ABS HYUNDAI I800 2016 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: I800, Model: HYUNDAI I800 2016Pages: 419, PDF Size: 9.23 MB

Page 296 of 419

Driving your vehicle

50 5

Towbars

It's important to have the correct towbar

equipment. Crosswinds, large trucks

going by, and rough roads are a few rea-

sons why you’ll need the right towbar.

Here are some rules to follow:

• Will you have to make any holes in the

body of your vehicle when you install a

trailer towbar? If you do, then be sure

to seal the holes later when you

remove the towbar.

If you don’t seal them, deadly carbon

monoxide (CO) from your exhaust can

get into your vehicle, as well as dirt and

water.

• The bumpers on your vehicle are not

intended for towbars. Do not attach

rental towbars or other bumper-type

towbars to them. Use only a frame-

mounted towbar that does not attach to

the bumper.

Safety cables

You should always attach cables

between your vehicle and your trailer.

Cross the safety cables under the nose

of the trailer so that the nose will not drop

to the road if it becomes separated from

the towbar.

Instructions about safety cables may be

provided by the towbar manufacturer or

by the trailer manufacturer. Follow the

manufacturer’s recommendation for

attaching safety cables. Always leave just

enough slack so you can turn with your

trailer. And, never allow safety cables to

drag on the ground.

Trailer brakes

If your trailer is equipped with a braking

system, make sure it conforms to local

regulations and that it is properly

installed and operating correctly.

If your trailer weighs more than the max-

imum trailer weight without trailer brakes

loaded, then it needs its own brakes and

they must be adequate. Be sure to read

and follow the instructions for the trailer

brakes so you’ll be able to install, adjust

and maintain them properly.

• Don’t tap into your vehicle's brake sys-

tem.

WARNING- Trailer brakes

Do not use a trailer with its own

brakes unless you are absolutely

certain that you have properly set

up the brake system. This is not a

task for amateurs. Use an experi-

enced, competent trailer shop for

this work.

procarmanuals.com

Page 300 of 419

Driving your vehicle

54 5

However, if you ever have to park your

trailer on a hill, here's how to do it:

1. Pull the vehicle into the parking space.

Turn the steering wheel in the direction

of the kerb (right if headed down hill,

left if headed up hill).

2. If the vehicle has a manual transmis-

sion, place the car in neutral. If the

vehicle has an automatic transmission,

place the car in P (Park).

3. Set the parking brake and shut off the

vehicle.

4. Place chocks under the trailer wheels

on the down hill side of the wheels.

5. Start the vehicle, hold the brakes, shift

to neutral, release the parking brake

and slowly release the brakes until the

trailer chocks absorb the load.

6. Reapply the brakes, reapply the park-

ing brake and shift the vehicle to R

(Reverse) for manual transmission or

P (Park) automatic transmission.

7. Shut off the vehicle and release the

vehicle brakes but leave the parking

brake set.When you are ready to leave after park-

ing on a hill

1. With the manual transmission in

Neutral or automatic transmission in P

(Park), apply your brakes and hold the

brake pedal down whilst you:

• Start your engine;

• Shift into gear; and

• Release the parking brake.

2. Slowly remove your foot from the

brake pedal.

3. Drive slowly until the trailer is clear of

the chocks.

4. Stop and have someone pick up and

store the chocks.

WARNING- Parking brake

It can be dangerous to get out of

your vehicle if the parking brake is

not firmly set.

If you have left the engine running,

the vehicle can move suddenly. You

or others could be seriously or

fatally injured.

procarmanuals.com

Page 320 of 419

What to do in an emergency

16 6

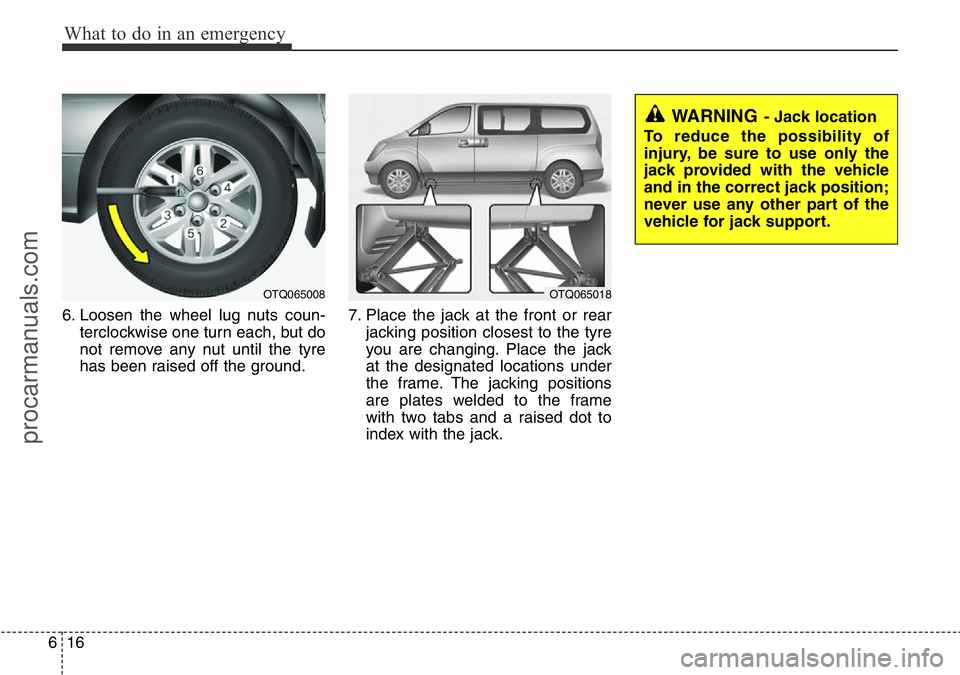

6. Loosen the wheel lug nuts coun-

terclockwise one turn each, but do

not remove any nut until the tyre

has been raised off the ground.7. Place the jack at the front or rear

jacking position closest to the tyre

you are changing. Place the jack

at the designated locations under

the frame. The jacking positions

are plates welded to the frame

with two tabs and a raised dot to

index with the jack.

OTQ065008

WARNING- Jack location

To reduce the possibility of

injury, be sure to use only the

jack provided with the vehicle

and in the correct jack position;

never use any other part of the

vehicle for jack support.

OTQ065018

procarmanuals.com

Page 368 of 419

Maintenance

38 7

Wheel replacement

When replacing the metal wheels for

any reason, make sure the new

wheels are equivalent to the original

factory units in diameter, rim width

and offset.Tyre traction

Tyre traction can be reduced if you

drive on worn tyres, tyres that are

improperly inflated or on slippery

road surfaces. Tyres should be

replaced when tread wear indicators

appear. To reduce the possibility of

losing control, slow down whenever

there is rain, snow or ice on the road.

Tyre maintenance

In addition to proper inflation, correct

wheel alignment helps to decrease

tyre wear. If you find a tyre is worn

unevenly, we recommend that the

wheel alignment be checked by a

HYUNDAI authorised repairer.

When you have new tyres installed,

make sure they are balanced. This

will increase vehicle ride comfort and

tyre life. Additionally, a tyre should

always be rebalanced if it is removed

from the wheel.(Continued)

• Using tyres and wheel other

than the recommended sizes

could cause unusual handling

characteristics and poor vehi-

cle control, resulting in a seri-

ous accident.

• Wheels that do not meet

HYUNDAI’s specifications

may fit poorly and result in

damage to the vehicle or

unusual handling and poor

vehicle control.

• The ABS works by comparing

the speed of the wheels. Tyre

size can affect wheel speed.

When replacing tyres, all 4

tyres must use the same size

originally supplied with the

vehicle. Using tyres of a dif-

ferent size can cause the ABS

(Anti-lock Brake System) and

ESC (Electronic Stability

Control) (if equipped) to work

irregularly.

WARNING

A wheel that is not the correct

size may adversely affect wheel

and bearing life, braking and

stopping abilities, handling

characteristics, ground clear-

ance, body-to-tyre clearance,

snow chain clearance,

speedometer and odometer cal-

ibration, headlight aim and

bumper height.

procarmanuals.com

Page 380 of 419

Maintenance

50 7

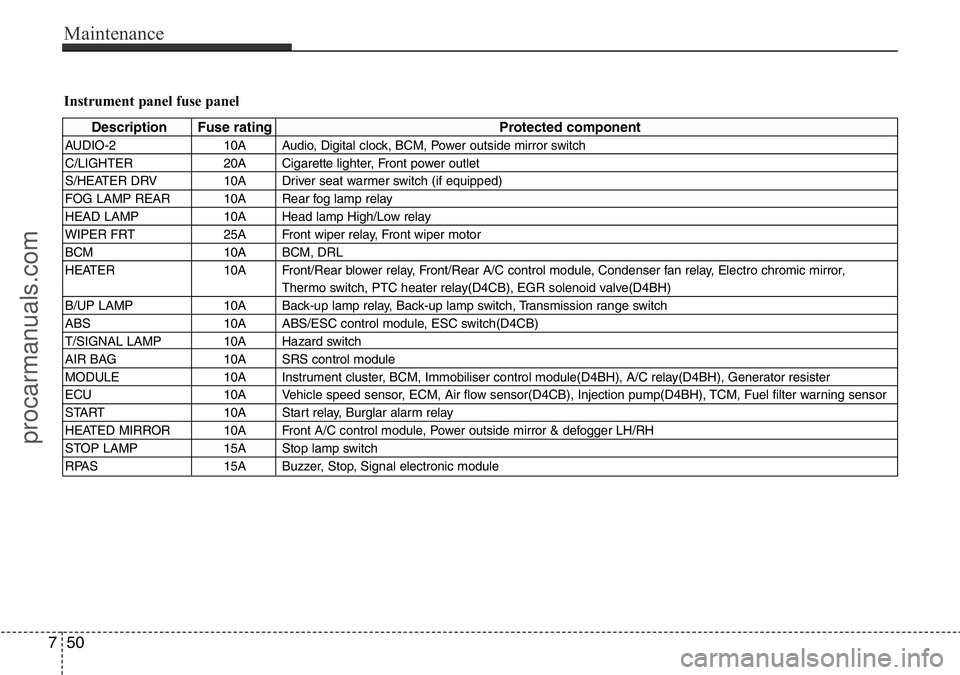

Instrument panel fuse panel

Description Fuse rating Protected component

AUDIO-2 10A Audio, Digital clock, BCM, Power outside mirror switch

C/LIGHTER 20A Cigarette lighter, Front power outlet

S/HEATER DRV 10A Driver seat warmer switch (if equipped)

FOG LAMP REAR 10A Rear fog lamp relay

HEAD LAMP 10A Head lamp High/Low relay

WIPER FRT 25A Front wiper relay, Front wiper motor

BCM 10A BCM, DRL

HEATER 10A Front/Rear blower relay, Front/Rear A/C control module, Condenser fan relay, Electro chromic mirror,

Thermo switch, PTC heater relay(D4CB), EGR solenoid valve(D4BH)

B/UP LAMP 10A Back-up lamp relay, Back-up lamp switch, Transmission range switch

ABS 10A ABS/ESC control module, ESC switch(D4CB)

T/SIGNAL LAMP 10A Hazard switch

AIR BAG 10A SRS control module

MODULE 10A Instrument cluster, BCM, Immobiliser control module(D4BH), A/C relay(D4BH), Generator resister

ECU 10A Vehicle speed sensor, ECM, Air flow sensor(D4CB), Injection pump(D4BH), TCM, Fuel filter warning sensor

START 10A Start relay, Burglar alarm relay

HEATED MIRROR 10A Front A/C control module, Power outside mirror & defogger LH/RH

STOP LAMP 15A Stop lamp switch

RPAS 15A Buzzer, Stop, Signal electronic module

procarmanuals.com

Page 382 of 419

Maintenance

52 7

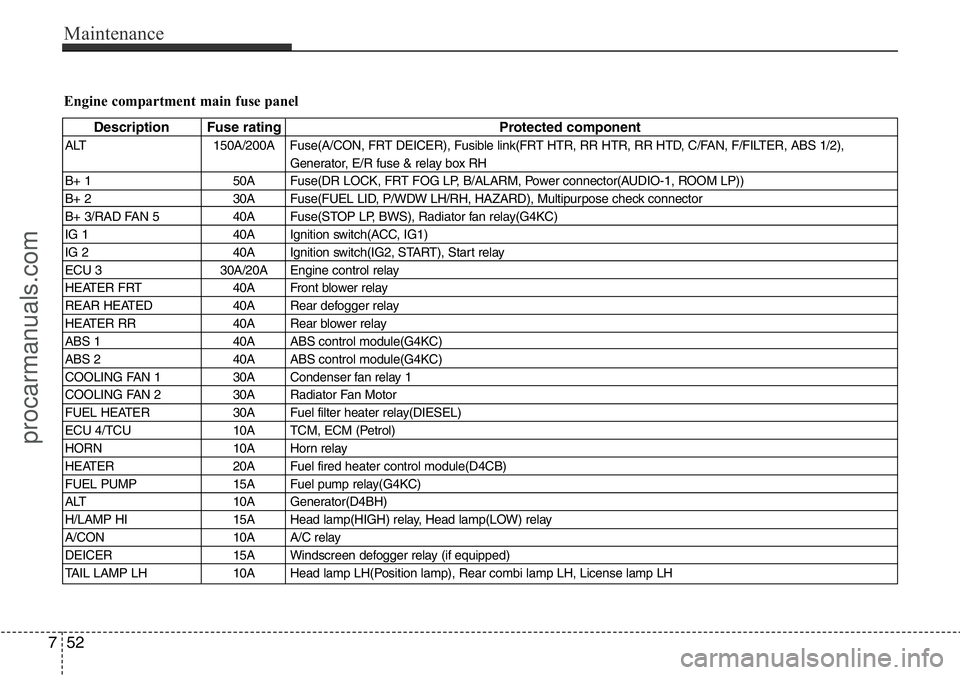

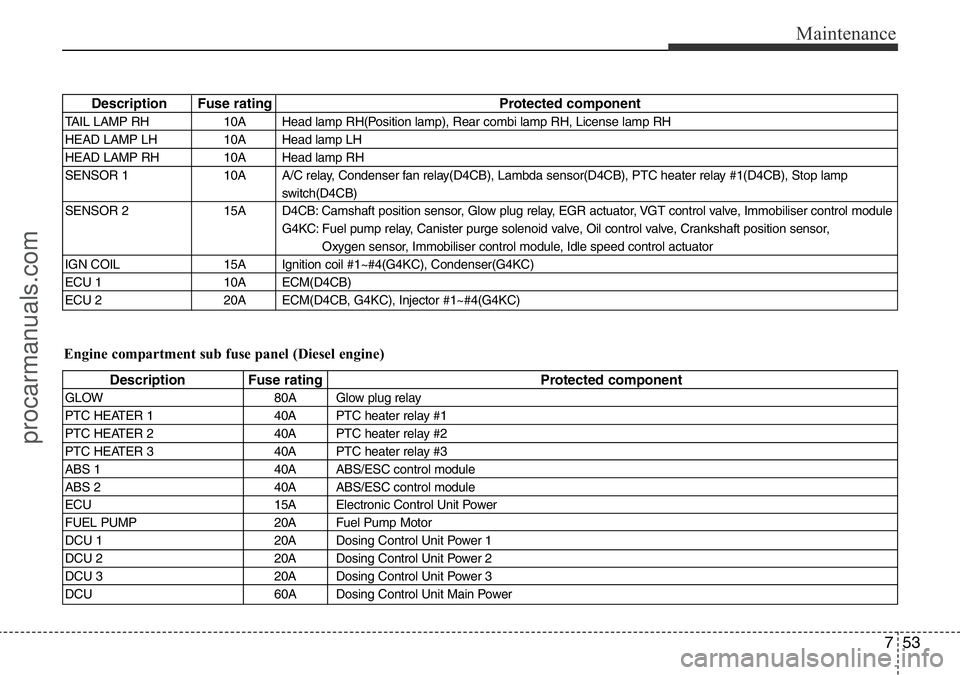

Engine compartment main fuse panel

Description Fuse rating Protected component

ALT 150A/200A Fuse(A/CON, FRT DEICER), Fusible link(FRT HTR, RR HTR, RR HTD, C/FAN, F/FILTER, ABS 1/2),

Generator, E/R fuse & relay box RH

B+ 1 50A Fuse(DR LOCK, FRT FOG LP, B/ALARM, Power connector(AUDIO-1, ROOM LP))

B+ 2 30A Fuse(FUEL LID, P/WDW LH/RH, HAZARD), Multipurpose check connector

B+ 3/RAD FAN 5 40A Fuse(STOP LP, BWS), Radiator fan relay(G4KC)

IG 1 40A Ignition switch(ACC, IG1)

IG 2 40A Ignition switch(IG2, START), Start relay

ECU 3 30A/20A Engine control relay

HEATER FRT 40A Front blower relay

REAR HEATED 40A Rear defogger relay

HEATER RR 40A Rear blower relay

ABS 1 40A ABS control module(G4KC)

ABS 2 40A ABS control module(G4KC)

COOLING FAN 1 30A Condenser fan relay 1

COOLING FAN 2 30A Radiator Fan Motor

FUEL HEATER 30A Fuel filter heater relay(DIESEL)

ECU 4/TCU 10A TCM, ECM (Petrol)

HORN 10A Horn relay

HEATER 20A Fuel fired heater control module(D4CB)

FUEL PUMP 15A Fuel pump relay(G4KC)

ALT 10A Generator(D4BH)

H/LAMP HI 15A Head lamp(HIGH) relay, Head lamp(LOW) relay

A/CON 10A A/C relay

DEICER 15A Windscreen defogger relay (if equipped)

TAIL LAMP LH 10A Head lamp LH(Position lamp), Rear combi lamp LH, License lamp LH

procarmanuals.com

Page 383 of 419

753

Maintenance

Description Fuse rating Protected component

TAIL LAMP RH 10A Head lamp RH(Position lamp), Rear combi lamp RH, License lamp RH

HEAD LAMP LH 10A Head lamp LH

HEAD LAMP RH 10A Head lamp RH

SENSOR 1 10A A/C relay, Condenser fan relay(D4CB), Lambda sensor(D4CB), PTC heater relay #1(D4CB), Stop lamp

switch(D4CB)

SENSOR 2 15A D4CB: Camshaft position sensor, Glow plug relay, EGR actuator, VGT control valve, Immobiliser control module

G4KC: Fuel pump relay, Canister purge solenoid valve, Oil control valve, Crankshaft position sensor,

Oxygen sensor, Immobiliser control module, Idle speed control actuator

IGN COIL 15A Ignition coil #1~#4(G4KC), Condenser(G4KC)

ECU 1 10A ECM(D4CB)

ECU 2 20A ECM(D4CB, G4KC), Injector #1~#4(G4KC)

Engine compartment sub fuse panel (Diesel engine)

Description Fuse rating Protected component

GLOW 80A Glow plug relay

PTC HEATER 1 40A PTC heater relay #1

PTC HEATER 2 40A PTC heater relay #2

PTC HEATER 3 40A PTC heater relay #3

ABS 1 40A ABS/ESC control module

ABS 2 40A ABS/ESC control module

ECU 15A Electronic Control Unit Power

FUEL PUMP 20A Fuel Pump Motor

DCU 1 20A Dosing Control Unit Power 1

DCU 2 20A Dosing Control Unit Power 2

DCU 3 20A Dosing Control Unit Power 3

DCU 60A Dosing Control Unit Main Power

procarmanuals.com

Page 386 of 419

Maintenance

56 7

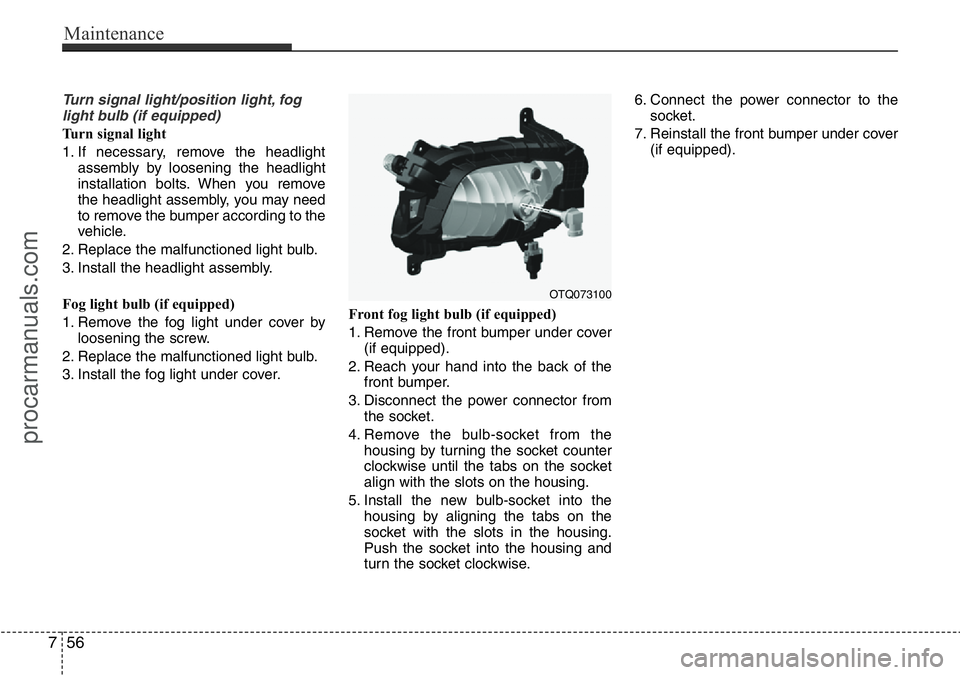

Turn signal light/position light, fog

light bulb (if equipped)

Turn signal light

1. If necessary, remove the headlight

assembly by loosening the headlight

installation bolts. When you remove

the headlight assembly, you may need

to remove the bumper according to the

vehicle.

2. Replace the malfunctioned light bulb.

3. Install the headlight assembly.

Fog light bulb (if equipped)

1. Remove the fog light under cover by

loosening the screw.

2. Replace the malfunctioned light bulb.

3. Install the fog light under cover.Front fog light bulb (if equipped)

1. Remove the front bumper under cover

(if equipped).

2. Reach your hand into the back of the

front bumper.

3. Disconnect the power connector from

the socket.

4. Remove the bulb-socket from the

housing by turning the socket counter

clockwise until the tabs on the socket

align with the slots on the housing.

5. Install the new bulb-socket into the

housing by aligning the tabs on the

socket with the slots in the housing.

Push the socket into the housing and

turn the socket clockwise.6. Connect the power connector to the

socket.

7. Reinstall the front bumper under cover

(if equipped).

OTQ073100

procarmanuals.com

Page 387 of 419

757

Maintenance

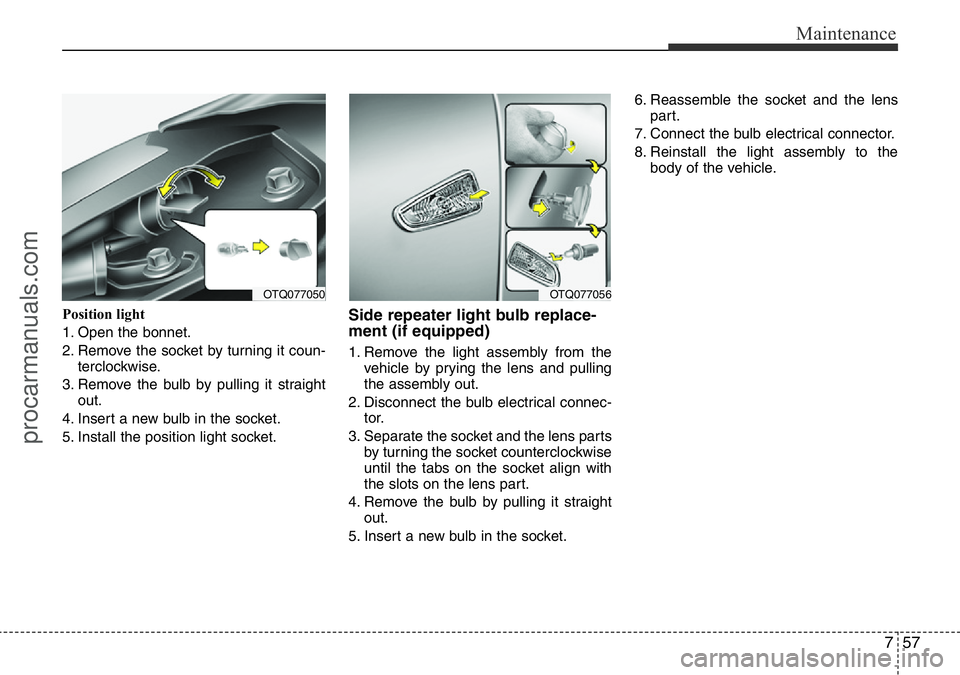

Position light

1. Open the bonnet.

2. Remove the socket by turning it coun-

terclockwise.

3. Remove the bulb by pulling it straight

out.

4. Insert a new bulb in the socket.

5. Install the position light socket.Side repeater light bulb replace-

ment (if equipped)

1. Remove the light assembly from the

vehicle by prying the lens and pulling

the assembly out.

2. Disconnect the bulb electrical connec-

tor.

3. Separate the socket and the lens parts

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the lens part.

4. Remove the bulb by pulling it straight

out.

5. Insert a new bulb in the socket.6. Reassemble the socket and the lens

part.

7. Connect the bulb electrical connector.

8. Reinstall the light assembly to the

body of the vehicle.

OTQ077056OTQ077050

procarmanuals.com

Page 389 of 419

759

Maintenance

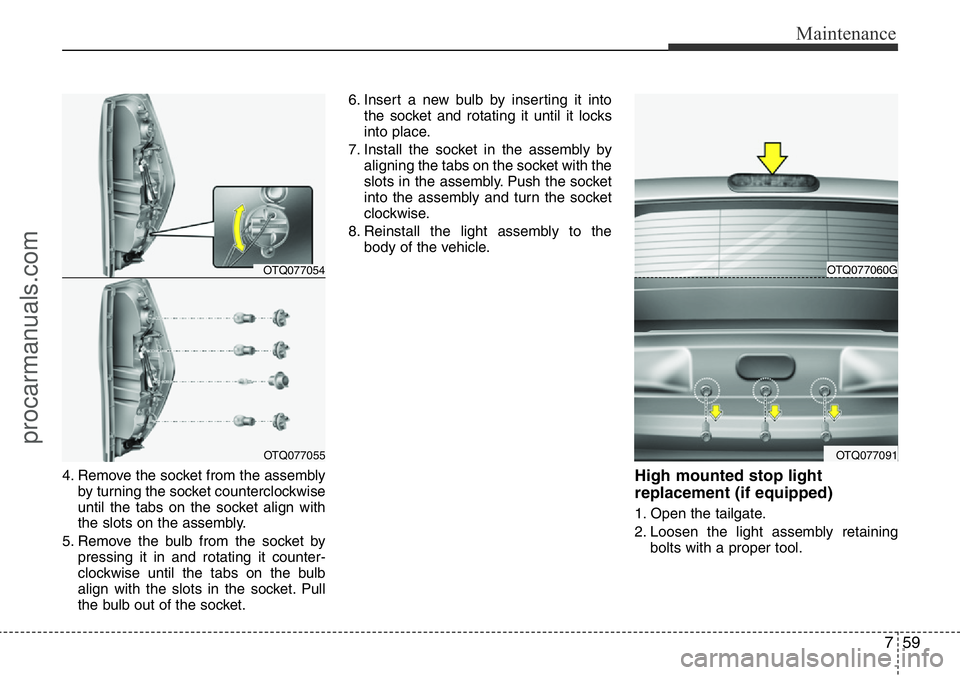

4. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

5. Remove the bulb from the socket by

pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.6. Insert a new bulb by inserting it into

the socket and rotating it until it locks

into place.

7. Install the socket in the assembly by

aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

8. Reinstall the light assembly to the

body of the vehicle.High mounted stop light

replacement (if equipped)

1. Open the tailgate.

2. Loosen the light assembly retaining

bolts with a proper tool.

OTQ077054

OTQ077055

OTQ077060G

OTQ077091

procarmanuals.com