fuel HYUNDAI I800 2016 Service Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: I800, Model: HYUNDAI I800 2016Pages: 419, PDF Size: 9.23 MB

Page 363 of 419

733

Maintenance

TYRES AND WHEELS

Tyre care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tyre

inflation pressures and stay within

the load limits and weight distribution

recommended for your vehicle.

Recommended cold tyre inflation

pressures

All tyre pressures (including the

spare) should be checked when the

tyres are cold. “Cold Tyres” means

the vehicle has not been driven for at

least three hours or driven less than

one mile (1.6 km).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tyre

wear.

For recommended inflation pressure,

refer to “Tyre and wheels” in section

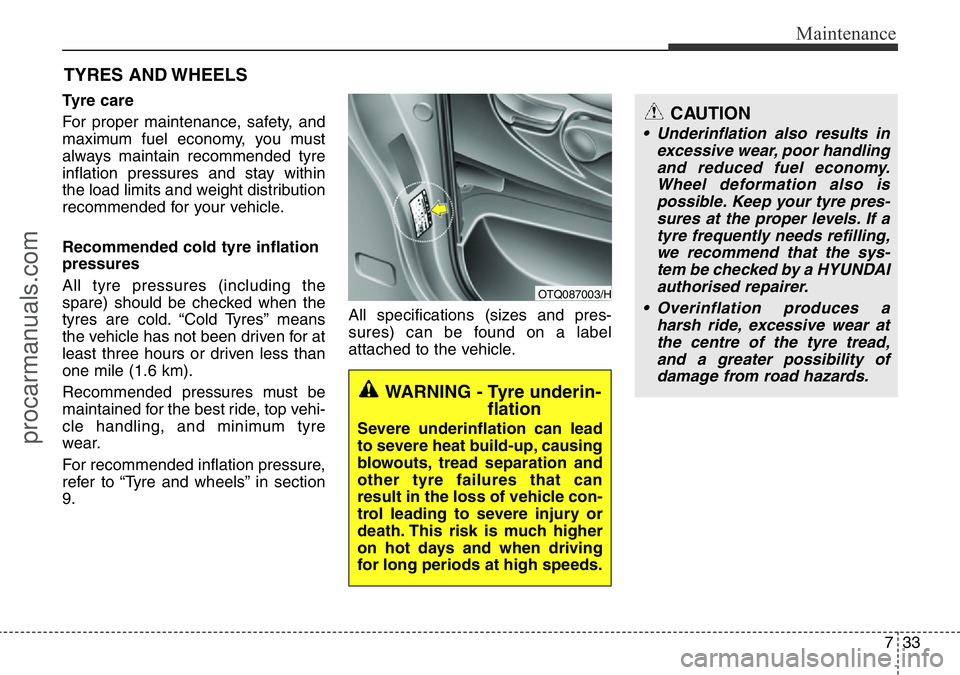

9.All specifications (sizes and pres-

sures) can be found on a label

attached to the vehicle.

WARNING - Tyre underin-

flation

Severe underinflation can lead

to severe heat build-up, causing

blowouts, tread separation and

other tyre failures that can

result in the loss of vehicle con-

trol leading to severe injury or

death. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OTQ087003/H

CAUTION

• Underinflation also results in

excessive wear, poor handling

and reduced fuel economy.

Wheel deformation also is

possible. Keep your tyre pres-

sures at the proper levels. If a

tyre frequently needs refilling,

we recommend that the sys-

tem be checked by a HYUNDAI

authorised repairer.

• Overinflation produces a

harsh ride, excessive wear at

the centre of the tyre tread,

and a greater possibility of

damage from road hazards.

procarmanuals.com

Page 380 of 419

Maintenance

50 7

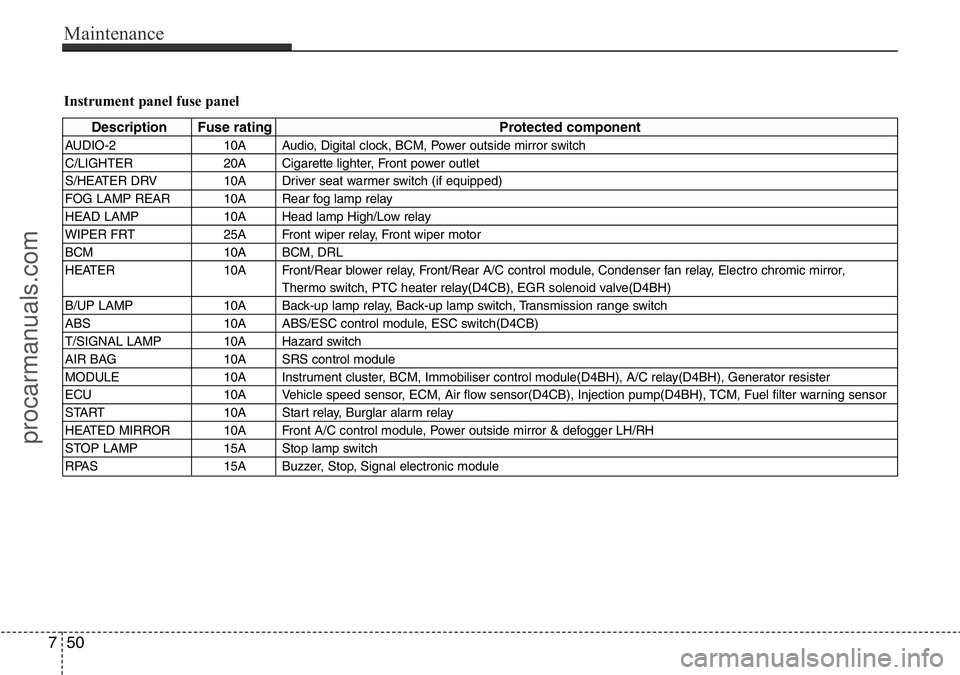

Instrument panel fuse panel

Description Fuse rating Protected component

AUDIO-2 10A Audio, Digital clock, BCM, Power outside mirror switch

C/LIGHTER 20A Cigarette lighter, Front power outlet

S/HEATER DRV 10A Driver seat warmer switch (if equipped)

FOG LAMP REAR 10A Rear fog lamp relay

HEAD LAMP 10A Head lamp High/Low relay

WIPER FRT 25A Front wiper relay, Front wiper motor

BCM 10A BCM, DRL

HEATER 10A Front/Rear blower relay, Front/Rear A/C control module, Condenser fan relay, Electro chromic mirror,

Thermo switch, PTC heater relay(D4CB), EGR solenoid valve(D4BH)

B/UP LAMP 10A Back-up lamp relay, Back-up lamp switch, Transmission range switch

ABS 10A ABS/ESC control module, ESC switch(D4CB)

T/SIGNAL LAMP 10A Hazard switch

AIR BAG 10A SRS control module

MODULE 10A Instrument cluster, BCM, Immobiliser control module(D4BH), A/C relay(D4BH), Generator resister

ECU 10A Vehicle speed sensor, ECM, Air flow sensor(D4CB), Injection pump(D4BH), TCM, Fuel filter warning sensor

START 10A Start relay, Burglar alarm relay

HEATED MIRROR 10A Front A/C control module, Power outside mirror & defogger LH/RH

STOP LAMP 15A Stop lamp switch

RPAS 15A Buzzer, Stop, Signal electronic module

procarmanuals.com

Page 381 of 419

751

Maintenance

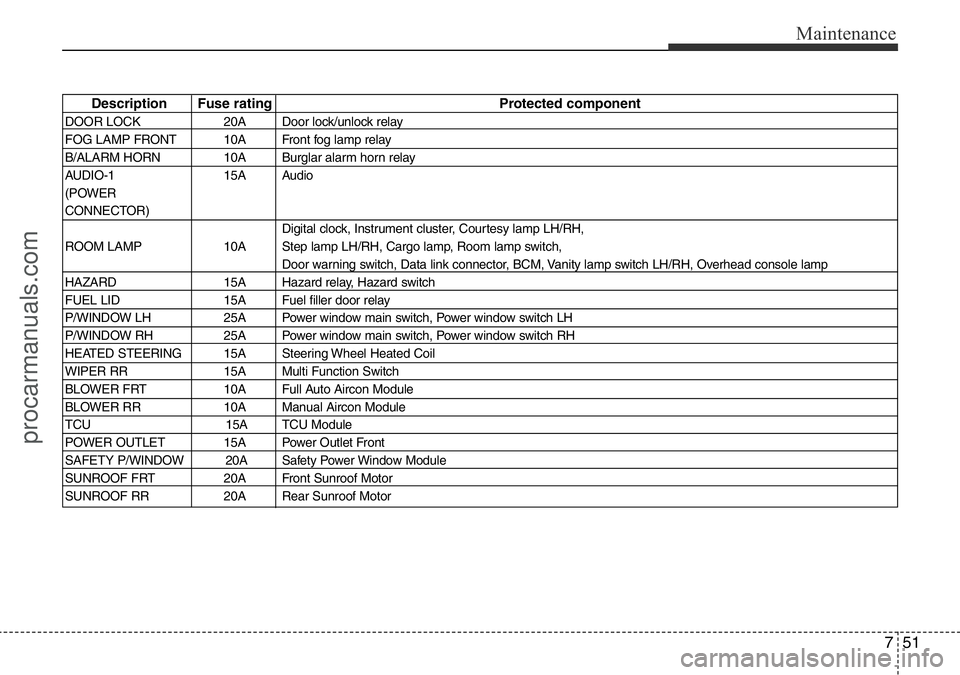

Description Fuse rating Protected component

DOOR LOCK 20A Door lock/unlock relay

FOG LAMP FRONT 10A Front fog lamp relay

B/ALARM HORN 10A Burglar alarm horn relay

AUDIO-1 15A Audio

(POWER

CONNECTOR)

Digital clock, Instrument cluster, Courtesy lamp LH/RH,

ROOM LAMP 10A Step lamp LH/RH, Cargo lamp, Room lamp switch,

Door warning switch, Data link connector, BCM, Vanity lamp switch LH/RH, Overhead console lamp

HAZARD 15A Hazard relay, Hazard switch

FUEL LID 15A Fuel filler door relay

P/WINDOW LH 25A Power window main switch, Power window switch LH

P/WINDOW RH 25A Power window main switch, Power window switch RH

HEATED STEERING 15A Steering Wheel Heated Coil

WIPER RR 15A Multi Function Switch

BLOWER FRT 10A Full Auto Aircon Module

BLOWER RR 10A Manual Aircon Module

TCU 15A TCU Module

POWER OUTLET 15A Power Outlet Front

SAFETY P/WINDOW 20A Safety Power Window Module

SUNROOF FRT 20A Front Sunroof Motor

SUNROOF RR 20A Rear Sunroof Motor

procarmanuals.com

Page 382 of 419

Maintenance

52 7

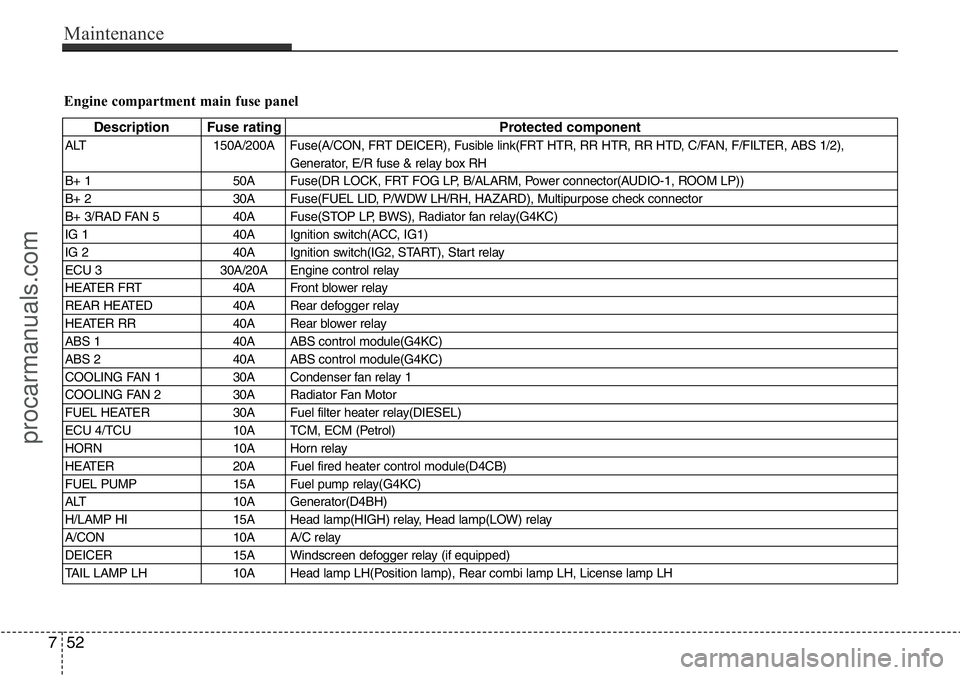

Engine compartment main fuse panel

Description Fuse rating Protected component

ALT 150A/200A Fuse(A/CON, FRT DEICER), Fusible link(FRT HTR, RR HTR, RR HTD, C/FAN, F/FILTER, ABS 1/2),

Generator, E/R fuse & relay box RH

B+ 1 50A Fuse(DR LOCK, FRT FOG LP, B/ALARM, Power connector(AUDIO-1, ROOM LP))

B+ 2 30A Fuse(FUEL LID, P/WDW LH/RH, HAZARD), Multipurpose check connector

B+ 3/RAD FAN 5 40A Fuse(STOP LP, BWS), Radiator fan relay(G4KC)

IG 1 40A Ignition switch(ACC, IG1)

IG 2 40A Ignition switch(IG2, START), Start relay

ECU 3 30A/20A Engine control relay

HEATER FRT 40A Front blower relay

REAR HEATED 40A Rear defogger relay

HEATER RR 40A Rear blower relay

ABS 1 40A ABS control module(G4KC)

ABS 2 40A ABS control module(G4KC)

COOLING FAN 1 30A Condenser fan relay 1

COOLING FAN 2 30A Radiator Fan Motor

FUEL HEATER 30A Fuel filter heater relay(DIESEL)

ECU 4/TCU 10A TCM, ECM (Petrol)

HORN 10A Horn relay

HEATER 20A Fuel fired heater control module(D4CB)

FUEL PUMP 15A Fuel pump relay(G4KC)

ALT 10A Generator(D4BH)

H/LAMP HI 15A Head lamp(HIGH) relay, Head lamp(LOW) relay

A/CON 10A A/C relay

DEICER 15A Windscreen defogger relay (if equipped)

TAIL LAMP LH 10A Head lamp LH(Position lamp), Rear combi lamp LH, License lamp LH

procarmanuals.com

Page 383 of 419

753

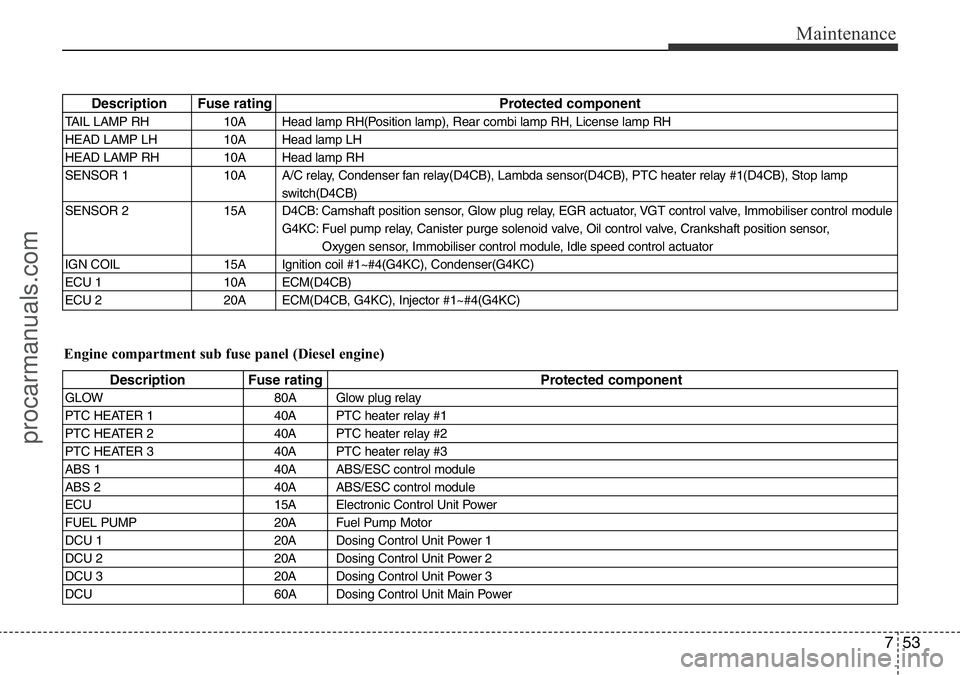

Maintenance

Description Fuse rating Protected component

TAIL LAMP RH 10A Head lamp RH(Position lamp), Rear combi lamp RH, License lamp RH

HEAD LAMP LH 10A Head lamp LH

HEAD LAMP RH 10A Head lamp RH

SENSOR 1 10A A/C relay, Condenser fan relay(D4CB), Lambda sensor(D4CB), PTC heater relay #1(D4CB), Stop lamp

switch(D4CB)

SENSOR 2 15A D4CB: Camshaft position sensor, Glow plug relay, EGR actuator, VGT control valve, Immobiliser control module

G4KC: Fuel pump relay, Canister purge solenoid valve, Oil control valve, Crankshaft position sensor,

Oxygen sensor, Immobiliser control module, Idle speed control actuator

IGN COIL 15A Ignition coil #1~#4(G4KC), Condenser(G4KC)

ECU 1 10A ECM(D4CB)

ECU 2 20A ECM(D4CB, G4KC), Injector #1~#4(G4KC)

Engine compartment sub fuse panel (Diesel engine)

Description Fuse rating Protected component

GLOW 80A Glow plug relay

PTC HEATER 1 40A PTC heater relay #1

PTC HEATER 2 40A PTC heater relay #2

PTC HEATER 3 40A PTC heater relay #3

ABS 1 40A ABS/ESC control module

ABS 2 40A ABS/ESC control module

ECU 15A Electronic Control Unit Power

FUEL PUMP 20A Fuel Pump Motor

DCU 1 20A Dosing Control Unit Power 1

DCU 2 20A Dosing Control Unit Power 2

DCU 3 20A Dosing Control Unit Power 3

DCU 60A Dosing Control Unit Main Power

procarmanuals.com

Page 394 of 419

Maintenance

64 7

Bright-metal maintenance

• To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

• To protect the surfaces of bright-metal

parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

• During winter weather or in coastal

areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Pay

special attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting.WARNING

After washing the vehicle, test the

brakes whilst driving slowly to see

if they have been affected by water.

If braking performance is impaired,

dry the brakes by applying them

lightly whilst maintaining a slow

forward speed.

procarmanuals.com

Page 399 of 419

769

Maintenance

EMISSION CONTROL SYSTEM (IF EQUIPPED)

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Service Passport

in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all applicable

emission regulations.

There are three emission control sys-

tems, as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by a

HYUNDAI authorised repairer in accor-

dance with the maintenance schedule in

this manual.Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

• To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

• After dynamometer testing is com-

pleted, turn the ESC system back on

by pressing the ESC switch again.

1. Crankcase emission control

system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative emission control

system

The Evaporative Emission Control

System is designed to prevent fuel

vapours from escaping into the atmos-

phere.

Canister

Fuel vapours generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapours absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.

procarmanuals.com

Page 401 of 419

771

Maintenance

Operating precautions for catalytic

converters (if equipped)Your vehicle is equipped with a catalytic

converter emission control device.

Therefore, the following precautions

must be observed:

• Use only UNLEADED FUEL for petrol

engines.

• Do not operate the vehicle when there

are signs of engine malfunction, such

as misfire or a noticeable loss of per-

formance.

• Do not misuse or abuse the engine.

Examples of misuse are coasting with

the ignition off and descending steep

grades in gear with the ignition off.

• Do not operate the engine at high idle

speed for extended periods (5 minutes

or more).

• Do not modify or tamper with any part

of the engine or emission control sys-

tem. We recommend that the system

be inspected by a HYUNDAI autho-

rised repairer.

• Avoid driving with a very low fuel level.

If you run out of petrol, it could cause

the engine to misfire and result in

excessive loading of the catalytic con-

verter.

Failure to observe these precautions

could result in damage to the catalytic

converter and to your vehicle.

Additionally, such actions could void your

warranties.Diesel Particulate Filter (if equipped)

The Diesel Particulate Filter (DPF) sys-

tem removes the soot in the exhaust gas.

Unlike a disposable air filter, the DPF

system automatically burns (oxidizes)

and removes the accumulated soot

according to the driving condition. In

other words, the active burning by engine

control system and high exhaust gas

temperature caused by normal/high driv-

ing condition burns and removes the

accumulated soot.

However, if the vehicle continues to be

driven at repeated short distance or driv-

en at low speed for a long time, the accu-

mulate soot may not be automatically

removed because of low exhaust gas

temperature. More than a certain amount

of soot deposited, the malfunction indica-

tor light ( ) illuminates.

When the malfunction indicator light

blinks, it may stop blinking by driving the

vehicle at more than 37 mph (60km/h) or

at more than second gear with 1500 ~

2500 engine rpm for a certain time (for

about 25 minutes).

WARNING- Fire

• A hot exhaust system can ignite

flammable items under your vehi-

cle. Do not park, idle, or drive the

vehicle over or near flammable

objects, such as grass, vegeta-

tion, paper, leaves, etc.

• The exhaust system and catalytic

system are very hot whilst the

engine is running or immediately

after the engine is turned off. Keep

away from the exhaust system

and catalytic, you may get burned.

Also, do not remove the heat sink

around the exhaust system, do

not seal the bottom of the vehicle

or do not coat the vehicle for cor-

rosion control. It may present a

fire risk under certain conditions.

procarmanuals.com

Page 402 of 419

If the malfunction indicator light ( )

continues to be blinked or the warn-

ing massage "check exhaust system"

illuminates in spite of the procedure,

please visit a HYUNDAI authorised

repairer and the check the DPF system.

If you continue to drive with the malfunc-

tion indicator light blinking for a long

time, the DPF system can be damaged

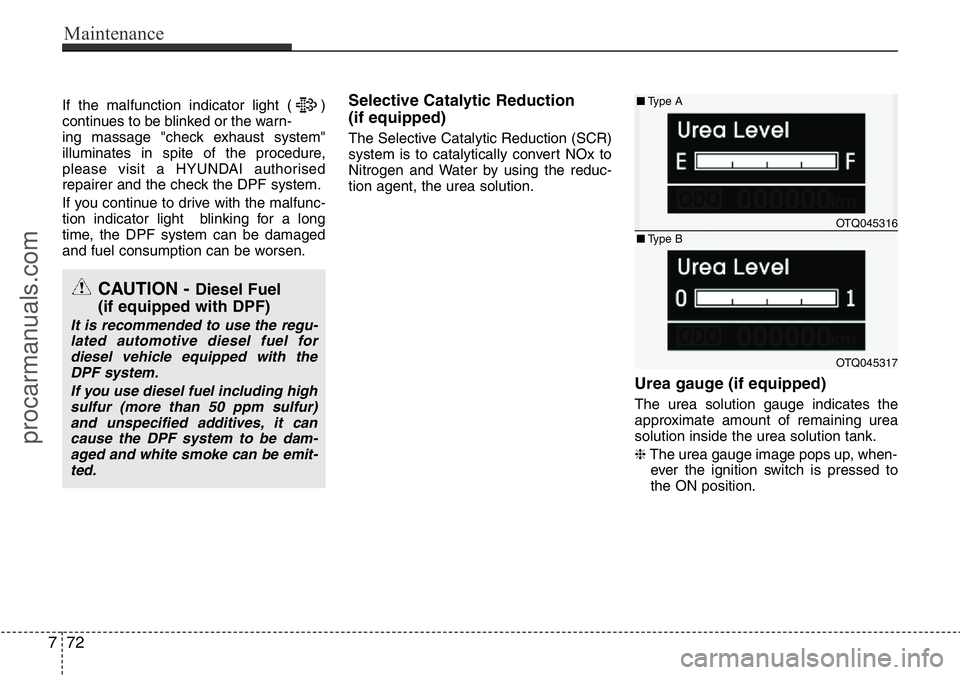

and fuel consumption can be worsen.Selective Catalytic Reduction

(if equipped)

The Selective Catalytic Reduction (SCR)

system is to catalytically convert NOx to

Nitrogen and Water by using the reduc-

tion agent, the urea solution.

Urea gauge (if equipped)

The urea solution gauge indicates the

approximate amount of remaining urea

solution inside the urea solution tank.

❈The urea gauge image pops up, when-

ever the ignition switch is pressed to

the ON position.

CAUTION - Diesel Fuel

(if equipped with DPF)

It is recommended to use the regu-

lated automotive diesel fuel for

diesel vehicle equipped with the

DPF system.

If you use diesel fuel including high

sulfur (more than 50 ppm sulfur)

and unspecified additives, it can

cause the DPF system to be dam-

aged and white smoke can be emit-

ted.

772

Maintenance

OTQ045316

OTQ045317 ■Type A

■Type B

procarmanuals.com

Page 404 of 419

Maintenance

74 7

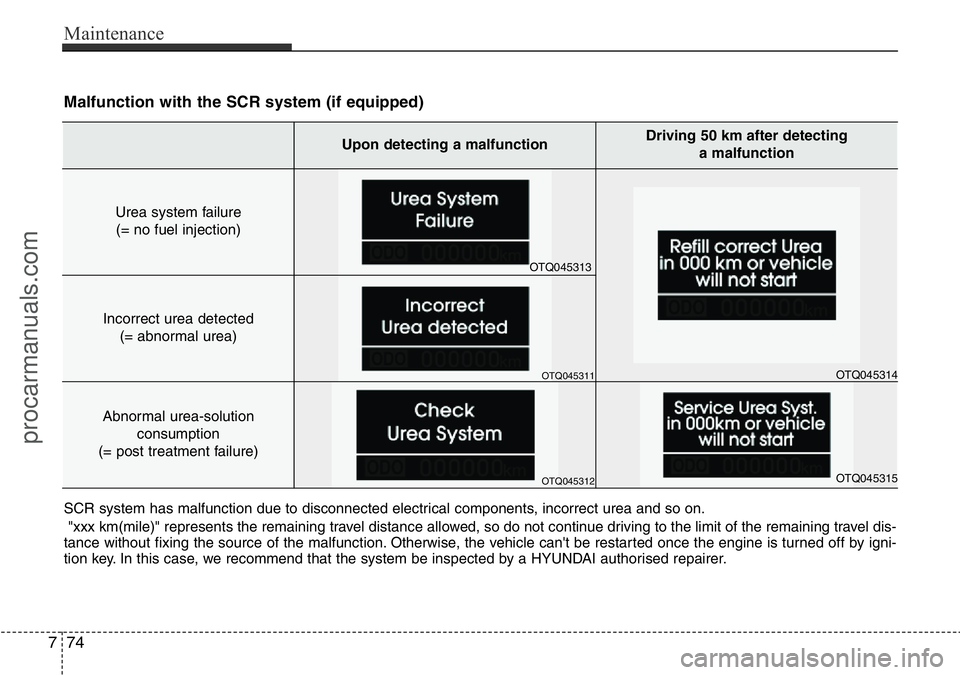

Malfunction with the SCR system (if equipped)

SCR system has malfunction due to disconnected electrical components, incorrect urea and so on.

"xxx km(mile)" represents the remaining travel distance allowed, so do not continue driving to the limit of the remaining travel dis-

tance without fixing the source of the malfunction. Otherwise, the vehicle can't be restarted once the engine is turned off by igni-

tion key. In this case, we recommend that the system be inspected by a HYUNDAI authorised repairer.

Upon detecting a malfunctionDriving 50 km after detecting

a malfunction

Urea system failure

(= no fuel injection)

Incorrect urea detected

(= abnormal urea)

Abnormal urea-solution

consumption

(= post treatment failure)

OTQ045313

OTQ045311

OTQ045312OTQ045314

OTQ045315

procarmanuals.com