sensor Hyundai Ioniq Electric 2019 - RHD (UK, Australia) Workshop Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: Ioniq Electric, Model: Hyundai Ioniq Electric 2019Pages: 526, PDF Size: 16.63 MB

Page 444 of 526

6-21

What to do in an emergency

6

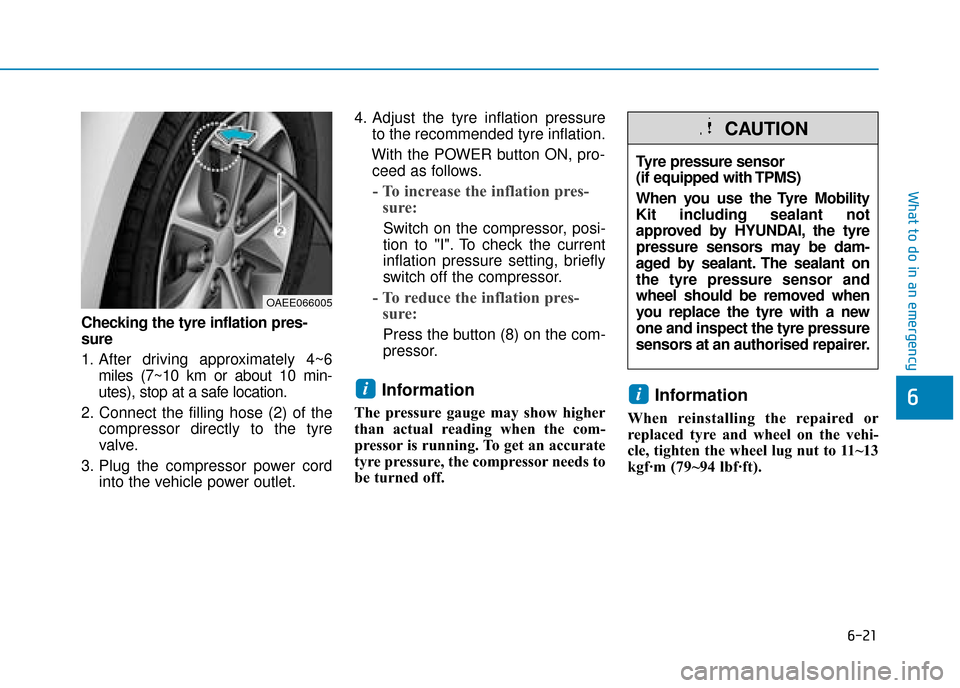

Checking the tyre inflation pres-

sure

1. After driving approximately 4~6miles (7~10 km or about 10 min-

utes), stop at a safe location.

2. Connect the filling hose (2) of the compressor directly to the tyre

valve.

3. Plug the compressor power cord into the vehicle power outlet. 4. Adjust the tyre inflation pressure

to the recommended tyre inflation.

With the POWER button ON, pro- ceed as follows.

- To increase the inflation pres- sure:

Switch on the compressor, posi-

tion to "I". To check the current

inflation pressure setting, briefly

switch off the compressor.

- To reduce the inflation pres- sure:

Press the button (8) on the com-

pressor.

Information

The pressure gauge may show higher

than actual reading when the com-

pressor is running. To get an accurate

tyre pressure, the compressor needs to

be turned off.

Information

When reinstalling the repaired or

replaced tyre and wheel on the vehi-

cle, tighten the wheel lug nut to 11~13

kgf·m (79~94 lbf·ft).

ii

OAEE066005

Tyre pressure sensor

(if equipped with TPMS)

When you use the Tyre Mobility

Kit including sealant not

approved by HYUNDAI, the tyre

pressure sensors may be dam-

aged by sealant. The sealant on

the tyre pressure sensor and

wheel should be removed when

you replace the tyre with a new

one and inspect the tyre pressure

sensors at an authorised repairer.

CAUTION

Page 487 of 526

7-39

7

Maintenance

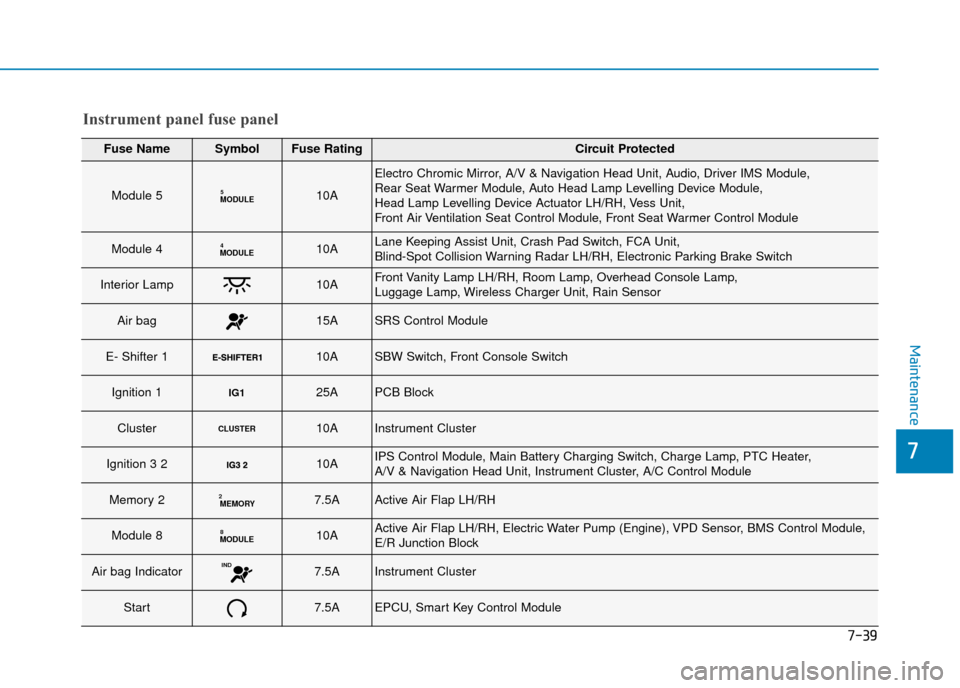

Instrument panel fuse panel

Fuse NameSymbolFuse RatingCircuit Protected

Module 5MODULE510A

Electro Chromic Mirror, A/V & Navigation Head Unit, Audio, Driver IMS Module,

Rear Seat Warmer Module, Auto Head Lamp Levelling Device Module,

Head Lamp Levelling Device Actuator LH/RH, Vess Unit,

Front Air Ventilation Seat Control Module, Front Seat Warmer Control Module

Module 4MODULE410ALane Keeping Assist Unit, Crash Pad Switch, FCA Unit,

Blind-Spot Collision Warning Radar LH/RH, Electronic Parking Brake Switch

Interior Lamp10AFront Vanity Lamp LH/RH, Room Lamp, Overhead Console Lamp,

Luggage Lamp, Wireless Charger Unit, Rain Sensor

Air bag15ASRS Control Module

E- Shifter 1 10ASBW Switch, Front Console Switch

Ignition 1IG125APCB Block

ClusterCLUSTER10AInstrument Cluster

Ignition 3 2 10AIPS Control Module, Main Battery Charging Switch, Charge Lamp, PTC Heater,

A/V & Navigation Head Unit, Instrument Cluster, A/C Control Module

Memory 2MEMORY27.5AActive Air Flap LH/RH

Module 8MODULE810AActive Air Flap LH/RH, Electric Water Pump (Engine), VPD Sensor, BMS Control Module,

E/R Junction Block

Air bag IndicatorIND7.5AInstrument Cluster

Start7.5AEPCU, Smart Key Control Module

Page 488 of 526

7-40

Maintenance

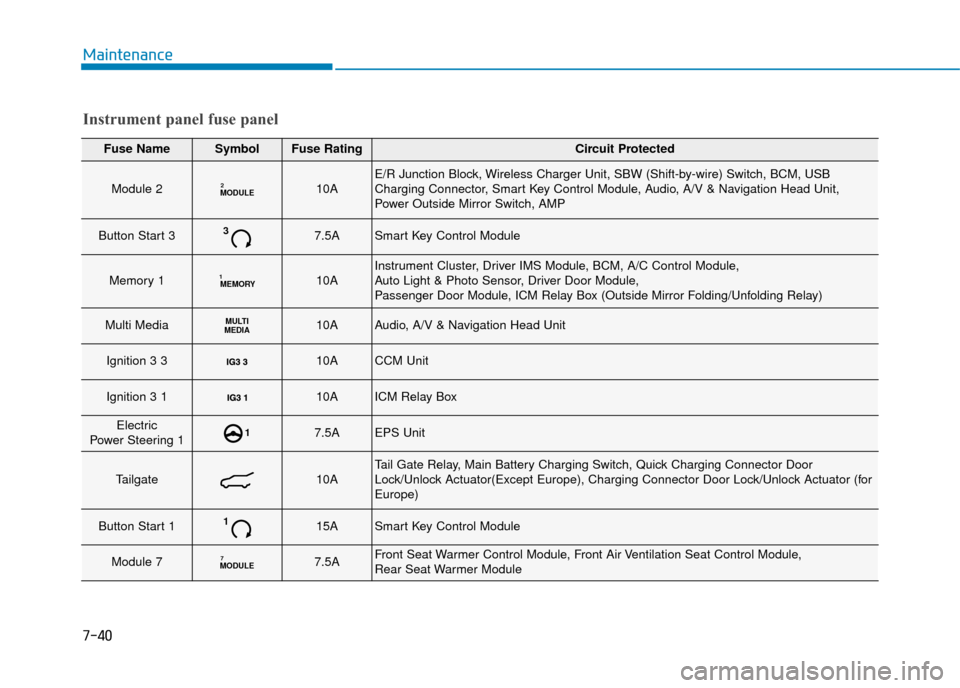

Fuse NameSymbolFuse RatingCircuit Protected

Module 2MODULE210AE/R Junction Block, Wireless Charger Unit, SBW (Shift-by-wire) Switch, BCM, USB

Charging Connector, Smart Key Control Module, Audio, A/V & Navigation Head Unit,

Power Outside Mirror Switch, AMP

Button Start 337.5ASmart Key Control Module

Memory 1MEMORY110AInstrument Cluster, Driver IMS Module, BCM, A/C Control Module,

Auto Light & Photo Sensor, Driver Door Module,

Passenger Door Module, ICM Relay Box (Outside Mirror Folding/Unfolding Relay)

Multi MediaMULTI

MEDIA10AAudio, A/V & Navigation Head Unit

Ignition 3 3 10ACCM Unit

Ignition 3 1 10AICM Relay Box

Electric

Power Steering 117.5AEPS Unit

Tailgate10ATail Gate Relay, Main Battery Charging Switch, Quick Charging Connector Door

Lock/Unlock Actuator(Except Europe), Charging Connector Door Lock/Unlock Actuator (for

Europe)

Button Start 1115ASmart Key Control Module

Module 7MODULE77.5AFront Seat Warmer Control Module, Front Air Ventilation Seat Control Module,

Rear Seat Warmer Module

Instrument panel fuse panel

Page 510 of 526

7-62

Maintenance

A

AP

PP

PE

EA

A R

RA

A N

N C

CE

E

C

C A

A R

RE

E

Exterior care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning

and caution statements that appear

on the label.

High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water.

Finish maintenance

Washing

To help protect your vehicle’s finish

from rust and deterioration, wash it

thoroughly and frequently at least

once a month with lukewarm or cold

water.

If you use your vehicle for off-road

driving, you should wash it after each

off-road trip. Pay special attention to

the removal of any accumulation of

salt, dirt, mud, and other foreign

materials. Make sure the drain holes

in the lower edges of the doors and

rocker panels are kept clear and

clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar

deposits can damage your vehicle’s

finish if not removed immediately.

Even prompt washing with plain

water may not completely remove all

these deposits. A mild soap, safe for

use on painted surfaces, should be

used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water.

Do not allow soap to dry on the finish. After washing the vehicle, test

the brakes whilst driving slowly

to see if they have been affected

by water before getting on the

road. If braking performance is

impaired, dry the brakes by

applying them lightly whilst

maintaining a slow forward

speed.

WARNING