h4 high HYUNDAI I10 2009 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2009, Model line: I10, Model: HYUNDAI I10 2009Pages: 354, PDF Size: 37.04 MB

Page 303 of 354

741

Maintenance

CAUTION

Underinflation also results inexcessive wear, poor handlingand reduced fuel economy. Wheel deformation also ispossible. Keep your tire pres-sures at the proper levels. If a tire frequently needs refilling,have it checked by an author-ized HYUNDAI dealer.

Overinflation produces a harsh ride, excessive wear atthe center of the tire tread, anda greater possibility of dam-age from road hazards.

TIRES AND WHEELS

G200100AUN Tire care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tire

inflation pressures and stay within

the load limits and weight distribution

recommended for your vehicle. G200200AEN Recommended cold tire inflation pressures All tire pressures (including the

spare) should be checked when the

tires are cold. “Cold Tires” means the

vehicle has not been driven for at

least three hours or driven less than1.6 km (one mile).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tire wear.

For recommended inflation pressure,

refer to “Tire and wheels” in section9. All specifications (sizes and pres-

sures) can be found on a label

attached to the vehicle.

WARNING - Tire underin-

flation

Severe underinflation can lead

to severe heat build-up, causing

blowouts, tread separation andother tire failures that can result

in the loss of vehicle control

leading to severe injury or

death. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OPA087003

Page 310 of 354

Maintenance

48

7

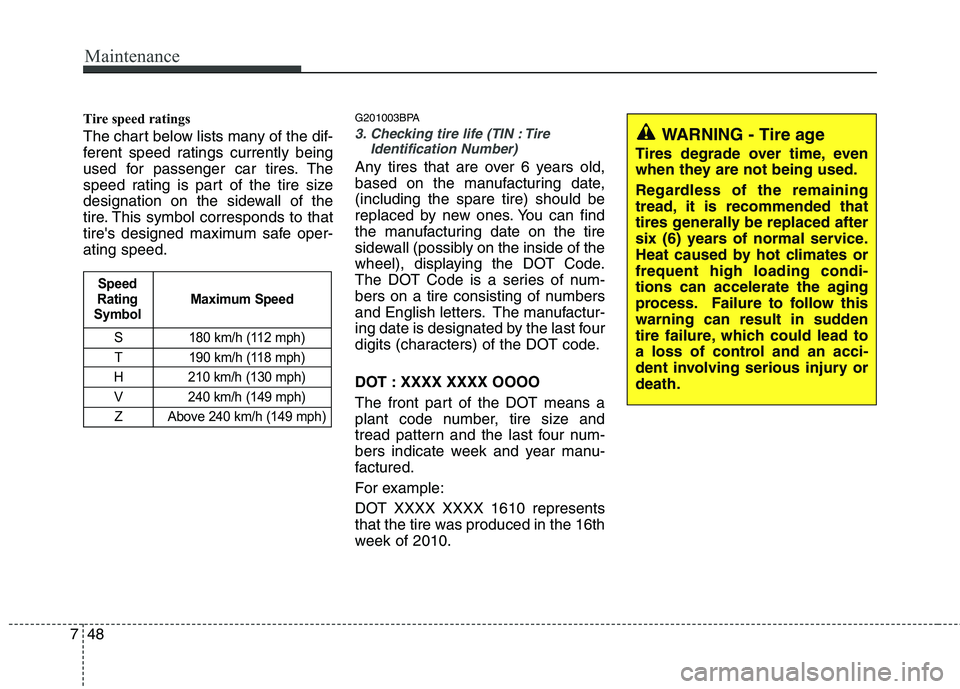

Tire speed ratings

The chart below lists many of the dif-

ferent speed ratings currently being

used for passenger car tires. The

speed rating is part of the tire size

designation on the sidewall of the

tire. This symbol corresponds to that

tire's designed maximum safe oper-ating speed. G201003BPA

3. Checking tire life (TIN : Tire

Identification Number)

Any tires that are over 6 years old,

based on the manufacturing date,(including the spare tire) should be

replaced by new ones. You can find

the manufacturing date on the tire

sidewall (possibly on the inside of the

wheel), displaying the DOT Code.

The DOT Code is a series of num-

bers on a tire consisting of numbers

and English letters. The manufactur-

ing date is designated by the last four

digits (characters) of the DOT code.

DOT : XXXX XXXX OOOO

The front part of the DOT means a

plant code number, tire size and

tread pattern and the last four num-

bers indicate week and year manu-

factured.

For example:

DOT XXXX XXXX 1610 represents

that the tire was produced in the 16th

week of 2010.

S 180 km/h (112 mph)

T 190 km/h (118 mph)

H 210 km/h (130 mph) V 240 km/h (149 mph)

Z Above 240 km/h (149 mph)

Maximum Speed

Speed

Rating

Symbol

WARNING - Tire age

Tires degrade over time, even

when they are not being used.

Regardless of the remaining

tread, it is recommended that

tires generally be replaced after

six (6) years of normal service.

Heat caused by hot climates orfrequent high loading condi-

tions can accelerate the aging

process. Failure to follow this

warning can result in sudden

tire failure, which could lead to

a loss of control and an acci-

dent involving serious injury ordeath.

Page 312 of 354

Maintenance

50

7

Traction - AA, A, B & C

The traction grades, from highest to

lowest, are AA, A, B and C. Those

grades represent the tire’s ability to

stop on wet pavement as measuredunder controlled conditions on spec-

ified government test surfaces of

asphalt and concrete. A tire marked

C may have poor traction perform-

ance. Temperature -A, B & C

The temperature grades are A (the

highest), B, and C, representing the

tire’s resistance to the generation ofheat and its ability to dissipate heatwhen tested under controlled condi-

tions on a specified indoor laboratorytest wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. Grades B and A

represent higher levels of perform-

ance on the laboratory test wheel

than the minimum required by law.

WARNING - Tire

temperature

The temperature grade for this

tire is established for a tire that

is properly inflated and not

overloaded. Excessive speed,

underinflation, or excessive

loading, either separately or in

combination, can cause heat

build-up and possible sudden

tire failure. This can cause loss

of vehicle control and serious

injury or death.

WARNING

The traction grade assigned to this tire is based on straight-ahead braking traction tests,

and does not include accelera-

tion, cornering, hydroplaning,

or peak traction characteristics.

Page 313 of 354

751

Maintenance

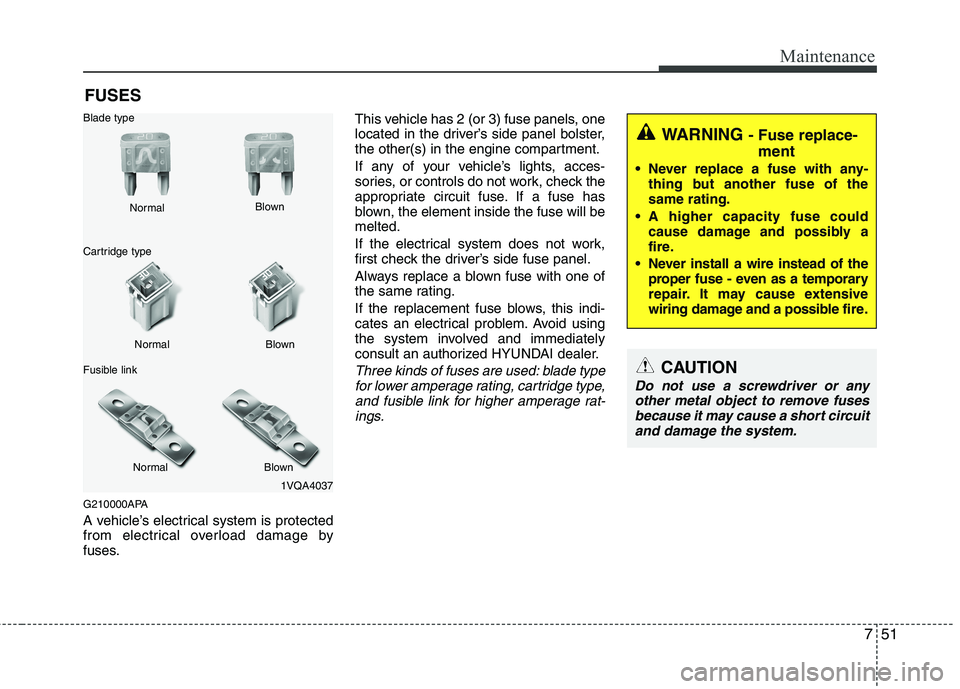

FUSES

G210000APA

A vehicle’s electrical system is protected

from electrical overload damage by

fuses. This vehicle has 2 (or 3) fuse panels, one

located in the driver’s side panel bolster,

the other(s) in the engine compartment.

If any of your vehicle’s lights, acces-

sories, or controls do not work, check the

appropriate circuit fuse. If a fuse has

blown, the element inside the fuse will bemelted.

If the electrical system does not work,

first check the driver’s side fuse panel.

Always replace a blown fuse with one of

the same rating.

If the replacement fuse blows, this indi-

cates an electrical problem. Avoid using

the system involved and immediately

consult an authorized HYUNDAI dealer.

Three kinds of fuses are used: blade type

for lower amperage rating, cartridge type,

and fusible link for higher amperage rat- ings.

1VQA4037

Normal

Normal

Blade type

Cartridge type

Fusible link Blown

Blown

Normal Blown

WARNING - Fuse replace-

ment

Never replace a fuse with any- thing but another fuse of the same rating.

A higher capacity fuse could cause damage and possibly a

fire.

Never install a wire instead of the proper fuse - even as a temporary

repair. It may cause extensive

wiring damage and a possible fire.

CAUTION

Do not use a screwdriver or any

other metal object to remove fuses because it may cause a short circuitand damage the system.

Page 325 of 354

763

Maintenance

LIGHT BULBS

G220000AEN

Use only the bulbs of the specified wattage.

✽✽ NOTICE

After heavy, driving rain or washing,

headlight and taillight lenses could

appear frosty. This condition is caused by

the temperature difference between the

lamp inside and outside. This is similar

to the condensation on your windows

inside your vehicle during the rain and

doesn’t indicate a problem with your

vehicle. If the water leaks into the lamp

bulb circuitry, have the vehicle checked

by an authorized HYUNDAI dealer.

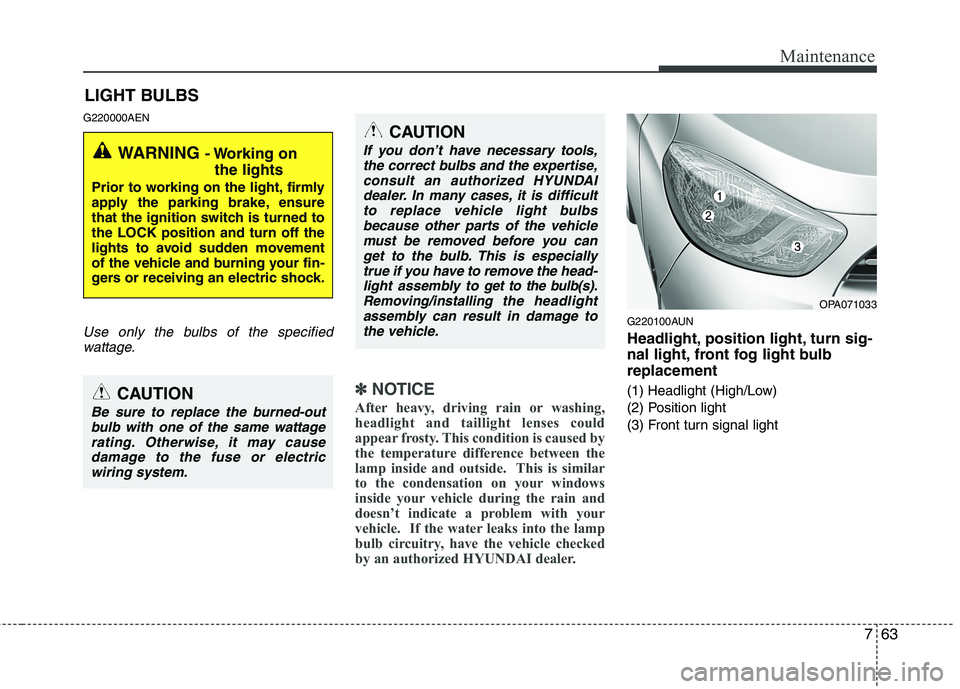

G220100AUN

Headlight, position light, turn sig-

nal light, front fog light bulbreplacement

(1) Headlight (High/Low)

(2) Position light

(3) Front turn signal light

WARNING - Working on

the lights

Prior to working on the light, firmly

apply the parking brake, ensure

that the ignition switch is turned tothe LOCK position and turn off the

lights to avoid sudden movement

of the vehicle and burning your fin-

gers or receiving an electric shock.

CAUTION

Be sure to replace the burned-out bulb with one of the same wattage

rating. Otherwise, it may cause damage to the fuse or electricwiring system.

CAUTION

If you don’t have necessary tools,the correct bulbs and the expertise,

consult an authorized HYUNDAIdealer. In many cases, it is difficultto replace vehicle light bulbs because other parts of the vehicle

must be removed before you canget to the bulb. This is especiallytrue if you have to remove the head-

light assembly to

get to the bulb(s).

Removing/installingthe headlight

assembly can result in damage to the vehicle.OPA071033

Page 331 of 354

769

Maintenance

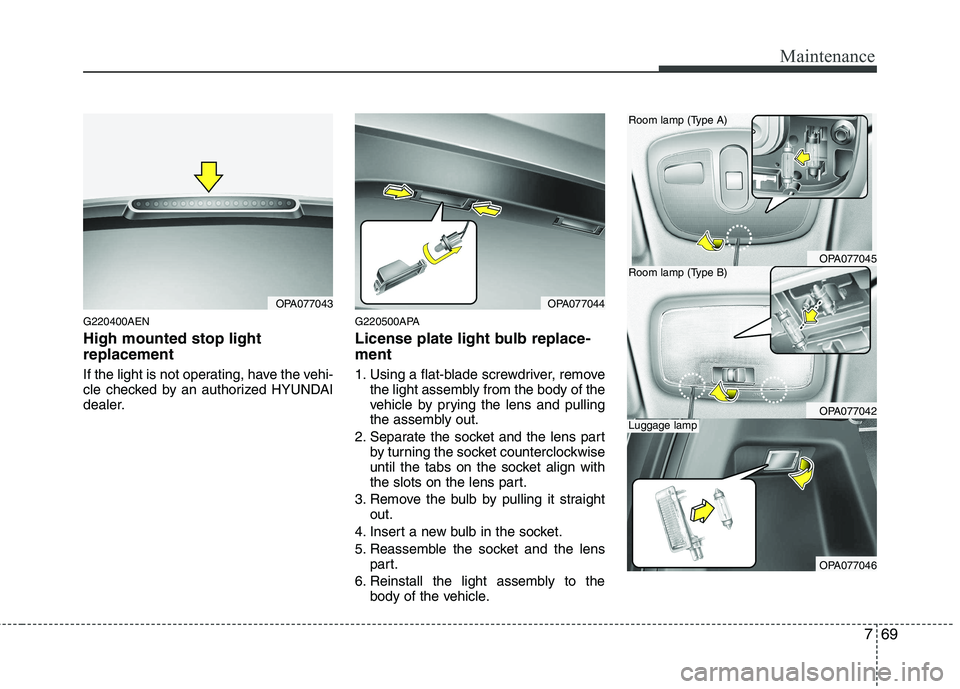

G220400AEN High mounted stop light replacement

If the light is not operating, have the vehi-

cle checked by an authorized HYUNDAI

dealer.G220500APA

License plate light bulb replace- ment

1. Using a flat-blade screwdriver, remove

the light assembly from the body of the

vehicle by prying the lens and pulling

the assembly out.

2. Separate the socket and the lens part by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the lens part.

3. Remove the bulb by pulling it straight out.

4. Insert a new bulb in the socket.

5. Reassemble the socket and the lens part.

6. Reinstall the light assembly to the body of the vehicle.

OPA077043OPA077044

OPA077045

OPA077042

OPA077046

Room lamp (Type A)

Room lamp (Type B)

Luggage lamp

Page 333 of 354

771

Maintenance

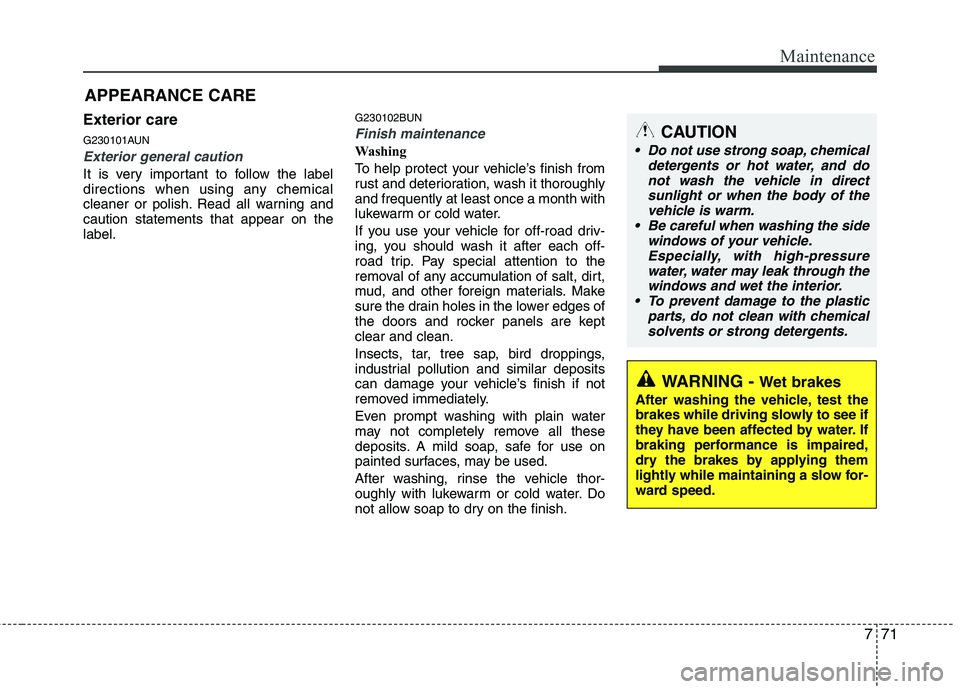

Exterior care

G230101AUN

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning andcaution statements that appear on thelabel.G230102BUN

Finish maintenance

Washing

To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughlyand frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are keptclear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.

APPEARANCE CARE

CAUTION

Do not use strong soap, chemical

detergents or hot water, and do

not wash the vehicle in direct sunlight or when the body of thevehicle is warm.

Be careful when washing the side

windows of your vehicle.Especially, with high-pressure water, water may leak through the

windows and wet the interior.

To prevent damage to the plastic parts, do not clean with chemicalsolvents or strong detergents.

WARNING - Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 334 of 354

Maintenance

72

7

Waxing

Wax the vehicle when water will no longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing. G230103AUN

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽✽

NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

CAUTION

Water washing in the engine com- partment including high pressure

water washing may cause the fail-ure of electrical circuits located in the engine compartment.

Never allow water or other liquids to come in contact with electri-cal/electronic components insidethe vehicle as this may damage them.

OJB037800

CAUTION

Wiping dust or dirt off the body with a dry cloth will scratch the

finish.

Do not use steel wool, abrasive cleaners, or strong detergentscontaining highly alkaline orcaustic agents on chrome-plated

or anodized aluminum parts. Thismay result in damage to the pro-tective coating and cause discol-oration or paint deterioration.

Page 335 of 354

773

Maintenance

G230104AUN

Bright-metal maintenance

To remove road tar and insects, use atar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound. G230105AUN

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Payspecial attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 336 of 354

Maintenance

74

7

G230106AUN

Aluminum wheel maintenance

The aluminum wheels are coated with a

clear protective finish.

Do not use any abrasive cleaner, pol-

ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

Use only a mild soap or neutral deter- gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

Avoid washing the wheels with high- speed car wash brushes.

Do not use any acid detergent. It may damage and corrode the aluminum

wheels coated with a clear protectivefinish. G230107AUN

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design and

construction practices to combat corro-

sion, we produces cars of the highest

quality. However, this is only part of the

job. To achieve the long-term corrosion

resistance your vehicle can deliver, the

owner's cooperation and assistance isalso required.

Common causes of corrosion The most common causes of corrosion

on your car are:

allowed to accumulate underneath the

car.

Removal of paint or protective coatings by stones, gravel, abrasion or minor

scrapes and dents which leave unpro-

tected metal exposed to corrosion. High-corrosion areas

If you live in an area where your car is

regularly exposed to corrosive materials,

corrosion protection is particularly impor-

tant. Some of the common causes of

accelerated corrosion are road salts,

dust control chemicals, ocean air and

industrial pollution.