistributor-trained technicians at your Hyundai authorised repairer becauseof the need for specialised knowledge and tooling and to ensure that no possibility of invalidating the manufac-turers warranty exists.

The maintenance schedules relate to

vehicles operated under normal con- ditions, vehicles which are operated under adverse conditions will requiremore frequent maintenance which is described at page 5-6. NOTE:

Service schedules may change de-

pending on individual country needs. Please ask your localHyundai authorised repairer for a copy of the service schedule that relates to that country.

SF030B1-E

SERVICE HISTORY

It is important that all scheduled main-

tenance services are recorded in thewarranty and service passport to en-sure that proof of maintenance is avail- able when warranty service is required.

Page 322 of 383

VEHICLE MAINTENANCE REQUIREMENTS 5- 3

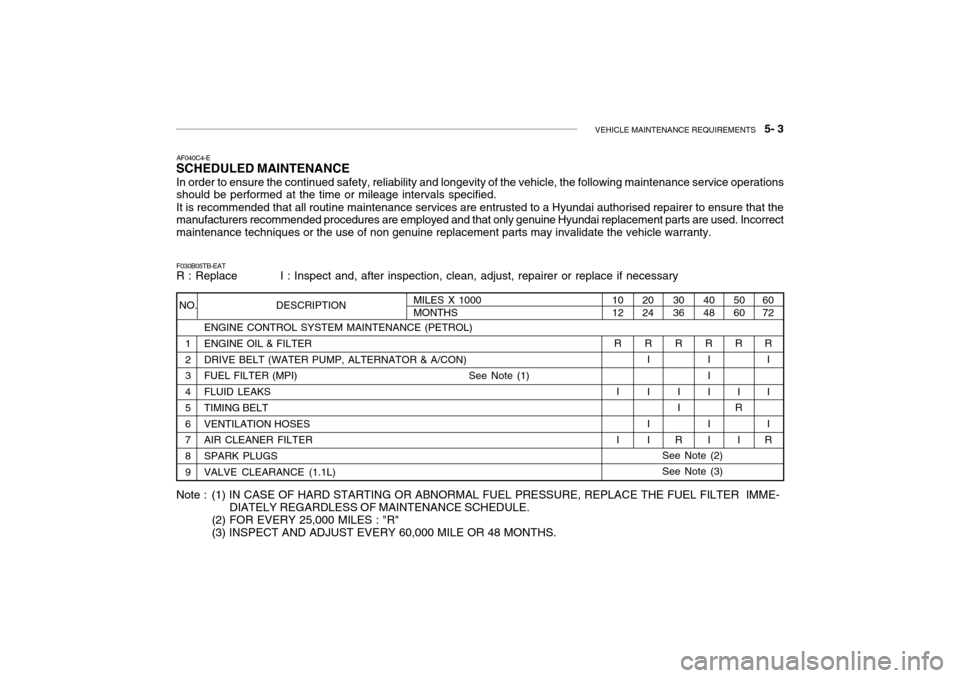

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL)

1 ENGINE OIL & FILTER

2 DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON)

3 FUEL FILTER (MPI) See Note (1)

4 FLUID LEAKS

5 TIMING BELT

6 VENTILATION HOSES

7 AIR CLEANER FILTER

8 SPARK PLUGS

9 VALVE CLEARANCE (1.1L)

AF040C4-E

SCHEDULED MAINTENANCE

In order to ensure the continued safety, reliability and longevity of the vehicle, the following maintenance service operations should be performed at the time or mileage intervals specified. It is recommended that all routine maintenance services are entrusted to a Hyundai authorised repairer to ensure that the manufacturers recommended procedures are employed and that only genuine Hyundai replacement parts are used. Incorrect maintenance techniques or the use of non genuine replacement parts may invalidate the vehicle warranty. F030B05TB-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repairer or replace if necessary

Note : (1) IN CASE OF HARD STARTING OR ABNORMAL FUEL PRESSURE, REPLACE THE FUEL FILTER IMME- DIATELY REGARDLESS OF MAINTENANCE SCHEDULE.

(2) FOR EVERY 25,000 MILES : "R" (3) INSPECT AND ADJUST EVERY 60,000 MILE OR 48 MONTHS.

NO. DESCRIPTION60 72

5060

4048

3036

2024

1012

MILES X 1000 MONTHS

R

I II

R

R

I

R

I

R

I I I I I

R

II

R

R

I II I

R

I I

See Note (2) See Note (3)

Page 323 of 383

5- 4 VEHICLE MAINTENANCE REQUIREMENTS

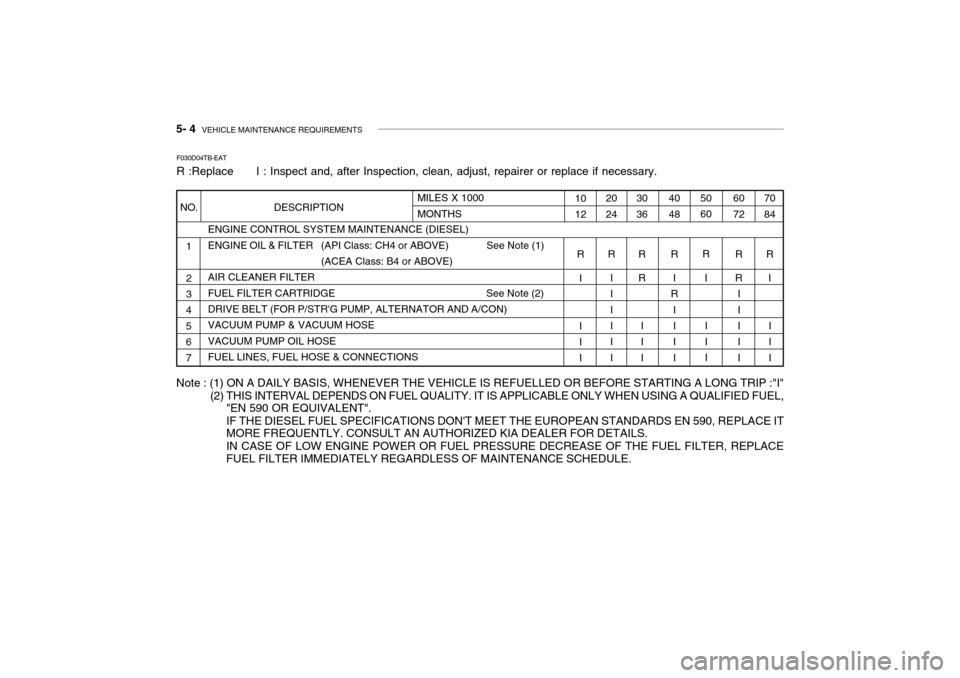

F030D04TB-EAT R :Replace I : Inspect and, after Inspection, clean, adjust, repairer or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL)

ENGINE OIL & FILTER (API Class: CH4 or ABOVE) See Note (1)

(ACEA Class: B4 or ABOVE)

AIR CLEANER FILTER

FUEL FILTER CARTRIDGE See Note (2) DRIVE BELT (FOR P/STR'G PUMP, ALTERNATOR AND A/CON) VACUUM PUMP & VACUUM HOSEVACUUM PUMP OIL HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

1 2 3 4

5 6 7 60 72

R

R III I I

50 60

R I

I I I40 48 R I

R

II I I30 36

R R

I I I20 24R I I II I I

10 12

R I I I IMILES X 1000 MONTHS70 84

R I

I I I

Note : (1) ON A DAILY BASIS, WHENEVER THE VEHICLE IS REFUELLED OR BEFORE STARTING A LONG TRIP :"I" (2) THIS INTERVAL DEPENDS ON FUEL QUALITY. IT IS APPLICABLE ONLY WHEN USING A QUALIFIED FUEL,"EN 590 OR EQUIVALENT". IF THE DIESEL FUEL SPECIFICATIONS DON'T MEET THE EUROPEAN STANDARDS EN 590, REPLACE IT MORE FREQUENTLY. CONSULT AN AUTHORIZED KIA DEALER FOR DETAILS. IN CASE OF LOW ENGINE POWER OR FUEL PRESSURE DECREASE OF THE FUEL FILTER, REPLACE FUEL FILTER IMMEDIATELY REGARDLESS OF MAINTENANCE SCHEDULE.

NO. DESCRIPTION

Page 326 of 383

VEHICLE MAINTENANCE REQUIREMENTS 5- 7

!

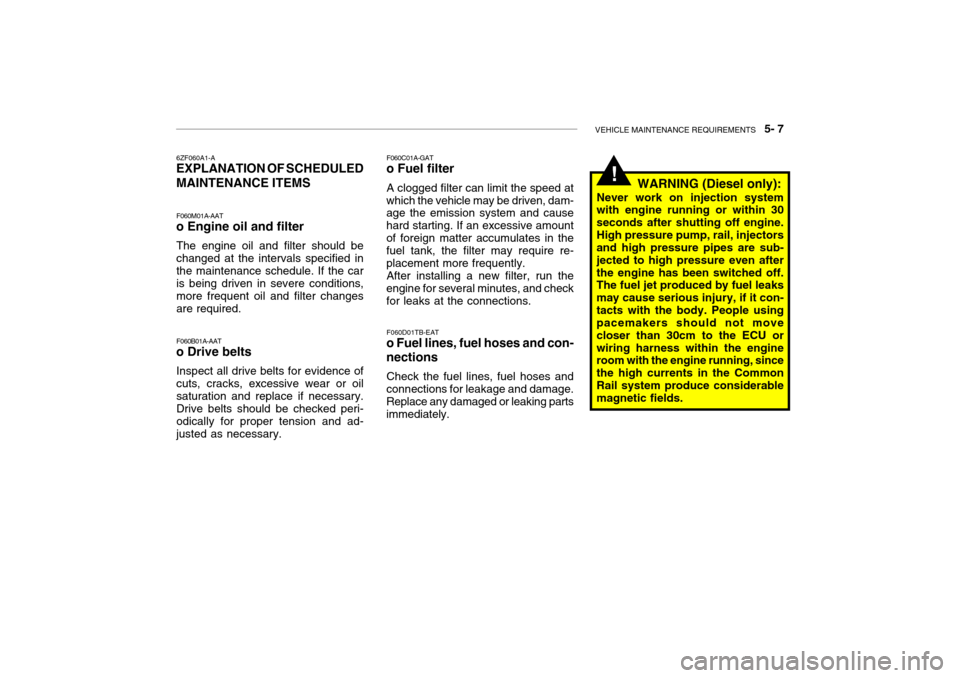

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

F060M01A-AAT

o Engine oil and filter

The engine oil and filter should be changed at the intervals specified inthe maintenance schedule. If the car is being driven in severe conditions, more frequent oil and filter changesare required. F060B01A-AAT

o Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oilsaturation and replace if necessary. Drive belts should be checked peri- odically for proper tension and ad-justed as necessary. F060C01A-GAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.

After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections.

F060D01TB-EAT

o Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Replace any damaged or leaking parts immediately. WARNING (Diesel only):

Never work on injection systemwith engine running or within 30 seconds after shutting off engine.High pressure pump, rail, injectors and high pressure pipes are sub- jected to high pressure even afterthe engine has been switched off. The fuel jet produced by fuel leaks may cause serious injury, if it con-tacts with the body. People using pacemakers should not move closer than 30cm to the ECU orwiring harness within the engine room with the engine running, since the high currents in the CommonRail system produce considerable magnetic fields.

Page 328 of 383

VEHICLE MAINTENANCE REQUIREMENTS 5- 9

F070C01A-AAT

o Engine coolant

The coolant should be changed at

the intervals specified in the mainte- nance schedule. F070B01A-GAT

o Cooling system

Check the cooling system part, suchas radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts. F070D01A-AAT

o Manual transaxle oil

Inspect the manual transaxle oil ac- cording to the maintenance schedule.

NOTE: If the oil level is low, check forpossible leaks before adding oil. Do not overfill. F070F01A-AAT

o Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any leakage. Replace any deteriorated or damaged parts immediately. F070G02A-AAT o Brake fluid Check brake fluid level in the brake fluid reservoir. The level should be between "MIN" and "MAX" marks on the side of the reservoir. Use onlyhydraulic brake fluid conforming to DOT 3 or DOT 4. F070H01B-AAT o Rear brake drums and linings/ parking brake Check the rear brake drums and lin- ings for scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parking brake system in-cluding the parking brake lever and cables. For detailed service proce- dures, refer to the Shop Manual.

F070E05A-AAT

o Automatic Transaxle Fluid

The fluid level should be in the "HOT"

range of the dipstick, after the engine and transaxle are at normal operating temperature. Check the automatictransaxle fluid level with the engine running and the transaxle in neutral, with the parking brake properly ap-plied. Use Hyundai Genuine ATF SP- III, DIAMOND ATF SP-III, SK ATF SP-III or other brands approved byHyundai Motor Co., when adding or changing fluid.

Page 339 of 383

6- 10 DO-IT-YOURSELF MAINTENANCE

Diesel engine Only ethylene glycol based coolant with a corrosion inhibitor suited to aluminium alloy engine components should beused in the cooling system. No further additives or inhibitors should be used. The coolant specific gravity should bechecked as prescribed in the mainte- nance schedule to ensure adequate frost and corrosion protection. In addi-tion, the engine coolant must be re- placed at the specified interval since the corrosion inhibitor properties dete-riorate with time. It is important to note that whilst an increase in the concentration of antifreeze gives an increase in the level of frost protection, a solution which is in excess of 65% anti freeze will result inreduced frost protection and engine overheating. Therefore the recom- mended concentration of 50% shouldnot be exceeded for general use. The use of methanol based anti freeze compounds may result in engine over-heating and will invalidate the vehicle warranty.

Petrol engine

SG050B1-E Coolant recommendations

HTB170

HTB170A NOTE: It is imperative that vehicles fitted with an air conditioning system have a coolant concentration of the rec-ommended strength at all times. The use of the air conditioning system when the cooling system is filledwith water only will result in the heater matrix freezing and subse- quently bursting.

Page 344 of 383

DO-IT-YOURSELF MAINTENANCE 6- 15

G100B03A-GAT Checking the automatic transaxle fluid level

SG110A1-E AUTOMATIC TRANSAXLE FLUID The automatic transaxle fluid level should be checked and changed at those intervals prescribed in the main-tenance schedule. It is of paramount importance that only the specified fluid is used when replenishing or changingthe fluid. The use of other fluids may irreparably damage the transaxle and invalidate the manufacturers warranty.In addition the ingress of dirt or lint may prevent correct functioning of the transaxle and care must be exercisedto prevent the ingress of such matter.

CAUTION:

The transaxle fluid level must bechecked with the engine running and at normal operating temperature and therefore care must be exercised toprevent injury occurring through contact with rotating or hot parts of the engine.

! G110B04A-AAT Recommended Fluid Your Hyundai automatic transaxle is specially designed to operate withHyundai Genuine ATF SP-III, DIA- MOND ATF SP-III, SK ATF SP-III or other brands approved by Hyundai MotorCo., Damage caused by a nonspecified fluid is not covered by your new vehicle limited warranty.

The automatic transaxle fluid level should be checked regularly. Keep the vehicle on the level groundwith the parking brake applied and check the fluid level according to the following procedure.

1. Place the selector lever in N (Neu-tral) position and confirm the engine is running at normal idle speed.

2. After the transaxle is warmed up

sufficiently (fluid temperature70~80°C (158~176°F)), for example by 10 minutes usual driving, shift the selector lever through all positionsthen place the selector lever in N (Neutral) or P (Park) position.

HTB164

Page 350 of 383

DO-IT-YOURSELF MAINTENANCE 6- 21

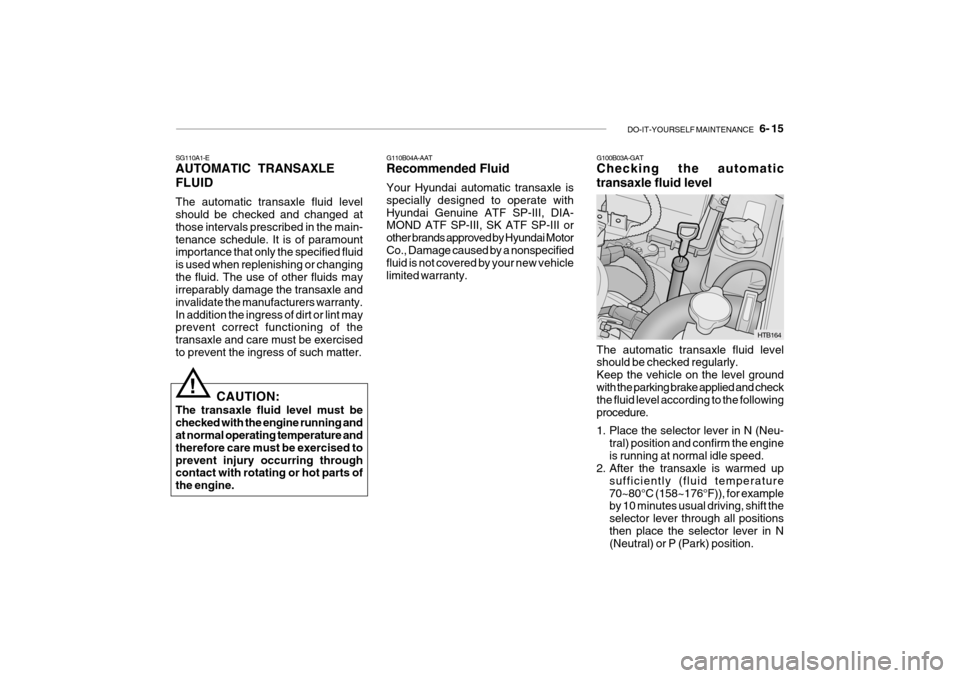

G190B01TB-GAT CHECKING DRIVE BELTS (Diesel) At the scheduled maintenance inspec- tion, belts should be examined forcracks, wear, fraying or other evidence of deterioration and replaced if neces- sary.Belt routing should also be checked to be sure there is no interference be- tween the belts and other parts of theengine.

!

SG200A1-E FUSIBLE LINKS The fusible link prevents damage to the wiring harness in the event of an elec-trical system malfunction. Failure of a fusiblelink is indicative of a serious overload condition having occurred andtherefore the electrical system should be checked by a Hyundai authorised repairer before a replacement link isfitted.

WARNING:

Under no circumstances should afusible link be replaced with any- thing other than a new link of the same rating. The use of higher ratedlinks or other means of connecting the circuit will create a potential fire hazard.G200B01E-EAT INDIVIDUAL CIRCUIT FUSES The fuse box containing the individual circuit fuses will be found in the back-side of multi box located in the right side of driver. The multi box is removed by pulling lightly and then releasing the lid.A fuse rating grid will be found on the reverse side of the cover. In the event of fuse failure, the fuse should be re-placed with one of equivalent rating. A fuse removal tool is provided within the fuse box to facilitate replacement. HTB180-D

A/C comp.

Water pump pulley

G190B01TB

Alternator Power steering pump

Tensioner

Crankshaft pulley

Page 364 of 383

7- 2 EMISSION CONTROL SYSTEMS

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the vehicle is destined, the emissioncontrol system will comprise one or more of the following emission con- trol devices.

1) Crankcase emission control sys-

tem

2) Evaporative emission control sys-

tem

3) Exhaust emission control systemIn order that the proper functioning of the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintainedby a Hyundai authorised repairer in accordance with the maintenance schedule in this manual. SH010B1-E

1. Crankcase emission

controlsystem

The positive crankcase ventilation

system is employed to prevent airpollution caused by blow-by gasesbeing emitted from the crankcase by introducing fresh air to the crankcase through the air cleaner where thismixes with blow-by gases and then passes through the PCV valve into the intake manifold from where it sub-sequently enters the combustion chamber and is burned.

SH010C1-E

2. Evaporative emission control

system

The Evaporative Emission Control

System is designed to prevent fuel vapours from escaping into the atmo- sphere through the fuel tank ventila- tion system. SH010D1-E

3. Exhaust emission con trol

system

The exhaust emission control system

is a highly effective system whichcontrols exhaust emission while main- taining good vehicle performance. Whilst the engine is not running, fuel

vapours generated inside the fuel tank are absorbed and stored in a char-coal canister. When the engine is started, the vapours stored in the canister are drawn into the inductionsystem through the purge control sole- noid valve and are subsequently burned.

The purge control solenoid valve is

controlled by the ECU; when the en-gine coolant temperature is low or the engine is idling, the purge control valve is closed and fuel vapours re-main stored in the canister. Under normal running conditions when the engine is warm, the valve opens andthe vapours are drawn into the inlet tract and subsequently burned in the combustion chamber.

Page 380 of 383

10- 4 INDEX

L LIGHTING SWITCH .................................................... 1-58

LUGGAGE BOARD ..................................................... 1-81

LUGGAGE NET .......................................................... 1-81

LUGGAGE ROOM ...................................................... 1-79

LUGGAGE UNDER TRAY ............... ...........................1-80

LUMBAR SUPPORT ADJUSTMENT ..........................1-15

MMAINTENANCE AND SERVICING REQUIREMENTS .................................................... 5-2

MAINTENANCE UNDER SEVERE USAGE CONDITIONS .......................................................... 5-6

MANUAL TRANSAXLE ............................................... 2-8

MANUAL TRANSAXLE LUBRICANT.......................... 6-14

MIRROR ..................................................................... 1-72

MULTI FUNCTION SWITCH .......................................1-57

OODOMETER ............................................................... 1-54

OUTSIDE REAR VIEW MIRROR .....................1-72 ~ 1-73

OUTSIDE REAR VIEW MIRROR HEAT ..................... 1-73

OVERDRIVE SWITCH ................................................ 2-13PPARKING

BRAKE ...................................................... 1-74

POLISHING ................................................................. 4-4

POLLEN FILTER ............................................... 1-93, 6-19

POWER OUTLET ....................................................... 1-65

POWER STEERING FLUID LEVEL ............................6-23

POWER STEERING HOSES ...................................... 6-23

POWER WINDOW ...................................................... 1-11

PROTECTING YOUR HYUNDAI FROM CORROSION ........................................................... 4-2

RREAR FOG LIGHT SWITCH ....................................... 1-64

REAR SEAT ............................................................... 1-16

REAR SEAT WARNI NG ............................................. 1-19

RECOMMENDED SHIFT SPEEDS ............................. 2-9

REMOTE FUEL FILLER LID RELEASE ...................... 1-77

REMOVAL OF WATER FROM THE FUEL FI LTER ................................................. 6-24

REPLACING LIGHT BULBS ....................................... 6-26

RUNNING IN YOUR NEW HYUNDAI ........................... 1-4

SSCHEDULED MAINTENANCE .................................... 5-3

SEAT ADJUSTMENT ................................................. 1-12

SEATBACK HOL DER ................................................. 1-79