Gas Hyundai Kona 2019 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: Kona, Model: Hyundai Kona 2019Pages: 485, PDF Size: 15.75 MB

Page 250 of 485

5-18

Driving your vehicle

5. Move the shift lever.

6. Remove the tool from the shift- lock override access hole then

install the cap.

If you need to use the shift-lock

release, have your vehicle inspected

by an authorized HYUNDAI dealer

as soon as possible.

Parking

Always come to a complete stop and

continue to depress the brake pedal.

Move the shift lever into the P (Park)

position, apply the parking brake,

and place the ignition switch in the

LOCK/OFF position. Take the Key

with you when exiting the vehicle.

Good Driving Practices

Never move the shift lever from P (Park) or N (Neutral) to any other

position with the accelerator pedal

depressed.

Never move the shift lever into P (Park) when the vehicle is in

motion.

Be sure the vehicle is completely

stopped before you attempt to shift

into R (Reverse) or D (Drive).

Do not move the shift lever to N (Neutral) when driving. If the shift

lever is moved to N (Neutral) while

driving the vehicle loses the ability

to provide engine braking. Doing

so may increase the risk of an acci-

dent.

Also, moving the shift lever back to

D (Drive) while the vehicle is mov-

ing may severely damage the

transmission.

Do not drive with your foot resting on the brake pedal. Even light, but

consistent pedal pressure can

result in the brakes overheating,

brake wear and possibly even

brake failure.

When you stay in the vehicle

with the engine running, be

careful not to depress the

accelerator pedal for a long

period of time. The engine or

exhaust system may overheat

and start a fire.

The exhaust gas and the

exhaust system are very hot.

Keep away from the exhaust

system components.

Do not stop or park over flam-

mable materials, such as dry

grass, paper or leaves. They

may ignite and cause a fire.

WARNING

Page 259 of 485

5-27

Driving your vehicle

5

5. Move the shift lever.

6. Remove the tool from the shift-lock override access hole then

install the cap.

If you need to use the shift-lock

release, have your vehicle inspected

by an authorized HYUNDAI dealer

immediately.

Parking

Always come to a complete stop and

continue to depress the brake pedal.

Move the shift lever into the P (Park)

position, apply the parking brake,

and place the ignition switch in the

LOCK/OFF position. Take the key

with you when exiting the vehicle.

Moving up a steep grade from a standing start

To move up a steep grade from a

standing start, depress the brake

pedal, shift the shift lever to D

(Drive). Depress the accelerator

pedal gradually while releasing the

brake pedal.

Good Driving Practices

Never move the shift lever from P

(Park) or N (Neutral) to any other

position with the accelerator pedal

depressed.

Never move the shift lever into P (Park) when the vehicle is in

motion.

Be sure the vehicle is completely

stopped before you attempt to shift

into R (Reverse) or D (Drive).

Do not move the shift lever to N (Neutral) when driving. Doing so

may result in an accident because

of a loss of engine braking and the

transmission could be damaged.

Do not drive with your foot resting on the brake pedal. Even light, but

consistent pedal pressure can

result in the brakes overheating,

brake wear and possibly even

brake failure.

Depressing both accelerator and brake pedals at the same time can

trigger logic for engine power

reduction to assure vehicle decel-

eration. Vehicle acceleration will

resume after the brake pedal is

released.

When you stay in the vehicle

with the engine running, be

careful not to depress the accel-

erator pedal for a long period of

time. The engine or exhaust

system may overheat and start

a fire.

The exhaust gas and the

exhaust system are very hot.

Keep away from the exhaust

system components.

Do not stop or park over flam-

mable materials, such as dry

grass, paper or leaves. They

may ignite and cause a fire.WARNING

Page 380 of 485

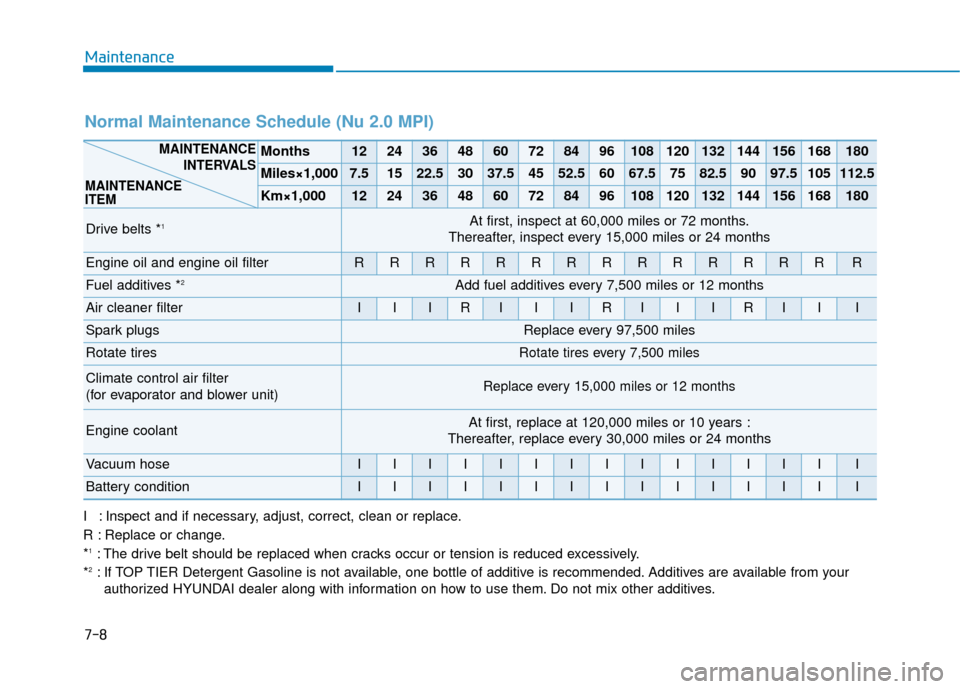

7-8

Maintenance

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

1: The drive belt should be replaced when cracks occur or tension is reduced excessively.

*2: If TOP TIER Detergent Gasoline is not available, one bottle of additive is recommended. Additives are available from your authorized HYUNDAI dealer along with information on how to use them. Do not mix other additives.

Normal Maintenance Schedule (Nu 2.0 MPI)

Months1224364860728496108120132144156168180

Miles×1,0007.51522.53037.54552.56067.57582.59097.5105112.5

Km×1,0001224364860728496108120132144156168180

Drive belts *1At first, inspect at 60,000 miles or 72 months.

Thereafter, inspect every 15,000 miles or 24 months

Engine oil and engine oil filterRRRRRRRRRRRRRRR

Fuel additives *2Add fuel additives every 7,500 miles or 12 months

Air cleaner filterIIIRIIIRIIIRIII

Spark plugsReplace every 97,500 miles

Rotate tiresRotate tires every 7,500 miles

Climate control air filter

(for evaporator and blower unit)Replace every 15,000 miles or 12 months

Engine coolantAt first, replace at 120,000 miles or 10 years :

Thereafter, replace every 30,000 miles or 24 months

Vacuum hoseIIIIIIIIIIIIIII

Battery conditionIIIIIIIIIIIIIII

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Page 385 of 485

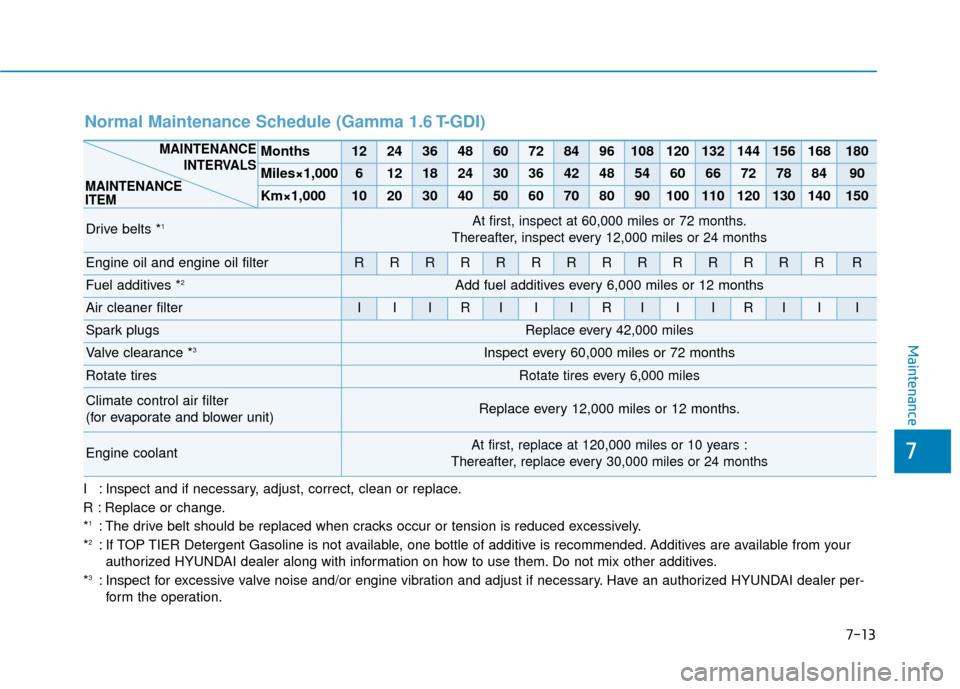

7-13

7

Maintenance

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

1: The drive belt should be replaced when cracks occur or tension is reduced excessively.

*2: If TOP TIER Detergent Gasoline is not available, one bottle of additive is recommended. Additives are available from your authorized HYUNDAI dealer along with information on how to use them. Do not mix other additives.

*

3: Inspect for excessive valve noise and/or engine vibration and adjust if necessary. Have an authorized HYUNDAI dealer per- form the operation.

Normal Maintenance Schedule (Gamma 1.6 T-GDI)

Months1224364860728496108120132144156168180

Miles×1,00061218243036424854606672788490

Km×1,000102030405060708090100110120130140150

Drive belts *1At first, inspect at 60,000 miles or 72 months.

Thereafter, inspect every 12,000 miles or 24 months

Engine oil and engine oil filterRRRRRRRRRRRRRRR

Fuel additives *2Add fuel additives every 6,000 miles or 12 months

Air cleaner filterIIIRIIIRIIIRIII

Spark plugsReplace every 42,000 miles

Valve clearance *3Inspect every 60,000 miles or 72 months

Rotate tiresRotate tires every 6,000 miles

Climate control air filter

(for evaporate and blower unit)Replace every 12,000 miles or 12 months.

Engine coolantAt first, replace at 120,000 miles or 10 years :

Thereafter, replace every 30,000 miles or 24 months

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Page 392 of 485

7-20

Maintenance

Brake Hoses and Lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake Fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between the MIN and the MAX

marks on the side of the reservoir.

Use only hydraulic brake fluid con-

forming to DOT 3 or DOT 4 specifi-

cation.

Parking Brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake Discs, Pads, Calipers

and Rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the engine

and listen carefully for any exhaust

gas leakage. Tighten connections or

replace parts as necessary.

Suspension Mounting Bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering Gear Box, Linkage &

Boots/Lower Arm Ball Joint

With the vehicle stopped and the

engine off, check for excessive free-

play in the steering wheel. Check the

linkage for bends or damage. Check

the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 404 of 485

7-32

Maintenance

W

WI

IP

P E

ER

R

B

B L

LA

A D

DE

ES

S

Blade Inspection

Contamination of either the windshield

or the wiper blades with foreign matter

can reduce the effectiveness of the

windshield wiper functionality.

Common sources of contamination

are insects, tree sap, and hot wax

treatments used by some commercial

car washes. If the blades are not wip-

ing properly, clean both the window

and the blades with a clean cloth

dampened with washer fluid.

To prevent damage to the wiper

blades, arms or other compo-

nents, do not:

Use gasoline, kerosene, paint

thinner, or other solvents on or

near them.

Attempt to move the wipers manually.

Use non-specified wiper blades.

Information

Commercial hot waxes applied by auto-

matic car washes have been known to

make the windshield difficult to clean.

Blade Replacement

When the wipers no longer clean

adequately, the blades may be worn

or cracked, and require replacement.

To prevent damage to the wiper

arms or other components, do not

attempt to move the wipers manu-

ally.

The use of a non-specified wiper

blade could result in wiper mal-

function and failure.

In order to prevent damage to the hood and the wiper arms, the

wiper arms should only be lifted

when in the top wiping position.

Always return the wiper arms to the windshield before driving.

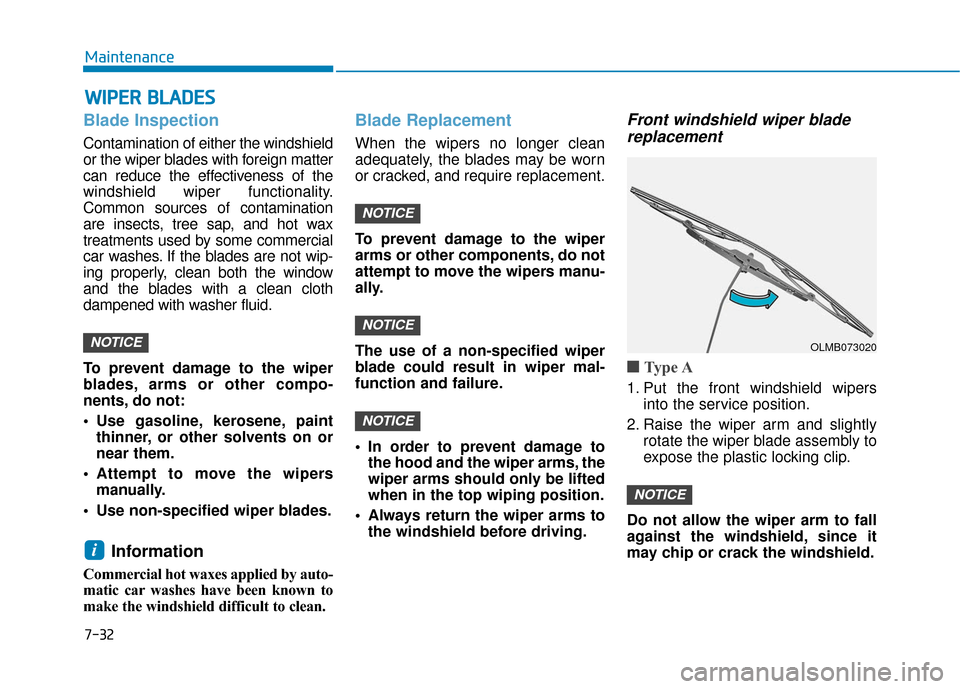

Front windshield wiper bladereplacement

■ ■

Type A

1. Put the front windshield wipers

into the service position.

2. Raise the wiper arm and slightly rotate the wiper blade assembly to

expose the plastic locking clip.

Do not allow the wiper arm to fall

against the windshield, since it

may chip or crack the windshield.

NOTICE

NOTICE

NOTICE

NOTICE

i

NOTICEOLMB073020

Page 421 of 485

7-49

7

Maintenance

Maximum Load Rating

The load rating for a tire at the maxi-

mum permissible inflation pressure

for that tire.

Maximum Loaded VehicleWeight

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight

The number of occupants a vehicle

is designed to seat multiplied by 150

pounds (68 kg).

Occupant Distribution

Designated seating positions.

Outward Facing Sidewall

An asymmetrical tire has a particular

side that faces outward when mount-

ed on a vehicle. The outward facing

sidewall bears white lettering or

bears manufacturer, brand, and/or

model name molding that is higher or

deeper than the same moldings on

the inner facing sidewall.

Passenger (P-Metric) tire

A tire used on passenger cars and

some light duty trucks and multipur-

pose vehicles.

Ply

A layer of rubber-coated parallel

cords.

Pneumatic tire

A mechanical device made of rubber,

chemicals, fabric and steel or other

materials, that, when mounted on an

automotive wheel provides the trac-

tion and contains the gas or fluid that

sustains the load.

Pneumatic options weight

The combined weight of installed

regular production options weighing

over 5 lb. (2.3 kg) in excess of the

standard items which they replace,

not previously considered in curb

weight or accessory weight, includ-

ing heavy duty breaks, ride levelers,

roof rack, heavy duty battery, and

special trim.

Recommended InflationPressure

Vehicle manufacturer's recommend-

ed tire inflation pressure as shown

on the tire placard.

Radial Ply Tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at 90 degrees to the centerline of

the tread.

Rim

A metal support for a tire and upon

which the tire beads are seated.

Sidewall

The portion of a tire between the

tread and the bead.

Speed Rating

An alphanumeric code assigned to a

tire indicating the maximum speed at

which a tire can operate.

Page 442 of 485

7-70

Maintenance Always handle them carefully, andavoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids.

Never touch the glass with bare hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only when installed in a headlamp.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.

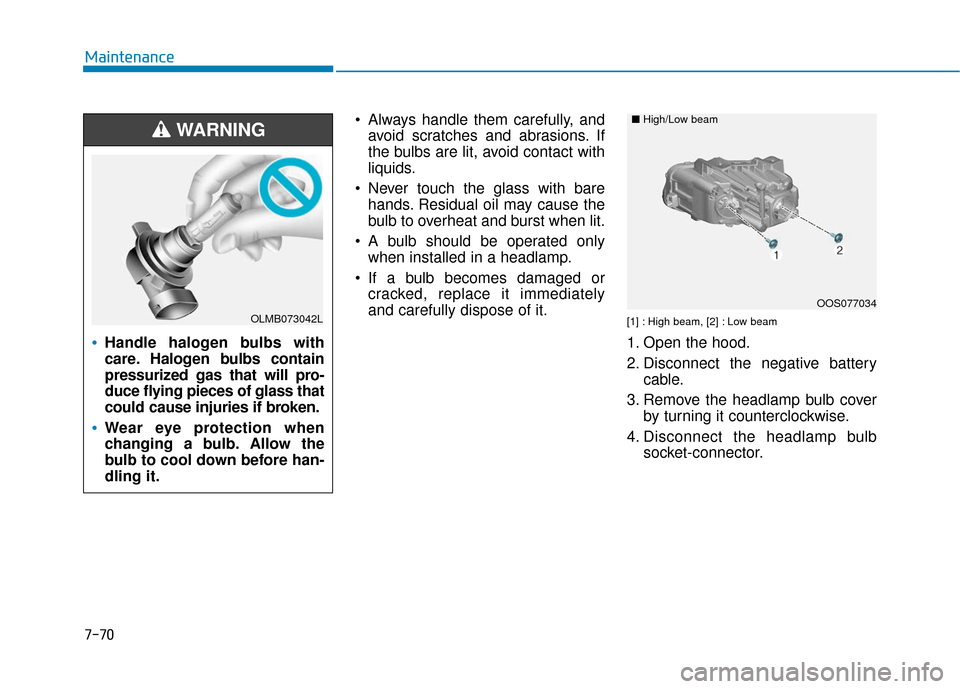

[1] : High beam, [2] : Low beam

1. Open the hood.

2. Disconnect the negative battery cable.

3. Remove the headlamp bulb cover by turning it counterclockwise.

4. Disconnect the headlamp bulb socket-connector.Handle halogen bulbs with

care. Halogen bulbs contain

pressurized gas that will pro-

duce flying pieces of glass that

could cause injuries if broken.

Wear eye protection when

changing a bulb. Allow the

bulb to cool down before han-

dling it.

WARNING

OLMB073042LOOS077034

■

High/Low beam

Page 444 of 485

7-72

Maintenance

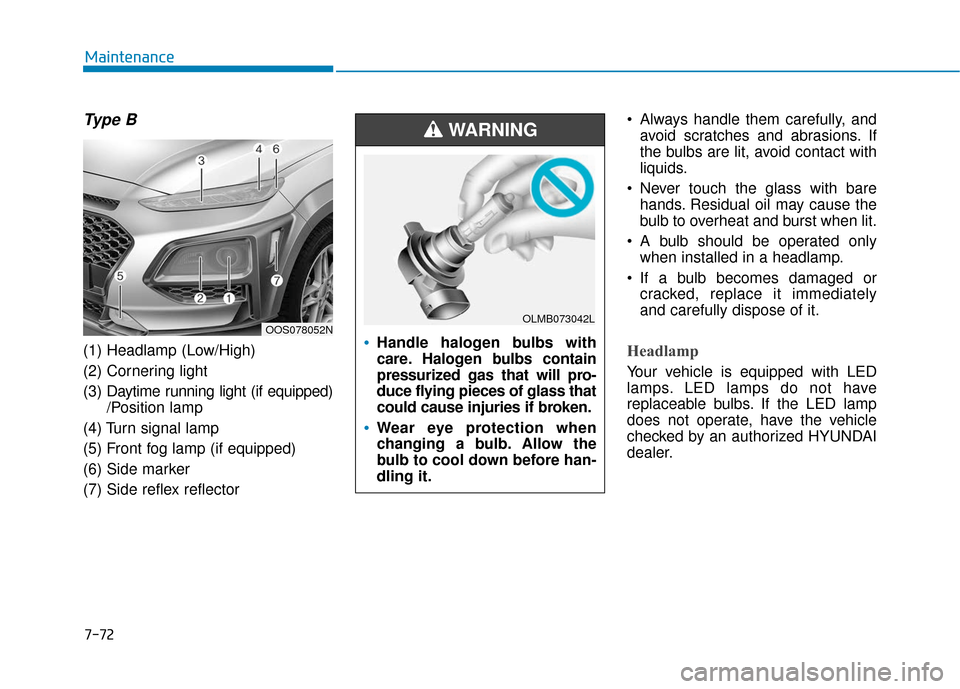

Type B

(1) Headlamp (Low/High)

(2) Cornering light

(3) Daytime running light (if equipped)

/Position lamp

(4) Turn signal lamp

(5) Front fog lamp (if equipped)

(6) Side marker

(7) Side reflex reflector Always handle them carefully, and

avoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids.

Never touch the glass with bare hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only when installed in a headlamp.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.Headlamp

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized HYUNDAI

dealer.

OOS078052NHandle halogen bulbs with

care. Halogen bulbs contain

pressurized gas that will pro-

duce flying pieces of glass that

could cause injuries if broken.

Wear eye protection when

changing a bulb. Allow the

bulb to cool down before han-

dling it.

WARNING

OLMB073042L

Page 459 of 485

7-87

7

Maintenance

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Owner’s

Handbook & Warranty Information

booklet in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations.

There are three emission control

systems, as follows.

(1) Crankcase emission control sys-tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order to ensure the proper func-

tion of the emission control systems,

it is recommended that you have

your vehicle inspected and main-

tained by an authorized HYUNDAI

dealer in accordance with the main-

tenance schedule in this manual. For the Inspection and

Maintenance Test (with Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch (ESC

OFF light illuminated).

After dynamometer testing is completed, turn the ESC system

back on by pressing the ESC

switch again.1. Crankcase Emission Control System

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative Emission ControlSystem Including Onboard

Refueling Vapor Recovery

(ORVR)

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere. The ORVR system is

designed to allow the vapors from

the fuel tank to be loaded into a can-

ister while refueling at the gas sta-

tion, preventing the escape of fuel

vapors into the atmosphere.

NOTICE

E EM

M I

IS

S S

SI

IO

O N

N

C

C O

O N

NT

TR

R O

O L

L

S

S Y

Y S

ST

T E

EM

M