h4 high HYUNDAI I10 2009 Workshop Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2009, Model line: I10, Model: HYUNDAI I10 2009Pages: 354, PDF Size: 37.04 MB

Page 250 of 354

What to do in an emergency

12

6

If you have a tire gauge, remove the

valve cap and check the air pressure.

If the pressure is lower than recom-

mended, drive slowly to the nearest

service station and inflate to the cor-

rect pressure. If it is too high, adjust

it until it is correct. Always reinstall

the valve cap after checking or

adjusting tire pressure. If the cap is

not replaced, air may leak from the

tire. If you lose a valve cap, buyanother and install it as soon as pos-

sible.

After you have changed wheels,

always secure the flat tire in its place

and return the jack and tools to their

proper storage locations. To prevent the jack, jack handle,

wheel lug nut wrench and spare tire

from rattling while the vehicle is in

motion, store them properly.CAUTION

Your vehicle has metric threads

on the wheel studs and nuts.Make certain during wheel removal that the same nuts thatwere removed are reinstalled -or, if replaced, that nuts with metric threads and the samechamfer configuration are used.Installation of a non-metricthread nut on a metric stud or vice-versa will not secure thewheel to the hub properly andwill damage the stud so that it must be replaced.

Note that most lug nuts do nothave metric threads. Be sure touse extreme care in checkingfor thread style before installing aftermarket lug nuts or wheels.If in doubt, consult an author-ized HYUNDAI dealer.

WARNING - Wheel studs

If the studs are damaged, they

may lose their ability to retain

the wheel. This could lead to theloss of the wheel and a collisionresulting in serious injuries.

WARNING - Inadequate

spare tire pressure

Check the inflation pressures as

soon as possible after installing

the spare tire. Adjust it to the

specified pressure, if necessary.

Refer to “Tires and wheels” sec-tion 9.

Page 251 of 354

613

What to do in an emergency

F070301AUN

Important - use of compact spare tire(if equipped)

Your vehicle is equipped with a com-

pact spare tire. This compact spare

tire takes up less space than a regu-

lar-size tire. This tire is smaller than a

conventional tire and is designed for

temporary use only.

The compact spare should be inflat-

ed to 420 kPa (60 psi).

✽✽NOTICE

Check the inflation pressure after

installing the spare tire. Adjust it to

the specified pressure, as necessary.

When using a compact spare tire,

observe the following precautions:

Under no circumstances should you exceed 80 km/h (50 mph); a higher speed could damage the

tire.

Ensure that you drive slowly enough for the road conditions to

avoid all hazards. Any road hazard,

such as a pothole or debris, could

seriously damage the compact

spare.

Any continuous road use of this tire could result in tire failure, loss of

vehicle control, and possible per-

sonal injury.

Do not exceed the vehicle’s maxi- mum load rating or the load-carry-

ing capacity shown on the sidewall

of the compact spare tire.

Avoid driving over obstacles. The compact spare tire diameter issmaller than the diameter of a con-

ventional tire and reduces the

ground clearance approximately25 mm (1 inch), which could result

in damage to the vehicle.

CAUTION

You should drive carefully

when the compact spare is inuse. The compact spareshould be replaced by theproper conventional tire and rim at the first opportunity.

The operation of this vehicle is not recommended withmore than one compact sparetire in use at the same time.

WARNING

The compact spare tire is for

emergency use only. Do not

operate your vehicle on this

compact spare at speeds over

80 km/h (50 mph). The originaltire should be repaired or

replaced as soon as is possible

to avoid failure of the spare

possibly leading to personal

injury or death.

Page 255 of 354

617

What to do in an emergency

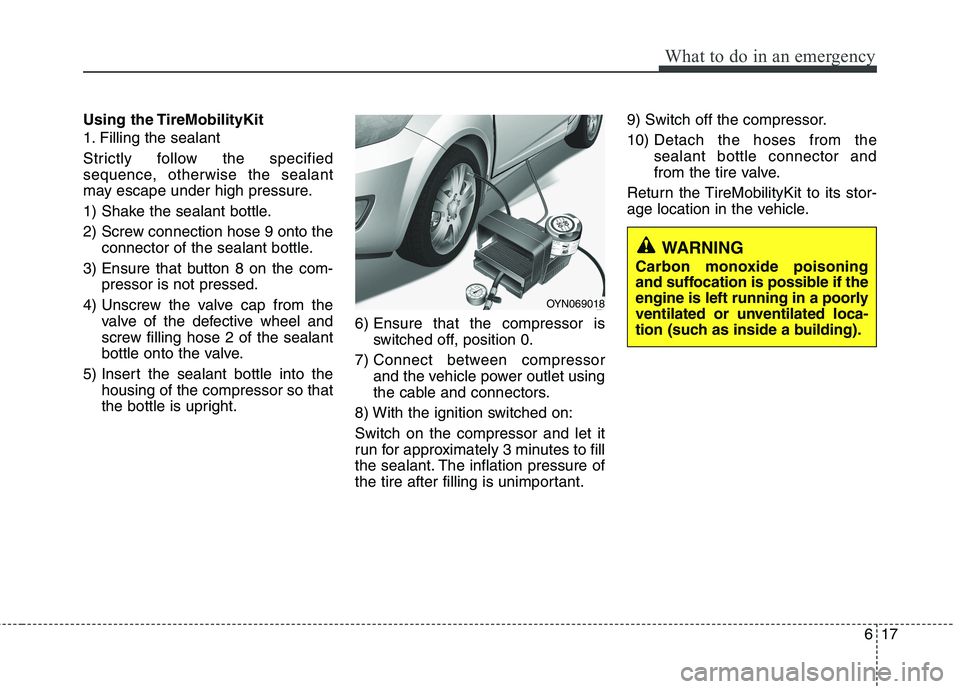

Using the TireMobilityKit

1. Filling the sealant

Strictly follow the specified

sequence, otherwise the sealant

may escape under high pressure.

1) Shake the sealant bottle.

2) Screw connection hose 9 onto theconnector of the sealant bottle.

3) Ensure that button 8 on the com- pressor is not pressed.

4) Unscrew the valve cap from the valve of the defective wheel and

screw filling hose 2 of the sealant

bottle onto the valve.

5) Insert the sealant bottle into the housing of the compressor so that

the bottle is upright. 6) Ensure that the compressor is

switched off, position 0.

7) Connect between compressor and the vehicle power outlet using

the cable and connectors.

8) With the ignition switched on: Switch on the compressor and let it

run for approximately 3 minutes to fill

the sealant. The inflation pressure of

the tire after filling is unimportant. 9) Switch off the compressor. 10)

Detach the hoses from the sealant bottle connector and

from the tire valve.

Return the TireMobilityKit to its stor-

age location in the vehicle.

WARNING

Carbon monoxide poisoning

and suffocation is possible if the

engine is left running in a poorly

ventilated or unventilated loca-

tion (such as inside a building).

OYN069018

Page 262 of 354

What to do in an emergency

24

6

EMERGENCY COMMODITY (IF EQUIPPED)

F110000AUN There are some emergency commodities

in the vehicle to help you respond to theemergency situation.

F110100AUN

Fire extinguisher

If there is small fire and you know how to

use the fire extinguisher, take the follow-

ing steps carefully.

1. Pull the pin at the top of the extin- guisher that keeps the handle from being accidentally pressed.

2. Aim the nozzle toward the base of the fire.

3. Stand approximately 2.5 m (8 ft) away from the fire and squeeze the handle

to discharge the extinguisher. If you

release the handle, the discharge will

stop.

4. Sweep the nozzle back and forth at the base of the fire. After the fire appears

to be out, watch it carefully since it

may re-ignite. F110200AUN

First aid kit

There are some items such as scissors,

bandage and adhesive tape and etc. in

the kit to give first aid to an injured per-son.

F110300AUN

Triangle reflector

Place the triangle reflector on the road to

warn oncoming vehicles during emer-

gencies, such as when the vehicle is

parked by the roadside due to any prob-

lems.

F110400AUN

Tire pressure gauge (If equipped)

Tires normally lose some air in day-to-

day use, and you may have to add a few

pounds of air periodically and it is not

usually a sign of a leaking tire, but of nor-

mal wear. Always check tire pressurewhen the tires are cold because tire pres-

sure increases with temperature. To check the tire pressure, take the fol-

lowing steps;

1. Unscrew the inflation valve cap that is

located on the rim of the tire.

2. Press and hold the gauge against the tire valve. Some air will escape as you

begin and more will escape if you don't

press the gauge in firmly.

3. A firm non-leaking push will activate the gauge.

4. Read the tire pressure on the gauge to know whether the tire pressure is lowor high.

5. Adjust the tire pressures to the speci- fied pressure. Refer to “Tires and

wheels” in section 9.

6. Reinstall the inflation valve cap.

Page 267 of 354

75

Maintenance

MAINTENANCE SERVICES

G020000AEN

You should exercise the utmost care to

prevent damage to your vehicle and

injury to yourself whenever performing

any maintenance or inspection proce-

dures.

Should you have any doubts concerning

the inspection or servicing of your vehi-

cle, we strongly recommend that you

have an authorized HYUNDAI dealer

perform this work.

An authorized HYUNDAI dealer has fac-

tory-trained technicians and genuine

HYUNDAI parts to service your vehicle

properly. For expert advice and quality

service, see an authorized HYUNDAI

dealer.

Inadequate, incomplete or insufficient

servicing may result in operational prob-

lems with your vehicle that could lead to

vehicle damage, an accident, or person-

al injury. G020100AEN

Owner’s responsibility

✽✽

NOTICE

Maintenance Service and Record

Retention are the owner's responsibility.

You should retain documents that show

proper maintenance has been performed

on your vehicle in accordance with the

scheduled maintenance service charts

shown on the following pages. You need

this information to establish your compli-

ance with the servicing and maintenance

requirements of your vehicle warranties.

Detailed warranty information is provided

in your Service Passport. Repairs and adjustments required as a

result of improper maintenance or a lack

of required maintenance are not covered.

We recommend you have your vehicle

maintained and repaired by an author-

ized HYUNDAI dealer. An authorized

HYUNDAI dealer meets HYUNDAI’s high

service quality standards and receives

technical support from HYUNDAI in

order to provide you with a high level of

service satisfaction. G020200APA Owner maintenance precautions

Improper or incomplete service may

result in problems. This section gives

instructions only for the maintenance

items that are easy to perform.

As explained earlier in this section, sev-

eral procedures can be done only by an

authorized HYUNDAI dealer with special

tools.

✽✽

NOTICE

Improper owner maintenance during

the warranty period may affect warran-

ty coverage. For details, read the sepa-

rate Service Passport provided with the

vehicle. If you're unsure about any serv-

icing or maintenance procedure, have it

done by an authorized HYUNDAI deal-

er.

Page 285 of 354

723

Maintenance

G050600AUN

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap iscorrectly replaced.

G050700AUN

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.G050800AEN

Air cleaner filter

A Genuine HYUNDAI air cleaner filter is recommended when the filter isreplaced.

G050900AUN Spark plugs

Make sure to install new spark plugs of

the correct heat range. G051000AEN

Valve clearance (if equipped)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized HYUNDAI dealer should

perform the operation.

G051100AUN Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

G051200AUN Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

G051300AUN

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

G051400AUN

Automatic transaxle fluid (if equipped)

The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.

G051500AUN Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Page 289 of 354

727

Maintenance

ENGINE COOLANT

G070000AUN The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at thebeginning of the winter season, and

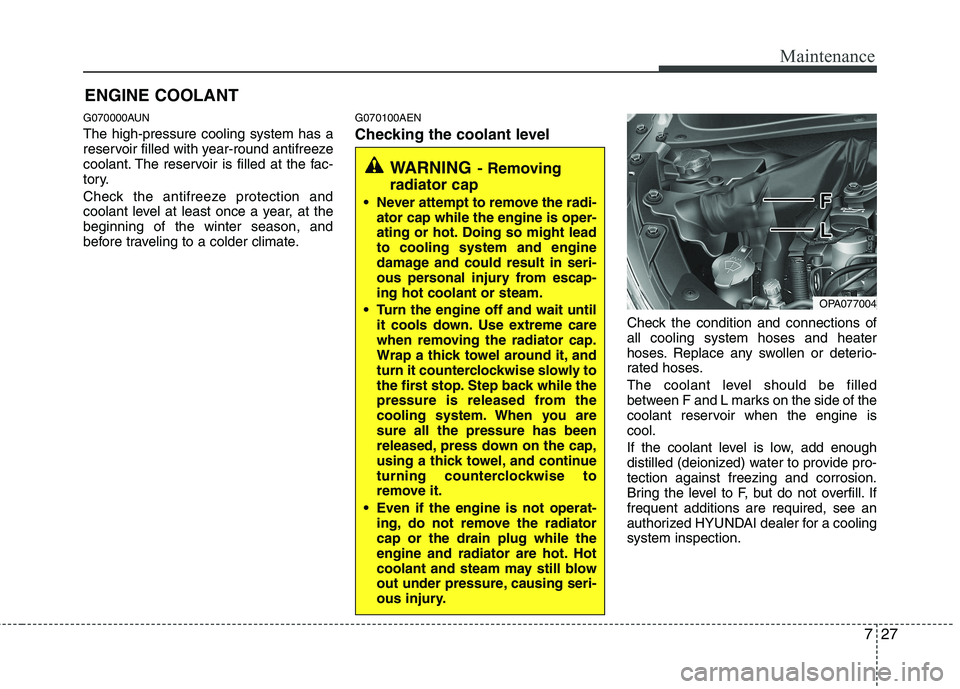

before traveling to a colder climate.G070100AEN

Checking the coolant level

Check the condition and connections of all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F and L marks on the side of the

coolant reservoir when the engine iscool.

If the coolant level is low, add enough

distilled (deionized) water to provide pro-tection against freezing and corrosion.

Bring the level to F, but do not overfill. Iffrequent additions are required, see an

authorized HYUNDAI dealer for a coolingsystem inspection.

WARNING- Removing

radiator cap

Never attempt to remove the radi- ator cap while the engine is oper-

ating or hot. Doing so might leadto cooling system and engine

damage and could result in seri-

ous personal injury from escap-ing hot coolant or steam.

Turn the engine off and wait until it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

Even if the engine is not operat- ing, do not remove the radiatorcap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

OPA077004

Page 292 of 354

Maintenance

30

7

AUTOMATIC TRANSAXLE FLUID (IF EQUIPPED)

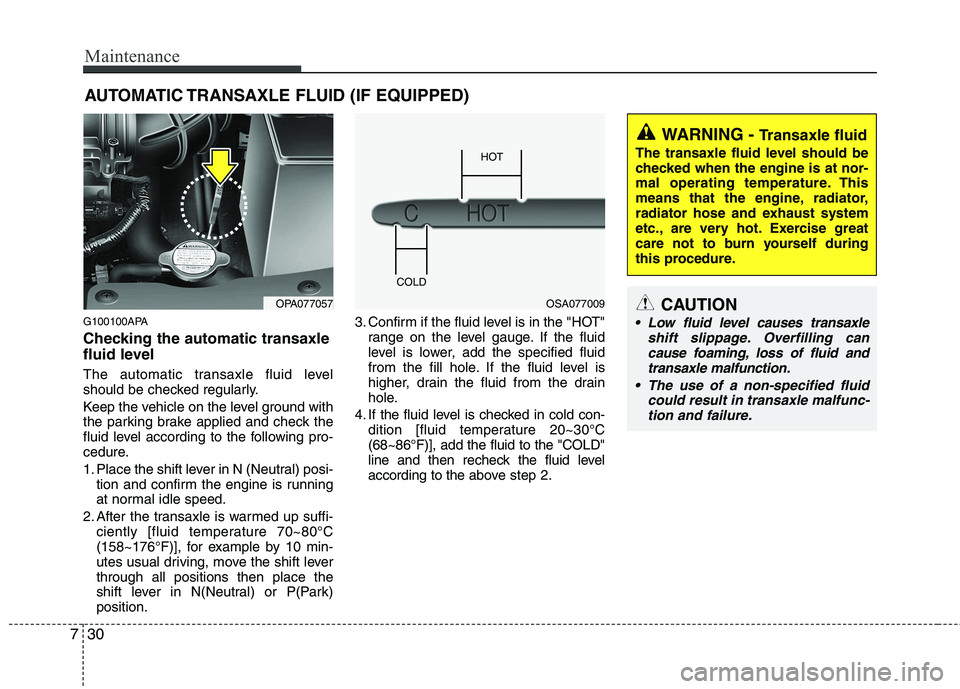

G100100APA

Checking the automatic transaxle

fluid level

The automatic transaxle fluid level

should be checked regularly.

Keep the vehicle on the level ground with

the parking brake applied and check the

fluid level according to the following pro-

cedure.

1. Place the shift lever in N (Neutral) posi- tion and confirm the engine is running

at normal idle speed.

2. After the transaxle is warmed up suffi- ciently [fluid temperature 70~80°C

(158~176°F)], for example by 10 min-

utes usual driving, move the shift leverthrough all positions then place the

shift lever in N(Neutral) or P(Park)position. 3. Confirm if the fluid level is in the "HOT"

range on the level gauge. If the fluid

level is lower, add the specified fluid

from the fill hole. If the fluid level is

higher, drain the fluid from the drain

hole.

4. If the fluid level is checked in cold con- dition [fluid temperature 20~30°C(68~86°F)], add the fluid to the "COLD"

line and then recheck the fluid level

according to the above step 2.

OPA077057OSA077009

HOT

COLD

WARNING - Transaxle fluid

The transaxle fluid level should be

checked when the engine is at nor-

mal operating temperature. This

means that the engine, radiator,

radiator hose and exhaust system

etc., are very hot. Exercise great

care not to burn yourself during

this procedure.

CAUTION

Low fluid level causes transaxle shift slippage. Overfilling cancause foaming, loss of fluid andtransaxle malfunction.

The use of a non-specified fluid could result in transaxle malfunc-

tion and failure.

Page 301 of 354

739

Maintenance

G190100AUN

For best battery service

Keep the battery securely mounted.

Keep the battery top clean and dry.

Keep the terminals and connectionsclean, tight, and coated with petroleum

jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a solution of

water and baking soda.

If the vehicle is not going to be used for an extended time, disconnect the bat-

tery cables.

BATTERY

OPA071119N

WARNING

- Battery

dangers

Always read the following

instructions carefully when

handling a battery.

Keep lighted cigarettes and all other flames or sparks

away from the battery.

Hydrogen, a highly com- bustible gas, is always

present in battery cells and

may explode if ignited.

Keep batteries out of the reach of children because

batteries contain highly

corrosive SULFURIC ACID.

Do not allow battery acid to

contact your skin, eyes,

clothing or paint finish.

If any electrolyte gets into your eyes, flush your eyes

with clean water for at least

15 minutes and get immedi-ate medical attention.

(Continued)(Continued)

If electrolyte gets on your

skin, thoroughly wash the

contacted area. If you feel a

pain or a burning sensa-

tion, get medical attention

immediately.

Wear eye protection whencharging or working near a

battery. Always provide

ventilation when working in

an enclosed space.

An inappropriately dis- posed battery can be harm-

ful to the environment and

human health. Dispose the

battery according to your

local law(s) or regulation.

When lifting a plastic-cased bat- tery, excessive pressure on the

case may cause battery acid to

leak, resulting in personal injury.

Lift with a battery carrier or with

your hands on opposite corners.

Never attempt to recharge the battery when the battery cablesare connected.

(Continued)

Page 302 of 354

Maintenance

40

7

G190200AUN

Battery recharging

Your vehicle has a maintenance-free,

calcium-based battery.

If the battery becomes discharged in a

short time (because, for example, the

headlights or interior lights were left on

while the vehicle was not in use),

recharge it by slow charging (trickle)

for 10 hours.

If the battery gradually discharges because of high electric load while the

vehicle is being used, recharge it at 20-

30A for two hours. G190300APA Reset items

Items should be reset after the battery

has been discharged or the battery hasbeen disconnected.

Sunroof (See section 4)

Digital clock (See section 4)

Audio (See section 4)

(Continued)

The electrical ignition system

works with high voltage. Never

touch these components with theengine running or the ignition

switched on.

Failure to follow the above warn-

ings can result in serious bodily

injury or death.(Continued)

Before performing maintenance or recharging the battery, turn off all accessories and stop the

engine.

The negative battery cable must be removed first and installed

last when the battery is discon-nected.WARNING - Recharging

battery

When recharging the battery,

observe the following precautions:

The battery must be removed from the vehicle and placed in an area with good ventilation.

Do not allow cigarettes, sparks, or flame near the battery.

Watch the battery during charg- ing, and stop or reduce the charg-

ing rate if the battery cells begin

gassing (boiling) violently or if

the temperature of the electrolyte

of any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

(Continued)