cap HYUNDAI I30 2019 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: I30, Model: HYUNDAI I30 2019Pages: 659, PDF Size: 17.14 MB

Page 489 of 659

6-19

What to do in an emergency

6

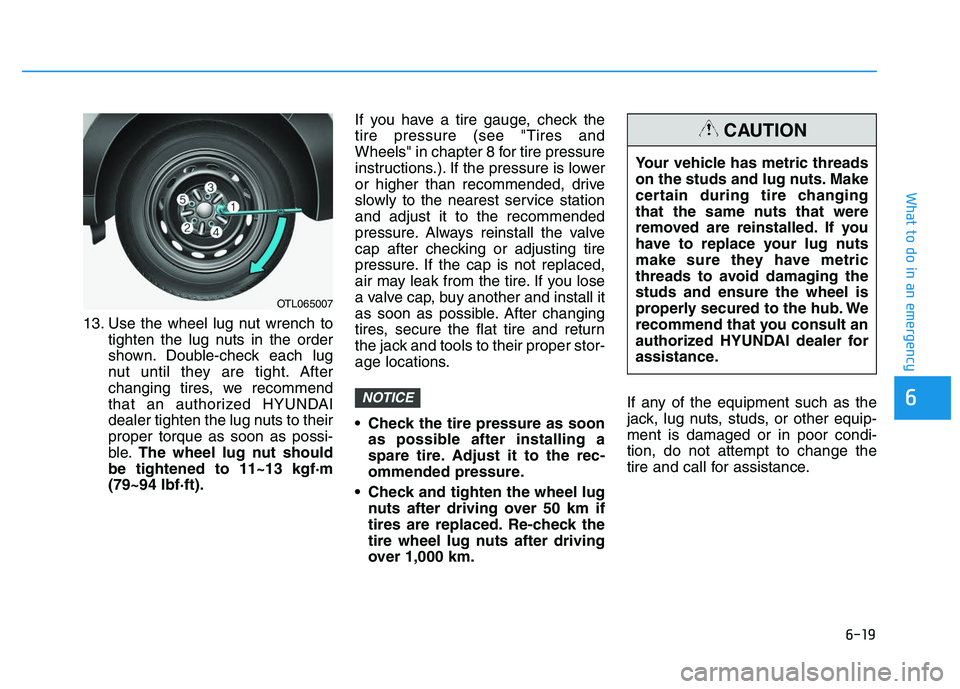

13. Use the wheel lug nut wrench totighten the lug nuts in the order

shown. Double-check each lug

nut until they are tight. After

changing tires, we recommend

that an authorized HYUNDAI

dealer tighten the lug nuts to their

proper torque as soon as possi-

ble. The wheel lug nut should

be tightened to 11~13 kgf·m

(79~94 lbf·ft). If you have a tire gauge, check the

tire pressure (see "Tires and

Wheels" in chapter 8 for tire pressure

instructions.). If the pressure is lower

or higher than recommended, drive

slowly to the nearest service station

and adjust it to the recommended

pressure. Always reinstall the valve

cap after checking or adjusting tire

pressure. If the cap is not replaced,

air may leak from the tire. If you lose

a valve cap, buy another and install it

as soon as possible. After changing

tires, secure the flat tire and return

the jack and tools to their proper stor-

age locations.

Check the tire pressure as soon

as possible after installing a

spare tire. Adjust it to the rec-

ommended pressure.

Check and tighten the wheel lug nuts after driving over 50 km if

tires are replaced. Re-check the

tire wheel lug nuts after driving

over 1,000 km. If any of the equipment such as the

jack, lug nuts, studs, or other equip-

ment is damaged or in poor condi-

tion, do not attempt to change the

tire and call for assistance.

NOTICE

OTL065007

Your vehicle has metric threads

on the studs and lug nuts. Make

certain during tire changing

that the same nuts that were

removed are reinstalled. If you

have to replace your lug nuts

make sure they have metric

threads to avoid damaging the

studs and ensure the wheel is

properly secured to the hub. We

recommend that you consult an

authorized HYUNDAI dealer for

assistance.

CAUTION

Page 490 of 659

6-20

What to do in an emergency

Use of compact spare tires (if equipped)

Compact spare tires are designed for

emergency use only. Drive carefully

on the compact spare tire and

always follow the safety precautions. When driving with the compact spare

tire mounted to your vehicle:

Check the tire pressure after

installing the compact spare tire.

The compact spare tire should be

inflated to 420 kPa (60 psi).

Do not take this vehicle through an automatic car wash while the com-

pact spare tire is installed.

Do not use the compact spare tire on any other vehicle because this

tire has been designed especially

for your vehicle.

The compact spare tire’s tread life is shorter than a regular tire. Inspect

your compact spare tire regularly

and replace worn compact spare

tires with the same size and design,

mounted on the same wheel.

Do not use more than one compact spare tire at a time.

Do not tow a trailer while the com- pact spare tire is installed. When the original tire and wheel

are repaired and reinstalled on the

vehicle, the lug nut torque must be

set correctly. The correct lug nut

tightening torque is 11~13 kgf·m

(79~94 lbf·ft).

NOTICE

To prevent compact spare tire

failure and loss of control pos-

sibly resulting in an accident:

Use the compact spare tire

only in an emergency.

NEVER operate your vehicle

over 80 km/h (50 mph).

Do not exceed the vehicle’s

maximum load rating or the

load carrying capacity shown

on the sidewall of the com-

pact spare tire.

Do not use the compact spare

tire continuously. Repair or

replace the original tire as

soon as possible to avoid fail-

ure of the compact spare tire.

WARNING

Page 495 of 659

6-25

What to do in an emergency

6

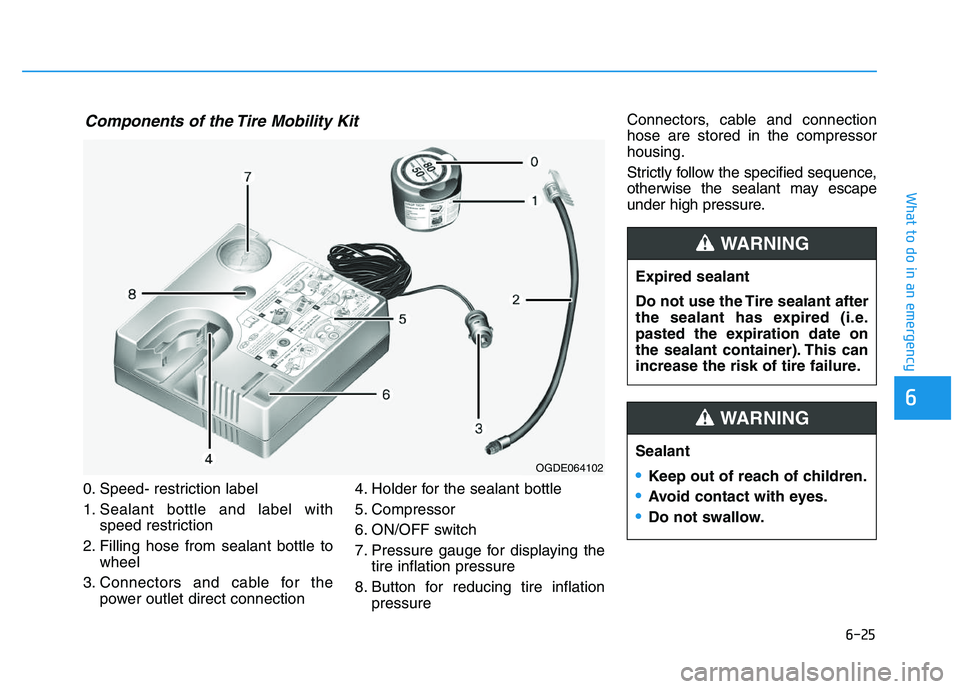

0. Speed- restriction label

1. Sealant bottle and label withspeed restriction

2. Filling hose from sealant bottle to wheel

3. Connectors and cable for the power outlet direct connection 4. Holder for the sealant bottle

5. Compressor

6. ON/OFF switch

7. Pressure gauge for displaying the

tire inflation pressure

8. Button for reducing tire inflation pressure Connectors, cable and connection

hose are stored in the compressor

housing.

Strictly follow the specified sequence,

otherwise the sealant may escape

under high pressure.

Components of the Tire Mobility Kit

OGDE064102

Expired sealant

Do not use the Tire sealant after

the sealant has expired (i.e.

pasted the expiration date on

the sealant container). This can

increase the risk of tire failure.

WARNING

Sealant

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

WARNING

Page 497 of 659

6-27

What to do in an emergency

6

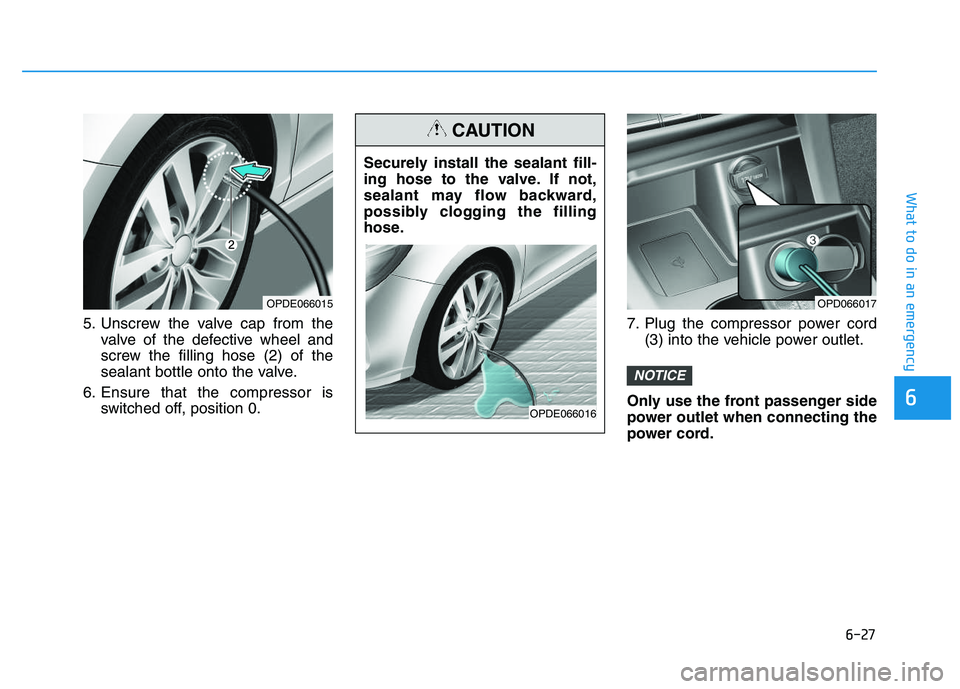

5. Unscrew the valve cap from thevalve of the defective wheel and

screw the filling hose (2) of the

sealant bottle onto the valve.

6. Ensure that the compressor is switched off, position 0. 7. Plug the compressor power cord

(3) into the vehicle power outlet.

Only use the front passenger side

power outlet when connecting the

power cord.

NOTICE

OPD066017OPDE066015

Securely install the sealant fill-

ing hose to the valve. If not,

sealant may flow backward,

possibly clogging the filling

hose.

CAUTION

OPDE066016

Page 503 of 659

6-33

What to do in an emergency

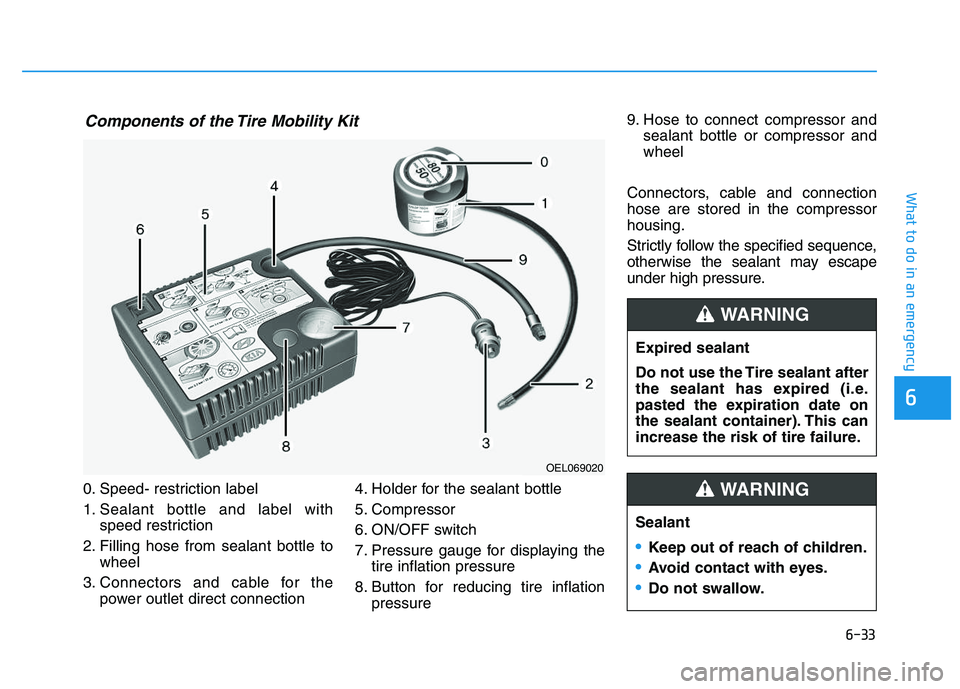

0. Speed- restriction label

1. Sealant bottle and label withspeed restriction

2. Filling hose from sealant bottle to wheel

3. Connectors and cable for the power outlet direct connection 4. Holder for the sealant bottle

5. Compressor

6. ON/OFF switch

7. Pressure gauge for displaying the

tire inflation pressure

8. Button for reducing tire inflation pressure 9. Hose to connect compressor and

sealant bottle or compressor and

wheel

Connectors, cable and connection

hose are stored in the compressor

housing.

Strictly follow the specified sequence,

otherwise the sealant may escape

under high pressure.

6

Components of the Tire Mobility Kit

OEL069020

Expired sealant

Do not use the Tire sealant after

the sealant has expired (i.e.

pasted the expiration date on

the sealant container). This can

increase the risk of tire failure.

WARNING

Sealant

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

WARNING

Page 505 of 659

6-35

What to do in an emergency

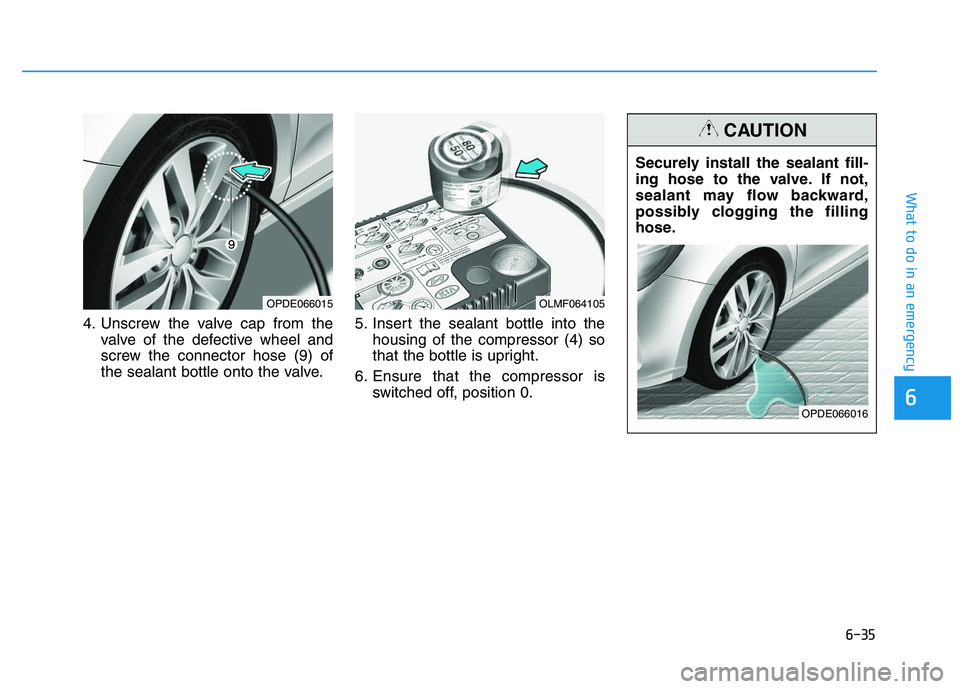

4. Unscrew the valve cap from thevalve of the defective wheel and

screw the connector hose (9) of

the sealant bottle onto the valve. 5. Insert the sealant bottle into the

housing of the compressor (4) so

that the bottle is upright.

6. Ensure that the compressor is switched off, position 0.

6

OLMF064105

Securely install the sealant fill-

ing hose to the valve. If not,

sealant may flow backward,

possibly clogging the filling

hose.

CAUTION

OPDE066016

OPDE066015

Page 513 of 659

6-43

What to do in an emergency

6

Your vehicle is equipped with emer-

gency commodities to help you

respond to emergency situation.

Fire extinguisher

If there is small fire and you know how

to use the fire extinguisher, follow

these steps carefully.

1. Pull out the safety pin at the top ofthe extinguisher that keeps the han-

dle from being accidentally pressed.

2. Aim the nozzle towards the base of the fire.

3. Stand approximately 2.5 m (8 ft) away from the fire and squeeze

the handle to discharge the extin-

guisher. If you release the handle,

the discharge will stop.

4. Sweep the nozzle back and forth at the base of the fire. After the fire

appears to be out, watch carefully

since it may re-ignite.

First aid kit

Supplies for use in giving first aid

such as scissors, bandage and

adhesive tape, etc. are provided.

Triangle reflector

Place the triangle reflector on the

road to warn oncoming vehicles dur-

ing emergencies, such as when the

vehicle is parked by the roadside due

to problems.

Tire pressure gauge

(if equipped)

Tires normally lose some air in day-

to-day use, and you may have to add

a air periodically and usually it is not

a sign of a leaking tire, but of normal

wear. Always check tire pressure

when the tires are cold because tire

pressure increases with temperature. To check the tire pressure, take the

following steps:

1. Unscrew the inflation valve cap

that is located on the rim of the

tire.

2. Press and hold the gauge against the tire valve. Some air will leak as

you begin and more will leak if you

don't press the gauge in firmly.

3. A firm non-leaking push will acti- vate the gauge.

4. Read the tire pressure on the gauge to see whether the tire pressure is

low or high.

5. Adjust the tire pressure to the specified pressure. Refer to “Tires

and Wheels” in chapter 8.

6. Reinstall the inflation valve cap.

E

E M

M E

E R

R G

G E

E N

N C

C Y

Y

C

C O

O M

M M

M O

O D

D I

I T

T Y

Y

(

( I

I F

F

E

E Q

Q U

U I

I P

P P

P E

E D

D )

)

Page 515 of 659

7

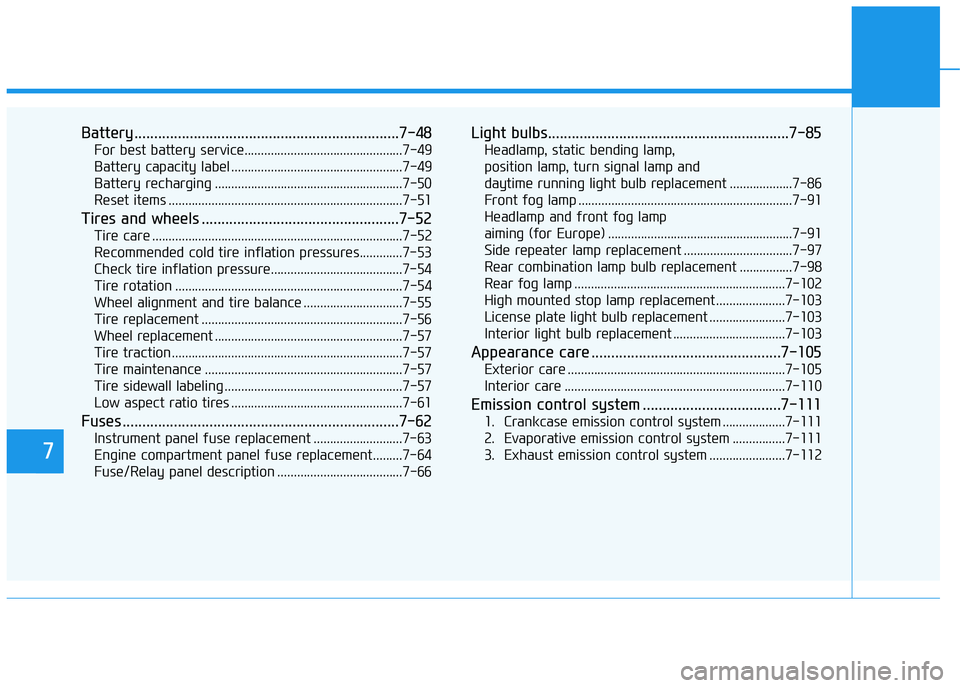

Battery...................................................................7-48

For best battery service................................................7-49

Battery capacity label ....................................................7-49

Battery recharging .........................................................7-50

Reset items .......................................................................7-51

Tires and wheels ..................................................7-52

Tire care ............................................................................7-52

Recommended cold tire inflation pressures.............7-53

Check tire inflation pressure........................................7-54

Tire rotation .....................................................................7-54

Wheel alignment and tire balance ..............................7-55

Tire replacement .............................................................7-56

Wheel replacement .........................................................7-57

Tire traction ......................................................................7-57

Tire maintenance ............................................................7-57

Tire sidewall labeling ......................................................7-57

Low aspect ratio tires ....................................................7-61

Fuses ......................................................................7-62

Instrument panel fuse replacement ...........................7-63

Engine compartment panel fuse replacement.........7-64

Fuse/Relay panel description ......................................7-66

Light bulbs.............................................................7-85

Headlamp, static bending lamp,

position lamp, turn signal lamp and

daytime running light bulb replacement ...................7-86Front fog lamp .................................................................7-91

Headlamp and front fog lamp

aiming (for Europe) ........................................................7-91 Side repeater lamp replacement .................................7-97

Rear combination lamp bulb replacement ................7-98

Rear fog lamp ................................................................7-102

High mounted stop lamp replacement .....................7-103

License plate light bulb replacement .......................7-103

Interior light bulb replacement ..................................7-103

Appearance care ................................................7-105

Exterior care ..................................................................7-105

Interior care ...................................................................7-110

Emission control system ...................................7-111

1. Crankcase emission control system ...................7-111

2. Evaporative emission control system ................7-111

3. Exhaust emission control system .......................7-112

Page 516 of 659

7-3

7

Maintenance

E

E N

N G

G I

I N

N E

E

C

C O

O M

M P

P A

A R

R T

T M

M E

E N

N T

T

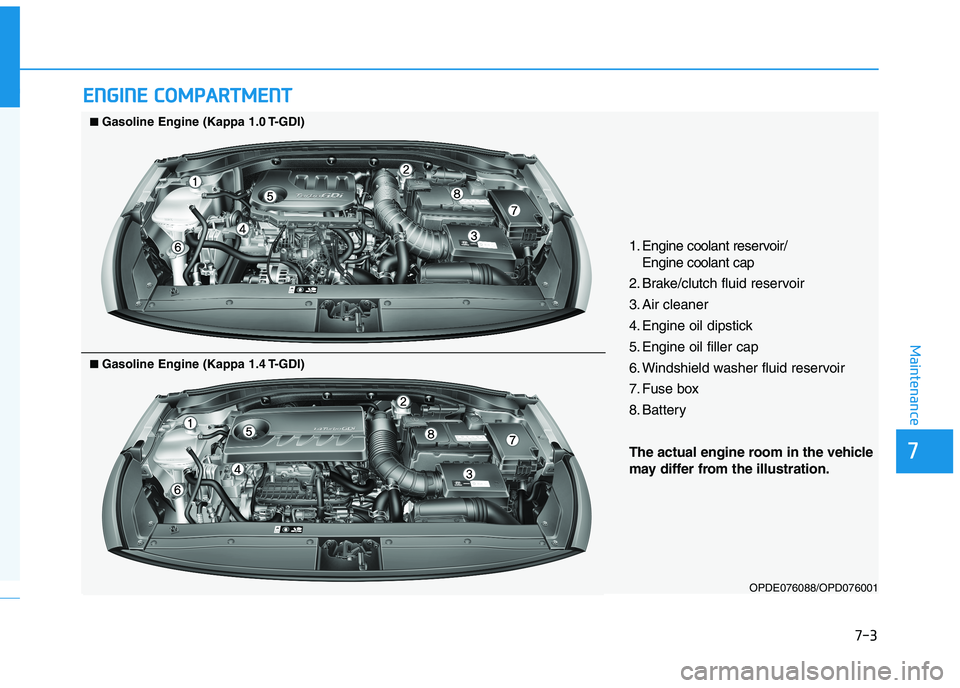

1. Engine coolant reservoir/

Engine coolant cap

2. Brake/clutch fluid reservoir

3. Air cleaner

4. Engine oil dipstick

5. Engine oil filler cap

6. Windshield washer fluid reservoir

7. Fuse box

8. Battery

The actual engine room in the vehicle

may differ from the illustration.

OPDE076088/OPD076001

■

■Gasoline Engine (Kappa 1.0 T-GDI)

■

■Gasoline Engine (Kappa 1.4 T-GDI)

Page 517 of 659

7-4

Maintenance

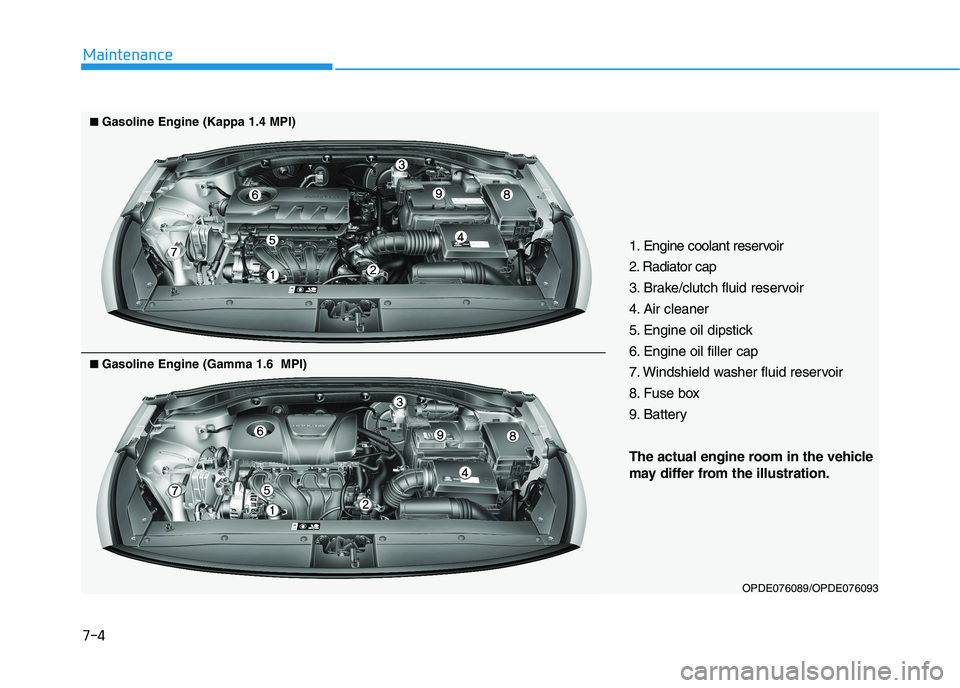

1. Engine coolant reservoir

2. Radiator cap

3. Brake/clutch fluid reservoir

4. Air cleaner

5. Engine oil dipstick

6. Engine oil filler cap

7. Windshield washer fluid reservoir

8. Fuse box

9. Battery

The actual engine room in the vehicle

may differ from the illustration.

OPDE076089/OPDE076093

■

■

Gasoline Engine (Kappa 1.4 MPI)

■

■Gasoline Engine (Gamma 1.6 MPI)