heater HYUNDAI I800 2016 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: I800, Model: HYUNDAI I800 2016Pages: 419, PDF Size: 9.23 MB

Page 248 of 419

Driving your vehicle

2 5

WARNING- ENGINE EXHAUST CAN BE DANGEROUS!

Engine exhaust gases are potentially lethal. If at any time engine exhaust gas is detected within the passenger compartment,

move the vehicle to an open area and open all windows.

• Never inhale exhaust gas.

Exhaust gases contain Carbon Monoxide which is colourless and odourless. Carbon Monoxide is poisonous and can cause

unconsciousness and death by asphyxiation.

• Exhaust System Maintenance.

Ensure that the exhaust system is maintained in good condition and is free from excessive corrosion and damage which may

result in leakage. If you hear a change in the sound of the exhaust or if you drive over something that strikes the underneath

side of the car, we recommend that the system be checked by a HYUNDAI authorised repairer.

• Confined Areas.

Do not run the engine in confined spaces, allowing the engine to idle in a garage, even when the doors are open is danger-

ous practice. Only start the engine immediately prior to moving the vehicle out of the garage.

• Prolonged Idling.

If it is necessary to allow the vehicle to idle for prolonged periods, ensure that the heating system air intake control is set to

the "Fresh" position, the blower is set to high speed operation and that the vehicle is standing in an open area.

To ensure correct operation of the heater system, the air intake grilles at the base of the windscreen must not be obstructed by

snow leaves etc..

procarmanuals.com

Page 337 of 419

77

Maintenance

At least monthly:

• Check coolant level in the engine

coolant reservoir.

• Check the operation of all exterior

lights, including the stoplights, turn sig-

nals and hazard warning flashers.

• Check the inflation pressures of all

tyres including the spare.

At least twice a year

(i.e., every Spring and Fall) :

• Check radiator, heater and air condi-

tioning hoses for leaks or damage.

• Check windscreen washer spray and

wiper operation. Clean wiper blades

with clean cloth dampened with wash-

er fluid.

• Check headlight alignment.

• Check muffler, exhaust pipes, shields

and clamps.

• Check the lap/shoulder belts for wear

and function.

• Check for worn tyres and loose wheel

lug nuts.

At least once a year:

• Clean body and door drain holes.

• Lubricate door hinges and checks, and

bonnet hinges.

• Lubricate door and bonnet locks and

latches.

• Lubricate door rubber weatherstrips.

• Check the air conditioning system.

• Check the power steering fluid level.

• Inspect and lubricate automatic trans-

mission linkage and controls.

• Clean battery and terminals.

• Check the brake fluid level.

procarmanuals.com

Page 346 of 419

Maintenance

16 7

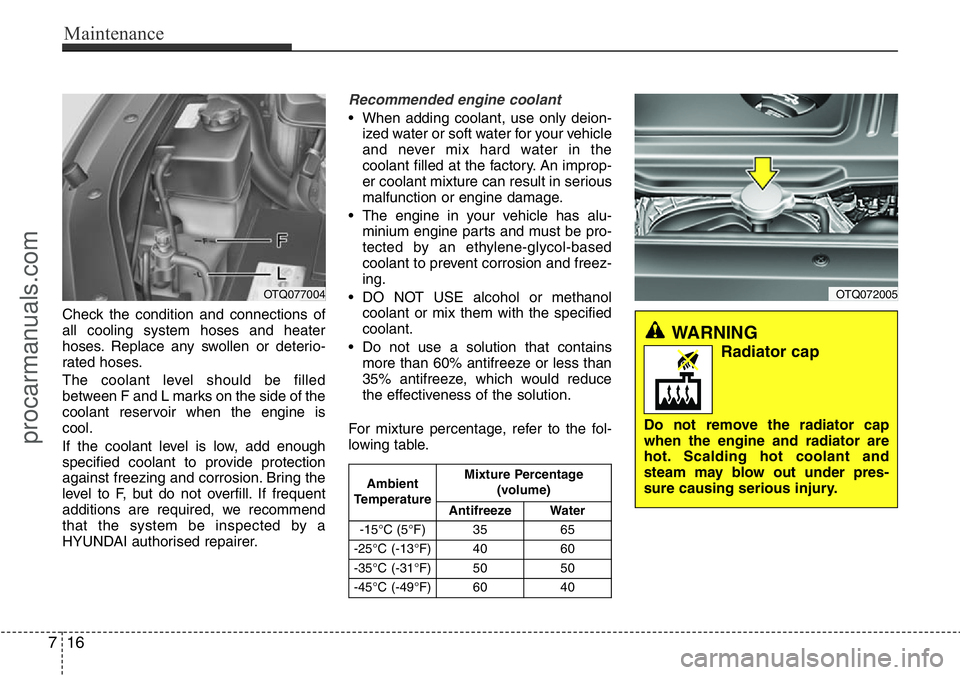

Check the condition and connections of

all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F and L marks on the side of the

coolant reservoir when the engine is

cool.

If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion. Bring the

level to F, but do not overfill. If frequent

additions are required, we recommend

that the system be inspected by a

HYUNDAI authorised repairer.

Recommended engine coolant

• When adding coolant, use only deion-

ized water or soft water for your vehicle

and never mix hard water in the

coolant filled at the factory. An improp-

er coolant mixture can result in serious

malfunction or engine damage.

• The engine in your vehicle has alu-

minium engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-

ing.

• DO NOT USE alcohol or methanol

coolant or mix them with the specified

coolant.

• Do not use a solution that contains

more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution.

For mixture percentage, refer to the fol-

lowing table.

OTQ077004

WARNING

Radiator cap

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot coolant and

steam may blow out under pres-

sure causing serious injury.

OTQ072005

Ambient

TemperatureMixture Percentage

(volume)

Antifreeze Water

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

procarmanuals.com

Page 380 of 419

Maintenance

50 7

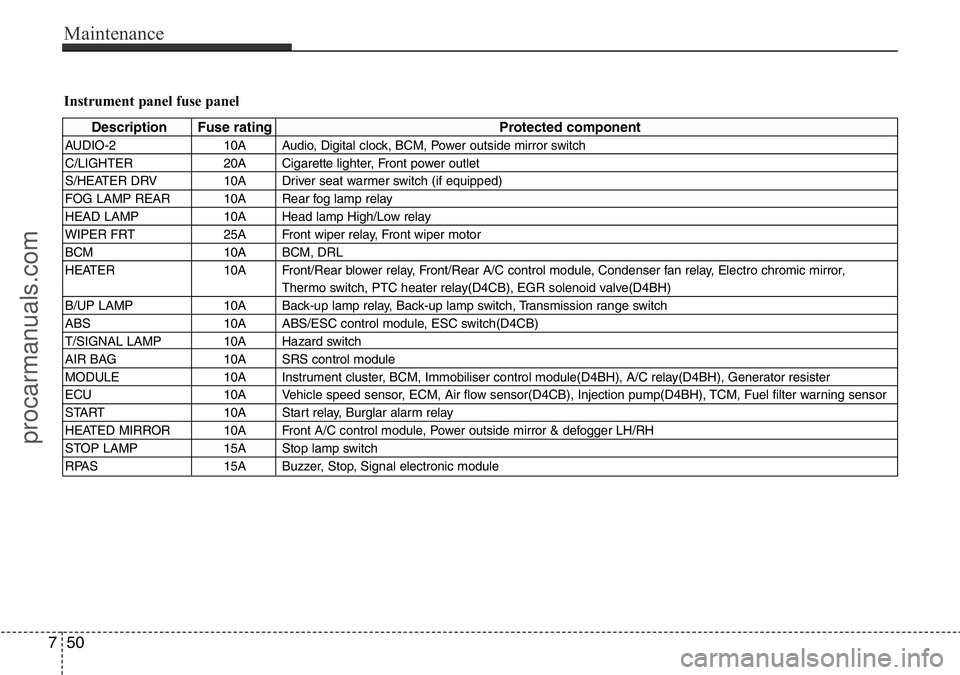

Instrument panel fuse panel

Description Fuse rating Protected component

AUDIO-2 10A Audio, Digital clock, BCM, Power outside mirror switch

C/LIGHTER 20A Cigarette lighter, Front power outlet

S/HEATER DRV 10A Driver seat warmer switch (if equipped)

FOG LAMP REAR 10A Rear fog lamp relay

HEAD LAMP 10A Head lamp High/Low relay

WIPER FRT 25A Front wiper relay, Front wiper motor

BCM 10A BCM, DRL

HEATER 10A Front/Rear blower relay, Front/Rear A/C control module, Condenser fan relay, Electro chromic mirror,

Thermo switch, PTC heater relay(D4CB), EGR solenoid valve(D4BH)

B/UP LAMP 10A Back-up lamp relay, Back-up lamp switch, Transmission range switch

ABS 10A ABS/ESC control module, ESC switch(D4CB)

T/SIGNAL LAMP 10A Hazard switch

AIR BAG 10A SRS control module

MODULE 10A Instrument cluster, BCM, Immobiliser control module(D4BH), A/C relay(D4BH), Generator resister

ECU 10A Vehicle speed sensor, ECM, Air flow sensor(D4CB), Injection pump(D4BH), TCM, Fuel filter warning sensor

START 10A Start relay, Burglar alarm relay

HEATED MIRROR 10A Front A/C control module, Power outside mirror & defogger LH/RH

STOP LAMP 15A Stop lamp switch

RPAS 15A Buzzer, Stop, Signal electronic module

procarmanuals.com

Page 382 of 419

Maintenance

52 7

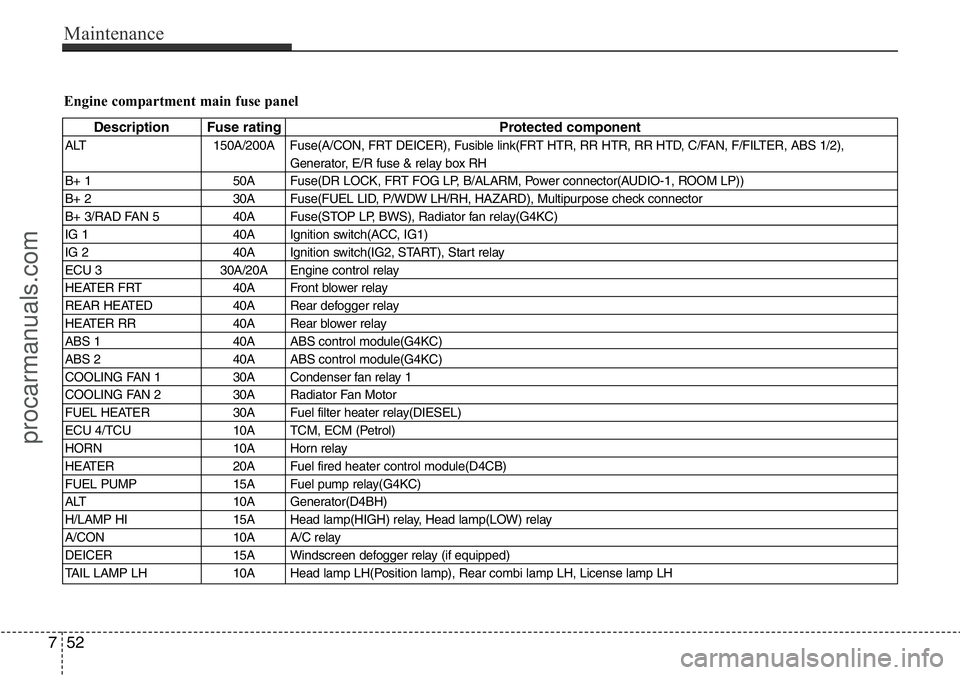

Engine compartment main fuse panel

Description Fuse rating Protected component

ALT 150A/200A Fuse(A/CON, FRT DEICER), Fusible link(FRT HTR, RR HTR, RR HTD, C/FAN, F/FILTER, ABS 1/2),

Generator, E/R fuse & relay box RH

B+ 1 50A Fuse(DR LOCK, FRT FOG LP, B/ALARM, Power connector(AUDIO-1, ROOM LP))

B+ 2 30A Fuse(FUEL LID, P/WDW LH/RH, HAZARD), Multipurpose check connector

B+ 3/RAD FAN 5 40A Fuse(STOP LP, BWS), Radiator fan relay(G4KC)

IG 1 40A Ignition switch(ACC, IG1)

IG 2 40A Ignition switch(IG2, START), Start relay

ECU 3 30A/20A Engine control relay

HEATER FRT 40A Front blower relay

REAR HEATED 40A Rear defogger relay

HEATER RR 40A Rear blower relay

ABS 1 40A ABS control module(G4KC)

ABS 2 40A ABS control module(G4KC)

COOLING FAN 1 30A Condenser fan relay 1

COOLING FAN 2 30A Radiator Fan Motor

FUEL HEATER 30A Fuel filter heater relay(DIESEL)

ECU 4/TCU 10A TCM, ECM (Petrol)

HORN 10A Horn relay

HEATER 20A Fuel fired heater control module(D4CB)

FUEL PUMP 15A Fuel pump relay(G4KC)

ALT 10A Generator(D4BH)

H/LAMP HI 15A Head lamp(HIGH) relay, Head lamp(LOW) relay

A/CON 10A A/C relay

DEICER 15A Windscreen defogger relay (if equipped)

TAIL LAMP LH 10A Head lamp LH(Position lamp), Rear combi lamp LH, License lamp LH

procarmanuals.com

Page 383 of 419

753

Maintenance

Description Fuse rating Protected component

TAIL LAMP RH 10A Head lamp RH(Position lamp), Rear combi lamp RH, License lamp RH

HEAD LAMP LH 10A Head lamp LH

HEAD LAMP RH 10A Head lamp RH

SENSOR 1 10A A/C relay, Condenser fan relay(D4CB), Lambda sensor(D4CB), PTC heater relay #1(D4CB), Stop lamp

switch(D4CB)

SENSOR 2 15A D4CB: Camshaft position sensor, Glow plug relay, EGR actuator, VGT control valve, Immobiliser control module

G4KC: Fuel pump relay, Canister purge solenoid valve, Oil control valve, Crankshaft position sensor,

Oxygen sensor, Immobiliser control module, Idle speed control actuator

IGN COIL 15A Ignition coil #1~#4(G4KC), Condenser(G4KC)

ECU 1 10A ECM(D4CB)

ECU 2 20A ECM(D4CB, G4KC), Injector #1~#4(G4KC)

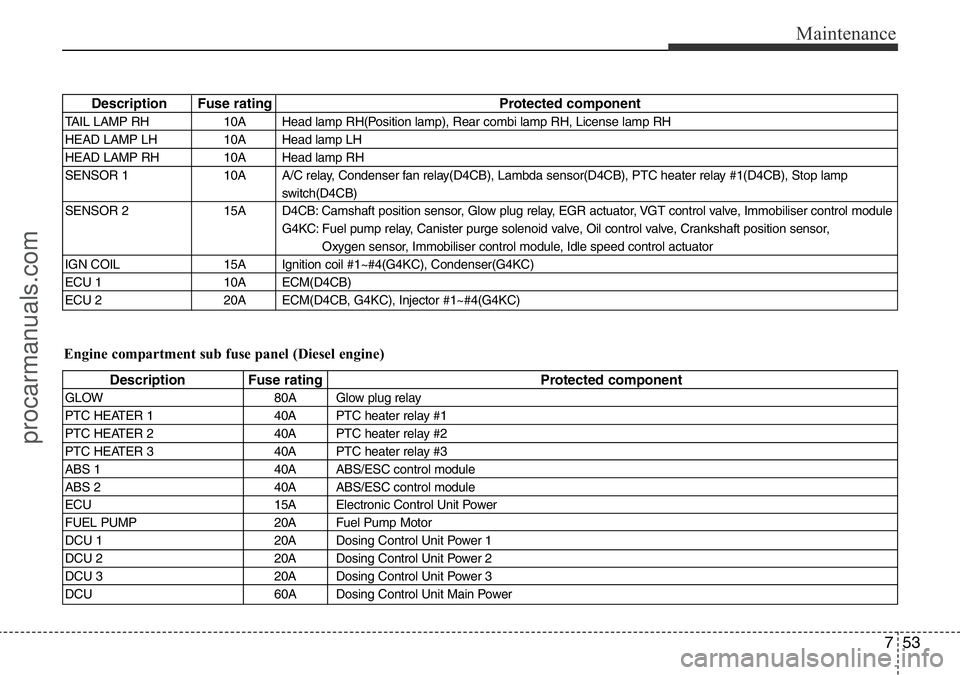

Engine compartment sub fuse panel (Diesel engine)

Description Fuse rating Protected component

GLOW 80A Glow plug relay

PTC HEATER 1 40A PTC heater relay #1

PTC HEATER 2 40A PTC heater relay #2

PTC HEATER 3 40A PTC heater relay #3

ABS 1 40A ABS/ESC control module

ABS 2 40A ABS/ESC control module

ECU 15A Electronic Control Unit Power

FUEL PUMP 20A Fuel Pump Motor

DCU 1 20A Dosing Control Unit Power 1

DCU 2 20A Dosing Control Unit Power 2

DCU 3 20A Dosing Control Unit Power 3

DCU 60A Dosing Control Unit Main Power

procarmanuals.com

Page 410 of 419

Maintenance

80 7

CAUTION

• If defective urea solution or liquid

that is not recommended is sup-

plied, there may be damage on

the parts of the vehicle such as

processing device. If defective

fuel is used, foreign objects will

be accumulated to SCR catalyst

and cause catalyst pushed away

or breaking.

After adding the incorrect urea

solution, please visit the closest

service centre as early as possi-

ble.

• Liquid that are not recommended

such as diesel, petrol, and alcohol

shall never be used other than the

recommended urea solution that

satisfy ISO22241 or DIN70070.

• If defective urea solution or liquid

that is not recommended is sup-

plied, there may be damage on

the parts of the vehicle such as

processing device. If defective

fuel is used, foreign objects will

be accumulated to SCR catalyst

and cause catalyst pushed away

or breaking.

(Continued)

• The time to defrost the urea solu-

tion varies in accordance with

driving conditions and outside

temperatures.(Continued)

• Keep urea solution out of reach

of children.

• When urea solution overflows

into vehicle surface, wash out

vehicle surface with clean water

to prohibit corrosion from occur-

ring.

• When replenishing, be careful

lest the urea solution should

overflow.

• In case the vehicle was parked at

very low ambient temperature

(below 11 dgree Celcius) for a

long time, the urea solution will

be frozen in the urea solution

tank. With frozen urea, the tank

level may not be detected cor-

rectly until the urea solution will

be defrosted by activated heater.

Incorrect urea or diluted urea can

increase the freezing point, and

thus defrosting may not be prop-

erly done by the heater which is

activated below certain tempera-

tures. This phenomenon may

cause malfunction of the SCR

system which can lead to the pro-

hibition of engine restarting.

(Continued)

procarmanuals.com