Hyundai Ioniq Plug-in Hybrid 2019 Owner's Manual - RHD (UK, Australia)

Manufacturer: HYUNDAI, Model Year: 2019, Model line: Ioniq Plug-in Hybrid, Model: Hyundai Ioniq Plug-in Hybrid 2019Pages: 599, PDF Size: 17.32 MB

Page 501 of 599

6-40

7. Switch off the compressor.

8. Detach the hoses from the sealantbottle connector and from the tyre

valve.

Return the Tyre Mobility Kit to its

storage location in the vehicle.

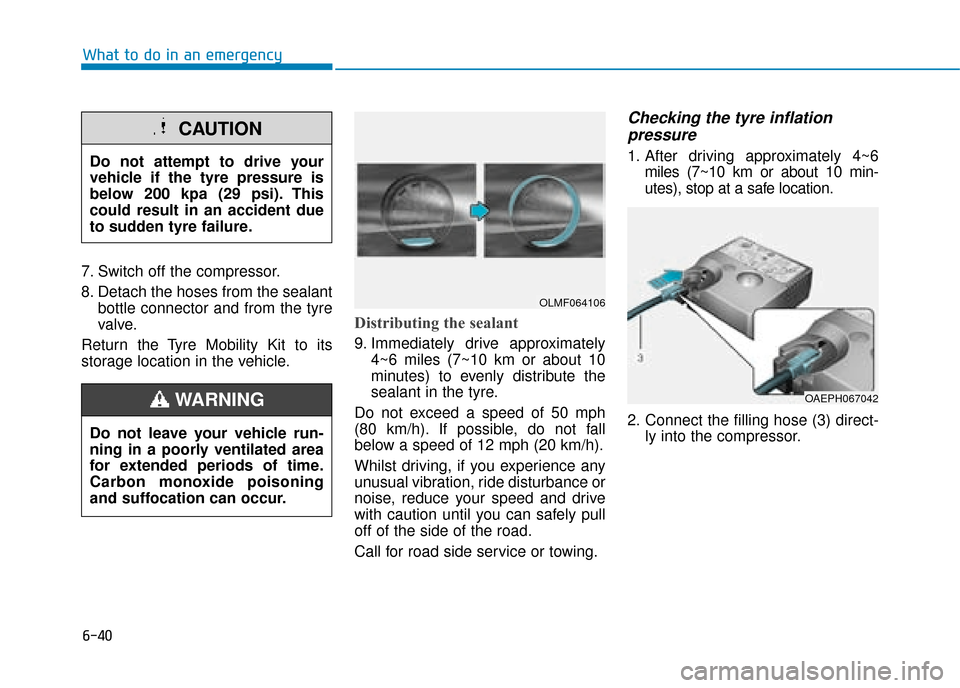

Distributing the sealant

9. Immediately drive approximately 4~6 miles (7~10 km or about 10

minutes) to evenly distribute the

sealant in the tyre.

Do not exceed a speed of 50 mph

(80 km/h). If possible, do not fall

below a speed of 12 mph (20 km/h).

Whilst driving, if you experience any

unusual vibration, ride disturbance or

noise, reduce your speed and drive

with caution until you can safely pull

off of the side of the road.

Call for road side service or towing.

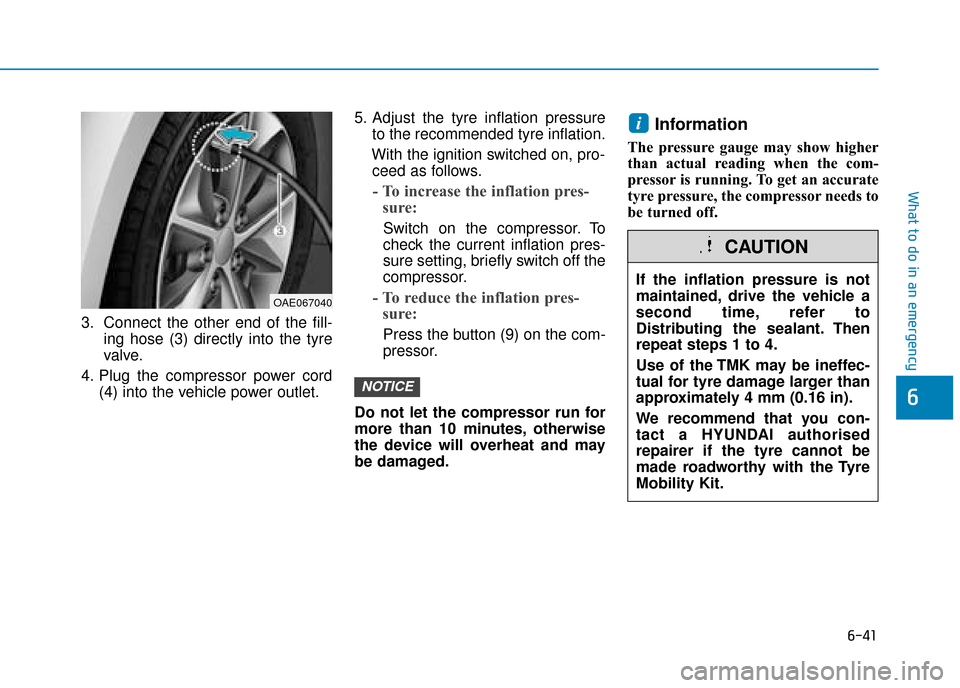

Checking the tyre inflation pressure

1. After driving approximately 4~6

miles (7~10 km or about 10 min-

utes), stop at a safe location.

2. Connect the filling hose (3) direct- ly into the compressor.

What to do in an emergency

Do not attempt to drive your

vehicle if the tyre pressure is

below 200 kpa (29 psi). This

could result in an accident due

to sudden tyre failure.

CAUTION

Do not leave your vehicle run-

ning in a poorly ventilated area

for extended periods of time.

Carbon monoxide poisoning

and suffocation can occur.

WARNING

OLMF064106

OAEPH067042

Page 502 of 599

6-41

What to do in an emergency

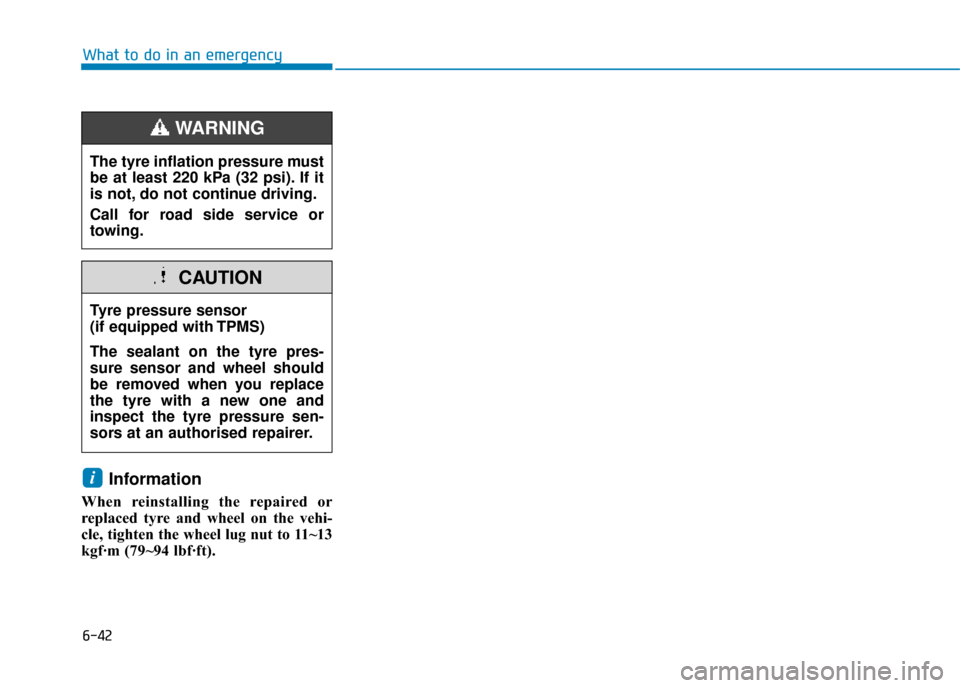

3. Connect the other end of the fill-ing hose (3) directly into the tyre

valve.

4. Plug the compressor power cord (4) into the vehicle power outlet. 5. Adjust the tyre inflation pressure

to the recommended tyre inflation.

With the ignition switched on, pro- ceed as follows.

- To increase the inflation pres- sure:

Switch on the compressor. To

check the current inflation pres-

sure setting, briefly switch off the

compressor.

- To reduce the inflation pres- sure:

Press the button (9) on the com-

pressor.

Do not let the compressor run for

more than 10 minutes, otherwise

the device will overheat and may

be damaged.

Information

The pressure gauge may show higher

than actual reading when the com-

pressor is running. To get an accurate

tyre pressure, the compressor needs to

be turned off.

i

NOTICE6

If the inflation pressure is not

maintained, drive the vehicle a

second time, refer to

Distributing the sealant. Then

repeat steps 1 to 4.

Use of the TMK may be ineffec-

tual for tyre damage larger than

approximately 4 mm (0.16 in).

We recommend that you con-

tact a HYUNDAI authorised

repairer if the tyre cannot be

made roadworthy with the Tyre

Mobility Kit.

CAUTION

OAE067040

Page 503 of 599

6-42

Information

When reinstalling the repaired or

replaced tyre and wheel on the vehi-

cle, tighten the wheel lug nut to 11~13

kgf·m (79~94 lbf·ft).

i

What to do in an emergencyTyre pressure sensor

(if equipped with TPMS)

The sealant on the tyre pres-

sure sensor and wheel should

be removed when you replace

the tyre with a new one and

inspect the tyre pressure sen-

sors at an authorised repairer.

CAUTION

The tyre inflation pressure must

be at least 220 kPa (32 psi). If it

is not, do not continue driving.

Call for road side service or

towing.

WARNING

Page 504 of 599

6-43

What to do in an emergency

6

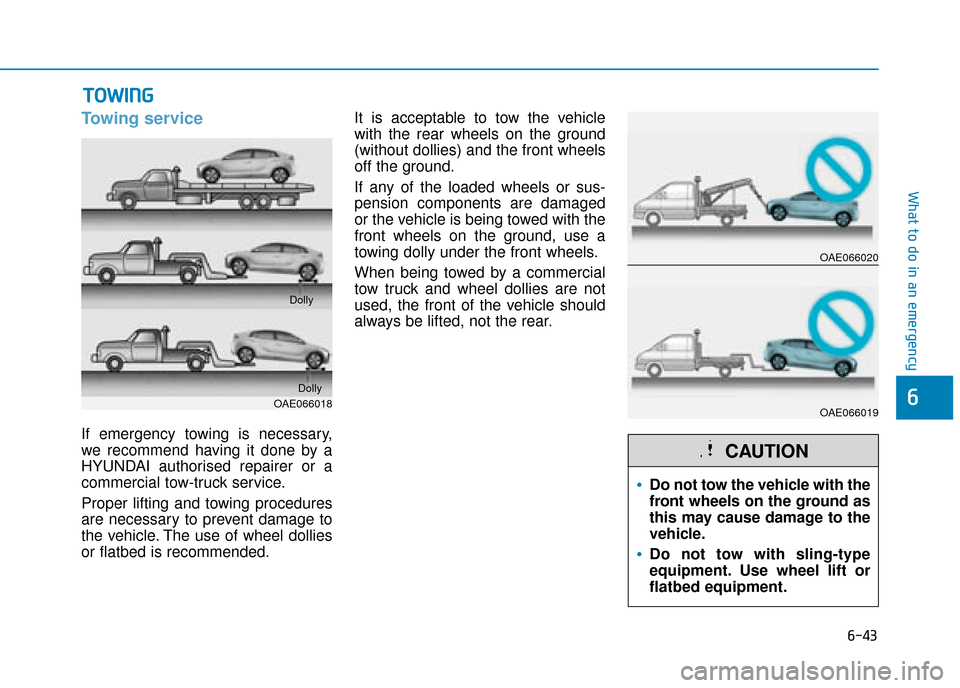

Towing service

If emergency towing is necessary,

we recommend having it done by a

HYUNDAI authorised repairer or a

commercial tow-truck service.

Proper lifting and towing procedures

are necessary to prevent damage to

the vehicle. The use of wheel dollies

or flatbed is recommended.It is acceptable to tow the vehicle

with the rear wheels on the ground

(without dollies) and the front wheels

off the ground.

If any of the loaded wheels or sus-

pension components are damaged

or the vehicle is being towed with the

front wheels on the ground, use a

towing dolly under the front wheels.

When being towed by a commercial

tow truck and wheel dollies are not

used, the front of the vehicle should

always be lifted, not the rear.

T T

O

O W

W I

IN

N G

G

OAE066018 Dolly

Dolly

Do not tow the vehicle with the

front wheels on the ground as

this may cause damage to the

vehicle.

Do not tow with sling-type

equipment. Use wheel lift or

flatbed equipment.

CAUTION

OAE066020

OAE066019

Page 505 of 599

6-44

What to do in an emergency

When towing your vehicle in an

emergency without wheel dollies:

1. Place the ignition switch in the ACC position.

2. Place the shift lever in N (Neutral).

3. Release the parking brake.

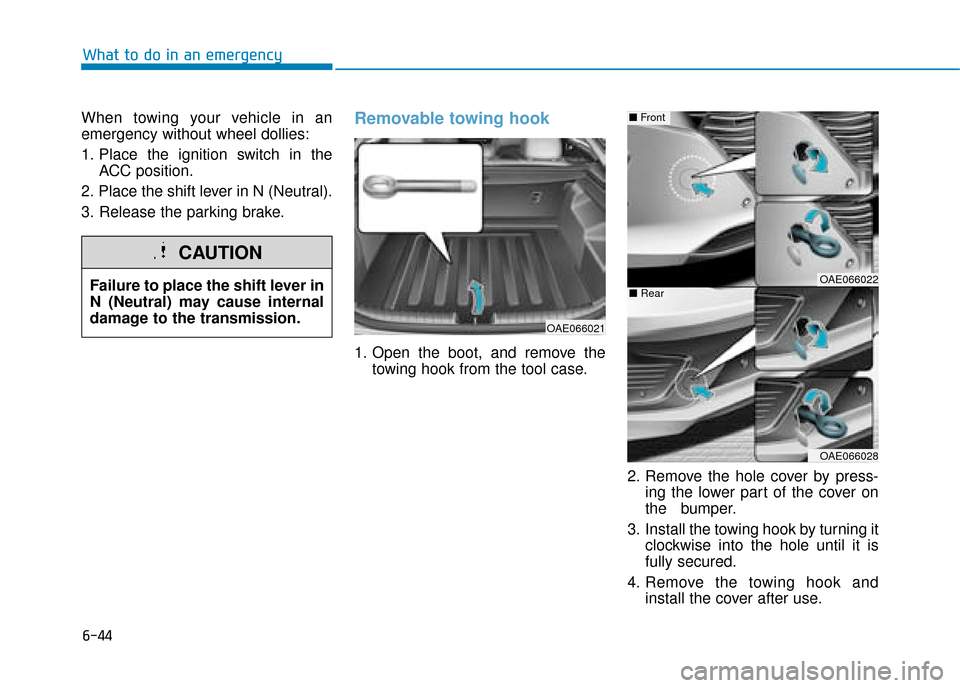

Removable towing hook

1. Open the boot, and remove the towing hook from the tool case.

2. Remove the hole cover by press-ing the lower part of the cover on

the bumper.

3. Install the towing hook by turning it clockwise into the hole until it is

fully secured.

4. Remove the towing hook and install the cover after use.

Failure to place the shift lever in

N (Neutral) may cause internal

damage to the transmission.

CAUTION

OAE066021

OAE066022

OAE066028

■

Front

■Rear

Page 506 of 599

6-45

What to do in an emergency

6

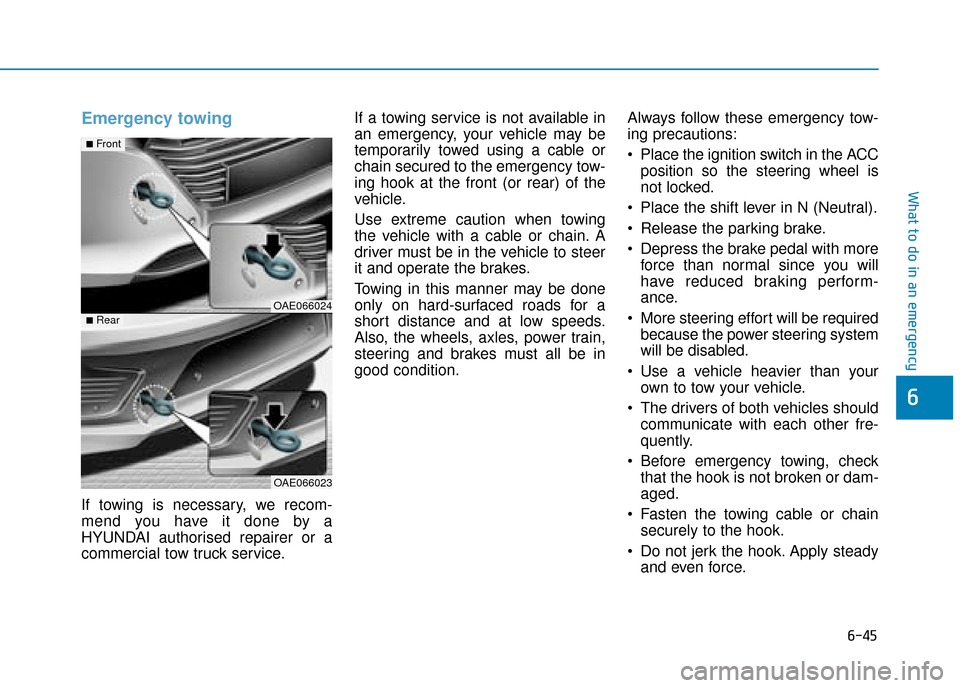

Emergency towing

If towing is necessary, we recom-

mend you have it done by a

HYUNDAI authorised repairer or a

commercial tow truck service.If a towing service is not available in

an emergency, your vehicle may be

temporarily towed using a cable or

chain secured to the emergency tow-

ing hook at the front (or rear) of the

vehicle.

Use extreme caution when towing

the vehicle with a cable or chain. A

driver must be in the vehicle to steer

it and operate the brakes.

Towing in this manner may be done

only on hard-surfaced roads for a

short distance and at low speeds.

Also, the wheels, axles, power train,

steering and brakes must all be in

good condition.

Always follow these emergency tow-

ing precautions:

Place the ignition switch in the ACC

position so the steering wheel is

not locked.

Place the shift lever in N (Neutral).

Release the parking brake.

Depress the brake pedal with more force than normal since you will

have reduced braking perform-

ance.

More steering effort will be required because the power steering system

will be disabled.

Use a vehicle heavier than your own to tow your vehicle.

The drivers of both vehicles should communicate with each other fre-

quently.

Before emergency towing, check that the hook is not broken or dam-

aged.

Fasten the towing cable or chain securely to the hook.

Do not jerk the hook. Apply steady and even force.

OAE066024

OAE066023

■Front

■Rear

Page 507 of 599

6-46

What to do in an emergency

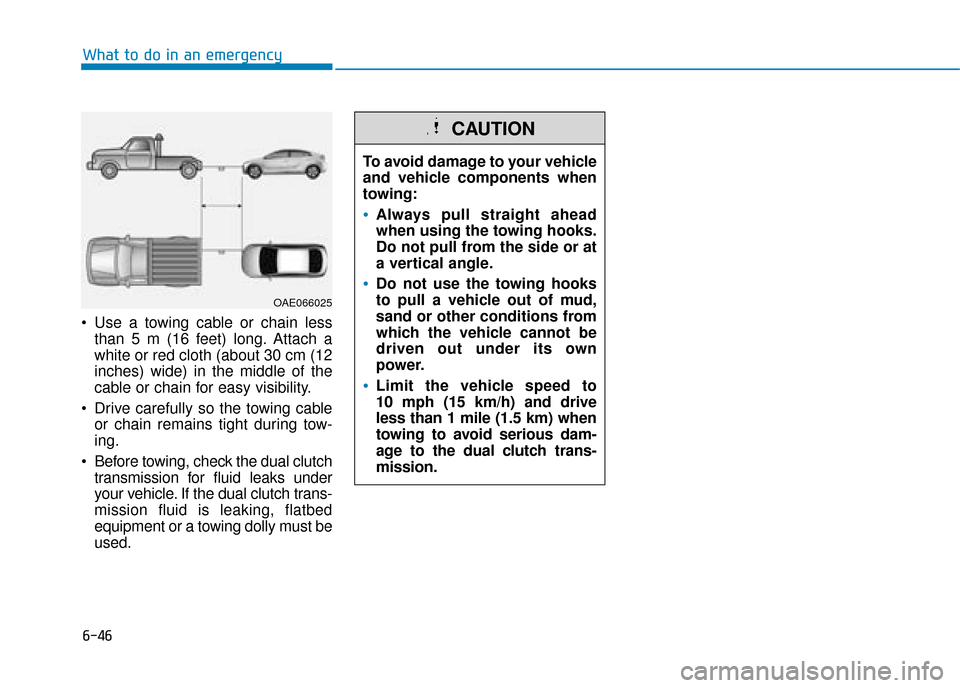

Use a towing cable or chain less than 5 m (16 feet) long. Attach a

white or red cloth (about 30 cm (12

inches) wide) in the middle of the

cable or chain for easy visibility.

Drive carefully so the towing cable or chain remains tight during tow-

ing.

Before towing, check the dual clutch transmission for fluid leaks under

your vehicle. If the dual clutch trans-

mission fluid is leaking, flatbed

equipment or a towing dolly must be

used. To avoid damage to your vehicle

and vehicle components when

towing:

Always pull straight ahead

when using the towing hooks.

Do not pull from the side or at

a vertical angle.

Do not use the towing hooks

to pull a vehicle out of mud,

sand or other conditions from

which the vehicle cannot be

driven out under its own

power.

Limit the vehicle speed to

10 mph (15 km/h) and drive

less than 1 mile (1.5 km) when

towing to avoid serious dam-

age to the dual clutch trans-

mission.

CAUTION

OAE066025

Page 508 of 599

6-47

What to do in an emergency

6

Your vehicle is equipped with emer-

gency commodities to help you

respond to emergency situation.

Fire extinguisher

If there is small fire and you know

how to use the fire extinguisher, fol-

low these steps carefully.

1. Pull out the safety pin at the top ofthe extinguisher that keeps the

handle from being accidentally

pressed.

2. Aim the nozzle towards the base of the fire.

3. Stand approximately 2.5 m (8 ft) away from the fire and squeeze

the handle to discharge the extin-

guisher. If you release the handle,

the discharge will stop.

4. Sweep the nozzle back and forth at the base of the fire. After the fire

appears to be out, watch carefully

since it may re-ignite.

First aid kit

Supplies for use in giving first aid

such as scissors, bandage and

adhesive tape, etc. are provided.

Triangle reflector

Place the triangle reflector on the

road to warn oncoming vehicles dur-

ing emergencies, such as when the

vehicle is parked by the roadside due

to problems.

Tyre pressure gauge

(if equipped)

Tyres normally lose some air in day-

to-day use, and you may have to add

a air periodically and usually it is not

a sign of a leaking tyre, but of normal

wear. Always check tyre pressure

when the tyres are cold because tyre

pressure increases with temperature. To check the tyre pressure, take the

following steps:

1. Unscrew the inflation valve cap

that is located on the rim of the

tyre.

2. Press and hold the gauge against the tyre valve. Some air will leak

as you begin and more will leak if

you don't press the gauge in firm-

ly.

3. A firm non-leaking push will acti- vate the gauge.

4. Read the tyre pressure on the gauge to see whether the tyre

pressure is low or high.

5. Adjust the tyre pressure to the specified pressure. Refer to "Tyres

and Wheels" in chapter 8.

6. Reinstall the inflation valve cap.

E E M

M E

ER

R G

G E

EN

N C

CY

Y

C

C O

O M

M M

MO

OD

DI

IT

T Y

Y

(

( I

IF

F

E

E Q

Q U

UI

IP

P P

PE

ED

D )

)

Page 509 of 599

7

Maintenance

7

Maintenance

Engine compartment .............................................7-3

Maintenance services ...........................................7-5

Owner's responsibility ......................................................7-5

Owner maintenance precautions ..................................7-5

Owner maintenance ...............................................7-6

How to Disconnect the (-) Cable for

Regular Maintenance .......................................................7-6

Owner maintenance schedule ........................................7-7

Scheduled maintenance services.........................7-8

Explanation of scheduled maintenance items ...7-9

Engine oil ..............................................................7-11

Checking the engine oil level .......................................7-11

Checking the engine oil and filter ..............................7-12

Engine coolant/inverter coolant .......................7-13

Checking the coolant level ...........................................7-13

Changing coolant........................................................\

.....7-16

Hybrid starter & generator (HSG) belt.............7-17

Checking the hybrid starter &

generator (HSG) belt ......................................................7-17

Brake fluid ............................................................7-17

Checking the brake fluid level .....................................7-17

Washer fluid .........................................................7-18

Checking the washer fluid level ..................................7-18

Parking brake .......................................................7-19

Checking the parking brake .........................................7-19

Air cleaner ............................................................7-19

Filter replacement ...........................................................7-19

Climate control air filter .....................................7-21

Filter inspection ...............................................................7-21

Wiper blades .........................................................7-23

Blade inspection ..............................................................7-23

Blade replacement ..........................................................7-23

Battery (12 volt, Plug-in hybrid vehicle) .........7-25

For best battery service................................................7-26

Battery capacity label ....................................................7-27

Battery recharging .........................................................7-27

Reset features .................................................................7-28

7

Page 510 of 599

Tyres and wheels .................................................7-29

Tyre care ........................................................................\

...7-29

Recommended cold tyre inflation pressures ...........7-30

Check tyre inflation pressure ......................................7-31

Tyre rotation ....................................................................7-32\

Wheel alignment and tyre balance.............................7-33

Tyre replacement ............................................................7-33

Wheel replacement .........................................................7-34

Tyre traction ...................................................................7-34

Tyre maintenance ...........................................................7-35

Tyre sidewall labeling .....................................................7-35

Low aspect ratio tyres...................................................7-39

Fuses ......................................................................7-\

40

Instrument panel fuse replacement ...........................7-41

Engine compartment panel fuse replacement.........7-42

Fuse/relay panel description .......................................7-44

Light bulbs.............................................................7-54

Headlamp, position lamp, turn signal lamp

bulb replacement .............................................................7-55

Headlamp aiming .............................................................7-59

Daytime running lamp ....................................................7-62

Side repeater lamp replacement .................................7-62

Rear combination lamp bulb replacement ................7-63

Rear fog lamp ..................................................................7-68

High mounted stop lamp ...............................................7-68

License plate light bulb replacement .........................7-68

Interior light bulb replacement ....................................7-68

Appearance care ..................................................7-70

Exterior care ....................................................................7-70\

Interior care......................................................................7-\

75

Emission control system .....................................7-77

Crankcase emission control system ...........................7-78

Evaporative emission control system.........................7-78

Exhaust emission control system ...............................7-78

Procedure for entering forced

engine activation mode .......................................7-81