ignition HYUNDAI I10 2012 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2012, Model line: I10, Model: HYUNDAI I10 2012Pages: 354, PDF Size: 37.04 MB

Page 255 of 354

617

What to do in an emergency

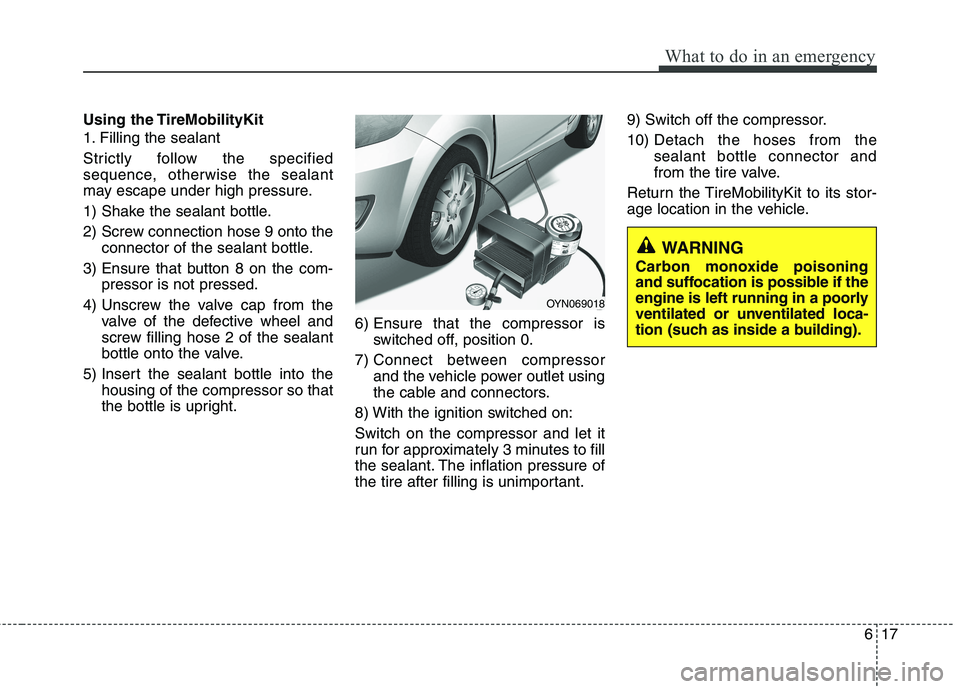

Using the TireMobilityKit

1. Filling the sealant

Strictly follow the specified

sequence, otherwise the sealant

may escape under high pressure.

1) Shake the sealant bottle.

2) Screw connection hose 9 onto theconnector of the sealant bottle.

3) Ensure that button 8 on the com- pressor is not pressed.

4) Unscrew the valve cap from the valve of the defective wheel and

screw filling hose 2 of the sealant

bottle onto the valve.

5) Insert the sealant bottle into the housing of the compressor so that

the bottle is upright. 6) Ensure that the compressor is

switched off, position 0.

7) Connect between compressor and the vehicle power outlet using

the cable and connectors.

8) With the ignition switched on: Switch on the compressor and let it

run for approximately 3 minutes to fill

the sealant. The inflation pressure of

the tire after filling is unimportant. 9) Switch off the compressor. 10)

Detach the hoses from the sealant bottle connector and

from the tire valve.

Return the TireMobilityKit to its stor-

age location in the vehicle.

WARNING

Carbon monoxide poisoning

and suffocation is possible if the

engine is left running in a poorly

ventilated or unventilated loca-

tion (such as inside a building).

OYN069018

Page 256 of 354

What to do in an emergency

18

6

Distributing the sealant

Immediately drive approximately 3

km (2 miles) to evenly distribute the

sealant in the tire. Producing the tire inflation pres- sure

1) After driving approximately 3 km

(2 miles), stop at a suitable loca- tion.

2) Connect connection hose 9 of the compressor directly to the tire

valve.

3) Connect between compressor and the vehicle power outlet using

the cable and connectors.

4) Adjust the tire inflation pressure to 230 kPa (33 psi). With the ignition

switched on, proceed as follows.

- To increase the inflation pres- sure: Switch on the compressor,

position I. To check the current

inflation pressure setting, briefly

switch off the compressor. - To reduce the inflation pres-

sure: Press the button 8 on the

compressor.

WARNING

Do not let the compressor run for

more than 10 minutes, otherwise

the device will overheat and may

be damaged.

WARNING

The tire inflation pressure must

be at least 230 kPa (33 psi). If it is

not, do not continue driving. Call

for road side service or towing.

CAUTION

Do not exceed a speed of 60 km/h (35 mph). If possible, donot fall below a speed of 20 km/h (12 mph).

While driving, if you experienceany unusual vibration, ride dis-turbance or noise, reduce yourspeed and drive with caution until you can safely pull off ofthe side of the road.

Call for road side service or tow-ing.

CAUTION

If the inflation pressure is notmaintained, drive the vehicle asecond time, refer to Distributing the sealant. Then repeat steps 1to 4.

Use of the TireMobilityKit maybe ineffectual for tire damagelarger than approximately 4 mm (0.16 in).

Please contact the nearestHYUNDAI A/S center, or a work-shop that works according toHYUNDAI repair procedures with correspondingly trainedpersonnel if the tire cannot bemade roadworthy with the TireMobilityKit.

Page 259 of 354

621

What to do in an emergency

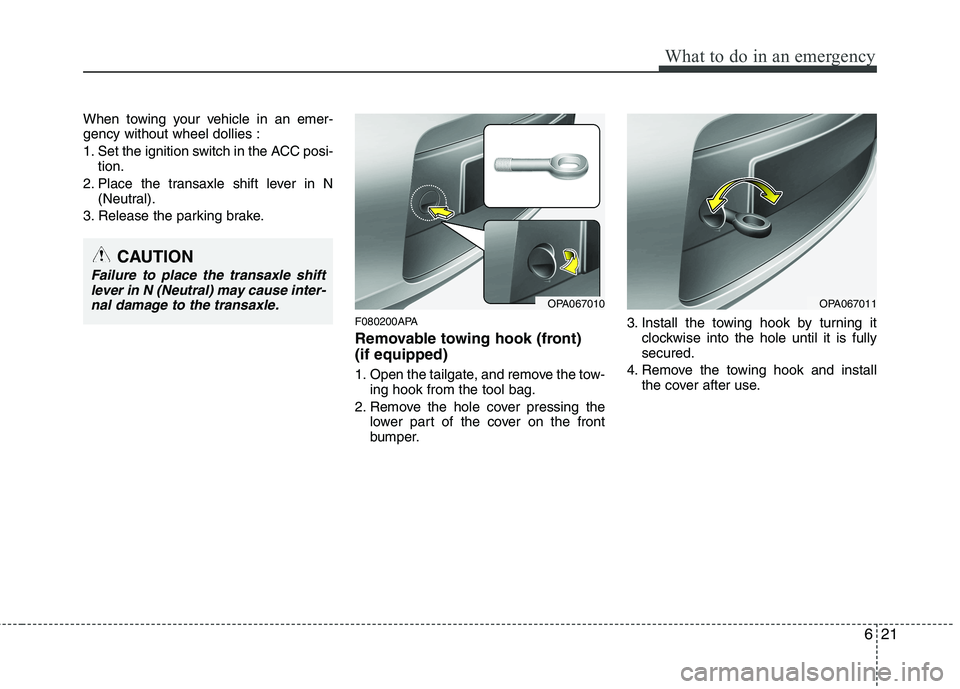

When towing your vehicle in an emer- gency without wheel dollies :

1. Set the ignition switch in the ACC posi-tion.

2. Place the transaxle shift lever in N (Neutral).

3. Release the parking brake.

F080200APA

Removable towing hook (front) (if equipped)

1. Open the tailgate, and remove the tow-ing hook from the tool bag.

2. Remove the hole cover pressing the lower part of the cover on the front

bumper. 3. Install the towing hook by turning it

clockwise into the hole until it is fullysecured.

4. Remove the towing hook and install the cover after use.

CAUTION

Failure to place the transaxle shift

lever in N (Neutral) may cause inter-nal damage to the transaxle.

OPA067010OPA067011

Page 261 of 354

623

What to do in an emergency

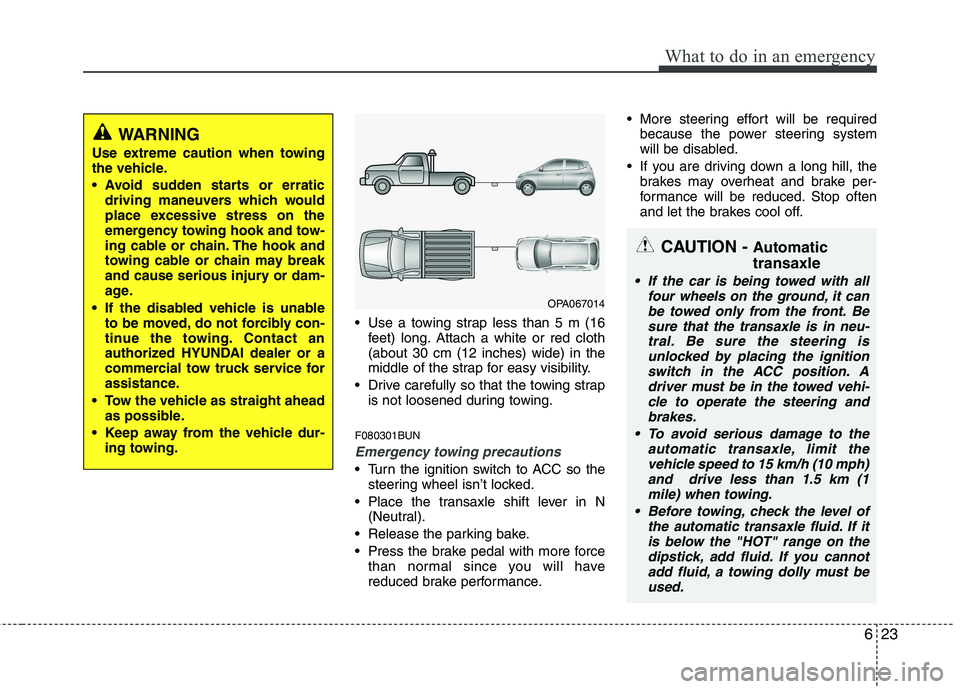

Use a towing strap less than 5 m (16feet) long. Attach a white or red cloth (about 30 cm (12 inches) wide) in the

middle of the strap for easy visibility.

Drive carefully so that the towing strap is not loosened during towing.

F080301BUN

Emergency towing precautions

Turn the ignition switch to ACC so the steering wheel isn’t locked.

Place the transaxle shift lever in N (Neutral).

Release the parking bake.

Press the brake pedal with more force than normal since you will have

reduced brake performance. More steering effort will be required

because the power steering system

will be disabled.

If you are driving down a long hill, the brakes may overheat and brake per-

formance will be reduced. Stop often

and let the brakes cool off.

WARNING

Use extreme caution when towing

the vehicle.

driving maneuvers which would

place excessive stress on the

emergency towing hook and tow-

ing cable or chain. The hook and

towing cable or chain may break

and cause serious injury or dam-

age.

If the disabled vehicle is unable to be moved, do not forcibly con-

tinue the towing. Contact an

authorized HYUNDAI dealer or a

commercial tow truck service for

assistance.

Tow the vehicle as straight ahead as possible.

Keep away from the vehicle dur- ing towing.

OPA067014

CAUTION - Automatic transaxle

If the car is being towed with all

four wheels on the ground, it can

be towed only from the front. Be sure that the transaxle is in neu-tral. Be sure the steering is unlocked by placing the ignition

switch in the ACC position. A driver must be in the towed vehi-cle to operate the steering and brakes.

To avoid serious damage to the automatic transaxle, limit thevehicle speed to 15 km/h (10 mph)and drive less than 1.5 km (1 mile) when towing.

Before towing, check the level of the automatic transaxle fluid. If itis below the "HOT" range on the dipstick, add fluid. If you cannot

add fluid, a towing dolly must be used.

Page 302 of 354

Maintenance

40

7

G190200AUN

Battery recharging

Your vehicle has a maintenance-free,

calcium-based battery.

If the battery becomes discharged in a

short time (because, for example, the

headlights or interior lights were left on

while the vehicle was not in use),

recharge it by slow charging (trickle)

for 10 hours.

If the battery gradually discharges because of high electric load while the

vehicle is being used, recharge it at 20-

30A for two hours. G190300APA Reset items

Items should be reset after the battery

has been discharged or the battery hasbeen disconnected.

Sunroof (See section 4)

Digital clock (See section 4)

Audio (See section 4)

(Continued)

The electrical ignition system

works with high voltage. Never

touch these components with theengine running or the ignition

switched on.

Failure to follow the above warn-

ings can result in serious bodily

injury or death.(Continued)

Before performing maintenance or recharging the battery, turn off all accessories and stop the

engine.

The negative battery cable must be removed first and installed

last when the battery is discon-nected.WARNING - Recharging

battery

When recharging the battery,

observe the following precautions:

The battery must be removed from the vehicle and placed in an area with good ventilation.

Do not allow cigarettes, sparks, or flame near the battery.

Watch the battery during charg- ing, and stop or reduce the charg-

ing rate if the battery cells begin

gassing (boiling) violently or if

the temperature of the electrolyte

of any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

(Continued)

Page 314 of 354

Maintenance

52

7

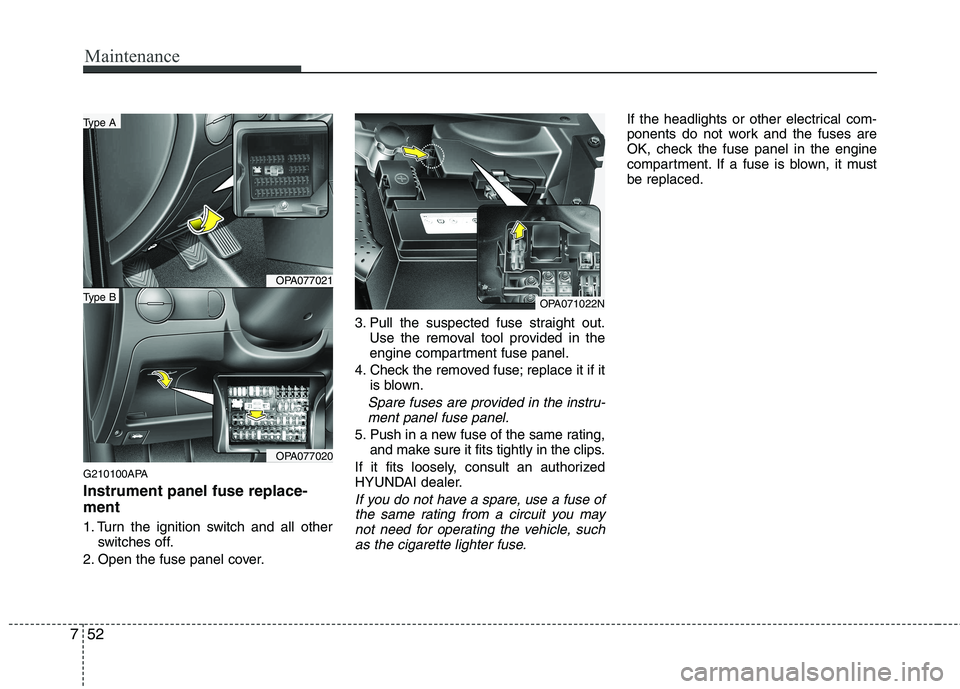

G210100APA Instrument panel fuse replace- ment

1. Turn the ignition switch and all other

switches off.

2. Open the fuse panel cover. 3. Pull the suspected fuse straight out.

Use the removal tool provided in the

engine compartment fuse panel.

4. Check the removed fuse; replace it if it is blown.

Spare fuses are provided in the instru-

ment panel fuse panel.

5. Push in a new fuse of the same rating, and make sure it fits tightly in the clips.

If it fits loosely, consult an authorized

HYUNDAI dealer.

If you do not have a spare, use a fuse of the same rating from a circuit you maynot need for operating the vehicle, suchas the cigarette lighter fuse.

If the headlights or other electrical com-

ponents do not work and the fuses are

OK, check the fuse panel in the engine

compartment. If a fuse is blown, it mustbe replaced.

OPA071022N

OPA077021

OPA077020

Type A

Type B

Page 315 of 354

753

Maintenance

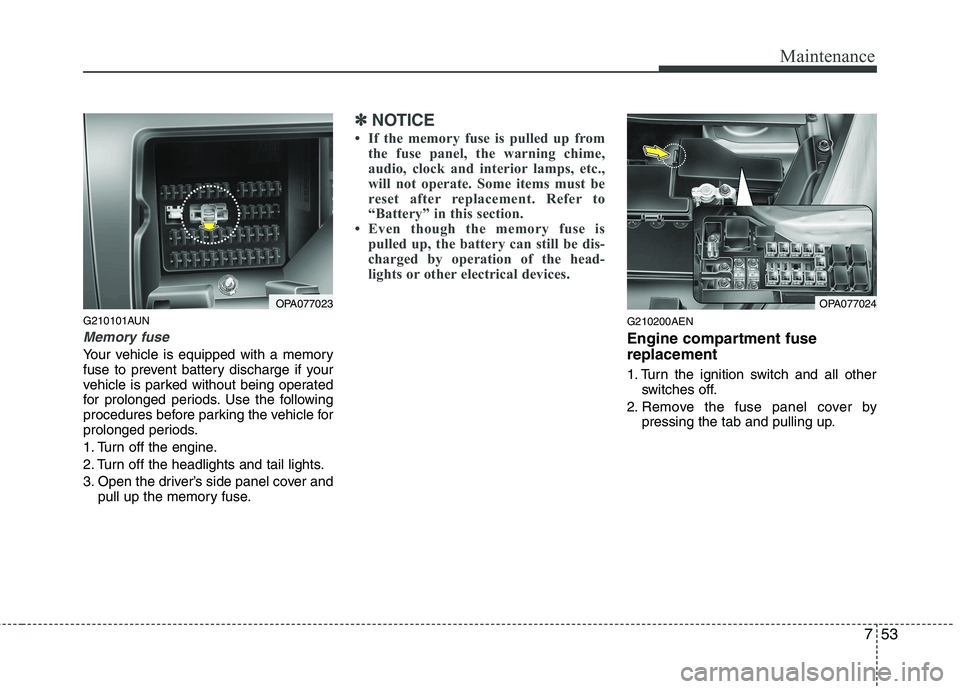

G210101AUN

Memory fuse

Your vehicle is equipped with a memory

fuse to prevent battery discharge if your

vehicle is parked without being operated

for prolonged periods. Use the following

procedures before parking the vehicle for

prolonged periods.

1. Turn off the engine.

2. Turn off the headlights and tail lights.

3. Open the driver’s side panel cover andpull up the memory fuse.

✽✽ NOTICE

If the memory fuse is pulled up from the fuse panel, the warning chime,

audio, clock and interior lamps, etc.,

will not operate. Some items must be

reset after replacement. Refer to

“Battery” in this section.

Even though the memory fuse is

pulled up, the battery can still be dis-

charged by operation of the head-

lights or other electrical devices.

G210200AEN

Engine compartment fuse replacement

1. Turn the ignition switch and all other switches off.

2. Remove the fuse panel cover by pressing the tab and pulling up.

OPA077023OPA077024

Page 319 of 354

757

Maintenance

Descrption Symbol Fuse ratingProtected component

IGN COIL

15A DCDC Converter, ECM, Vehicle Speed Dendor, Condenser, Ignition Coil #1~#3,

Ignition Coil, Pulse Generator 'A'/'B', Transaxle Range Switch

B/UP LP

10A Back-Up Lamp Switch, Rear Parking Assist Sensor LH/RH,

Rear Parking Assist Sensor Center LH/RH

A/BAG IND

10A Instrument Cluster

A/BAG

15A SRS Control Module

CLUSTER

10A Instrument Cluster, Heater Control Module, TACM, ETACM,

Seat Belt Lever, ISG Off Switch, Rear Parking Assist Buzzer

MDPS

10A EPS Control Module

AUDIO ACC

10A Digital Clock, Audio, DCDC Converter

RR P/OUTLET

10A Front Power Outlet, Rear Power Outlet

CIGAR LIGHTER

15A Cigarette Lighter

START

10A ICM RELAY BOX(Burglar Alram Relay), Start Relay, ECM,

Transaxle Range Switch

H/LP

10A Instrument Cluster, E/R Fuse & Relay Box (RLY : R3/R4)

DRL

10A DRL Control Module

IG2

10A Head Lamp LH/RH, Head Lamp Leveling Device Switch, Intake Switch, TACM, ETACM,

Heater Control Module, Dual Pressure Switch, Rear Defogger Relay, Diode5, Power

Window Switch, E/R Fuse & Relay Box (RLY : R6)

Page 321 of 354

759

Maintenance

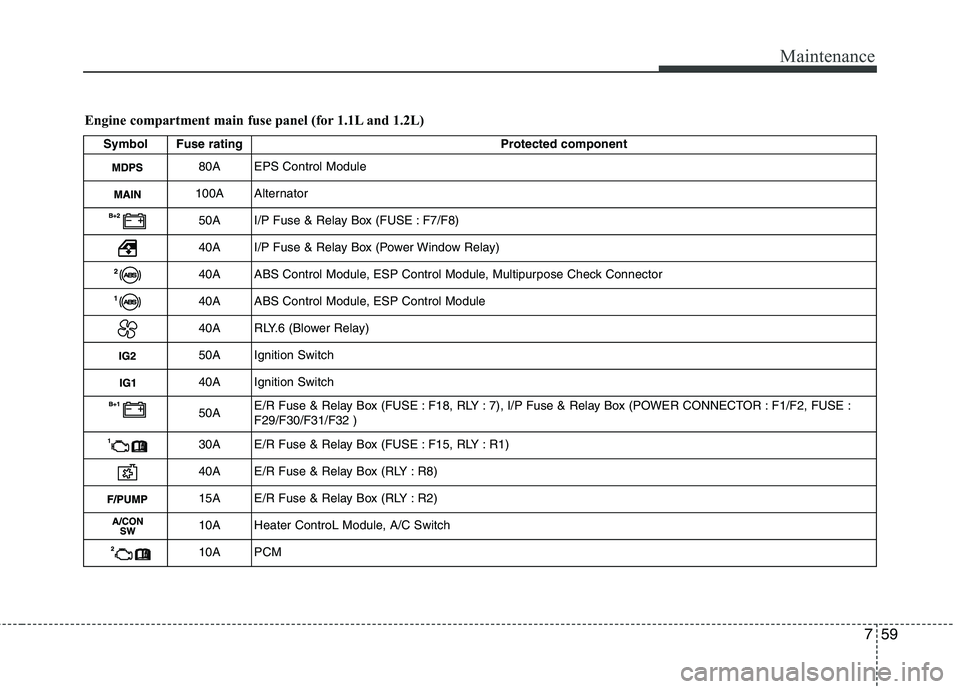

Engine compartment main fuse panel (for 1.1L and 1.2L)Symbol Fuse rating Protected component

80A EPS Control Module

100A Alternator

50A I/P Fuse & Relay Box (FUSE : F7/F8)

40A I/P Fuse & Relay Box (Power Window Relay)

40A ABS Control Module, ESP Control Module, Multipurpose Check Connector

40A ABS Control Module, ESP Control Module

40A RLY.6 (Blower Relay)

50A Ignition Switch

40A Ignition Switch

50AE/R Fuse & Relay Box (FUSE : F18, RLY : 7), I/P Fuse & Relay Box (POWER CONNECTOR : F1/F2, FUSE : F29/F30/F31/F32 )

30A E/R Fuse & Relay Box (FUSE : F15, RLY : R1)

40A E/R Fuse & Relay Box (RLY : R8)

15A E/R Fuse & Relay Box (RLY : R2)

10A Heater ControL Module, A/C Switch

10A PCM

Page 323 of 354

761

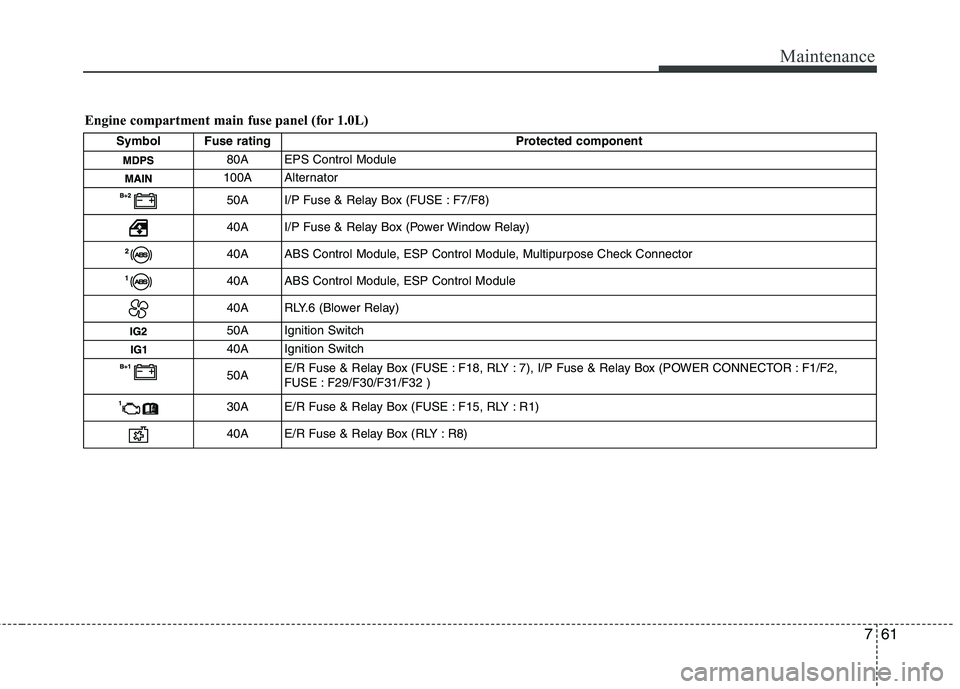

Maintenance

Engine compartment main fuse panel (for 1.0L)Symbol Fuse rating Protected component

80A EPS Control Module

100A Alternator

50A I/P Fuse & Relay Box (FUSE : F7/F8)

40A I/P Fuse & Relay Box (Power Window Relay)

40A ABS Control Module, ESP Control Module, Multipurpose Check Connector

40A ABS Control Module, ESP Control Module

40A RLY.6 (Blower Relay)

50A Ignition Switch

40A Ignition Switch

50AE/R Fuse & Relay Box (FUSE : F18, RLY : 7), I/P Fuse & Relay Box (POWER CONNECTOR : F1/F2,

FUSE : F29/F30/F31/F32 )

30A E/R Fuse & Relay Box (FUSE : F15, RLY : R1)

40A E/R Fuse & Relay Box (RLY : R8)