parking HYUNDAI I10 2018 Service Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2018, Model line: I10, Model: HYUNDAI I10 2018Pages: 343, PDF Size: 9.14 MB

Page 263 of 343

711

Maintenance

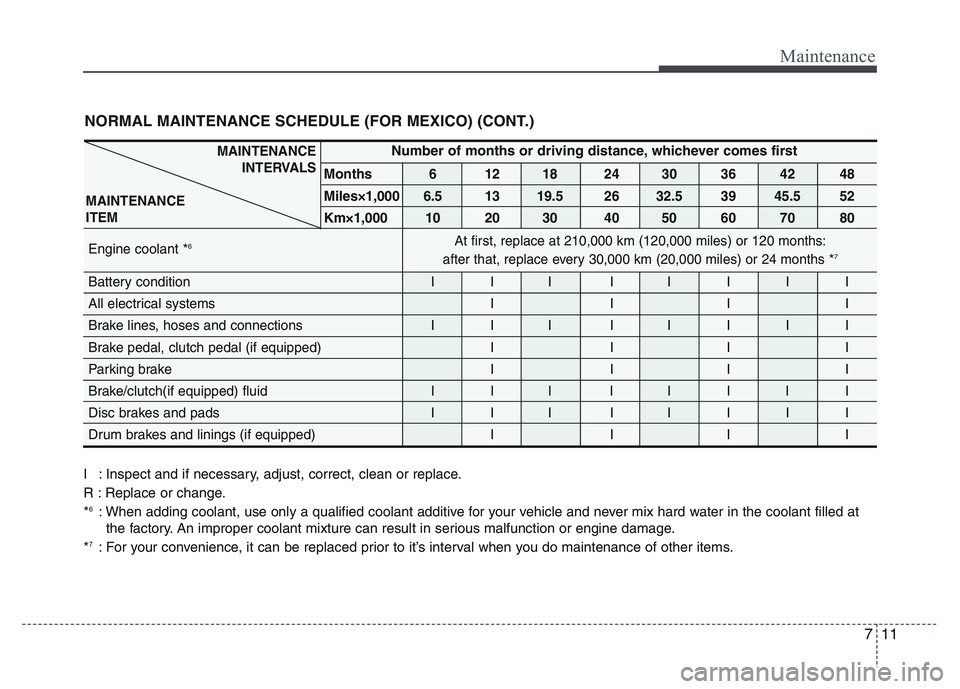

NORMAL MAINTENANCE SCHEDULE (FOR MEXICO) (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

6: When adding coolant, use only a qualified coolant additive for your vehicle and never mix hard water in the coolant filled at

the factory. An improper coolant mixture can result in serious malfunction or engine damage.

*

7: For your convenience, it can be replaced prior to it’s interval when you do maintenance of other items.

MAINTENANCE

INTERVALS

MAINTENANCE

ITEMNumber of months or driving distance, whichever comes first

Months 6 12 18 24 30 36 42 48

Miles×1,000 6.5 13 19.5 26 32.5 39 45.5 52

Km×1,000 10 20 30 40 50 60 70 80

Engine coolant *

6

Battery condition I I I I I I I I

All electrical systems I I I I

Brake lines, hoses and connections I I I I I I I I

Brake pedal, clutch pedal (if equipped) I I I I

Parking brake I I I I

Brake/clutch(if equipped) fluid

III IIIII

Disc brakes and pads I I I I I I I I

Drum brakes and linings (if equipped) I I I I

At first, replace at 210,000 km (120,000 miles) or 120 months:

after that, replace every 30,000 km (20,000 miles) or 24 months *7

Page 267 of 343

715

Maintenance

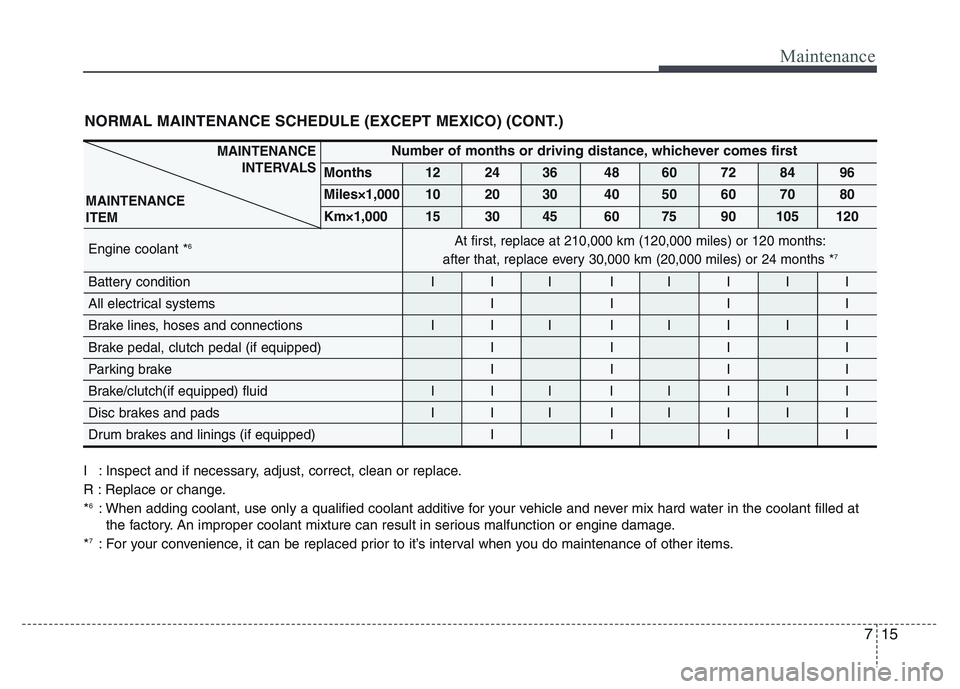

NORMAL MAINTENANCE SCHEDULE (EXCEPT MEXICO) (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

6: When adding coolant, use only a qualified coolant additive for your vehicle and never mix hard water in the coolant filled at

the factory. An improper coolant mixture can result in serious malfunction or engine damage.

*

7: For your convenience, it can be replaced prior to it’s interval when you do maintenance of other items.

MAINTENANCE

INTERVALS

MAINTENANCE

ITEMNumber of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96

Miles×1,000 10 20 30 40 50 60 70 80

Km×1,000 15 30 45 60 75 90 105 120

Engine coolant *

6

Battery condition I I I I I I I I

All electrical systems I I I I

Brake lines, hoses and connections I I I I I I I I

Brake pedal, clutch pedal (if equipped) I I I I

Parking brake I I I I

Brake/clutch(if equipped) fluid

III IIIII

Disc brakes and pads I I I I I I I I

Drum brakes and linings (if equipped) I I I I

At first, replace at 210,000 km (120,000 miles) or 120 months:

after that, replace every 30,000 km (20,000 miles) or 24 months *7

Page 270 of 343

Maintenance

18 7

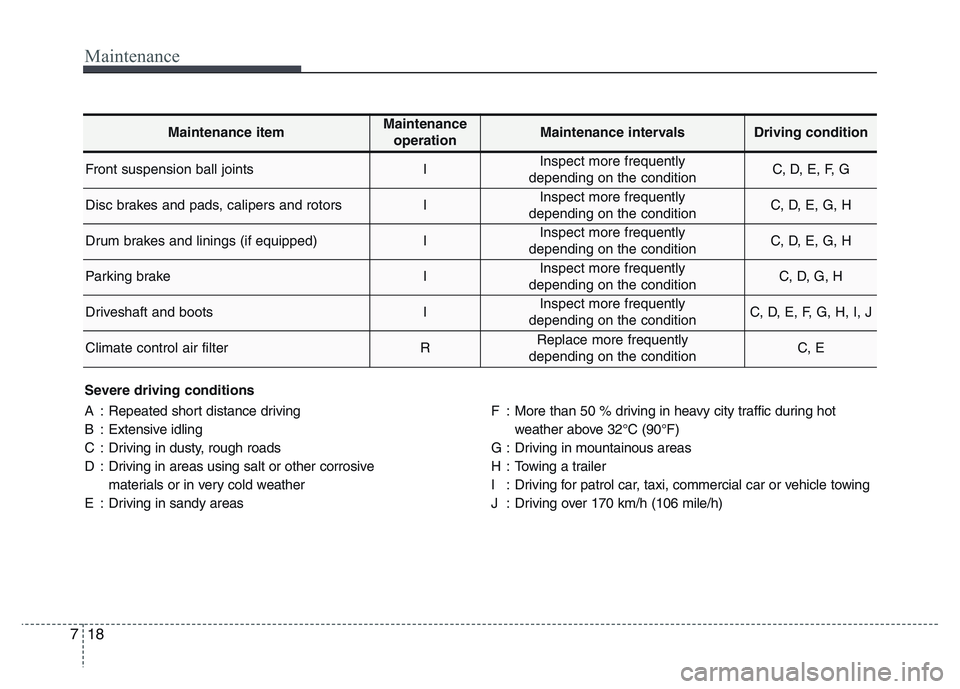

Severe driving conditions

A : Repeated short distance driving

B : Extensive idling

C : Driving in dusty, rough roads

D : Driving in areas using salt or other corrosive

materials or in very cold weather

E : Driving in sandy areasF : More than 50 % driving in heavy city traffic during hot

weather above 32°C (90°F)

G : Driving in mountainous areas

H : Towing a trailer

I : Driving for patrol car, taxi, commercial car or vehicle towing

J : Driving over 170 km/h (106 mile/h)

Maintenance itemMaintenance

operationMaintenance intervalsDriving condition

Front suspension ball jointsIInspect more frequently

depending on the conditionC, D, E, F, G

Disc brakes and pads, calipers and rotorsIInspect more frequently

depending on the conditionC, D, E, G, H

Drum brakes and linings (if equipped)IInspect more frequently

depending on the conditionC, D, E, G, H

Parking brakeIInspect more frequently

depending on the conditionC, D, G, H

Driveshaft and bootsIInspect more frequently

depending on the conditionC, D, E, F, G, H, I, J

Climate control air filterRReplace more frequently

depending on the conditionC, E

Page 272 of 343

Maintenance

20 7

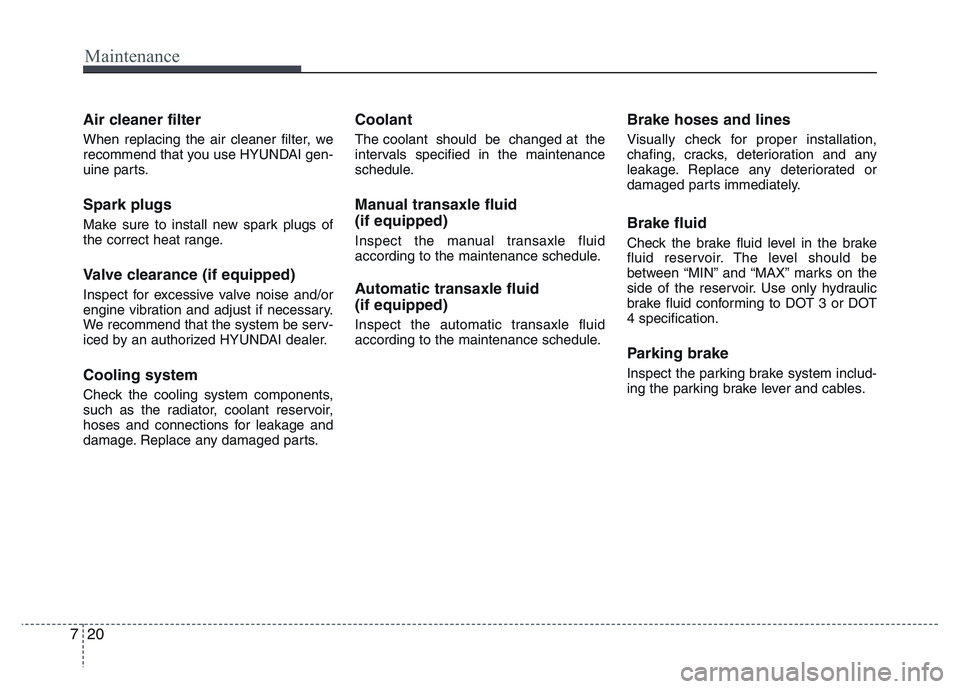

Air cleaner filter

When replacing the air cleaner filter, we

recommend that you use HYUNDAI gen-

uine parts.

Spark plugs

Make sure to install new spark plugs of

the correct heat range.

Valve clearance (if equipped)

Inspect for excessive valve noise and/or

engine vibration and adjust if necessary.

We recommend that the system be serv-

iced by an authorized HYUNDAI dealer.

Cooling system

Check the cooling system components,

such as the radiator, coolant reservoir,

hoses and connections for leakage and

damage. Replace any damaged parts.

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid

(if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid

(if equipped)

Inspect the automatic transaxle fluid

according to the maintenance schedule.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Brake fluid

Check the brake fluid level in the brake

fluid reservoir. The level should be

between “MIN” and “MAX” marks on the

side of the reservoir. Use only hydraulic

brake fluid conforming to DOT 3 or DOT

4 specification.

Parking brake

Inspect the parking brake system includ-

ing the parking brake lever and cables.

Page 279 of 343

727

Maintenance

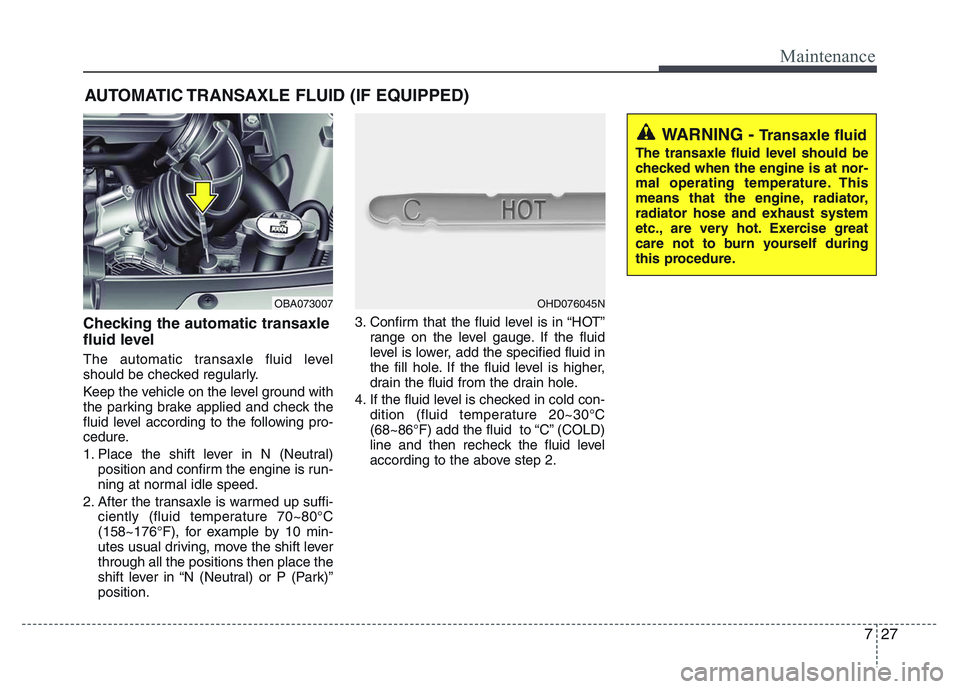

AUTOMATIC TRANSAXLE FLUID (IF EQUIPPED)

Checking the automatic transaxle

fluid level

The automatic transaxle fluid level

should be checked regularly.

Keep the vehicle on the level ground with

the parking brake applied and check the

fluid level according to the following pro-

cedure.

1. Place the shift lever in N (Neutral)

position and confirm the engine is run-

ning at normal idle speed.

2. After the transaxle is warmed up suffi-

ciently (fluid temperature 70~80°C

(158~176°F), for example by 10 min-

utes usual driving, move the shift lever

through all the positions then place the

shift lever in “N (Neutral) or P (Park)”

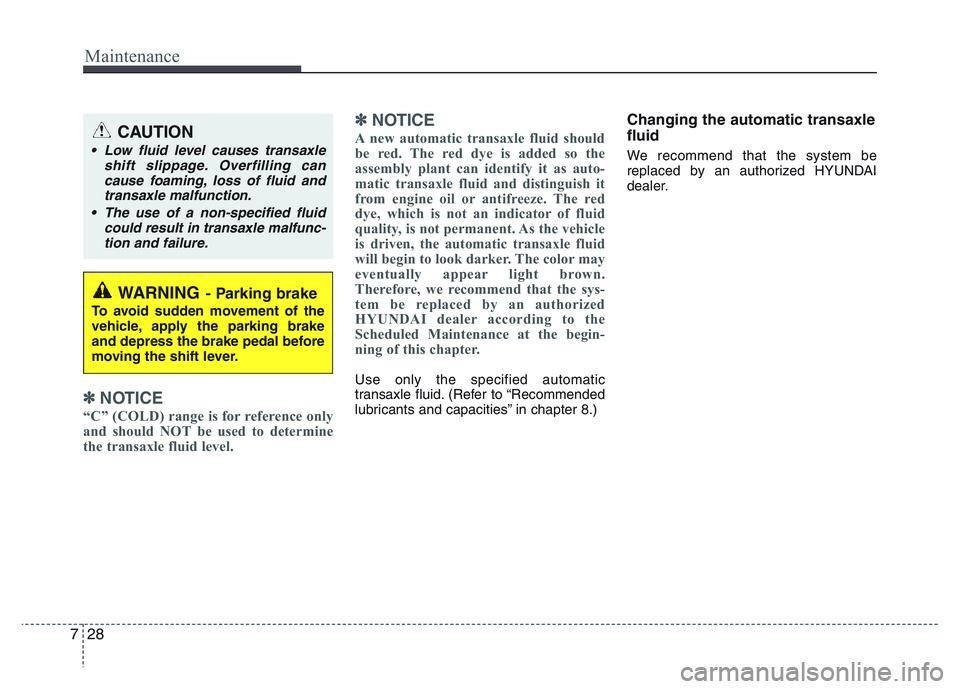

position.3. Confirm that the fluid level is in “HOT”

range on the level gauge. If the fluid

level is lower, add the specified fluid in

the fill hole. If the fluid level is higher,

drain the fluid from the drain hole.

4. If the fluid level is checked in cold con-

dition (fluid temperature 20~30°C

(68~86°F) add the fluid to “C” (COLD)

line and then recheck the fluid level

according to the above step 2.

OBA073007OHD076045N

WARNING - Transaxle fluid

The transaxle fluid level should be

checked when the engine is at nor-

mal operating temperature. This

means that the engine, radiator,

radiator hose and exhaust system

etc., are very hot. Exercise great

care not to burn yourself during

this procedure.

Page 280 of 343

Maintenance

28 7

✽NOTICE

“C” (COLD) range is for reference only

and should NOT be used to determine

the transaxle fluid level.

✽NOTICE

A new automatic transaxle fluid should

be red. The red dye is added so the

assembly plant can identify it as auto-

matic transaxle fluid and distinguish it

from engine oil or antifreeze. The red

dye, which is not an indicator of fluid

quality, is not permanent. As the vehicle

is driven, the automatic transaxle fluid

will begin to look darker. The color may

eventually appear light brown.

Therefore, we recommend that the sys-

tem be replaced by an authorized

HYUNDAI dealer according to the

Scheduled Maintenance at the begin-

ning of this chapter.

Use only the specified automatic

transaxle fluid. (Refer to “Recommended

lubricants and capacities” in chapter 8.)

Changing the automatic transaxle

fluid

We recommend that the system be

replaced by an authorized HYUNDAI

dealer.

WARNING- Parking brake

To avoid sudden movement of the

vehicle, apply the parking brake

and depress the brake pedal before

moving the shift lever.

CAUTION

• Low fluid level causes transaxle

shift slippage. Overfilling can

cause foaming, loss of fluid and

transaxle malfunction.

• The use of a non-specified fluid

could result in transaxle malfunc-

tion and failure.

Page 281 of 343

729

Maintenance

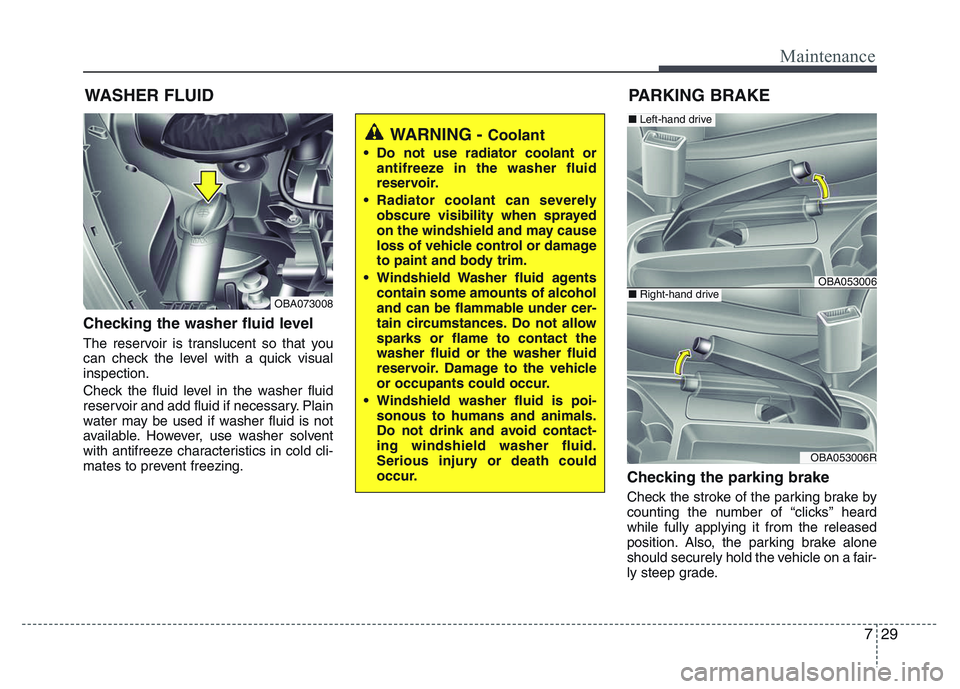

WASHER FLUID

Checking the washer fluid level

The reservoir is translucent so that you

can check the level with a quick visual

inspection.

Check the fluid level in the washer fluid

reservoir and add fluid if necessary. Plain

water may be used if washer fluid is not

available. However, use washer solvent

with antifreeze characteristics in cold cli-

mates to prevent freezing.

Checking the parking brake

Check the stroke of the parking brake by

counting the number of “clicks’’ heard

while fully applying it from the released

position. Also, the parking brake alone

should securely hold the vehicle on a fair-

ly steep grade.

WARNING - Coolant

• Do not use radiator coolant or

antifreeze in the washer fluid

reservoir.

• Radiator coolant can severely

obscure visibility when sprayed

on the windshield and may cause

loss of vehicle control or damage

to paint and body trim.

• Windshield Washer fluid agents

contain some amounts of alcohol

and can be flammable under cer-

tain circumstances. Do not allow

sparks or flame to contact the

washer fluid or the washer fluid

reservoir. Damage to the vehicle

or occupants could occur.

• Windshield washer fluid is poi-

sonous to humans and animals.

Do not drink and avoid contact-

ing windshield washer fluid.

Serious injury or death could

occur.

OBA073008

OBA053006

OBA053006R

PARKING BRAKE

■Left-hand drive

■Right-hand drive

Page 307 of 343

755

Maintenance

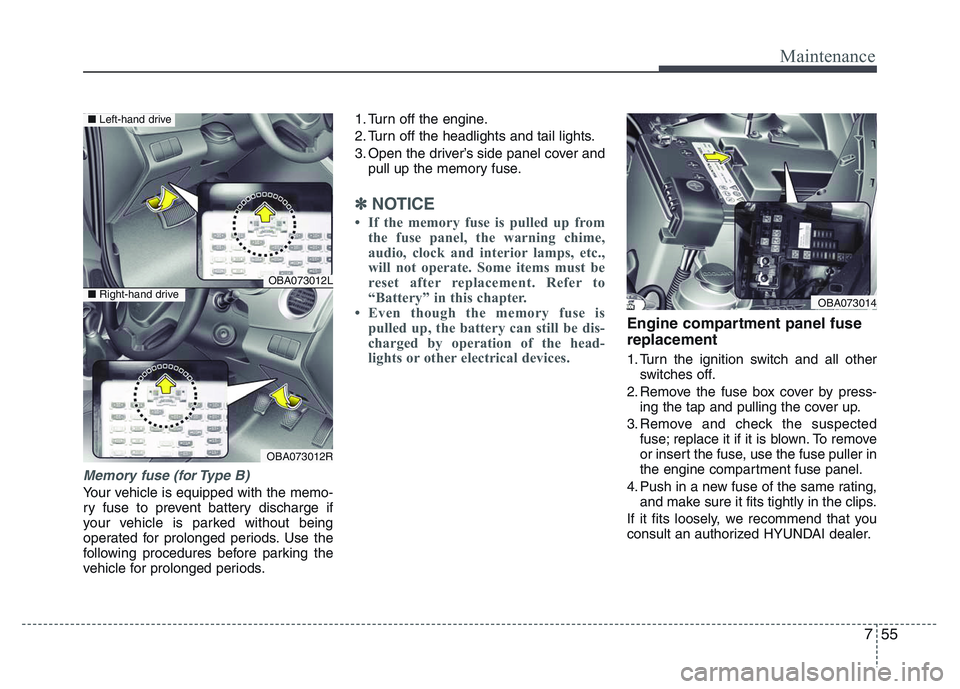

Memory fuse (for Type B)

Your vehicle is equipped with the memo-

ry fuse to prevent battery discharge if

your vehicle is parked without being

operated for prolonged periods. Use the

following procedures before parking the

vehicle for prolonged periods.1. Turn off the engine.

2. Turn off the headlights and tail lights.

3. Open the driver’s side panel cover and

pull up the memory fuse.

✽NOTICE

• If the memory fuse is pulled up from

the fuse panel, the warning chime,

audio, clock and interior lamps, etc.,

will not operate. Some items must be

reset after replacement. Refer to

“Battery” in this chapter.

• Even though the memory fuse is

pulled up, the battery can still be dis-

charged by operation of the head-

lights or other electrical devices.

Engine compartment panel fuse

replacement

1. Turn the ignition switch and all other

switches off.

2. Remove the fuse box cover by press-

ing the tap and pulling the cover up.

3. Remove and check the suspected

fuse; replace it if it is blown. To remove

or insert the fuse, use the fuse puller in

the engine compartment fuse panel.

4. Push in a new fuse of the same rating,

and make sure it fits tightly in the clips.

If it fits loosely, we recommend that you

consult an authorized HYUNDAI dealer.

OBA073012L

OBA073012R

■Left-hand drive

■Right-hand driveOBA073014

Page 311 of 343

759

Maintenance

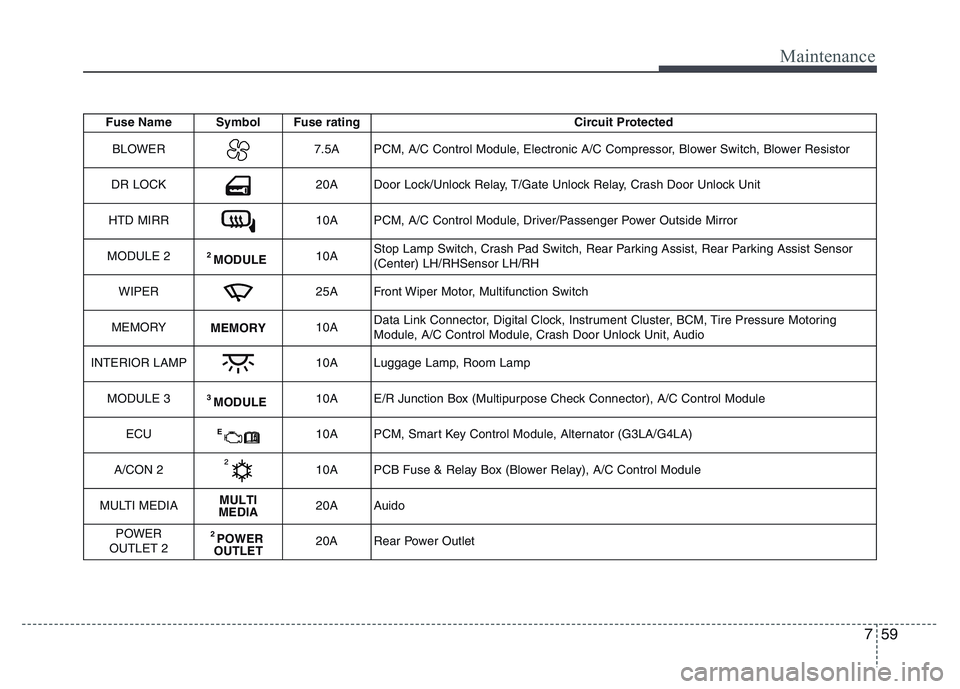

Fuse Name Symbol Fuse rating Circuit Protected

BLOWER

7.5A PCM, A/C Control Module, Electronic A/C Compressor, Blower Switch, Blower Resistor

DR LOCK

20A Door Lock/Unlock Relay, T/Gate Unlock Relay, Crash Door Unlock Unit

HTD MIRR

10A PCM, A/C Control Module, Driver/Passenger Power Outside Mirror

MODULE 2

2 MODULE10AStop Lamp Switch, Crash Pad Switch, Rear Parking Assist, Rear Parking Assist Sensor

(Center) LH/RHSensor LH/RH

WIPER

25A Front Wiper Motor, Multifunction Switch

MEMORY

MEMORY10AData Link Connector, Digital Clock, Instrument Cluster, BCM, Tire Pressure Motoring

Module, A/C Control Module, Crash Door Unlock Unit, Audio

INTERIOR LAMP

10A Luggage Lamp, Room Lamp

MODULE 3

3 MODULE10A E/R Junction Box (Multipurpose Check Connector), A/C Control Module

ECU

E10A PCM, Smart Key Control Module, Alternator (G3LA/G4LA)

A/CON 2

10A PCB Fuse & Relay Box (Blower Relay), A/C Control Module

MULTI MEDIA

MULTI

MEDIA20A Auido

POWER

OUTLET 2

2 POWER

OUTLET20A Rear Power Outlet

Page 315 of 343

763

Maintenance

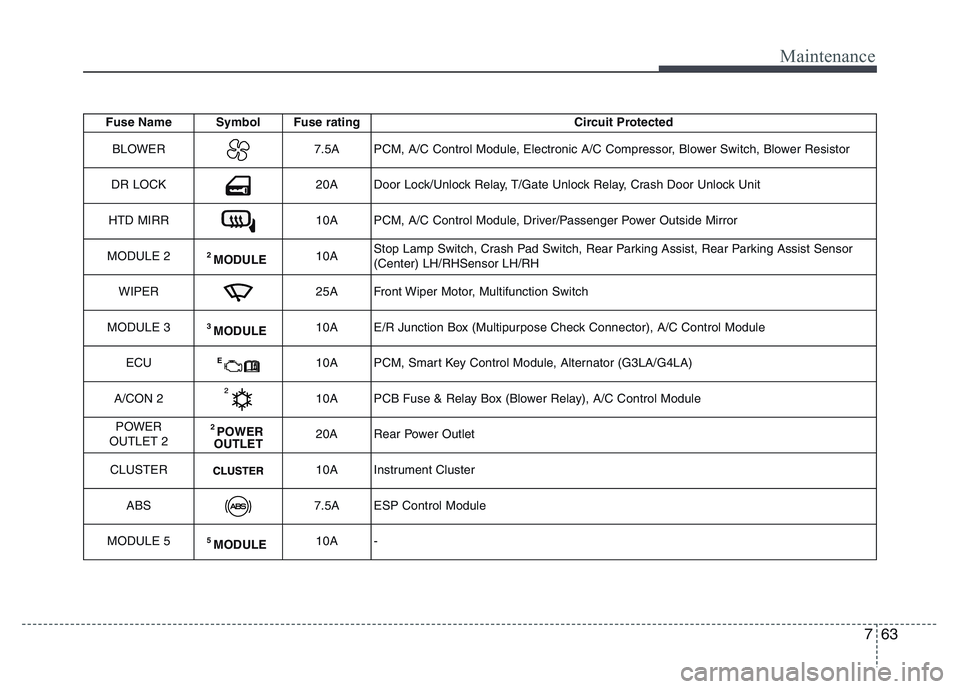

Fuse Name Symbol Fuse rating Circuit Protected

BLOWER

7.5A PCM, A/C Control Module, Electronic A/C Compressor, Blower Switch, Blower Resistor

DR LOCK

20A Door Lock/Unlock Relay, T/Gate Unlock Relay, Crash Door Unlock Unit

HTD MIRR

10A PCM, A/C Control Module, Driver/Passenger Power Outside Mirror

MODULE 2

2 MODULE10AStop Lamp Switch, Crash Pad Switch, Rear Parking Assist, Rear Parking Assist Sensor

(Center) LH/RHSensor LH/RH

WIPER

25A Front Wiper Motor, Multifunction Switch

MODULE 3

3 MODULE10A E/R Junction Box (Multipurpose Check Connector), A/C Control Module

ECU

E10A PCM, Smart Key Control Module, Alternator (G3LA/G4LA)

A/CON 2

10A PCB Fuse & Relay Box (Blower Relay), A/C Control Module

POWER

OUTLET 2

2 POWER

OUTLET20A Rear Power Outlet

CLUSTER

10A Instrument Cluster

ABS

7.5A ESP Control Module

MODULE 5

5 MODULE10A -