engine Hyundai Kona 2018 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2018, Model line: Kona, Model: Hyundai Kona 2018Pages: 523, PDF Size: 33.6 MB

Page 469 of 523

7-57

7

Maintenance

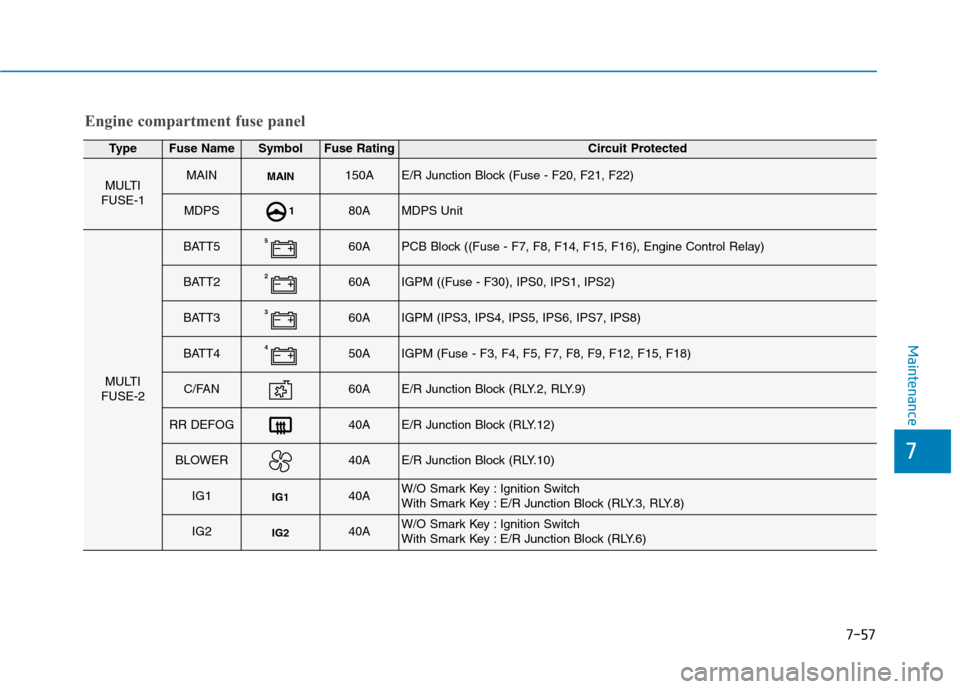

Engine compartment fuse panel

TypeFuse NameSymbolFuse RatingCircuit Protected

MULTI

FUSE-1MAINMAIN150AE/R Junction Block (Fuse - F20, F21, F22)

MDPS180AMDPS Unit

MULTI

FUSE-2

BATT5560APCB Block ((Fuse - F7, F8, F14, F15, F16), Engine Control Relay)

BATT2260AIGPM ((Fuse - F30), IPS0, IPS1, IPS2)

BATT3360AIGPM (IPS3, IPS4, IPS5, IPS6, IPS7, IPS8)

BATT4450AIGPM (Fuse - F3, F4, F5, F7, F8, F9, F12, F15, F18)

C/FAN60AE/R Junction Block (RLY.2, RLY.9)

RR DEFOG40AE/R Junction Block (RLY.12)

BLOWER40AE/R Junction Block (RLY.10)

IG1IG140AW/O Smark Key : Ignition Switch

With Smark Key : E/R Junction Block (RLY.3, RLY.8)

IG2IG240AW/O Smark Key : Ignition Switch

With Smark Key : E/R Junction Block (RLY.6)

Page 470 of 523

7-58

Maintenance

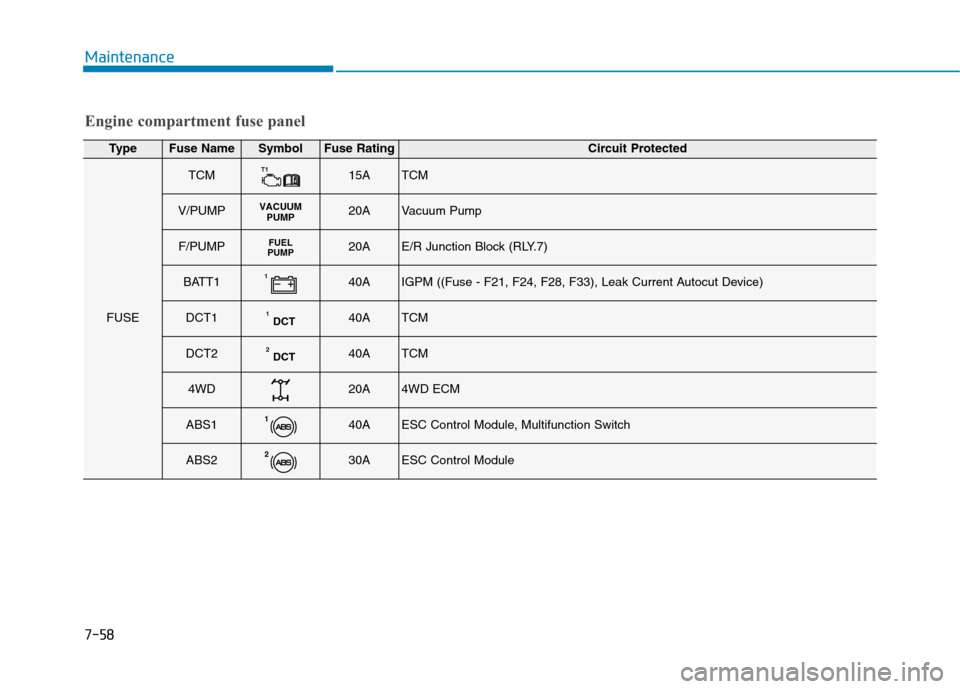

Engine compartment fuse panel

TypeFuse NameSymbolFuse RatingCircuit Protected

FUSE

TCMT115ATCM

V/PUMPVACUUMPUMP20AVacuum Pump

F/PUMPFUEL

PUMP20AE/R Junction Block (RLY.7)

BATT1140AIGPM ((Fuse - F21, F24, F28, F33), Leak Current Autocut Device)

DCT1DCT

140ATCM

DCT2DCT

240ATCM

4WD20A4WD ECM

ABS1140AESC Control Module, Multifunction Switch

ABS2230AESC Control Module

Page 471 of 523

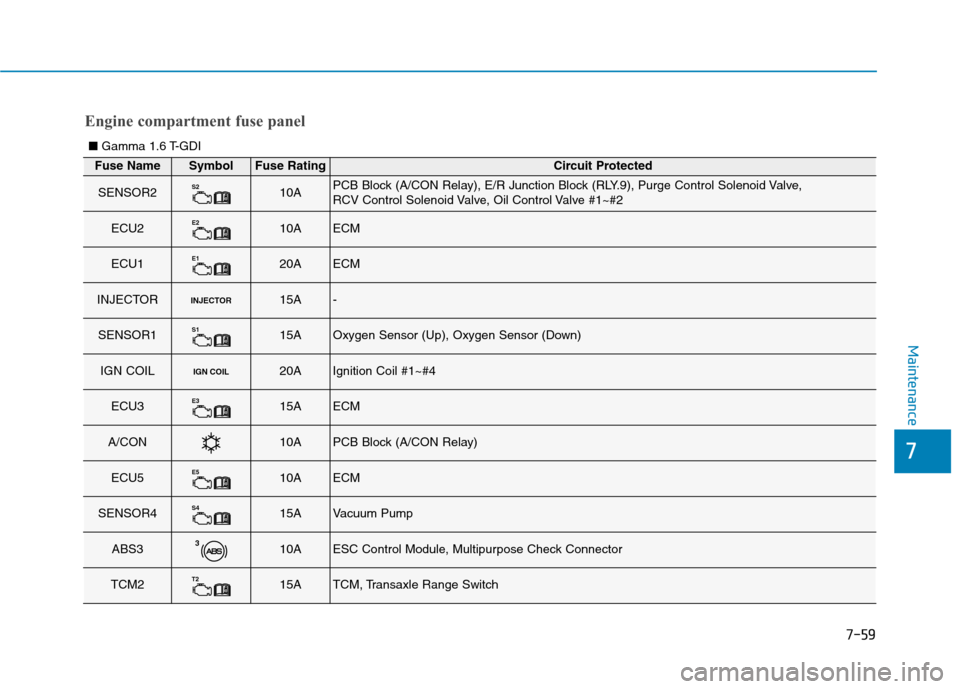

7-59

7

Maintenance

Fuse NameSymbolFuse RatingCircuit Protected

SENSOR2S210APCB Block (A/CON Relay), E/R Junction Block (RLY.9), Purge Control Solenoid Valve,

RCV Control Solenoid Valve, Oil Control Valve #1~#2

ECU2E210AECM

ECU1E120AECM

INJECTORINJECTOR15A-

SENSOR1S115AOxygen Sensor (Up), Oxygen Sensor (Down)

IGN COILIGN COIL20AIgnition Coil #1~#4

ECU3E315AECM

A/CON10APCB Block (A/CON Relay)

ECU5E510AECM

SENSOR4S415AVacuum Pump

ABS3310AESC Control Module, Multipurpose Check Connector

TCM2T215ATCM, Transaxle Range Switch

Engine compartment fuse panel

■ Gamma 1.6 T-GDI

Page 472 of 523

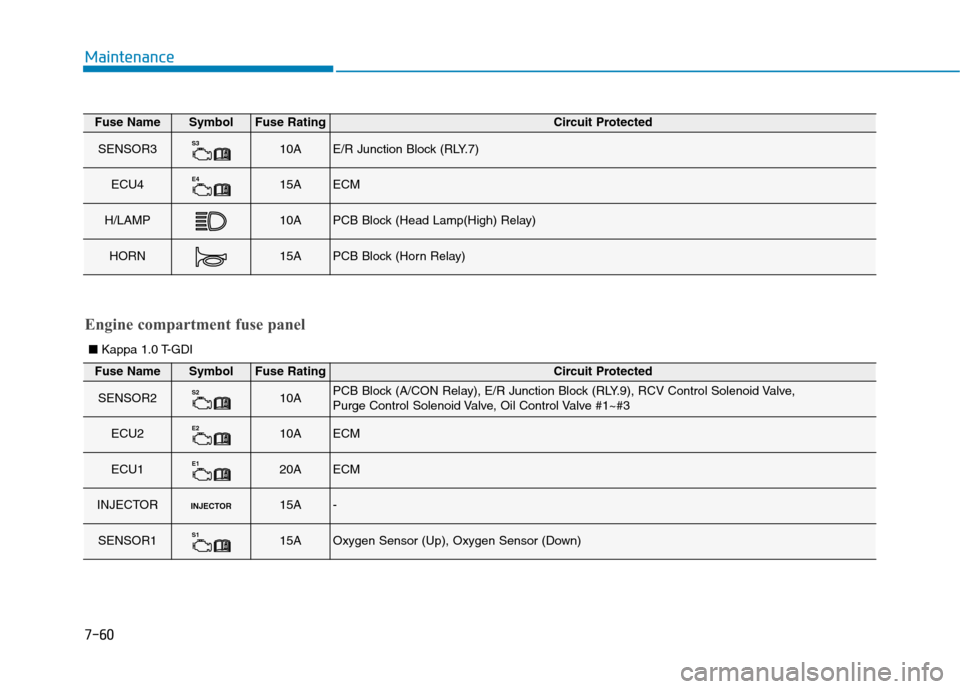

7-60

Maintenance

Fuse NameSymbolFuse RatingCircuit Protected

SENSOR3S310AE/R Junction Block (RLY.7)

ECU4E415AECM

H/LAMP10APCB Block (Head Lamp(High) Relay)

HORN15APCB Block (Horn Relay)

Engine compartment fuse panel

■ Kappa 1.0 T-GDI

Fuse NameSymbolFuse RatingCircuit Protected

SENSOR2S210APCB Block (A/CON Relay), E/R Junction Block (RLY.9), RCV Control Solenoid Valve,

Purge Control Solenoid Valve, Oil Control Valve #1~#3

ECU2E210AECM

ECU1E120AECM

INJECTORINJECTOR15A-

SENSOR1S115AOxygen Sensor (Up), Oxygen Sensor (Down)

Page 474 of 523

7-62

Maintenance

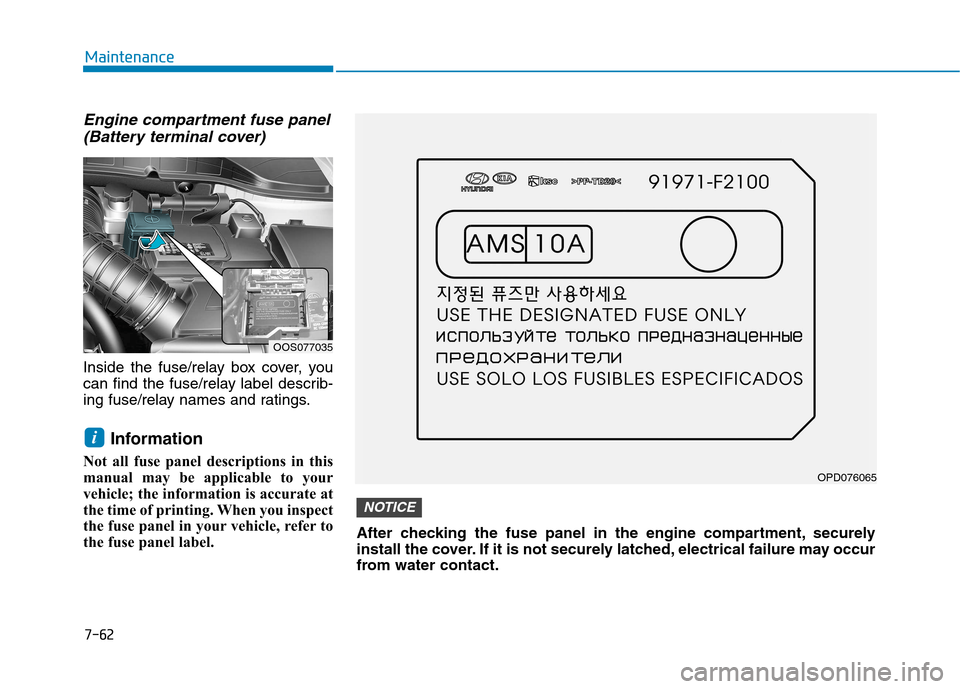

Engine compartment fuse panel(Battery terminal cover)

Inside the fuse/relay box cover, you

can find the fuse/relay label describ-

ing fuse/relay names and ratings.

Information

Not all fuse panel descriptions in this

manual may be applicable to your

vehicle; the information is accurate at

the time of printing. When you inspect

the fuse panel in your vehicle, refer to

the fuse panel label.

i

OOS077035

OPD076065

After checking the fuse panel in the engine compartment, securely

install the cover. If it is not securely latched, electrical failure may occur

from water contact.

NOTICE

Page 487 of 523

7-75

7

Maintenance

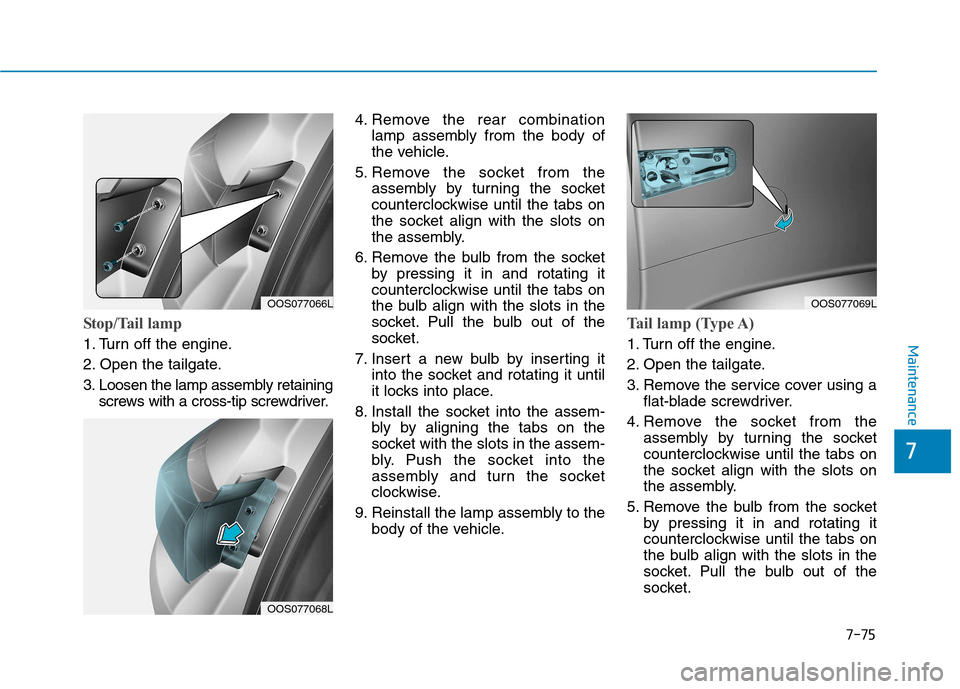

Stop/Tail lamp

1. Turn off the engine.

2. Open the tailgate.

3. Loosen the lamp assembly retainingscrews with a cross-tip screwdriver. 4. Remove the rear combination

lamp assembly from the body of

the vehicle.

5. Remove the socket from the assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly.

6. Remove the bulb from the socket by pressing it in and rotating it

counterclockwise until the tabs on

the bulb align with the slots in the

socket. Pull the bulb out of the

socket.

7. Insert a new bulb by inserting it into the socket and rotating it until

it locks into place.

8. Install the socket into the assem- bly by aligning the tabs on the

socket with the slots in the assem-

bly. Push the socket into the

assembly and turn the socket

clockwise.

9. Reinstall the lamp assembly to the body of the vehicle.

Tail lamp (Type A)

1. Turn off the engine.

2. Open the tailgate.

3. Remove the service cover using aflat-blade screwdriver.

4. Remove the socket from the assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly.

5. Remove the bulb from the socket by pressing it in and rotating it

counterclockwise until the tabs on

the bulb align with the slots in the

socket. Pull the bulb out of the

socket.

OOS077068L

OOS077069LOOS077066L

Page 491 of 523

7-79

7

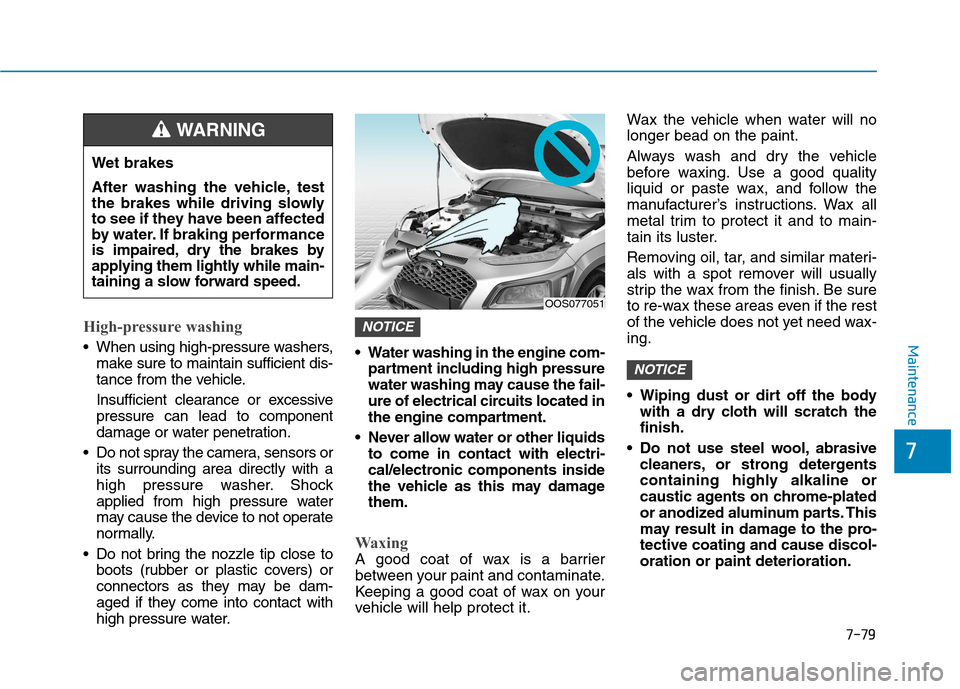

MaintenanceHigh-pressure washing

When using high-pressure washers,make sure to maintain sufficient dis-

tance from the vehicle.

Insufficient clearance or excessive pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with a

high pressure washer. Shock

applied from high pressure water

may cause the device to not operate

normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water. Water washing in the engine com-

partment including high pressure

water washing may cause the fail-

ure of electrical circuits located in

the engine compartment.

Never allow water or other liquids to come in contact with electri-

cal/electronic components inside

the vehicle as this may damagethem.

Waxing

A good coat of wax is a barrier

between your paint and contaminate.

Keeping a good coat of wax on your

vehicle will help protect it. Wax the vehicle when water will nolonger bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure

to re-wax these areas even if the rest

of the vehicle does not yet need wax-ing.

Wiping dust or dirt off the body

with a dry cloth will scratch the finish.

Do not use steel wool, abrasive cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plated

or anodized aluminum parts. This

may result in damage to the pro-tective coating and cause discol-oration or paint deterioration.

NOTICE

NOTICE

Wet brakes

After washing the vehicle, test

the brakes while driving slowly

to see if they have been affected

by water. If braking performance

is impaired, dry the brakes by

applying them lightly while main-

taining a slow forward speed.

WARNING

OOS077051

Page 497 of 523

7-85

7

Maintenance

EEMM IISS SSIIOO NN CC OO NNTTRR OO LL SS YY SSTT EEMM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Service

Passport in your vehicle.

Your vehicle is equipped with an emission control system to meet all

emission regulations. There are three emission control

systems which are as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control systemIn order to ensure the proper function

of the emission control systems, it is

recommended that you have your car

inspected and maintained by an

authorized HYUNDAI dealer in accor-dance with the maintenance schedule

in this manual.

1. Crankcase emission control system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-trol system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

Canister

Fuel vapors generated inside the fueltank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surgetank through the purge control sole-

noid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms-up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

For the Inspection and Maintenance

Test (with Electronic Stability Control(ESC) system)

To prevent the vehicle from

misfiring during dynamome-

ter testing, turn the Electronic

Stability Control (ESC) sys-

tem off by pressing the ESC

switch.

After dynamometer testing is

completed, turn the ESC sys-

tem back on by pressing the

ESC switch again.

CAUTION

Page 498 of 523

7-86

Maintenance

A hot exhaust system can

ignite flammable items under

your vehicle. Do not park, idle,

or drive the vehicle over or

near flammable objects, such

as dry grass, paper, leaves, etc.

The exhaust system and cat-

alytic system are very hotwhile the engine is running or

immediately after the engine

is turned off. Keep away from

the exhaust system and cat-

alytic converter as you may

get burned.

Also, do not remove the heat

sink around the exhaust sys-

tem, do not seal the bottom of

the vehicle and do not coat the

vehicle for corrosion control. It

may present a fire risk under

certain conditions.

WARNING

3. Exhaust emission control system

The Exhaust Emission Control System

is a highly effective system which con-

trols exhaust emissions while main-

taining good vehicle performance.

Engine exhaust gas precautions

(carbon monoxide)

Carbon monoxide can be present with other exhaust fumes. Therefore,

if you smell exhaust fumes of any

kind inside your vehicle, have it

inspected and repaired immediately.

If you ever suspect exhaust fumes

are coming into your vehicle, drive it

only with all the windows fully open.

Have your vehicle checked and

repaired immediately. Do not operate the engine in con-

fined or closed areas (such as

garages) any more than what is

necessary to move the vehicle in orout of the area.

When the vehicle is stopped in an open area for more than a short

time with the engine running,

adjust the ventilation system (as

needed) to draw outside air into the

vehicle.

Never sit in a parked or stopped vehicle for any extended time with

the engine running.

When the engine stalls or fails to start, excessive attempts to restart

the engine may cause damage tothe emission control system.

Operating precautions for cat-

alytic converters (if equipped)

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is dan-

gerous and could be lethal if

inhaled. Follow the instructions

following to avoid CO poisoning.

WARNING

Page 499 of 523

7-87

7

Maintenance

Your vehicle is equipped with a cat-

alytic converter emission control

device.

Therefore, the following precautions

must be observed:

Use only UNLEADED FUEL forgasoline engines.

Do not operate the vehicle when there are signs of engine malfunc-

tion, such as misfire or a noticeable

loss of performance.

Do not misuse or abuse the engine. Examples of misuse arecoasting with the engine off and

descending steep grades in gear

with the engine off.

Do not operate the engine at high idle speed for extended periods (5

minutes or more). Do not modify or tamper with any

part of the engine or emission con-

trol system. All inspections and

adjustments must be made by an

authorized HYUNDAI dealer.

Avoid driving with a very low fuel level. If you run out of gasoline, itcould cause the engine to misfire

and result in excessive loading of

the catalytic converter.

Failure to observe these precautionscould result in damage to the catalytic

converter and to your vehicle.

Additionally, such actions could void

your warranties.