battery HYUNDAI IX20 2011 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2011, Model line: IX20, Model: HYUNDAI IX20 2011Pages: 420, PDF Size: 20.53 MB

Page 288 of 420

What to do in an emergency

6

6

Jump starting procedure 1. Make sure the booster battery is 12-

volt and that its negative terminal is

grounded.

2. If the booster battery is in another vehicle, do not allow the vehicles comein contact.

3. Turn off all unnecessary electrical loads.

4. Connect the jumper cables in the exact sequence shown in the illustration.First connect one end of a jumper

cable to the positive terminal of the

discharged battery (1), then connect

the other end to the positive terminal

on the booster battery (2).

5. Proceed to connect one end of the other jumper cable to the negative ter-

minal of the booster battery (3), then

the other end to a solid, stationary,

metallic point (for example, the engine

lifting bracket) away from the battery

(4). Do not connect it to or near any

part that moves when the engine is

cranked.

Do not allow the jumper cables to con-

tact anything except the correct bat-

tery terminals or the correct ground.

Do not lean over the battery when

making connections. 6. Start the engine of the vehicle with the

booster battery and let it run at 2,000

rpm, then start the engine of the vehi-

cle with the discharged battery.

If the cause of your battery discharging is

not apparent, you should have your vehi- cle checked by an authorized HYUNDAI dealer.

CAUTION - Battery cables

Do not connect the jumper cable

from the negative terminal of the

booster battery to the negative ter- minal of the discharged battery.This can cause the discharged bat- tery to overheat and crack, releas-

ing battery acid.CAUTION -AGM battery (if equipped)

Absorbent Glass Matt (AGM) bat-

teries are maintenance-free andshould only be serviced by an

authorized HYUNDAI dealer. Forcharging your AGM battery, useonly fully automatic battery

chargers that are specially devel- oped for AGM batteries.

When replacing the AGM battery, use only the HYUNDAI genuinebattery for the ISG system.

If the AGM battery is reconnected or replaced, ISG function will notoperate immediately.

If you want to use the ISG func-tion, the battery sensor needs to

be calibrated for approximately 4hours with the ignition off.

JC ENG 6.QXP 9/7/2010 11:55 AM Page 6

procarmanuals.com

Page 303 of 420

621

What to do in an emergency

Notes on the safe use of the TireMobilityKit

Park your car at the side of theroad so that you can work with the

TireMobilityKit away from moving

traffic. Place your warning triangle

in a prominent place to make pass-

ing vehicles aware of your location.

To be sure your vehicle won't move, even when you're on fairly

level ground, always set your park-

ing brake.

Only use the TireMobilityKit for sealing/inflation passenger car

tires. Do not use on motorcycles,

bicycles or any other type of tires.

Do not remove any foreign objects- such as nails or screws -that have

penetrated the tire.

Before using the TireMobilityKit, read the precautionary advice

printed on the sealant bottle!

Provided the car is outdoors, leave the engine running. Otherwise

operating the compressor may

eventually drain the car battery. Never leave the TireMobilityKit

unattended while it is being used.

Do not leave the compressor run- ning for more than 10 min. at a time

or it may overheat.

Do not use the TireMobilityKit if the ambient temperature is below -30°C(-22°F).

Do not use the sealing compound after its expiration date which can

be found on the label of the bottle.

Keep away from children. Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 15 A

Suitable for use at temperatures:

-30 ~ +70°C (-22 ~ +158°F)

Max. working pressure: 6 bar (87 psi)

Size

Compressor: 170 x 150 x 60 mm (6.7 x 5.9 x 2.4 in.)

Sealant bottle: 85 x 77 ø mm (3.3 x 3.0 ø in.)

Compressor weight: 0.8 kg (1.8 lbs)

Sealant volume: 200 ml (12.2 cu. in.)

❈ Sealing compound and spare

parts can be obtained and

replaced at an authorized vehicle

or tire dealer. Empty sealing com-

pound bottles may be disposed of

at home. Liquid residue from thesealing compound should be dis-

posed of by your vehicle or tiredealer or in accordance with local

waste disposal regulations.

JC ENG 6.QXP 9/7/2010 11:56 AM Page 21

procarmanuals.com

Page 314 of 420

7

Engine compartment / 7-2 Maintenance services / 7-3

Owner maintenance / 7-5Scheduled maintenance service / 7-7Explanation of scheduled maintenance items / 7-30Engine oil / 7-34Engine coolant / 7-35Brake/clutch fluid / 7-38Automatic transaxle fluid / 7-39

Washer fluid / 7-41Parking brake / 7-41

Fuel filter / 7-42

Air cleaner / 7-43

Wiper blades / 7-44Battery / 7-47

Tires and wheels / 7-50Fuses / 7-60Light bulbs / 7-71

Appearance care / 7-79

Emission control system / 7-85

Maintenance

JC ENG 7.QXP 9/7/2010 11:58 AM Page 1

procarmanuals.com

Page 315 of 420

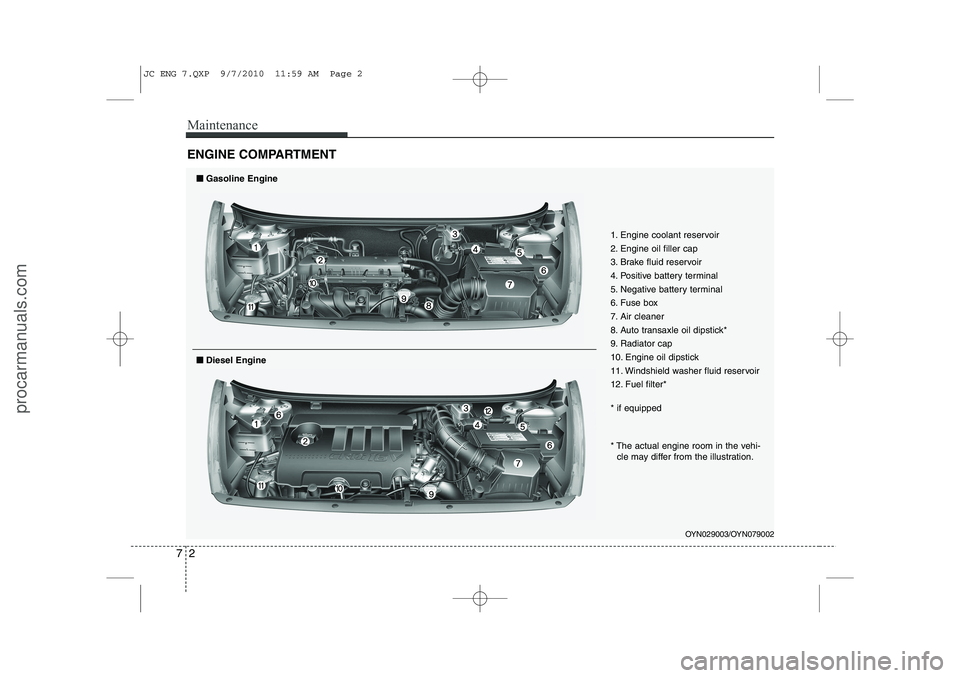

Maintenance

2

7

ENGINE COMPARTMENT

OYN029003/OYN079002

1. Engine coolant reservoir

2. Engine oil filler cap

3. Brake fluid reservoir

4. Positive battery terminal

5. Negative battery terminal

6. Fuse box

7. Air cleaner

8. Auto transaxle oil dipstick*

9. Radiator cap

10. Engine oil dipstick

11. Windshield washer fluid reservoir

12. Fuel filter* * if equipped

■■

Gasoline Engine

* The actual engine room in the vehi-

cle may differ from the illustration.

■■ Diesel Engine

JC ENG 7.QXP 9/7/2010 11:59 AM Page 2

procarmanuals.com

Page 319 of 420

Maintenance

6

7

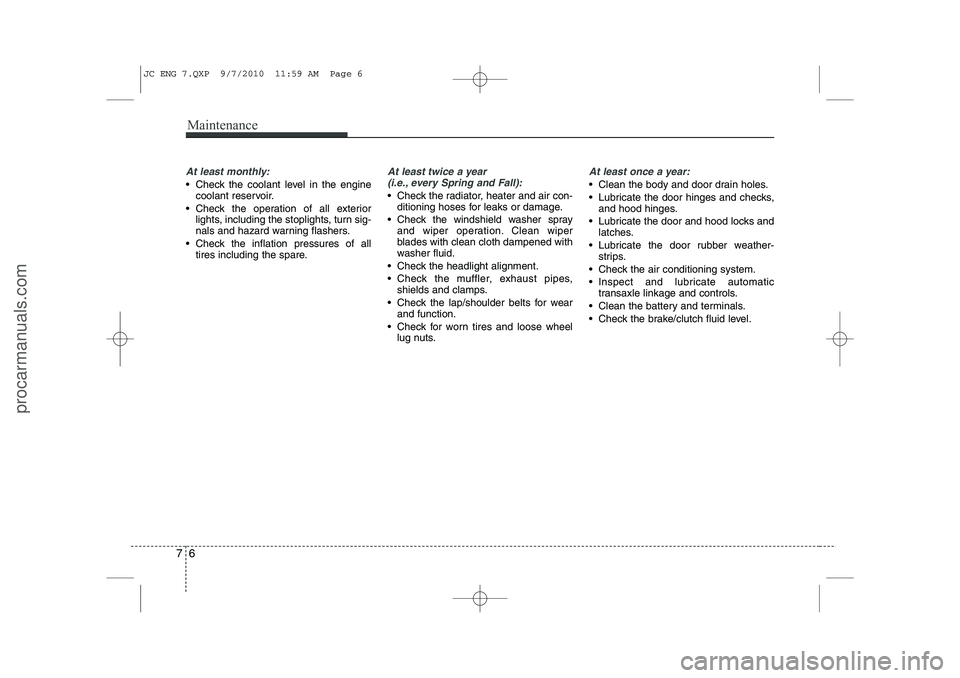

At least monthly:

Check the coolant level in the engine

coolant reservoir.

Check the operation of all exterior lights, including the stoplights, turn sig-

nals and hazard warning flashers.

Check the inflation pressures of all tires including the spare.

At least twice a year

(i.e., every Spring and Fall):

Check the radiator, heater and air con- ditioning hoses for leaks or damage.

Check the windshield washer spray and wiper operation. Clean wiper

blades with clean cloth dampened with

washer fluid.

Check the headlight alignment.

Check the muffler, exhaust pipes, shields and clamps.

Check the lap/shoulder belts for wear and function.

Check for worn tires and loose wheel lug nuts.

At least once a year:

Clean the body and door drain holes.

Lubricate the door hinges and checks,and hood hinges.

Lubricate the door and hood locks and latches.

Lubricate the door rubber weather- strips.

Check the air conditioning system.

Inspect and lubricate automatic transaxle linkage and controls.

Clean the battery and terminals.

Check the brake/clutch fluid level.

JC ENG 7.QXP 9/7/2010 11:59 AM Page 6

procarmanuals.com

Page 322 of 420

79

Maintenance

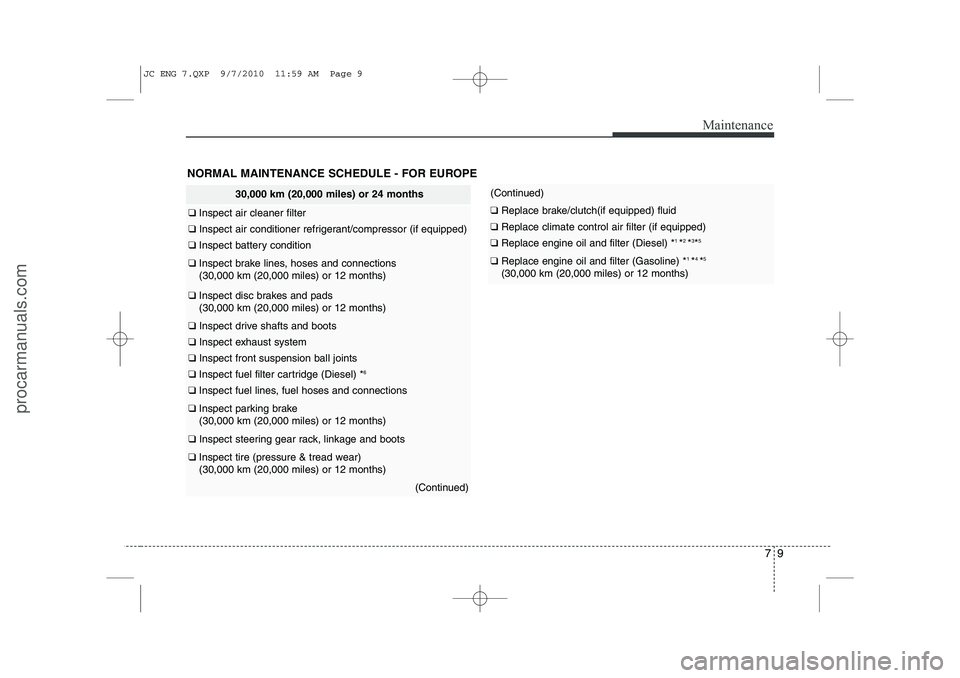

30,000 km (20,000 miles) or 24 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections (30,000 km (20,000 miles) or 12 months)

❑ Inspect disc brakes and pads (30,000 km (20,000 miles) or 12 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter cartridge (Diesel) * 6

❑

Inspect fuel lines, fuel hoses and connections

❑ Inspect parking brake (30,000 km (20,000 miles) or 12 months)

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear) (30,000 km (20,000 miles) or 12 months)

(Continued)

NORMAL MAINTENANCE SCHEDULE - FOR EUROPE

(Continued)

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter (Diesel) * 1

*2

*3

* 5

❑

Replace engine oil and filter (Gasoline) * 1

*4

*5

(30,000 km (20,000 miles) or 12 months)

JC ENG 7.QXP 9/7/2010 11:59 AM Page 9

procarmanuals.com

Page 323 of 420

Maintenance

10

7

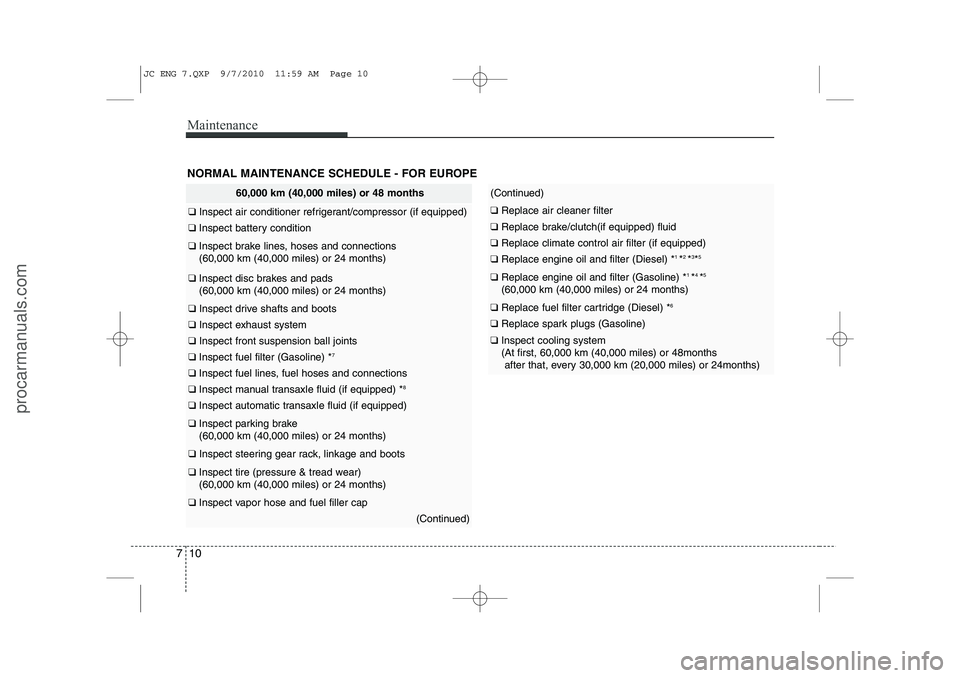

NORMAL MAINTENANCE SCHEDULE - FOR EUROPE

60,000 km (40,000 miles) or 48 months

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections (60,000 km (40,000 miles) or 24 months)

❑ Inspect disc brakes and pads (60,000 km (40,000 miles) or 24 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter (Gasoline) * 7

❑

Inspect fuel lines, fuel hoses and connections

❑ Inspect manual transaxle fluid (if equipped) * 8

❑

Inspect automatic transaxle fluid (if equipped)

❑ Inspect parking brake (60,000 km (40,000 miles) or 24 months)

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear) (60,000 km (40,000 miles) or 24 months)

❑ Inspect vapor hose and fuel filler cap

(Continued)

(Continued)

❑ Replace air cleaner filter

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter (Diesel) * 1

*2

*3

* 5

❑

Replace engine oil and filter (Gasoline) * 1

*4

*5

(60,000 km (40,000 miles) or 24 months)

❑ Replace fuel filter cartridge (Diesel) * 6

❑

Replace spark plugs (Gasoline)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

JC ENG 7.QXP 9/7/2010 11:59 AM Page 10

procarmanuals.com

Page 324 of 420

711

Maintenance

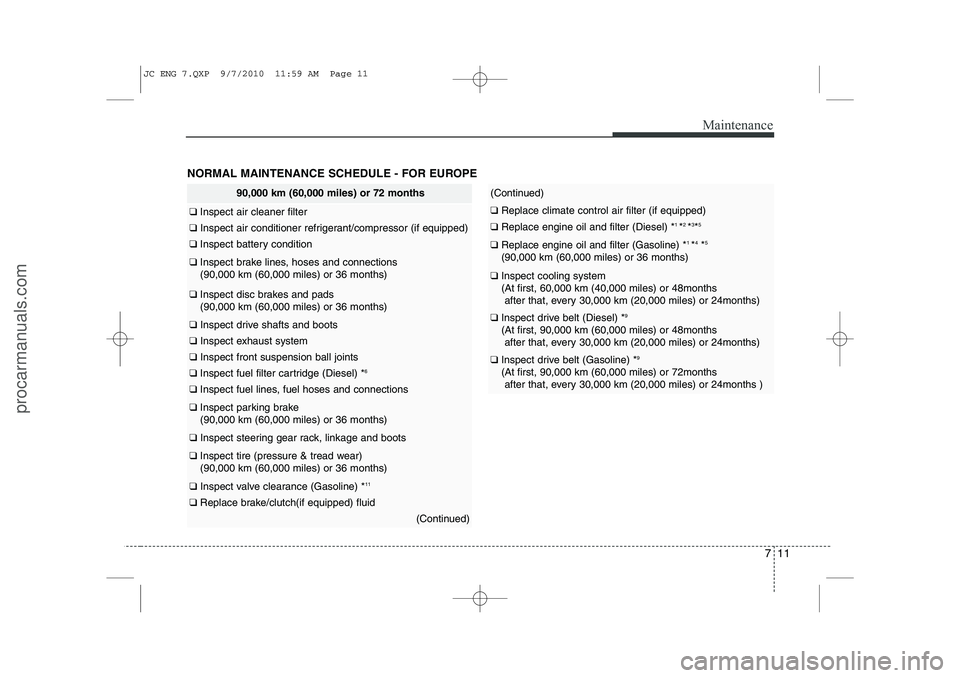

NORMAL MAINTENANCE SCHEDULE - FOR EUROPE

90,000 km (60,000 miles) or 72 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections (90,000 km (60,000 miles) or 36 months)

❑ Inspect disc brakes and pads (90,000 km (60,000 miles) or 36 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter cartridge (Diesel) * 6

❑

Inspect fuel lines, fuel hoses and connections

❑ Inspect parking brake (90,000 km (60,000 miles) or 36 months)

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear) (90,000 km (60,000 miles) or 36 months)

❑ Inspect valve clearance (Gasoline) * 11

❑

Replace brake/clutch(if equipped) fluid

(Continued)

(Continued)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter (Diesel) * 1

*2

*3

* 5

❑

Replace engine oil and filter (Gasoline) * 1

*4

*5

(90,000 km (60,000 miles) or 36 months)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect drive belt (Diesel) * 9

(At first, 90,000 km (60,000 miles) or 48months after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect drive belt (Gasoline) * 9

(At first, 90,000 km (60,000 miles) or 72months after that, every 30,000 km (20,000 miles) or 24months )

JC ENG 7.QXP 9/7/2010 11:59 AM Page 11

procarmanuals.com

Page 325 of 420

Maintenance

12

7

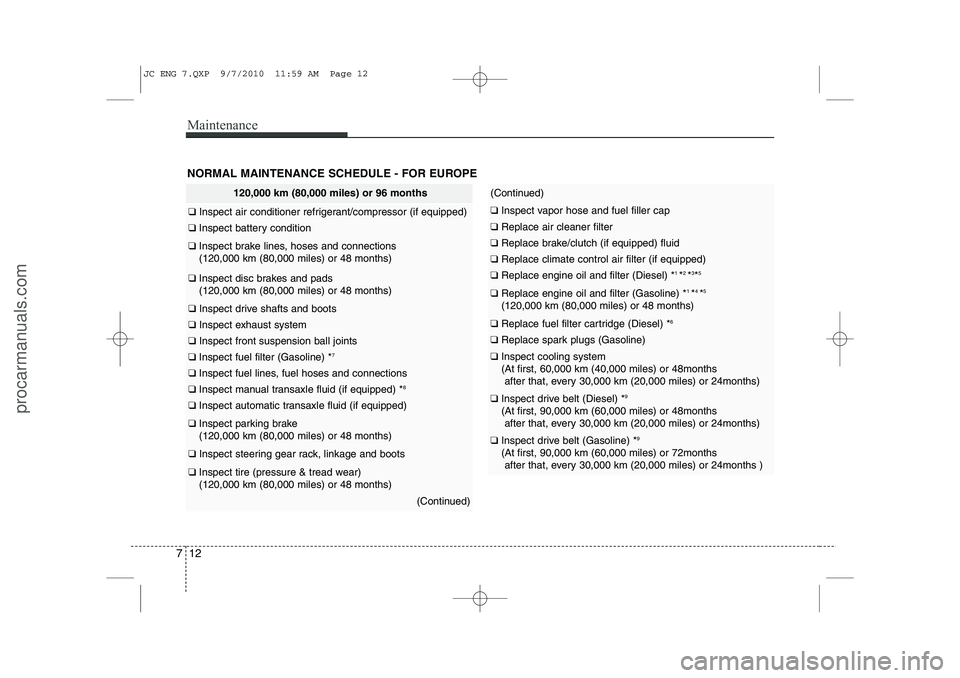

NORMAL MAINTENANCE SCHEDULE - FOR EUROPE

120,000 km (80,000 miles) or 96 months

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections (120,000 km (80,000 miles) or 48 months)

❑ Inspect disc brakes and pads (120,000 km (80,000 miles) or 48 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter (Gasoline) * 7

❑

Inspect fuel lines, fuel hoses and connections

❑ Inspect manual transaxle fluid (if equipped) * 8

❑

Inspect automatic transaxle fluid (if equipped)

❑ Inspect parking brake (120,000 km (80,000 miles) or 48 months)

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear) (120,000 km (80,000 miles) or 48 months)

(Continued)

(Continued)

❑ Inspect vapor hose and fuel filler cap

❑ Replace air cleaner filter

❑ Replace brake/clutch (if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter (Diesel) * 1

*2

*3

* 5

❑

Replace engine oil and filter (Gasoline) * 1

*4

*5

(120,000 km (80,000 miles) or 48 months)

❑ Replace fuel filter cartridge (Diesel) * 6

❑

Replace spark plugs (Gasoline)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect drive belt (Diesel) * 9

(At first, 90,000 km (60,000 miles) or 48months after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect drive belt (Gasoline) * 9

(At first, 90,000 km (60,000 miles) or 72months after that, every 30,000 km (20,000 miles) or 24months )

JC ENG 7.QXP 9/7/2010 11:59 AM Page 12

procarmanuals.com

Page 326 of 420

713

Maintenance

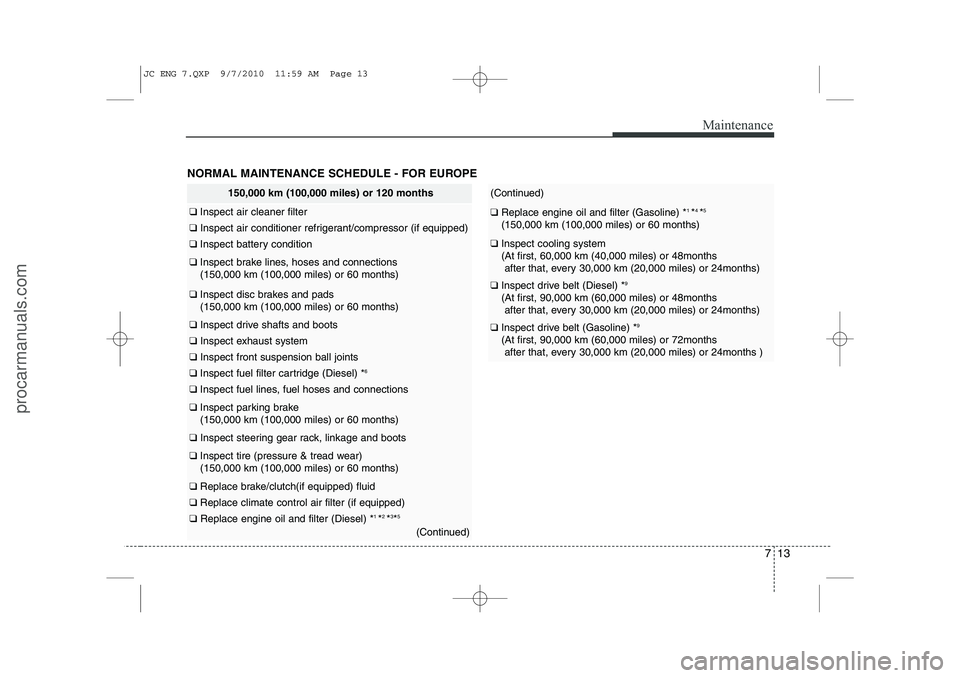

NORMAL MAINTENANCE SCHEDULE - FOR EUROPE

150,000 km (100,000 miles) or 120 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections (150,000 km (100,000 miles) or 60 months)

❑ Inspect disc brakes and pads (150,000 km (100,000 miles) or 60 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter cartridge (Diesel) * 6

❑

Inspect fuel lines, fuel hoses and connections

❑ Inspect parking brake (150,000 km (100,000 miles) or 60 months)

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear) (150,000 km (100,000 miles) or 60 months)

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter (Diesel) * 1

*2

*3

* 5

(Continued)

(Continued)

❑

Replace engine oil and filter (Gasoline) * 1

*4

*5

(150,000 km (100,000 miles) or 60 months)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect drive belt (Diesel) * 9

(At first, 90,000 km (60,000 miles) or 48months after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect drive belt (Gasoline) * 9

(At first, 90,000 km (60,000 miles) or 72months after that, every 30,000 km (20,000 miles) or 24months )

JC ENG 7.QXP 9/7/2010 11:59 AM Page 13

procarmanuals.com