Oil Hyundai Kona 2019 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: Kona, Model: Hyundai Kona 2019Pages: 485, PDF Size: 15.75 MB

Page 420 of 485

7-48

Maintenance

Bead

The tire bead contains steel wires

wrapped by steel cords that hold the

tire onto the rim.

Bias Ply Tire

A pneumatic tire in which the plies

are laid at alternate angles less than

90 degrees to the centerline of the

tread.

Cold Tire Pressure

The amount of air pressure in a tire,

measured in pounds per square inch

(psi) or kilopascals (kPa) before a tire

has built up heat from driving.

Curb Weight

This means the weight of a motor

vehicle with standard and optional

equipment including the maximum

capacity of fuel, oil and coolant, but

without passengers and cargo.

DOT Markings

A code molded into the sidewall of a

tire signifying that the tire is in com-

pliance with the U.S. Department of

Transportation motor vehicle safety

standards. The DOT code includes

the Tire Identification Number (TIN),

an alphanumeric designator which

can also identify the tire manufactur-

er, production plant, brand and date

of production.

GVWR

Gross Vehicle Weight Rating

GAWR FRT

Gross Axle Weight Rating for the

Front Axle.

GAWR RR

Gross Axle Weight Rating for the

Rear axle.

Intended Outboard Sidewall

The side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa)

The metric unit for air pressure.

Light truck(LT) tire

A tire designated by its manufacturer

as primarily intended for use on light-

weight trucks or multipurpose pas-

senger vehicles.

Load ratings

The maximum load that a tire is rated

to carry for a given inflation pressure.

Load Index

An assigned number ranging from 1

to 279 that corresponds to the load

carrying capacity of a tire.

Maximum Inflation Pressure

The maximum air pressure to which

a cold tire may be inflated. The max-

imum air pressure is molded onto the

sidewall.

Page 425 of 485

7-53

7

Maintenance

F

FU

U S

SE

E S

S

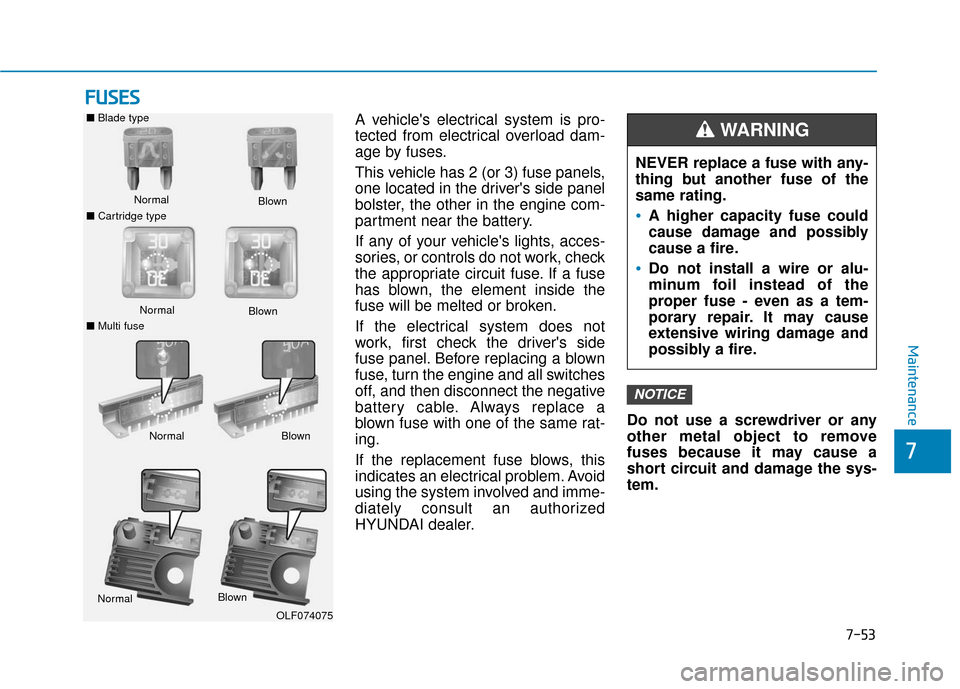

A vehicle's electrical system is pro-

tected from electrical overload dam-

age by fuses.

This vehicle has 2 (or 3) fuse panels,

one located in the driver's side panel

bolster, the other in the engine com-

partment near the battery.

If any of your vehicle's lights, acces-

sories, or controls do not work, check

the appropriate circuit fuse. If a fuse

has blown, the element inside the

fuse will be melted or broken.

If the electrical system does not

work, first check the driver's side

fuse panel. Before replacing a blown

fuse, turn the engine and all switches

off, and then disconnect the negative

battery cable. Always replace a

blown fuse with one of the same rat-

ing.

If the replacement fuse blows, this

indicates an electrical problem. Avoid

using the system involved and imme-

diately consult an authorized

HYUNDAI dealer. Do not use a screwdriver or any

other metal object to remove

fuses because it may cause a

short circuit and damage the sys-

tem.

NOTICE

NEVER replace a fuse with any-

thing but another fuse of the

same rating.

A higher capacity fuse could

cause damage and possibly

cause a fire.

Do not install a wire or alu-

minum foil instead of the

proper fuse - even as a tem-

porary repair. It may cause

extensive wiring damage and

possibly a fire.

WARNING ■

Blade type

Normal

■ Cartridge type Blown

Normal

Blown

■ Multi fuse

Normal Blown

NormalBlown

OLF074075

Page 437 of 485

7-65

7

Maintenance

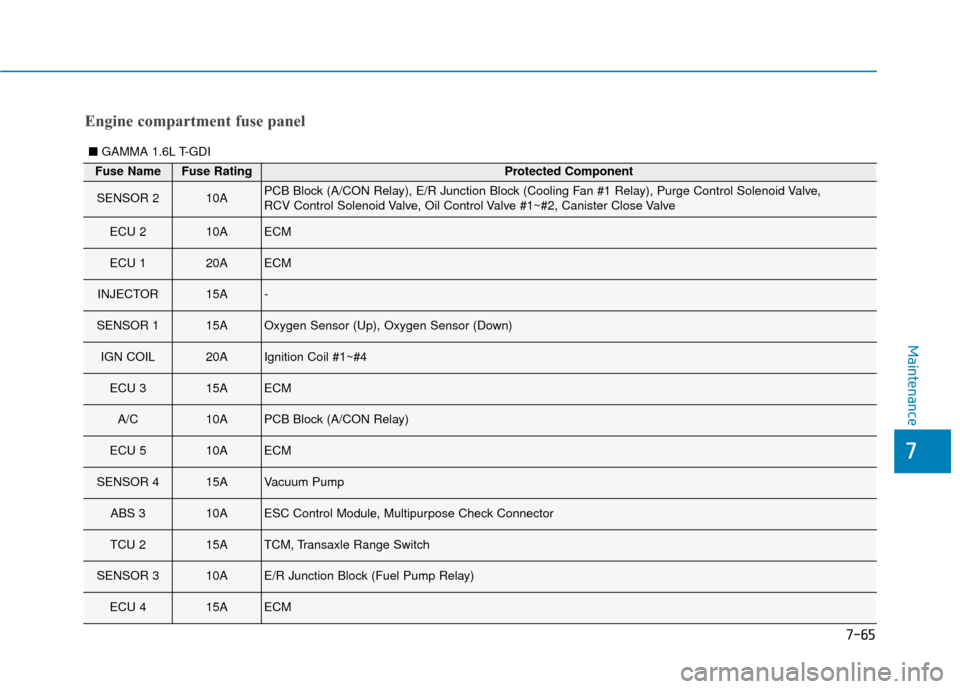

Fuse NameFuse RatingProtected Component

SENSOR 210APCB Block (A/CON Relay), E/R Junction Block (Cooling Fan #1 Relay), Purge Control Solenoid Valve,

RCV Control Solenoid Valve, Oil Control Valve #1~#2, Canister Close Valve

ECU 210AECM

ECU 120AECM

INJECTOR15A-

SENSOR 115AOxygen Sensor (Up), Oxygen Sensor (Down)

IGN COIL20AIgnition Coil #1~#4

ECU 315AECM

A/C10APCB Block (A/CON Relay)

ECU 510AECM

SENSOR 415AVacuum Pump

ABS 310AESC Control Module, Multipurpose Check Connector

TCU 215ATCM, Transaxle Range Switch

SENSOR 310AE/R Junction Block (Fuel Pump Relay)

ECU 415AECM

■ GAMMA 1.6L T-GDI

Engine compartment fuse panel

Page 438 of 485

7-66

Maintenance

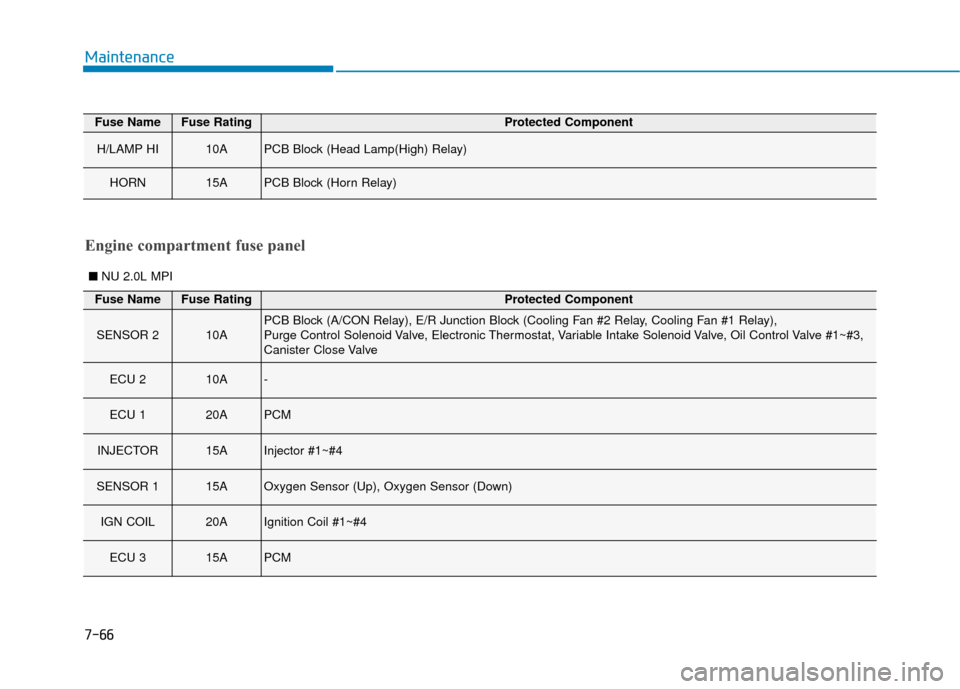

■NU 2.0L MPI

Engine compartment fuse panel

Fuse NameFuse RatingProtected Component

H/LAMP HI10APCB Block (Head Lamp(High) Relay)

HORN15APCB Block (Horn Relay)

Fuse NameFuse RatingProtected Component

SENSOR 210APCB Block (A/CON Relay), E/R Junction Block (Cooling Fan #2 Relay, Cooling Fan #1 Relay),

Purge Control Solenoid Valve, Electronic Thermostat, Variable Intake Solenoid Valve, Oil Control Valve #1~#3,

Canister Close Valve

ECU 210A-

ECU 120APCM

INJECTOR15AInjector #1~#4

SENSOR 115AOxygen Sensor (Up), Oxygen Sensor (Down)

IGN COIL20AIgnition Coil #1~#4

ECU 315APCM

Page 442 of 485

7-70

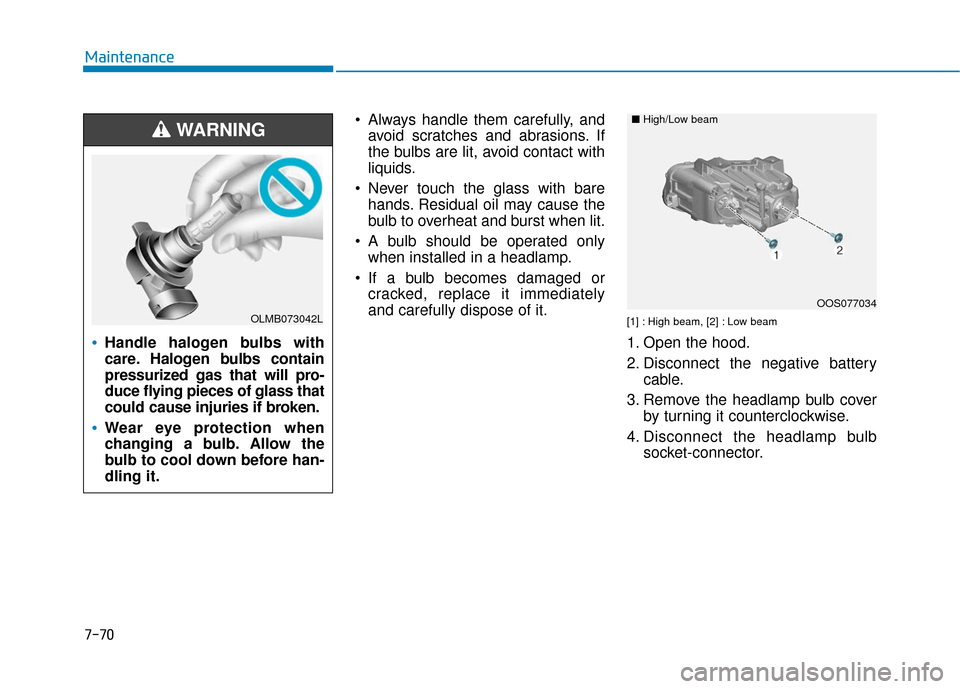

Maintenance Always handle them carefully, andavoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids.

Never touch the glass with bare hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only when installed in a headlamp.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.

[1] : High beam, [2] : Low beam

1. Open the hood.

2. Disconnect the negative battery cable.

3. Remove the headlamp bulb cover by turning it counterclockwise.

4. Disconnect the headlamp bulb socket-connector.Handle halogen bulbs with

care. Halogen bulbs contain

pressurized gas that will pro-

duce flying pieces of glass that

could cause injuries if broken.

Wear eye protection when

changing a bulb. Allow the

bulb to cool down before han-

dling it.

WARNING

OLMB073042LOOS077034

■

High/Low beam

Page 444 of 485

7-72

Maintenance

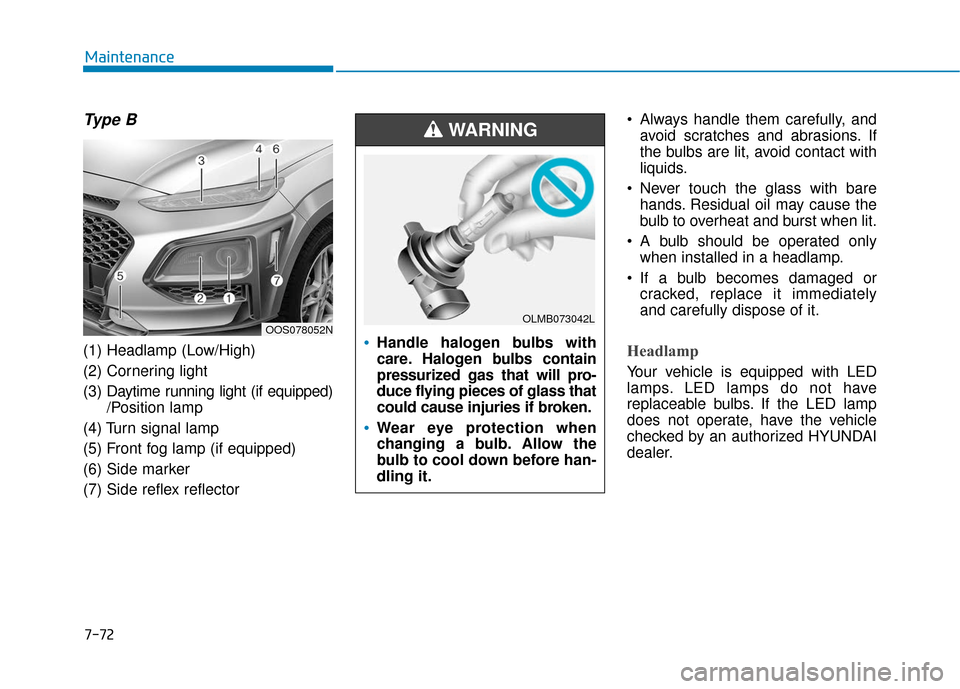

Type B

(1) Headlamp (Low/High)

(2) Cornering light

(3) Daytime running light (if equipped)

/Position lamp

(4) Turn signal lamp

(5) Front fog lamp (if equipped)

(6) Side marker

(7) Side reflex reflector Always handle them carefully, and

avoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids.

Never touch the glass with bare hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only when installed in a headlamp.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.Headlamp

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized HYUNDAI

dealer.

OOS078052NHandle halogen bulbs with

care. Halogen bulbs contain

pressurized gas that will pro-

duce flying pieces of glass that

could cause injuries if broken.

Wear eye protection when

changing a bulb. Allow the

bulb to cool down before han-

dling it.

WARNING

OLMB073042L

Page 449 of 485

7-77

7

Maintenance

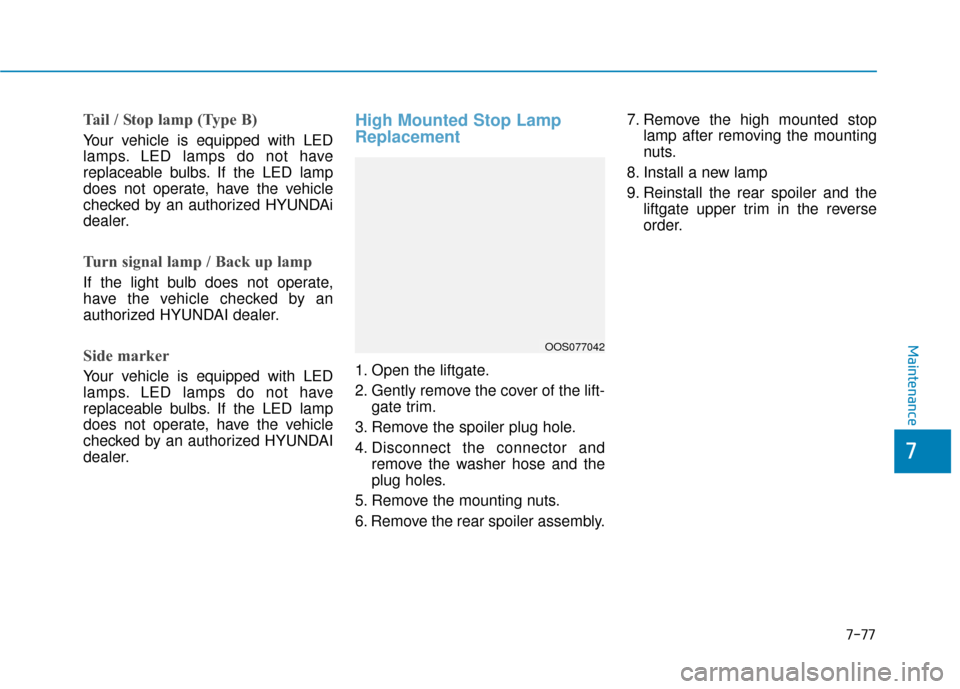

Tail / Stop lamp (Type B)

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized HYUNDAi

dealer.

Turn signal lamp / Back up lamp

If the light bulb does not operate,

have the vehicle checked by an

authorized HYUNDAI dealer.

Side marker

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized HYUNDAI

dealer.

High Mounted Stop Lamp

Replacement

1. Open the liftgate.

2. Gently remove the cover of the lift-gate trim.

3. Remove the spoiler plug hole.

4. Disconnect the connector and remove the washer hose and the

plug holes.

5. Remove the mounting nuts.

6. Remove the rear spoiler assembly. 7. Remove the high mounted stop

lamp after removing the mounting

nuts.

8. Install a new lamp

9. Reinstall the rear spoiler and the liftgate upper trim in the reverse

order.

OOS077042

Page 453 of 485

7-81

7

Maintenance Water washing in the enginecompartment including high

pressure water washing may

cause the failure of electrical cir-

cuits located in the engine com-

partment.

Never allow water or other liq- uids to come in contact with

electrical/electronic compo-

nents inside the vehicle as this

may damage them.

Waxing

A good coat of wax provides a barri-

er between your paint and environ-

mental contamination.

Keeping a good coat of wax on your

vehicle will help protect it.

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure

to re-wax these areas even if the rest

of the vehicle does not yet need wax-

ing. Wiping dust or dirt off the body

with a dry cloth will scratch the

finish.

Do not use steel wool, abrasive cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plat-

ed or anodized aluminum parts.

This may result in damage to the

protective coating and cause

discoloration or paint deteriora-

tion.

Repairing your vehicle's finish

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or

replacement, be sure the body

shop applies anti-corrosion mate-

rials to the parts repaired or

replaced.

NOTICE

NOTICE

NOTICE

OOS077051

Page 456 of 485

7-84

Maintenance

vehicle, pay particular attention to

the components under the fenders

and other areas that are hidden

from view. Do a thorough job; just

dampening the accumulated mud

rather than washing it away will

accelerate corrosion rather than

prevent it. Water under high pres-

sure and steam are particularly

effective in removing accumulated

mud and corrosive materials.

When cleaning lower door panels, rocker panels and frame members,

be sure that drain holes are kept

open so that moisture can escape

and not be trapped inside to accel-

erate corrosion.

Keep your garage dry

Don't park your vehicle in a damp,

poorly ventilated garage. This cre-

ates a favorable environment for cor-

rosion. This is particularly true if you

wash your vehicle in the garage or

drive it into the garage when it is still

wet or covered with snow, ice or

mud. Even a heated garage can con-

tribute to corrosion unless it is well

ventilated so moisture is dispersed.

Keep paint and trim in good condition

Scratches or chips in the finish

should be covered with "touch-up"

paint as soon as possible to reduce

the possibility of corrosion. If bare

metal is showing through, the atten-

tion of a qualified body and paint

shop is recommended.

Bird droppings are highly corrosive

and may damage painted surfaces in

just a few hours. Always remove bird

droppings as soon as possible.

Interior Care

Interior general precautions

Prevent caustic solutions such as

perfume and cosmetic oil, from con-

tacting the interior parts because

they may cause damage or discol-

oration. If they do contact the interior

parts, wipe them off immediately.

See the instructions for the proper

way to clean vinyl.

Never allow water or other liq-uids to come in contact with

electrical/electronic compo-

nents inside the vehicle as this

may damage them.

When cleaning leather products (steering wheel, seats etc.), use

neutral detergents or low alco-

hol content solutions. If you use

high alcohol content solutions

or acid/ alkaline detergents, the

color of the leather may fade or

the surface may get stripped off.

NOTICE

Page 458 of 485

7-86

Maintenance

Caring for the leather seats - Vacuum the seat periodically toremove dust and sand on the seat.

It will prevent abrasion or damage

of the leather and maintain its qual-

ity.

- Wipe the natural leather seat cover often with dry or soft cloth.

- Use of proper leather protector may prevent abrasion of the cover

and helps maintain the color. Be

sure to read the instructions and

consult a specialist when using

leather coating or protective agent.

- Light colored (beige, cream beige) leather is easily contaminated and

the stain is noticeable. Clean the

seats frequently.

- Avoid wiping with wet cloth. It may cause the surface to crack. Cleaning the leather seats

- Remove all contaminations instant-ly. Refer to instructions below for

removal of each contaminant.

- Cosmetic products (sunscreen, foundation, etc.)

Apply cleansing cream on a cloth

and wipe the contaminated spot.

Wipe off the cream with a wet cloth

and remove water with a dry cloth.

- Beverages (coffee, soft drink, etc.) Apply a small amount of neutral

detergent and wipe until contami-

nations do not smear.

- Oil Remove oil instantly with

absorbable cloth and wipe with

stain remover used only for natural

leather.

- Chewing gum Harden the gum with ice and

remove gradually.

Cleaning the seat belt webbing

Clean the belt webbing with any mild

soap solution recommended for

cleaning upholstery or carpet. Follow

the instructions provided with the

soap. Do not bleach or re-dye the

webbing because this may weaken

the seat belt.

Cleaning the interior windowglass

If the interior glass surfaces of the

vehicle become fogged (that is, cov-

ered with an oily, greasy or waxy

film), they should be cleaned with

glass cleaner. Follow the directions

on the glass cleaner container.

Do not scrape or scratch the

inside of the rear window. This

may result in damage to the rear

window defroster grid.

NOTICE